High Performance Indexable Insert Systems - Komeetstaal · The AMEC Indexable range is a powerful...

Transcript of High Performance Indexable Insert Systems - Komeetstaal · The AMEC Indexable range is a powerful...

AM-CAT-COREV(GB)-11/08

and

High Performance Indexable Insert Systems

®Allied Maxcut Engineering Co. Limited

AMEC Indexable Drill RangeThe AMEC range of adjustable indexable carbide drills provides the ultimate in

versatility as they can be pre-set to cut any diameter hole within their range of

47.75mm to 142.75mm.

Incorporating two complementary drilling systems, the AMEC Revolution Drill™ and

the AMEC Core Drill™, the new range reinforces AMEC’s reputation for innovation

and delivers an adaptable, high performance drilling solution to meet a range of

production needs.

The AMEC Core Drill™ is designed to increase the diameter of an existing hole,

while the AMEC Revolution™ drilling system uses ‘over-centre’ cutting to drill from

solid without the need for a pilot hole.

Available in a range of shank styles and capable of drilling to depth up to 5 times

diameter. The AMEC Indexable range is a powerful and versatile drilling solution that

can deliver high productivity and a low cost per hole in a diversity of applications and

industry sectors

For additional information on all AMEC products, please visit www.alliedmaxcut.com

or contact our Application Engineering department for technical support and

assistance on +44 (0)1384 400900.

®Contents

AMEC Revolution DrillTM Features and Benefits Page 2

AMEC Revolution DrillTM Holders, Inserts and Speeds & Feeds Page 3

AMEC Core DrillTM Features and Benefits Page 4

AMEC Core DrillTM Item Reference Page 5

AMEC Core DrillTM Straight Shank & ABS Page 6

AMEC Core DrillTM DV40 & DV50 Flange Page 7

AMEC Core DrillTM BT40 & BT50 Page 8

AMEC Core DrillTM HSK63A/C & HSK100A/C Page 9

AMEC Core DrillTM Operation & Set Up Procedure Page 10

AMEC Core DrillTM Speeds & Feeds Minimum Pilot Hole Calculation Page 11

Request for Guaranteed Application Page 12

®

Place the tool in a presetter to ensure correct diameter setting.

Setting the Revolution Drill™

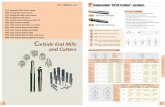

FixedCartridge ADJ Cartridge

LoosenMountingScrew onAdjustableCartridge Set diameter

using theadjustmentscrew

Tighten mounting screw,locking cartridge intoposition.

2

Features and Benefits

• Drills from Solid, no pilot required

• Revolutionary design allows adjustability up to5.1mm on diameter

• Drill Depths up to 4.5 times diameter

• Removable cartridges for easy replacement

• Insert design allows for excellent chip control andaggressive penetration rates

• Less tool inventory needed for range of diameters

• The proprietary AM200® coating increases tool lifeabove competitors premium coatings.

PartNumber

DiameterRange(D1)

MaxDrill Depth(MDD)

BodyLength(L1)

ShankDia(D2)

ShankLength(L2) Cartridges

Replacements

MountingScrew(1 Pack)

AdjustmentScrew(1 Pack)

InsertScrews(10 Pack)

Stk.Stk.

MaterialMaterialHardness(BHN)

M/min FEED(mm/rev)

AM200® TiN

Free Machining Steel 110-250 76-198 61-152 0.10-0.23

Low Carbon Steel 85-275 76-198 61-152 0.10-0.20

Medium Carbon Steel 125-325 122-244 91-183 0.10-0.20

Alloy Steel 125-375 76-244 61-183 0.10-0.20

High Strength Alloy 225-400 76-122 61-91 0.08-0.15

Structural Steel 100-350 76-122 61-91 0.08-0.15

MaterialMaterialHardness(BHN)

M/min FEED(mm/rev)

