Heterogeneous–homogeneous composite bipolar membrane for the conversion of salt of homologous...

-

Upload

mahendra-kumar -

Category

Documents

-

view

231 -

download

6

Transcript of Heterogeneous–homogeneous composite bipolar membrane for the conversion of salt of homologous...

Ho

MEG

a

ARRAA

KBESCI

1

fatwtatcEatSCha

0d

Journal of Membrane Science 349 (2010) 130–137

Contents lists available at ScienceDirect

Journal of Membrane Science

journa l homepage: www.e lsev ier .com/ locate /memsci

eterogeneous–homogeneous composite bipolar membrane for the conversionf salt of homologous carboxylates into their corresponding acids and bases

ahendra Kumar, Vinod K. Shahi ∗

lectro-Membrane Processes Division, Central Salt & Marine Chemicals Research Institute, Council of Scientific & Industrial Research (CSIR),.B. Marg, Bhavnagar 364002, Gujarat, India

r t i c l e i n f o

rticle history:eceived 10 August 2009eceived in revised form 12 October 2009ccepted 17 November 2009vailable online 26 November 2009

eywords:ipolar membranelectrodialysisalt splittingarboxylic acid

a b s t r a c t

For developing bipolar membrane electrodialysis (EDBPM), heterogeneous–homogeneous compositebipolar membrane (BPM) was prepared by casting method to achieve cost effectiveness, high watersplitting efficiency, permselectivity, low resistance, salt diffusion and good stability. For preparing BPM,heterogeneous anionic layer (AL) of desired thickness, was casted onto a clean glass plate. Interfaciallayer of highly sulphonated PEEK (degree of sulphonation: 80%) and poly(4-vinyl pyridine) were castedon cationic and anionic side, respectively. Finally the cationic layer (CL) of sulphonated poly(ether etherketone) (SPEEK) in the same solvent was casted onto the dried surface of interfacial layer. The fundamentalcharacteristics of BPM such as current–voltage curves in equilibration with NaCl and sodium carboxylatessolutions, are discussed in terms of first limiting current density (ilim1), second limiting current density(ilim2), operating current density (iop) and dissociation potential (Vdis). Water splitting efficiency of BPM

on-exchange membrane was also tested in a four compartments EDBPM cell (catholyte, anolyte, compartments 1 and 2) for con-verting NaCl or RCOONa (R-: HCOO−, CH3COO− and C2H5COO−) into their corresponding acids and NaOH.After passage of 7.68 × 103 C of electricity, NaCl solution (0.50 M) was converted into HCl and NaOH with67.6% current efficiency (CE) and 3.1 kWh kg−1 energy consumption. However, process performance (CEand recovery of RCOOH) was significantly reduced, while energy consumption increased for convertinghigher homologues of RCOONa under similar experimental conditions. It was also observed that smaller

igher

the carboxylate ion, the h. Introduction

Recent progress in the ion-exchange membranes has enabledor the preparation of new BPM to produce the corresponding acidnd base by water splitting. BPM is a polymeric layered struc-ure composed of CL and AL. The H+ and OH− ions, generated byater splitting in the interfacial region of the membrane under

he influence of electric field that migrate towards cathode andnode, respectively [1–6]. The AL and CL of BPM allow the selec-ive transport of H+, OH− and sufficient water flux to fill the wateronsumed by its dissociation reaction at the interfacial layer [2].DBPM has been used for production of acid/base or their regener-tion, acidification, alkalization and organic synthesis [7–15] dueo the ability of BPM to split water at membrane interfacial layer.

alt diffusion through BPM is a serious problem, which deterioratesE and product purity [16,17]. Thus, an efficient BPM should haveigh selectivity, water splitting efficiency, low salt diffusion, acidnd base stability over wide pH range, along with mechanical sta-∗ Corresponding author. Tel.: +91 278 56 77 60; fax: +91 278 56 69 70.E-mail addresses: [email protected], [email protected] (V.K. Shahi).

376-7388/$ – see front matter © 2009 Elsevier B.V. All rights reserved.oi:10.1016/j.memsci.2009.11.041

is its leakage through BPM under operating conditions.© 2009 Elsevier B.V. All rights reserved.

bility. These desired properties of BPM, can be obtained by suitablemembrane forming material and membrane casting methodology.

Till date, BPMs have been prepared by (i) adhering togetherCL and AL by heat pressuring with an adhesive paste [7]; (ii) bycasting a cation-exchange polyelectrolyte solution onto a com-mercial anion-exchange membrane or vice-versa [2,8]; and (iii)simultaneous selectively functionalization of membrane surfacesby cation- and anion-exchange groups [9,10]. Among above-mentioned methods, the casting method seems to be the mostattractive because of its simplicity and cost effectiveness. In thismethod, to achieve desire properties for BPM: such as goodmechanical strength, high limiting current density, high permse-lectivity, and low potential drop or membrane resistance, is easy[18]. Selection of anion-exchange layer is a key problem due tochloromethylation (use of chloromethyl methyl ether is consid-ered to be a carcinogen and has been restricted since the 1970s)and quaternary amination steps [19]. Cost effective preparation

of BPM and adhesion between two layers (AL and CL), whicheffects electrochemical properties and membrane stability, havelimited the practical applications. Thus it is imperative to adoptan alternate route for preparing AL of BPM to comply with thedictates of environmental regulations. Heterogeneous AL can be

embr

paPboicihat

tSiowactcCi

2

2

vPispSAni

2

2

pbew

M. Kumar, V.K. Shahi / Journal of M

repared by dispersing fine powders of anion-exchange resin withfilm-forming polymer as a binder in a suitable solvent [20,21].

ermselective and conductive heterogeneous ion-exchange mem-rane can be obtained when percolation concentration thresholdf the ion-exchange particles is surpassed (usually 30–40 wt%), butn order to obtain a practically acceptable ionic conductivity, theoncentration should be much higher (50–70 wt% for commercialon-exchange membranes) [22,23]. Influence of the degree of theeterogeneity on the electrochemical behaviors was investigatednd it was observed that heterogeneous structure affected the elec-rochemical properties of the heterogeneous membrane [24].

