HIGH FLUID CSA CEMENT - ULTRA FLUX

Click here to load reader

Transcript of HIGH FLUID CSA CEMENT - ULTRA FLUX

®

2

3

A formulated cement binder based on CALUMEX - calcium sulpho aluminate technology and designed for flooring application. It combines high fluidity with rapid hardening and develops quickly high early strength. The reduced shrinkage allows larger surfaces to be poured or pumped at one go. The excellent bonding to the substrate can further be enhanced by applying a primer.

• high fluidity • waterproofing • fast setting • quick drying • high early strength development • freeze resistance • improved impermeability • compensated drying shrinkage • low alkali • white and grey version

can be mixed with;

• Portlandcement • retarder / accelerator • pigments • natural and artificial fillers • fibers

4

FLOORING depending on the requirements mix ~50 % of and ~50 % of aggregate ≥ 0,1- ≤ 2,5 mm (≥ 0,1- ≤ 4 mm for screeds and thicker layers)

(prevent fines)

• prepare or prime substrate • mix mechanically for at least 4 minutes • pour or pump the slurry • level out the mortar • de-air with piked roller • takes foot traffic after 4 hours at an ambient temperature of 20°C. • prevent direct sunlight and draft - leave to dry evenly • is odorless non polluting or poisonous and gives no radiation • it can be recycled as concrete waste

5

pouring pumping

leveling de-airing

6

• easy mixed with water • shrinkage compensated guarantees volume stability • sets rapidly even at low temperatures • quick demoulding and installment • excellent flow properties • resistant to sulfates and chloride • has high density/low porosity • generates relative low heat on hydration • applied on large surfaces • non poisonous/odorless • low alkali / glass fiber reinforced cement • reduced risk on alkali/silica reaction • color stability • no efflorescence • can be disposed of as regular cement

®

7

®

based on purest raw materials and produced under tight control this white rapid hardening, high early strength cement is especially designed for making decorative concrete overlay , underlayment , self leveling floor screeds, colored concrete etc.

Depending on the application only water and fillers need to be added.

Natural and artificial aggregates can be used as filler to make artificial stone or marble , terrazzo , colored floors for offices , supermarkets , exhibition halls etc.

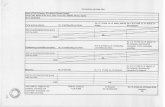

specification

whiteness ≥ 80 setting time begin 90~100 min end 100~120 min minimal thickness mm 10 after polishing mm 8

1 day 7 days 28 days compressive strength Mpa 10 18 27 flexural strength Mpa 2,9 3,8 4,5 tensile strength Mpa

> 1,0

shrinkage mm/m < -0,05 flow initial mm ≥ 140

20 min ≥ 130

working time min ≥ 20

working temperature °C 5~30

walk on time hour ~ 4

water / cement ratio ~ 0,25

after full hardening which takes normally 24 - 48 hours the floor can be polished - or treated with acid or stained - and finished with a wax or primer

®

CALTRA Nederland bv Communicatieweg 21 P.O.Box 306 3640 AH Mijdrecht The Netherlands T : + 31 297 289340 F : + 31 297 289350 E : [email protected] W: www.caltra.com