AM200® TiN

High Temperature Alloy 140-310 46-122 30-91 0.05-0.15

Stainless Steel 135-275 76-198 61-152 0.05-0.18

Tool Steel 150-250 122-152 85-122 0.05-0.15

Aluminium (use TiN coated insert) 30-180 228-335 183-259 0.10-0.23

Cast Iron 120-320 122-228 91-183 0.10-0.23

Brass 30-125 305-396 244-305 0.10-0.23

Formulas: mm/min=RPM • mm/rev M/min=RPM • 0.003 • DIA RPM • M/min • 318.47/DIA

The speeds and feeds listed above are considered a general starting point for all applications. Technical assistance is also available for yourspecific applications through the AMEC Application Engineering Team. Please provide any details about the application to the ApplicationEngineering Team. Accurate information will enable Allied Maxcut’s Application Engineers to give you the best possible solution.

®

3

Stk. - Stock Availability.� Stocked Item� Stocked in limited quantities� Non-Stocked Standard

(6 week lead time)

L2L1

D1

MDD

D2

Item Number, Coating and Availability - 10 Piece PacksGrade

AM200®Z55

OP-05T308-H �

Stk. TiN

OP-05T308-T �

Stk.

47.75mmto

50.80mm

50.80mmto

55.88mm

60.96mmto

66.04mm

66.04mmto

71.12mm

71.12mmto

76.20mm

R34X22-40M 114mm 136.6mm �

R34X35-40M 178mm 200.1mm � �

R34X45-40M 228mm 251.0mm �

R36X22-40M 127mm 149.2mm �

R36X35-40M 197mm 219.1mm � �

R36X45-40M 254mm 276.2mm �

R38X22-40M 140mm 162.0mm �

R38X35-40M 216mm 238.1mm � �

R38X45-40M 280mm 301.6mm �

R42X22-40M 146mm 171.5mm �

R42X35-40M 235mm 260.4mm � �

R42X45-40M 298mm 323.9mm �

R44x22-40M 159mm 191.0mm �

R44X35-40M 254mm 285.0mm � �

R46X22-40M 172mm 203.0mm �

R46X35-40M 267mm 299.9mm � �

R48X10-50M 82mm 114.3mm �

R48X25-50M 203mm 235.0mm � �

R52X10-50M 89mm 127.0mm �

R52X25-50M 216mm 254.0mm � �

R54X10-50M 95mm 133.4mm �

R54X25-50M 229mm 266.7mm � �

R56X10-50M 102mm 146.1mm �

R56X25-50M 241mm 285.8mm � �

R58X10-50M 102mm 146.1mm �

R58X25-50M 254mm 298.5mm � �

40mm 70mm

70mm

70mm

70mm

70mm

70mm

80mm

80mm

80mm

80mm

80mm

(Fixed)C34-FIX

(Adjustable)C34-ADJ

(Fixed)C36-FIX

(Adjustable)C36-ADJ

(Fixed)C38-FIX

(Adjustable)C38-ADJ

(Fixed)C42-FIX

(Adjustable)C42-ADJ

(Fixed)C44-FIX)

(Adjustable)C44-ADJ

(Fixed)C46-FIX

(Adjustable)C46-ADJ

(Fixed)C48-FIX

(Adjustable)C48-ADJ

(Fixed)C52-FIX

(Adjustable)C52-ADJ

(Fixed)C54-FIX

(Adjustable)C54-ADJ

(Fixed)C56-FIX

(Adjustable)C56-ADJ

(Fixed)C58-FIX

(Adjustable)C58-ADJ

MS-17 AS-16 IS-10-10

MS-17 AS-18 IS-10-10

MS-17 AS-18 IS-10-10

MS-19 AS-18 IS-10-10

MS-19 AS-18 IS-10-10

MS-19 AS-18 IS-10-10

MS-21 AS-18 IS-10-10

MS-19 AS-18 IS-10-10

MS-19 AS-18 IS-10-10

MS-21 AS-18 IS-10-10

MS-21 AS-18 IS-10-10

55.88mmto

60.96mm

86.36mmto

91.44mm

91.44mmto

96.52mm

40mm

40mm

40mm

40mm

40mm

50mm

50mm

50mm

50mm

50mm

76.20mmto

81.28mm

81.28mmto

86.36mm

96.52mmto

101.0mm

STRAIGHT SHANKISO 9766

®

Features and Benefits• Opens an existing hole in a single operation

• Ignores core shifts up to 3.175mm (1/8”) providing straight andtrue holes without boring