Herein, we are reporting an alternate method for the prepara-ion of heterogeneous–homogeneous composite BPM. Single CL ofPEEK was prepared by casting and evaporation. After the solid-fication of one layer, the next layer was casted onto the surfacef the former, which then was allowed to dry. This procedureas repeated for cationic, interfacial and anionic layers. Because

ll polymer solutions were prepared in the same solvent and theontact at the interface layers was firm [4,25]. The water split-ing efficiency of developed composite BPM was studied by theonversion of NaCl or sodium carboxylates (RCOONa; R-: HCOO−,H3COO− and C2H5COO−) into their corresponding acids and NaOH

n EDBPM process.

. Experimental

.1. Materials

Poly(ether ether ketone) (PEEK) powder, with medium meltiscosity Grade 450, PF was obtained from Victrex PLC (England).oly(ether sulfone) (PES) was received from Sigma–Aldrich Chem-cals. All other reagents such as dimethylacetamide (DMAC), NaCl,odium formate (HCOONa), sodium acetate (CH3COONa), sodiumropionate (C2H5COONa), and H2SO4 of AR grade obtained from.D. Fine Chemicals, India, were used without further purification.nion-exchange resin (Indian FFIP), a chloromethylated and ami-ated polystyrene (with 8% cross-link density and 3.4 mequiv./g

on-exchange capacity) was supplied by Ion-exchange (India).

.2. Membrane preparation

.2.1. Preparation of anionic layer

For the preparation of a heterogeneous AL, anion-exchange resinarticles were dried in an oven at 60 ◦C for 24 h, powdered in aall mill and sieved to the 100 mesh size. Finally, powdered anion-xchange resin was dispersed in PES solution in DMAC (60%, w/v)ith total solid:DMAC ratio: 1:5 (w/v). Then it was casted onto a

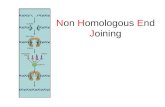

Fig. 1. Schematic drawing of a BPM prepara

ane Science 349 (2010) 130–137 131

cleaned glass plate at ambient temperature and allowed to dry at60 ◦C for 24 h.

2.2.2. Preparation of bipolar membraneSPEEK was prepared by sulphonation of poly(ether ether

ketone) (PEEK, 450PF) as described earlier [26]. Dried SPEEK wasdissolved in DMAC (10%, w/v) under constant stirring to get theclear solution. For the contact region of the BPM, poly(4-vinyl pyri-dine) layer was coated on the surface of heterogeneous AL, whileSPEEK (degree of sulphonation: 80%) layer was coated on top anddried under IR lamps. Then CL of desired thickness (SPEEK) wascasted onto the composite structure to get BPM and dried at roomtemperature under IR lamp for 12 h. Schematic procedure for thepreparation of BPM is presented in Fig. 1. To achieve good con-tact between the different layers, casting method was used asreported earlier [3]. After the solidification of one layer, next layerwas casted onto the top surface of the previous one and allowedto dry. Because all polymer solutions were prepared in the samesolvent, the contacts between the interfacial layers were firm. Theprepared membranes were dried in inert atmosphere at 40–80 ◦Cfor 24 h, and then immersed in water. Thus obtained membraneswere equilibrated by treatment with 1.0 M NaOH and 1.0 M HCl,and finally stored in a 2.0 M NaCl solution.

2.3. Membrane characterization

FTIR spectrum of dried CL was recorded using ATR techniquewith a spectrum GX series 49387 spectrometer in the range4000–600 cm−1. The surface and cross-section images of dried AL,CL and composite BPM were recorded by scanning electron micro-scope (SEM) after gold sputter coatings on a desired membranesamples.

Counter-ion transport numbers (tmi ) across the AL and CL were

estimated by membrane potential measurement using TMS (Teo-rell, Meyer, and Sievers) approach [27]. Detailed procedure is givenin S1 of supporting information. The tm

i values were used withadvantage for the estimation of permselectivity (Ps):

Ps = tmi − ti

1 − ti. (1)

where ti is the counter-ion transport number in the solution. Ps

values for CL and AL are presented in Table 1 in equilibration with

NaCl solution (0.055 M mean concentration).The equivalent membrane conductivity (�m) of CL, AL andBPM in equilibration with NaCl solution of different concentra-tions was determined and detailed procedure is included in S2of supporting information. Nyquist plots for AL, CL and composite

tion by the solution casting technique.

132 M. Kumar, V.K. Shahi / Journal of Membrane Science 349 (2010) 130–137

Table 1Physicochemical and electrochemical properties of CL, AL and BPM.

Properties CL AL BPM

Thickness (�m) 100 100 200Water content (%) 32.90 24.2 27.3Ion-exchange capacity (mequiv./g of dry membrane) 1.55 1.32 –Counter-ion transport number (tm

i)a, 0.95 0.92 –

Specific membrane conductivity (S cm−1)b 3.65 × 10−2 3.15 × 10−2 3.88 × 10−2

Permselectivityc 0.93 0.90 –

and 0.01 M concentration.

B(tmcbd(iwf

W

pseT1a

2s

ermpssi(cm

2

laauutrcmaPAc

a Estimated from membrane potential measurements using NaCl solutions of 0.1b Measured in equilibration with NaCl solution (0.10 M) by impedance system.c Estimated from tm

ivalues.