• Allows for large amounts of material removal

• Unique design enables larger holes to be made on lowerpowered machines

• Multi-insert design reduces chip size for easy chip evacuation

• Smooth cutting action and quiet operation in lathes and mills

• Can be used as a rotating or stationary tool

• Useable in rough boring operations

• Replaceable insert cartridges protect your investment

• Adjustable diameters reduce inventory and cost

• Special lengths, diameters and shanks available upon request

4

Item Reference

OP1-1S-40MAMEC Core DrillBody

AMEC Core Drill Drill Ø Range

1 (50.80-63.50)

2 (63.50-76.20)

3 (76.20-104.65)

4 (104.65-142.75)

Length1S – Short

1L - Long

Shank40M

50M

BT40

BT50

HSK 63A/C

HSK 100A/C

ABS63

DV40

DV50

OP – 05T308 - HAMEC Core DrillInsert

AMEC Core Drill Insert Specification

OP1 – WC05AMEC Core DrillCartridge

AMEC Core Drill Drill Ø Range

1 (50.80-63.50)

2 (63.50-76.20)

3 (76.20-104.65)

4 (104.65-142.75)

Cartridge Specification

CoatingH – AM200®

A - TiAlN

N - TiCN

T – TiN

U - Uncoated

®

5

L2L1

D1

MDD

D2

®

6

Straight Shank and ABSAMEC Core Drill

Item Number, Coating and Availability - 10 Piece Packs

Grade AM200®

Z55 OP-05T308-H �

Stk. TiN

OP-05T308-T �

TiAN

OP-05T308-A �

Stk. TiCN

OP-05T308-N �

Stk.

ItemNumber

ItemDescription

Diameter Range(D1)

Body Length(L1)

Max DrillDepth(MDD)

ShankLength(L2)

ShankDiameter(D2)

Stk.

OP1-1S-40M OP1 SS40M Short Length 50.80-63.50 101.60 82.55 70 40 �

OP1-1L-40M OP1 SS40M Long Length 50.80-63.50 158.75 139.70 70 40 �

OP2-1S-40M OP2 SS40M Short Length 63.50-76.20 139.70 120.65 70 40 �

OP2-1L-40M OP2 SS40M Long Length 63.50-76.20 215.90 196.85 70 40 �

OP3-1S-40M OP3 SS40M Short Length 76.20-104.65 152.40 127.00 70 40 �

OP3-1L-40M OP3 SS40M Long Length 76.20-104.65 254.00 228.60 70 40 �

OP4-1S-50M OP4 SS50M Short Length 104.65-142.75 152.40 127.00 80 50 �

OP4-1L-50M OP4 SS50M Long Length 104.65-142.75 292.10 266.70 80 50 �

StraightShank(Metric)

ItemNumber

ItemDescription

Diameter Range(D1)

Body Length(L1)

Max DrillDepth(MDD)

ShankLength(L2)

ShankDiameter(D2)

Stk.