PM, as representative case are included in supporting informationFig. S1(A), (B) and S2 (supplementary information)) and used forhe estimation of �m [28]. The thicknesses of AL, CL and BPM were

easured by a digital micrometer up to 0.10 �m accuracy. Waterontent was determined by weight difference of wet and dry mem-rane. For this purpose, different layers and composite BPM wereried in vacuum oven at 60 ◦C for 24 h and weight of dry membraneWd) were recorded. Dried membranes (AL, CL and BPM) were keptn distilled water for 12 h and their wet membrane weight (Ww)

as recorded. The water content was finally calculated using theollowing equation:

ater content (%) = Ww − Wd

Wd× 100. (2)

For the determination of ion-exchange capacity (IEC), desiredieces of CL and AL were conditioned in 1.0 M HCl or 1.0 M NaOHolution, respectively, for 12 h to convert into H+ or OH− form. Thexcess HCl or NaOH was removed by washing with distilled water.he membranes were then equilibrated in 0.50 M NaCl solution for2 h and amount of H+ or OH− ions liberated was determined bycid–base titration [27].

.4. Current–voltage (i–v) curves for BPM in different electrolytesolution

The current–voltage polarization curves of composite BPM inquilibration with 0.50 M solutions of different electrolytes wereecorded in a two compartments cell with four-electrode arrange-ent presented in Fig. S3 (supplementary information). BPM was

laced between the two compartments filled with electrolyticolution (50 cm3) of known concentration (0.50 M) under con-tant stirring by mechanical stirrer. Known constant current wasmposed across composite BPM with the help of DC power supplyAplab India, model L1285) using Ag/AgCl electrodes fixed in bothhambers. Resulting potential difference across the membrane waseasured with the help of saturated calomel electrodes.

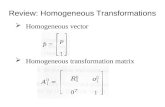

.5. EDBPM experiment

EDBPM experiments were carried out in a polytetraflouroethy-ene (PTFE) made cell, consisting 4 compartments (catholyte,nolyte, compartments 1 and 2) separated by two pieces of CLnd a BPM (Fig. 2). Parallel-cum-series flow arrangement wassed for each compartment separately. Peristaltic pumps weresed to feed the solution of electrolyte (500 cm3) in a recircula-ion mode into the respective compartments with constant flowate (0.006 m3/h) to maintain the turbulence. Precious metal oxideoated titanium sheet (TiO2 sheet coated with a triple precious

etal oxide (titanium–ruthenium–platinum); of 6.0 �m thickness,nd 8.0 × 10−3 m2 effective area) obtained from Titanium Tantalumroducts (TITAN, Chennai, India), were used as cathode and anode.DC power supply (Aplab India, model L1285) was used to apply

onstant potential across the electrodes and the resulting current

Fig. 2. Schematic diagram of EDBPM cell for the conversion of sodium salt of R (Cl− ,HCOO− , CH3COO− and CH3CH2COO−) into corresponding their acids and base.

variation was recorded as a function of time using a digital multi-meter in series. The whole setup was placed at ambient condition(303 K) without any additional temperature control. Na2SO4 solu-tion (0.10 M) was recirculated through electrode compartments,while distilled water and salt solution was initially fed into com-partments 1 and 2. pH and conductivity of each stream output wereregularly monitored and the change in concentrations of NaOH andRCOOH in compartments 1 and 2 were also monitored by acid–basetitration at regular time of interval.

3. Results and discussion

3.1. Membrane preparation and characterizations

Single ionic layer (AL or CL) and composite BPM were preparedby solution casting and evaporation technique [29]. Initially, AL(100 �m) was casted onto a clean glass plate and dried at 60 ◦C for12 h. After coating the interfacial layer onto the surface of AL, SPEEKlayer (CL) was coated with same thickness. FTIR spectrum of CL wasrecorded and depicted as Fig. S4 (supplementary information). Thecharacteristics absorption band at 1590–1410 cm−1 with sharp tomedium intensity was aroused due to the aromatic C–H stretch-ing vibrations. The absorption bands at 2040–1914 cm−1 were thecharacteristic peaks of 1,2-disubstituted and 1,2,4-trisubstitutedaromatic moiety [30]. The peak at 1710 cm−1 was attributed to thecarbonyl group, while stretching band at 1024 cm−1 was occurreddue to the O S O vibrations of sulfonic acid group [31]. Band at1283–1000 cm−1 was observed due to in plane C–H deformation.Observed bands confirmed successfully sulfonation of PEEK. TheSEM images of AL and CL are presented in Fig. 3A and B, respec-tively. No cracks, holes and phase separation were observed, whichindicate quite dense nature of composite BPM. Fig. 3C shows the

cross-section image of composite BPM. Two separate layers withstrong interfacial adhesion are clearly visible.Performance of bipolar membranes could be improved by intro-ducing a third contact region or catalytic layer between the twoion-selective layers. The contact region, also referred to as inter-

M. Kumar, V.K. Shahi / Journal of Membrane Science 349 (2010) 130–137 133

oss-se

ftnatp

lTtcAirte

�

wicctihd

FN

Fig. 3. SEM images of: (A) CL; (B) AL and (C) cr

acial layer, is the region where water dissociation occurs, andhe charged groups and structures of this region are of great sig-ificance for water dissociation [32]. In this case, ion-exchangecidic and basic groups have proved to be effective catalysts inhe interfacial layer when used to improve the bipolar membrane’serformance and minimizing the layer resistance [32–34].