OP1-1S-SS1.5 OP1 SS 1.50 Short Length 50.80-63.50 101.60 82.55 101.6 38.1 �

OP1-1L-SS1.5 OP1 SS 1.50 Long Length 50.80-63.50 158.75 139.70 101.6 38.1 �

OP2-1S-SS1.5 OP2 SS 1.50 Short Length 63.50-76.20 139.70 120.65 101.6 38.1 �

OP2-1L-SS1.5 OP2 SS 1.50 Long Length 63.50-76.20 215.90 196.85 101.6 38.1 �

OP3-1S-SS1.5 OP3 SS 1.50 Short Length 76.20-104.65 152.40 127.00 101.6 38.1 �

OP3-1L-SS1.5 OP3 SS 1.50 Long Length 76.20-104.65 254.00 228.60 101.6 38.1 �

OP4-1S-SS2.0 OP4 SS 2.00 Short Length 104.65-142.75 152.40 127.00 114.3 50.8 �

OP4-1L-SS2.0 OP4 SS 2.00 Long Length 104.65-142.75 292.10 266.70 114.3 50.8 �

StraightShank

(Imperial)

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

MaxDrill Depth(MDD)

Stk.

OP1-1S-ABS63 OP1 ABS63 Short Length 50.80-63.50 139.70 82.55 �

OP1-1L-ABS63 OP1 ABS63 Long Length 50.80-63.50 196.85 139.70 �

OP2-1S-ABS63 OP2 ABS63 Short Length 63.50-76.20 158.75 120.65 �

OP2-1L-ABS63 OP2 ABS63 Long Length 63.50-76.20 234.95 196.85 �

OP3-1S-ABS63 OP3 ABS63 Short Length 76.20-104.65 171.45 127.00 �

OP3-1L-ABS63 OP3 ABS63 Long Length 76.20-104.65 273.05 228.60 �

OP4-1S-ABS63 OP4 ABS63 Short Length 104.65-142.75 171.45 127.00 �

ABS63

Stk.

ReplacementCartridges Stk.

QtyInsertsRequired

InsertScrew10 Pack

MountingScrew4 Pack

AdjustingScrew4 Pack

OP1-WC05 � 2 IS-10-10 � MS-13-4 � AS-10-4 �

OP2-WC05 � 2 IS-10-10 � MS-15-4 � AS-10-4 �

OP3-WC05 � 2 IS-10-10 � MS-15-4 � AS-12-4 �

OP4-WC05 � 3 IS-10-10 � MS-15-4 � AS-14-4 �

ItemNumber

Stk. Stk. Stk.

STRAIGHT SHANK

Imperial

ABS 63

L1 L2

D2

MDD

MDD

L1

D1

D1

Metric

STRAIGHT SHANKISO 9766

®

7

DV40/DV50 FlangeAMEC Core Drill

Item Number, Coating and Availability - 10 Piece Packs

Grade AM200®

Z55 OP-05T308-H �

Stk. TiN

OP-05T308-T �

TiAN

OP-05T308-A �

Stk. TiCN

OP-05T308-N �

Stk.

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

Max DrillDepth(MDD)

Stk.

OP1-1S-DV40 OP1 DV40 Short Length 50.80-63.50 136.65 82.55 �

OP1-1L-DV40 OP1 DV40 Long Length 50.80-63.50 193.80 139.70 �

OP2-1S-DV40 OP2 DV40 Short Length 63.50-76.20 174.75 120.65 �

OP2-1L-DV40 OP2 DV40 Long Length 63.50-76.20 250.95 196.85 �

OP3-1S-DV40 OP3 DV40 Short Length 76.20-104.65 187.45 127.00 �

OP3-1L-DV40 OP3 DV40 Long Length 76.20-104.65 289.05 228.60 �

OP4-1S-DV40 OP4 DV40 Short Length 104.65-142.75 187.45 127.00 �

DV40

Stk.

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

Max DrillDepth(MDD)

Stk.

OP1-1S-DV50 OP1 DV50 Short Length 50.80-63.50 136.65 82.55 �

OP1-1L-DV50 OP1 DV50 Long Length 50.80-63.50 193.80 139.70 �

OP2-1S-DV50 OP2 DV50 Short Length 63.50-76.20 174.75 120.65 �

OP2-1L-DV50 OP2 DV50 Long Length 63.50-76.20 250.95 196.85 �

OP3-1S-DV50 OP3 DV50 Short Length 76.20-104.65 187.45 127.00 �

OP3-1L-DV50 OP3 DV50 Long Length 76.20-104.65 289.05 228.60 �

OP4-1S-DV50 OP4 DV50 Short Length 104.65-142.75 187.05 127.00 �

OP4-1L-DV50 OP4 DV50 Long Length 104.65-142.75 327.15 266.70 �

DV50

ReplacementCartridges Stk.