The physicochemical and electrochemical properties of ionicayers (AL and CL) and composite BPM are presented in Table 1.he membranes exhibited good water content, IEC, counter-ionransport numbers in the membrane phase, and high membraneonductivity under the operating conditions. The properties of CL,L and composite BPM are in good agreement with the best-known

on-exchange membranes [25]. The membrane resistance (Rm) wasecorded in equilibration with NaCl solution of different concentra-ions and specific membrane conductivity (�m) was estimated byquation given below:

m = �x

ARm (3)

here �x is the thickness of membrane in wet condition and As the membrane area. The variation in �m values for CL, AL andomposite BPM in equilibration with NaCl solutions of different

m

oncentrations is depicted in Fig. 4. The � values increased withhe concentration of equilibrating electrolyte solutions. BPM exhib-ted low conductivity in compare with CL, while comparativelyigher than AL. This may be attributed due to the higher chargeensity as well as ion-exchange capacity of BPM. The �m values ofig. 4. Membrane conductivity (�m) values for AL, CL and BPM in equilibration withaCl solution of different concentrations.

ction of composite bipolar membrane (BPM).

composite BPM, suggested its suitability in EDBPM process for theconversion of sodium salts into their corresponding acids (RCOOH)and base (NaOH).

3.2. Current–voltage (i–v) curves for bipolar membrane insolution of different electrolytes

Fig. 5 represents a typical steady state current–voltage curve fora composite BPM in equilibration with salt solutions of known con-centrations. Below the first limiting current density (ilim1), variationin current occurred due to ionic transportation [35,36]. At ilim1, theelectrical resistance increased significantly due to the depletion ofions in the interfacial region of BPM. The magnitude of ilim1 is ameasure of BPM selectivity towards co-ion leakage, and may beuse to predict its efficiency [35]. Beyond the dissociation poten-tial (Vdiss), water splitting products (OH−/H+) were also availablefor the current transport resulting in a steep increase in currentabove ilim1 [36]. The operating current density (iop) should be highto reduce the relative salt ion transport for high water splittingefficiency. Above the second limiting current (ilim2), if water trans-ported towards the interfacial region is not sufficient to replenishthe water dissociated at the interface, it may leads water diffu-sion limitations and therefore to a dry out of the membrane [33].

Fig. 6 shows i–v curves for composite BPM in equilibration with0.50 M solution of different electrolytes (NaCl and RCOONa). Thevalues of ilim1, ilim2, Vdiss, and iop, derived from i–v curves (Fig. 6)are presented in Table 2. Co-ion leakage through BPM was sig-nificantly reduced (ilim1) with increase in the carbon chain lengthFig. 5. Schematic presentation of i–v curve for a composite BPM in a salt solution(M+X−).

134 M. Kumar, V.K. Shahi / Journal of Membrane Science 349 (2010) 130–137

Fe

(cdIliihesfa

3

cd(wlaoaivfrwrido1iN

Tie

corresponding acid and base.Recovery of the product (NaOH in this case) is an important

parameter to examine the economic feasibility of any process,

ig. 6. Current–voltage curves of prepared composite bipolar membrane (BPM) inquilibration with different salt solution of 0.50 M concentration.

co-ion size). Second limiting current (ilim2) was also increased withhain length (R-), which diminished the possibility of membranery out in equilibration with carboxylate ion of higher homologues.

ncrease in iop values and reduction in Vdiss values with carbon chainength, indicated efficient water splitting across BPM under exper-mental environment. Furthermore, relatively high values of ilim1,lim2 and iop and low value of Vdiss for NaCl, were obtained due toigh dissociation and relatively high mobility of Cl− under givenxperimental conditions. Results obtained from i–v curves analy-is indicated the suitability of developed composite BPM in EDBPMor the conversion of homologous carboxylates into correspondingcids and base.

.3. The conversion of NaCl into HCl and NaOH by EDBPM

EDBPM experiments for converting NaCl solutions of differentoncentrations into HCl and NaOH, were carried out in under theifferent applied potentials (5.0–9.0 V). Initially, Na2SO4 solution0.10 M) was recirculated into the both electrode compartments,hile compartment 1 was fed by deionized water in a recircu-

ation mode. Variation in current density with time at constantpplied potential during water splitting at the interfacial zonef BPM, depicted in Fig. 7, as a representative case. At constantpplied potential, current density increased initially, after attain-ng the maximum value and it further decreased with time. Theoltage drop across the membrane depends on Donnan and dif-usion potentials at solution–membrane interface, and solutionesistance. At the beginning of the experiments, deionized wateras passed through compartment 1, which offered high electrical

esistance, due to high voltage drop. Progressively, ionic molalityn compartment 1 increased under constant applied potential gra-ient, due to water splitting (OH− and H+) at the interfacial zone

f a BPM. As a result, electrical resistance offered by compartmentdecreased in rapid manner with time, which caused an increasen current density under applied constant potential. Formations ofaOH and HCl in compartments 1 and 2 due to water splitting at

able 2lim1, ilim2, Vdiss, and iop values determined from i–v curves for composite BPM inquilibration with 0.50 M different solution of electrolytes.

ilim1 (mA cm−2) ilim2 (mA cm−2) Vdiss (V) iop (mA cm−2)

NaCl 3.75 29.8 2.02 17.81HCOONa 3.72 26.52 2.06 14.09CH3COONa 1.7 25.2 2.32 13.2C2H5COONa 0.98 13.07 2.37 6.4

Fig. 7. Variation in current density with time at different applied potential for theconversion of NaCl into acid (HCl) and base (NaOH) in EDBPM process.

the interfacial zone of a BPM were further assessed by the variationin pH for both streams and relevant data are presented in Fig. 8.

Ionic flux in electro-membrane processes (J) can be definedas change in concentration of Na+/R− or rate of formation ofNaOH/HCl. The J values were estimated from the variation inconcentrations of acid/base in compartment 2 or 1, respectively,considering negligible mass (water) transport, using followingequation [37,38].

J = Va

A

Ct − C0

�t(4)

where C0 and Ct is the initial and final concentration of NaOH or RH(R-: Cl− or HCOO−, CH3COO−, C2H5COO−) in compartments 1 and2 (mol m−3), �t is the time allowed for electro-membrane process(s), Va is the total volume of electrolyte solution (0.50 × 10−3 m3),and A is the effective membrane area (8.0 × 10−3 m2). Rate of NaOHformation (J) in EDBPM are presented in Fig. 9, as a function oftime at different applied potential ranging (5.0–9.0 V). Initially Jvalues increased linearly with time and after attaining maxima, itwas decreased due to the depletion of Na+ in anode compartmentand availability of NaCl in compartment 2 for the conversion into

Fig. 8. Variation of pH in compartments 1 and 2 for the conversion of 0.50 M NaClinto acid (HCl) and base (NaOH) during EDBPM process.

M. Kumar, V.K. Shahi / Journal of Membrane Science 349 (2010) 130–137 135

Ff

w

B

wscpNiwmeao

iiko

W

wtodoo

C

wb

Table 4Comparison of process performance of EDBPM for converting RCOONa (R-: Cl− ,HCOO− , CH3COO− , C2H5COO−) into RCOOH and NaOH at constant applied poten-tial (7.0 V), with constant concentration of salt solution (0.50 M) as initial feed ofcompartment 2 after passing of 7.0 × 103 (C).

Salts Co-ion leakage (M) CE (%) Recovery (%) W (kWh kg−1)

TC

ig. 9. Variation of rate of formation of NaOH (JNaOH) in compartment 1, at initialeed of 0.50 M NaCl solution with various applied potential.

hich may be defined as:

ase recovery (%) = CtpVtp

C0FV0F× 100 (5)

here V0F and Vtp are the initial and final volume of the basetream (compartment 1), C0F is the initial concentration of NaCl inompartment 2, and Ctp is the final concentration of NaOH in com-artment 1. Recoveries of NaOH at different feed concentrations ofaCl in compartment 2 were also studied as a function of electric-

ty passed (C). It was observed that the recovery of NaOH decreasedith the increase in feed concentration of NaCl in compartment 2,ay be due to the higher water splitting rate under less conductive

lectrolytic environment because of high resistance. Furthermore,bout 74–88% recovery of NaOH was achieved in EDBPM underperating conditions.

Energy consumption (W) and current efficiency (CE) are alsomportant parameters to assess the suitability of any electrochem-cal process for practical applications. The energy consumption (W,Wh kg−1 for producing acid or base) in EDBPM process may bebtained by using following equation [38]:

(kWh kg−1) =∫ t

0

VI dt

m(6)

here V is the applied potential (V), I is the current, t is theime allowed for the electrochemical process, and m is the weightf NaOH or RH (R-: Cl−, or HCOO−, CH3COO−, C2H5COO−) pro-uced. The overall current efficiency was defined as the fractionf Coulombs utilized for the water splitting and electro-migrationf ions:

E (%) = mnF

MQ× 100 (7)

here F is the Faraday constant, M is the molecular weight of thease or acid, n is the stoichiometric number (n = 1 in this case),

able 3o-ion leakage, CE, W, and base recovery data for converting NaCl into corresponding aci

Applied potential (V) Electricity passed ×103 (C) Conc. of feed NaCl (M) C

5.0 6.77 0.50 07.0 7.68 0.50 09.0 8.33 0.50 07.0 11.66 1.0 07.0 11.98 1.5 0

NaCl 0.011 68.8 88.2 3.10HCOONa 0.007 71.4 87.2 4.73CH3COONa 0.005 40.2 50.4 7.41C2H5COONa 0.005 35.1 40.4 7.97

and Q is the electricity passed (C). Feasibility for water splittingand formation of acid and base from salt was evaluated in terms ofenergy consumption, CE (%), and recovery (%) of NaOH data underdifferent experimental conditions (Table 3). The CE (%) and recoveryof NaOH were decreased while energy consumption increased withthe applied potential for the NaCl solution (0.50 M) as initial feedin the compartment 1. Under optimum operating conditions (afterpassing of 7.76 × 103 C electricity), CE and W were found to be 67.5%and 3.1 kWh kg−1, respectively corresponding to 88.2% recovery ofNaOH. Relatively low CE may be explained in terms of co-ion (Cl−)leakage through a BPM from compartment 2 to compartment 1.Co-ion leakage data through a BPM under different experimentalconditions is also presented in Table 3. It was observed that co-ionleakage increased with increase in applied potential and/or NaClfeed concentration. Furthermore, about 2–4% co-ion leakage wasobserved, which is negligible for product purity.

In EDBPM, relatively high energy consumption, low CE andrecovery may be attributed to the higher water splitting at the inter-facial zone of BPM and simultaneously ionic migration through CL’s.Thus electricity supplied to the system was consumed for watersplitting as well as for ionic migration [39,40]. After several exper-iments, electrochemical properties of CL and BPM were measuredwhich were reproduced with ±1.0% deterioration. Thus any type offouling or disintegration of the membranes was completely ruledout.