QtyInsertsRequired

InsertScrew10 Pack

MountingScrew4 Pack

AdjustingScrew4 Pack

ItemNumber

Stk. Stk. Stk.

DV40

Stk. - Stock Availability.� Stocked Item� Stocked in limited quantities� Non-Stocked Standard (6 week lead time)

L1

MDD DIN 69871 FORM ‘A’

DIN 69871 FORM ‘A’

D1

DV50

L1

MDD

D1

OP1-WC05 � 2 IS-10-10 � MS-13-4 � AS-10-4 �

OP2-WC05 � 2 IS-10-10 � MS-15-4 � AS-10-4 �

OP3-WC05 � 2 IS-10-10 � MS-15-4 � AS-12-4 �

OP4-WC05 � 3 IS-10-10 � MS-15-4 � AS-14-4 �

®

8

BT40/BT50 FlangeAMEC Core Drill

Item Number, Coating and Availability - 10 Piece Packs

Grade AM200®

Z55 OP-05T308-H �

Stk. TiN

OP-05T308-T �

TiAN

OP-05T308-A �

Stk. TiCN

OP-05T308-N �

Stk.Stk.

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

Max DrillDepth(MDD)

Stk.

OP1-1S-BT40 OP1 BT40 Short Length 50.80-63.50 136.65 82.55 �

OP1-1L-BT40 OP1 BT40 Long Length 50.80-63.50 193.80 139.70 �

OP2-1S-BT40 OP2 BT40 Short Length 63.50-76.20 174.75 120.65 �

OP2-1L-BT40 OP2 BT40 Long Length 63.50-76.20 250.95 120.65 �

OP3-1S-BT40 OP3 BT40 Short Length 76.20-104.65 187.45 127.00 �

OP3-1L-BT40 OP3 BT40 Long Length 76.20-104.65 289.05 228.60 �

OP4-1S-BT40 OP4 BT40 Short Length 104.65-142.75 187.45 127.00 �

BT40

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

Max DrillDepth(MDD)

Stk.

OP1-1S-BT50 OP1 BT50 Short Length 50.80-63.50 146.05 82.55 �

OP1-1L-BT50 OP1 BT50 Long Length 50.80-63.50 203.20 139.70 �

OP2-1S-BT50 OP2 BT50 Short Length 63.50-76.20 184.15 120.65 �

OP2-1L-BT50 OP2 BT50 Long Length 63.50-76.20 260.35 196.85 �

OP3-1S-BT50 OP3 BT50 Short Length 76.20-104.65 196.85 127.00 �

OP3-1L-BT50 OP3 BT50 Long Length 76.20-104.65 298.45 228.60 �

OP4-1S-BT50 OP4 BT50 Short Length 104.65-142.75 196.85 127.00 �

OP4-1L-BT50 OP4 BT50 Long Length 104.65-142.75 336.55 266.70 �

BT50

ReplacementCartridges Stk.

QtyInsertsRequired

InsertScrew10 Pack

MountingScrew4 Pack

AdjustingScrew4 Pack

OP1-WC05 � 2 IS-10-10 � MS-13-4 � AS-10-4 �

OP2-WC05 � 2 IS-10-10 � MS-15-4 � AS-10-4 �

OP3-WC05 � 2 IS-10-10 � MS-15-4 � AS-12-4 �

OP4-WC05 � 3 IS-10-10 � MS-15-4 � AS-14-4 �

ItemNumber

Stk. Stk. Stk.