3.4. Comparison of process performance of EDBPM for convertingRCOONa into RCOOH and NaOH

Conversion of RCOONa (R-: HCOO−, CH3COO−, C2H5COO−) intoRCOOH and NaOH, was achieved by EDBPM under different exper-imental conditions and process performance was compared inTable 4 for different salts. Data revealed that CE and recovery ofRCOOH were decreased, while energy consumption increased withthe increase in the carbon chain length. Theoretical interpretationto these variations can be explained by ionic transport, diffusionand water splitting at the interfacial zone of BPM. As shown inFig. 2, when a dc passed between the electrodes, protons producedon cathode side of BPM (compartment 2) and acidify organic saltinto corresponding acid. In the arrangement of two CLs and a BPM

between electrodes, there was possibility to electro-transport ofH+ towards catholyte through CL. However, in these experimentalconditions, the cations (Na+) have very high concentration com-pared with H+. Therefore, the electro-transport of H+ does not seemto be significant, when Na+ is available for the ion-substitution. Itd and base in EDBPM under different experimental conditions.

o-ion leakage through BPM (M) Recovery (%) CE (%) W (kWh kg−1)

.009 74.2 52.8 2.3

.012 87.2 67.6 3.1

.014 68.4 48.2 5.4

.018 71.2 58.4 5.7

.021 58.3 48.5 7.2

136 M. Kumar, V.K. Shahi / Journal of Membrane Science 349 (2010) 130–137

Fo

soHlc

itRbiRcsArccelspm

bPfcCCaceecc

cwBDec

Table 5Comparison of the process performance for developedheterogeneous–homogeneous composite and commercial available bipolarmembrane.

Membrane CE (%) W (kWh kg−1) Reference

FT-BP (FuMA-Tech GmbH, Germany)a 92 12–16 [41]BP-1 (Tokuyama Soda), Japanb 30 4.1 [42]BP-1 (NEOSEPTA)c 72 4.3–16.6 [43]Developed composite BPMd 71.4 4.73 This work

a Commercial BPM used for the production of tartaric acid from its sodium salt.b Commercial BPM used for the production of p-toluenesulfonic acid from its

ig. 10. Recovery of HCOOH in compartment 2, in EDBPM at various concentrationsf HCOONa solution as initial feed of compartment 2, at 7.0 V applied potential.

hould be pointed out that dissociation of RCOONa or availabilityf ions reduced with the increase in the carbon chain length (R-).igh resistivity offered by compartment 2 in case of higher homo-

ogues of RCOONa, may be responsible for low CE and high energyonsumption.

Low recovery of acid (RCOOH) and base (NaOH) with increasen carbon chain length of sodium salts (Table 4), may be attributedo: (i) low degree of dissociation for higher homologues ofCOOH/RCOONa and (ii) slow migration and co-ion leakage ofulkier anions (RCOO−) through BPM from compartment 2 to 1. Co-

on leakage data presented in Table 4, also supports above results.epresentative data for the recovery of HCOOH in EDBPM at 7.0 Vonstant applied potential and varied concentrations of HCOONaolution (initial feed of compartment 2), are presented in Fig. 10.n increase in initial feed concentration of HCOONa lowered theecovery significantly. However, data (Table 4) revealed that pro-ess performance was significantly reduced (low CE, high energyonsumption and low recovery of RCOOH after passage of constantlectricity) with increase in carbon chain length of R-, under simi-ar experimental conditions. Less than 1.0% co-ion leakage was notignificant. Lower dissociation of higher homologues of RCOONa,layed significant role for observed variation in process perfor-ance with increase in carbon chain length (R-).Both the CE and energy consumption were significantly affected

y the cell configuration, nature and resistance of CL as well as BPM.roposed configuration of EDBPM (Fig. 1) for ionic replacement iseasible due to low energy consumption, negligible possibility ofo-ion leakage, which affects the product purity and lowered theE. Also, due to the good electrochemical properties of preparedL and BPM, high CE, low energy consumption and co-ion leak-ge revealed the suitability of prepared composite BPM for theonversion of RCOONa into their corresponding acids and base,specially for lower homologues. Nevertheless, better CE and lownergy value can be obtained by means of a filter type press EDBPMell in which the compartment thickness and the hydrodynamiconditions should be more favorable.

In order to assess the membrane performance, current effi-iency and energy consumption of the developed composite BPMas compared with the reported values for commercial available

PM, using similar or different types of salts solutions [41–43].ata presented in Table 5, revealed that current efficiency andnergy consumption values of the developed composite BPM wereomparable with commercial available membrane. Especially, forsodium salt.c Commercial BPM used for the production of formic acid from its sodium salt.d Developed BPM used for the production of formic acid from its sodium salt.

converting HCOONa into corresponding acid and base, devel-oped membrane showed 71.4% CE corresponding to 4.73 kWh kg−1

energy consumption against 72% CE and 4.3–16.6 kWh kg−1 energyconsumption for Neosepta BP-1.

4. Conclusions

We prepared heterogeneous–homogeneous composite BPMwith interfacial layer, in same solvent to obtain good contactbetween cationic and anionc layer, mechanical stability and goodphysico- and electro-chemical properties. CL, AL and BPM were sep-arately prepared and examined. These membranes exhibited lowwater content and resistivity, while high ion-exchange capacity.The i–v curves for BPM were also recorded to determine ilim1, ilim2,iop and Vdis values. These parameters are essential to assess thewater splitting performance of a BPM. High values of ilim1, ilim2,iop and low Vdiss were obtained due to high dissociation of NaCland relatively high mobility of Cl− under given experimental con-ditions. Four-compartments EDBPM cell was devised, containinga BPM and two pieces of CL, for converting salts into their corre-sponding acids and base, under different experimental conditions.After passage of 7.68 × 103 C of electricity, 67.6% CE correspondingto 3.1 kWh kg−1(energy consumption) were observed for 0.50 MNaCl solution. However, process performance was significantlyreduced (low CE, high energy consumption and low recovery) forthe conversion of higher homologues of RCOONa under similarexperimental conditions. Less than ∼1.0% co-ion leakage was notsignificant. Relatively low dissociation of higher homologues ofRCOONa was responsible for the observed variation in process per-formance.

Furthermore, due to the good electrochemical properties of pre-pared CL and BPM, high CE, low energy consumption and co-ionleakage in EDBPM for conversion of NaCl and HCOONa into theircorresponding acid and base, revealed the suitability of preparedcomposite BPM for lower homologues of salt. It should be men-tioned that the above results are obtained with just one productioncell between electrode compartments. For commercial EDBPMstack with many production cells, the exact values of voltage drop,CE and energy consumption may be changed due to cell number.So, the preliminary results can be act as a basis to prepare efficientheterogonous–homogenous composite BPM for water splitting andconversion of salt into corresponding acid and base.

Acknowledgements

Authors are extremely thankful to the Ministry of Environ-

ment and Forest (MOEF), New Delhi, Govt. of India, for providingfinancial assistance by sanctioning project no.19/37/2006-RE. Weacknowledge the Analytical Science Division, CSMCRI, Bhavnagarfor instrumental support.

embr

A

t

R

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[[

[

[

[

[

[

[

[

[

[

[

[42] L. Yu, J. Su, J. Wang, Bipolar membrane-based process for the recycle ofp-toluenesulfonic acid in D-(−)-p-hydroxyphenylglycine production, Desali-nation 177 (2005) 209.

M. Kumar, V.K. Shahi / Journal of M

ppendix A. Supplementary data

Supplementary data associated with this article can be found, inhe online version, at doi:10.1016/j.memsci.2009.11.041.

eferences

[1] J. Balster, D.F. Stamatialis, M. Wessling, Electro-catalytic membrane reactorsand the development of bipolar membrane technology, Chem. Eng. Proc. 43(2004) 1115.

[2] F.G. Wilhelm, N.F.A. van der Vegt, M. Wessling, H. Strathmann, Bipolar mem-brane preparation, in: A.J.B. Kemperman (Ed.), Bipolar Membrane Handbook,Twente University Press, Enschede, The Netherlands, 2000.

[3] S. Mazrou, H. Kerdjoudj, A.T. Cherif, A. Elmidaoui, J. Molenat, Regeneration ofhydrochloric acid and sodium hydroxide with bipolar membrane electrodialy-sis from pure sodium chloride, New J. Chem. 22 (1998) 355.

[4] J. Balster, R. Sumbharaju, S. Srikantharajah, I. Punt, D.F. Stamatialis, V. Jordan,M. Wessling, Asymmetric bipolar membrane: a tool to improve product purity,J. Membr. Sci. 287 (2007) 246.

[5] M.-S. Kang, Y.-J. Choi, S.-H. Kim, S.-H. Moon, Enhancement of water split-ting in bipolar membranes by optimized composite anion-exchange layer andalkali-treated polyacrylonitrile catalytic junction, J. Membr. Sci. 229 (2004)137.

[6] T. Xu, W. Yang, Fundamental studies on a novel series of bipolar membranesprepared from poly(2,6-dimethyl-1,4-phenylene oxide) (PPO). I. Effect of anionexchange layers on I–V curves of bipolar membranes, J. Membr. Sci. 238 (2004)123.

[7] V. Frilette, Preparation and characterization of bipolar ion exchange mem-branes, J. Phys. Chem. 60 (1956) 435.

[8] J.H. Hao, C.X. Chen, L. Li, L.X. Yu, W.J. Jiang, Preparation of bipolar membranes(I), J. Appl. Polym. Sci. 80 (2001) 1658.

[9] R.Q. Fu, T.W. Xu, W.H. Yang, Z.X. Pan, Preparation of a mono-sheet bipolar mem-brane by simultaneous irradiation grafting polymerization of acrylic acid andchloromethylstyrene, J. Appl. Polym. Sci. 90 (2003) 572.

10] R. El Moussaoui, H. Hurwitz, Single-film membrane-process for obtaining it anduse thereof, US Patent 5,840 (1998) 192.

11] C.H. Huang, T.W. Xu, Y.P. Zhang, Y.H. Xue, G.W. Chen, Application of elec-trodialysis to the production of organic acids-state-of-the-art-and recentdevelopments, J. Membr. Sci. 288 (2007) 1.

12] J.S. Jaime-Ferrer, E. Couallier, P. Viers, G. Durand, M. Rakib, Three-compartmentbipolar membrane electrodialysis for splitting of sodium formate into formicacid and sodium hydroxide: role of diffusion of molecular acid, J. Membr. Sci.325 (2008) 528.

13] V. Cauwenberg, J. Peels, S. Resbeut, G. Pourcelly, Application of electrodialysiswith in fine chemistry, Sep. Purif. Technol. 22–23 (2001) 115.

14] J.S.J. Ferrer, S. Laborie, G. Durand, M. Rakib, Formic acid regeneration by elec-tromembrane processes, J. Membr. Sci. 280 (2006) 509.

15] S. Novalic, T. Kongbangkerd, K.D. Kulbe, Recovery of organic acids with highmolecular weight using a combined electrodialytic process, J. Membr. Sci. 166(2000) 99.

16] C.-X. Xu, R.-Y. Chen, X. Zheng, X. Chen, Z. Chen, Preparation of PVA-GA-CS/PVA-Fe-SA bipolar membrane and its application in electro-generation of2,2-dimethyl-3-hydroxypropionic acid, J. Membr. Sci. 307 (2008) 218.

17] A. Narebska, M. Kurantowicz, M. Staniszewski, Separation of fermentationproducts by membrane techniques. IV. Electrodialytic conversion of carboxy-lates to carboxylic acids, Sep. Sci. Technol. 36 (2001) 443.