BT40

L1

MDD

D1

BT50

L1

MDD

D1

Stk. - Stock Availability.� Stocked Item� Stocked in limited quantities� Non-Stocked Standard (6 week lead time)

®

9

HSK63A/C & HSK100A/CAMEC Core Drill

Item Number, Coating and Availability - 10 Piece Packs

Grade AM200®

Z55 OP-05T308-H �

Stk. TiN

OP-05T308-T �

TiAN

OP-05T308-A �

Stk. TiCN

OP-05T308-N �

Stk.

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

Max DrillDepth(MDD)

Stk.

OP1-1S-HSK63 OP1 HSK63A/C Short Length 50.80-63.50 143.51 82.55 �

OP1-1L-HSK63 OP1 HSK63A/C Long Length 50.80-63.50 200.66 139.70 �

OP2-1S-HSK63 OP2 HSK63A/C Short Length 63.50-76.20 181.61 120.65 �

OP2-1L-HSK63 OP2 HSK63A/C Long Length 63.50-76.20 257.81 196.85 �

OP3-1S-HSK63 OP3 HSK63A/C Short Length 76.20-104.65 194.31 127.00 �

OP3-1L-HSK63 OP3 HSK63A/C Long Length 76.20-104.65 295.91 228.60 �

OP4-1S-HSK63 OP4 HSK63A/C Short Length 104.65-142.75 194.31 127.00 �

HSK63A/C

Stk.

ItemNumber

ItemDescription

Diameter Range(D1)

BodyLength(L1)

Max DrillDepth(MDD)

Stk.

OP1-1S-HSK100 OP1 HSK100A/C Short Length 50.80-63.50 149.86 82.55 �

OP1-1L-HSK100 OP1 HSK100A/C Long Length 50.80-63.50 207.01 139.70 �

OP2-1S-HSK100 OP2 HSK100A/C Short Length 63.50-76.20 187.96 102.65 �

OP2-1L-HSK100 OP2 HSK100A/C Long Length 63.50-76.20 264.16 196.85 �

OP3-1S-HSK100 OP3 HSK100A/C Short Length 76.20-104.65 200.66 127.00 �

OP3-1L-HSK100 OP3 HSK100A/C Long Length 76.20-104.65 302.26 228.60 �

OP4-1S-HSK100 OP4 HSK100A/C Short Length 104.65-142.75 200.66 127.00 �

OP4-1L-HSK100 OP4 HSK100A/C Long Length 104.65-142.75 340.36 266.70 �

HSK100A/C

ReplacementCartridges Stk.

QtyInsertsRequired

InsertScrew10 Pack

MountingScrew4 Pack

AdjustingScrew4 Pack

OP1-WC05 � 2 IS-10-10 � MS-13-4 � AS-10-4 �

OP2-WC05 � 2 IS-10-10 � MS-15-4 � AS-10-4 �

OP3-WC05 � 2 IS-10-10 � MS-15-4 � AS-12-4 �

OP4-WC05 � 3 IS-10-10 � MS-15-4 � AS-14-4 �

ItemNumber

Stk. Stk. Stk.

HSK 63A/C

MDD

L1

D1

HSK 100A/C

MDD

L1

D1

Stk. - Stock Availability.� Stocked Item� Stocked in limited quantities� Non-Stocked Standard (6 week lead time)

®

10

Operation

• The AMEC Core Drill must be presented close to centre line. A stationary AMEC CoreDrill must be on centre line with the part within 0.381mm total runout.AMEC strongly suggests that the turret pod be indicated from the chuck before toolmounting. Applications on a machining centre will typically find their own centre,but we recommend TIR to be within 0.127mm.

• We recommend utilising coolant when using the AMEC Core Drill. Through the toolis ideal, although flood coolant is acceptable. The tool is designed with large gulletsto easily evacuate the chips from the hole.

• The AMEC Core Drill can be effectively used to core holes with 2 inserts, if bothopposed cartridges are set to the same cut diameter. However, this application willnot allow an enlargement greater than 12.7mm on diameter.

The AMEC Core Drill has 2 diametrically opposed cartridges that are phased to create an overlapping cut situation inuse. The cartridges are exactly the same until one is selected to cut the finish diameter, outer cartridge. The otheropposing cartridge would then become the inner cartridge. The inner cartridge would be adjusted to a smaller radius bya range of 4.06mm - 5.08mm. The phasing on the inner cartridge does not require close accuracy but using the meansize of 4.57mm is recommended.

Presetter:In setting the AMEC Core Drill the use of a presetter will allow for the most accurate setting of the tool.

• Set the presetter axis to diameter. Designate one of the cartridges to be the outer cartridge (finish diameter), theopposing cartridge then becomes the inner cartridge. Set the outer cartridge to the finish diameter required.

• We recommend adjusting the cartridge using the side adjusting screws that push against the pin. After this initialadjustment is made, tighten the mounting screws to secure the cartridges and then slightly tension the adjustingscrews to insure a friction fit in the screw threads.

• The inner cartridge is then adjusted to a smaller diameter within a range of 8.13mm - 10.16mm. The nominal Øvalue of 9.14mm is recommended. However, anything within the range is acceptable, for the inner cartridge doesnot require a close accuracy.

Dial Test Indicator (DTI):In the case that a presetter is unavailable the setting of the tool can be set accurately as follows:

1) Outer Cartridge Setting

Finish Ø Minus Body Ø (Figure 1) /2 = Distance indicator will need to travel from tool body (Figure 2) to set outercartridge at finish diameter (Figure 3)

2) Inner Cartridge Setting

Offset the inner cartridge inwards by Ø 9.14/2 = Distance indicator will need to travel from outer cartridge to setinner cartridge (Figure 4) ensuring optimum insert overlap.

Set Up Procedure

Body Diameter

Figure 1 Figure 2 Figure 3 Figure 4

OP1 46.7

OP2 56.4

OP3 71.3

OP4 88.9

4.57 mean on radius (Range 4.06mm - 5.08mm)9.14mm mean on dia (Range 8.13mm - 10.16mm)

Outer Arm

Inner Arm

®

11

Recommended Speeds and Feeds

Formulas: mm/min = RPM • mm/rev M/min = RPM • 0.003 • DIA RPM = M/min • 318.47/DIA

The speeds recommended for all coated tools are based on empirical data obtained under “Optimum Conditions”. Manyapplications do not exhibit “Optimum Conditions.” (Reductions in speed parameters may be required due to excessive tool weargenerated in the application.)

The speeds and feeds listed above are considered a general starting point for all applications. Factory technical assistance is alsoavailable for your specific applications through our Application Engineering Team. Please have item number, hole diameter, depth,material grade, BHN hardness and coolant pressure information available when you call. Additional information such as part andmachine rigidity, horsepower and thrust limits, vertical or horizontal spindle, revolving or stationary tool, flood or through holdercoolant will enable our Application Engineers to give you the best possible solution.

Minimum Pilot Hole Calculation

To determine the minimum diameter of the pilot hole, use the following calculation:

FINISH DIAMETER MINUS OPENING RANGE = MINIMUM PILOT HOLE DIAMETER

For example: To open up an existing diameter hole to 66mm diameter, OP2 tool would be used and the minimum pilot holediameter would be 66mm-47.75mm = 18.25mm.