18] J.H. Hao, L.X. Yu, C.X. Chen, L. Li, W.J. Jiang, Preparation of bipolar membranes(II), J. Appl. Polym. Sci. 82 (2001) 1733.

19] T. Xu, R. Fu, W. Yang, Y. Xue, Fundamental studies on a novel series of bipolar

membranes prepared from poly(2,6-dimethyl-1,4-phenylene oxide) (PPO). II.Effect of functional group type of anion-exchange layers on I–V curves of bipolarmembranes, J. Membr. Sci. 279 (2006) 282.20] P.V. Vyas, B.G. Shah, G.S. Trivedi, P. Ray, S.K. Adhikary, R. Rangarajan, Studieson heterogeneous cation-exchange membranes, React. Funt. Polym. 44 (2000)101.

[

ane Science 349 (2010) 130–137 137

21] B.G. Shah, V.K. Shahi, S.K. Thampy, R. Rangarajan, P.K. Ghosh, Comparativestudies on performance of interpolymer and heterogeneous ion-exchangemembranes for water desalination by electrodialysis, Desalination 172 (2005)257.

22] V. Shapiro, V. Freger, C. Linder, Y. Oren, Transport properties of highly orderedhereterogeneous ion-exchange membrane, J. Phys. Chem. B 112 (2008) 9389.

23] P.V. Vyas, P. Ray, R. Rangarajan, S.K. Adhikary, Electrical conductance of hetero-geneous cation-exchange membrane in electrolyte solutions, J. Phys. Chem. B106 (2009) 11910.

24] H.-J. Lee, M.-K. Hong, S.-D. Han, S.-H. Moon, Influence of the heterogenousstructure on the electrochemical properties of anion exchange membranes,J. Membr. Sci. 320 (2008) 549.

25] R.K. Nagarale, G.S. Gohil, V.K. Shahi, Recent developments on ion-exchangemembranes and electro-membrane processes, Adv. Colloid Interface Sci. 119(2006) 97.

26] G.S. Gohil, R.K. Nagarale, V.V. Binsu, V.K. Shahi, Preparation and characteriza-tion of monovalent cation selective sulfonated poly(ether ether ketone) andpoly(ether sulfone) composite membranes, J. Colloid Interface Sci. 298 (2006)845.

27] R.K. Nagarale, G.S. Gohil, V.K. Shahi, G.S. Trivedi, R. Rangarajan, Preparation andelectrochemical characterization of cation- and anion-exchange/polyanilinecomposite membranes, J. Colloid Interface Sci. 277 (2004) 162.

28] B.J. Robbins, R.W. Field, S.T. Kolaczkowski, A.D. Lockett, Rationalization of therelationship between proton leakage and water flux through anion exchangemembranes, J. Membr. Sci. 118 (1996) 101.

29] F.G. Wilhelm, I. Punt, N.F.A. van der Vegt, M. Wessling, H. Strathmann, Asym-metric bipolar membranes in acid–base electrodialysis, Ind. Eng. Chem. Res. 41(2002) 579.

30] G. Socrates, Infrared Characteristic Group Frequencies, Wiley, Chichester, 1980.31] G. Alberti, U. Costantino, M. Casciola, S. Ferroni, L. Massinelli, P. Staiti,

Preparation, characterization and proton conductivity of titanium phosphatesulfophenylphosphonate, Solid State Ionics 145 (2001) 249.

32] Y Xue, N. Wang, C. Huang, Y. Cheng, T. Xu, Catalytic water dissociation at theintermediate layer of a bipolar membrane: the role of carboxylated Boltorn®

H30, J. Membr. Sci. 344 (2009) 129.33] F.G. Wilhelm, I. Pünt, N.F.A. van der Vegt, M. Wessling, H. Strathmann1, Optimi-

sation strategies for the preparation of bipolar membranes with reduced saltion leakage in acid–base electrodialysis, J. Membr. Sci. 182 (2001) 13.

34] R. Simons, Water splitting in ion exchange membranes, Electrochim. Acta 30(1985) 275.

35] T. Aritomi, T. van der Boomgaard, H. Strathmann, Current voltage curve of abipolar membrane at high current density, Desalination 104 (1996) 13.

36] J.J. Krol, M. Jansink, M. Wessling, H. Strathmann, Behaviour of bipolar mem-branes at high current density: water diffusion limitation, Sep. Purif. Technol.14 (1998) 41.

37] M. Kumar, B.P. Tripathi, V.K. Shahi, Electro-membrane reactor for separationand in situ ion substitution of glutamic acid from its sodium salt, Electrochim.Acta 54 (2009) 4880.

38] M. Kumar, B.P. Tripathi, V.K. Shahi, Electro-membrane process for in situ ionsubstitution and separation of salicylic acid from its sodium salt, Ind. Eng. Chem.Res. 48 (2009) 923.

39] Y.H. Kim, S.-H. Moon, Lactic acid recovery from fermentation broth using one-stage electrodialysis, J. Chem. Technol. Biotechnol. 76 (2001) 169.

40] L. Madzingaidzo, H. Danner, R. Braun, Process development and optimizationof lactic acid purification using electrodialysis, J. Biotechnol. 96 (2002) 223.

41] K. Zhang, M. Wang, D. Wang, C. Gao, The energy-saving production of tar-taric acid using ion exchange resin-filling bipolar membrane electrodialysis,J. Membr. Sci. 341 (2009) 246.

43] N. Zhang, S. Peng, C. Huang, T. Xu, Y. Li, Simultaneous regeneration of formicacid and carbonic acid from oxalate discharge by using electrodialysis withbipolar membranes (EDBM, J. Membr. Sci. 309 (2008) 56.