Material

AM200® TiN TiAlN TiCN

MaterialHardness(BHN)

Feed(mm/rev)

Speed M/min

110-250 76-198 61-152 70-175 64-168 0.10-0.23

85-275 76-198 61-152 70-175 64-168 0.10-0.20

125-325 122-244 91-186 105-210 100-201 0.10-0.20

125-375 76-244 61-183 70-210 67-201 0.10-0.20

225-400 76-122 61-91 70-105 67-101 0.07-0.15

100-350 76-122 61-91 70-105 67-101 0.07-0.15

140-310 46-122 30-91 35-105 34-101 0.05-0.15

135-275 76-198 61-152 70-175 67-168 0.05-0.17

150-250 122-152 85-122 98-140 95-134 0.05-0.15

30-180 229-335 183-259 210-297 201-285 0.05-0.15

120-320 122-228 91-183 105-210 101-201 0.05-0.15

30-125 305-396 244-305 280-350 268-335 0.10-0.22

AMEC Core Adjustable O.D Opening RangeDrill Size Range Diameter

OP1 50.80 - 63.50 47.75

OP2 63.50 - 76.20 47.75

OP3 76.20 - 104.65 47.75

OP4 104.65 - 143.75 68.07

Pre-drilled partor core

AMEC Core Drill

Free Machining Steel

Low Carbon Steel

Medium Carbon Steel

Alloy Steel

High Strength Alloy

Structural Steel

High Temperature Alloy Hastelloy B, Inconel 600

Stainless Steel

Tool Steel

Aluminium

Cast Iron Grey, Ductile, Nodular

Brass

®

12

AMEC Request for Guaranteed Application

Trial P.O No............................................................................................ Date................... Proposed Test Date...........................................................

Distributor........................................................................................................................... Distributor Contact...........................................................

Customer Name.................................................................................................................. Contact Name..................................................................

APPLICATION INFORMATION

ATTENTION: The following information is required to enable the best combination of tooling to be recommended. Please check all that apply

Material Type............................. Specification...................................... Material Hardness........................................................ BHN RC

Material Condition Flat Stock Round Stock Tubular Stock Plate

Stacked Plate Hot Rolled Cold Rolled Casting Forging

Current Hole Diameter................ mm Inch Hole Depth ...................................... Thru Hole Blind Hol

Cored Hole Size......................................................

Drilled Hole Tolerance Req’d.................................... Drilled Hole RMS Finish Req’d......................................... Micro-Inch Micro-Metre

MACHINE AND SET-UP INFORMATION

Machine Tool Type Machining Centre Lathe Boring Mill Transfer Line

Screw Machine Multi-Spindle Drill Radial Arm Drill

Gantry Machine Dial Index Machine Pedestal Drill

Gun Drilling Machine Other

Machine Tool Builder.............................................................................. Model............................................................................................................

Machine Tool Control CNC NC Manual Other..........................................................................

Spindle Orientation Vertical Horizontal Other........................................................................................................

Tool Stationery Revolves

Available Power.......................... KW HP Available Feed Thrust....................... Newtons Lbs

Available Speed Variable Fixed RPM M/min

Preferred Shank Type mm Inch

Coolant Type Cutting Oil Water Soluble Oil Air Mist Air Dry

Coolant Pressure Bar PSI

Coolant Flow Rate..................... L/min GPM Coolant Application Through Tool Flood

CURRENT DRILL INFORMATION

Drill Manufacturer................................................................................ Part Number..................................................................................................

Drill Type.................................. Indexable Insert Gun Drill.

Tool Grade HSS Carbide Ceramic Other..........................................................................

Tool Coating Uncoated TiN TiCN TiAlN Other.............................................

Current Speed.......................... RPM M/min Current Feed Rate......................... mm/rev mm/min

Average Number of Holes Drilled.........................................................

Reason(s) for Tool Change Wear Chipping Fracture Chatter Performance

Losing Hole Tolerance Other.............................................

What criteria defines aSuccessful test ...................................................................................................................................................................................

Potential this application: Current Annual Usage /£: Tools per Annum?

®

European Headquarters:Allied Maxcut Engineering Co. Limited93 Vantage Point, Pensnett Estate, Kingswinford, West Midlands, DY6 7FR EnglandTel: +44 (0)1384 400900 Fax: +44 (0)1384 400105Email: [email protected] Website: www.alliedmaxcut.com

AM-CAT-COREV(GB)-11/08