Heavy Duty Turning Center - PUMA Machine Tools · The large 12 station heavy duty turret features a...

Transcript of Heavy Duty Turning Center - PUMA Machine Tools · The large 12 station heavy duty turret features a...

Heavy Duty Turning Center

The PUMA 500 turning centers are the most powerful machines in their class. Designed for heavy and interrupted cutting, holding long term accuracies, and maintaining superior finishes. High metal removal rates along with rapid positioning and high speed turret indexing, guarantee unmatched cycle times when real performance is essential. Proven manufacturing techniques and ultra rigid construction are combined with advanced technological features to produce superior machine with exceptional values.

The Most Powerful Machines in Their Class

2

3

Main Spindle

The 45 kW(PUMA 500) spindle motor provides power for heavy stock removal,greatly reducing the number of roughing passes required. The reliable digital ACspindle motor provides fast acceleration and is maintenance free. The preloadedspindle bearings are specifically calibrated to maintain the perfect balance of rigidityand speed. The geared headstock ensures optimal power throughout a wide speedrange. Full power is available from 76 r/min on the where the low end torque is 5645N.m. The large diameter spindle can handle chucks up to 813 mm in diameter.

T=564

5 N. m

r/min

T=220

5 N. m

T=839

N. m

45kW 30min

● Spindle speed range : 1500 r/min●Motor power : 45kW

Main Spindle Drive

Max. spindle speed

11550000 r/min

4455 kW

Motor (30 min)

The headstock casting is made of Meehanite andribbed on the outside to increase the surface area forbetter heat dissipation. The headstock and mainspindle are manufactured in a temperaturedcontrolled environment then assembled and testedin our clean room. The heavy duty cartridge typespindle is supported by a double row of cylindricalroller bearings in the front and rear, with duplexangular thrust bearings in between. The cylindricalroller bearings feature a large contact surface whichensures the highest rigidity for heavy loads andsuperior finishes. All spindle bearings arepermanently grease lubricated precision class P4.

Headstock and Spindle Construction

Headstock Cross Section

4

■Main spindle power-torque diagram

Power is delivered to the spindle through a threespeed geared head allowing high spindle speeds aswell as powerful low end torque.

Geared Head

00..2255 sIndex time (1-station swivel)

1122 stationsNo. of tool station

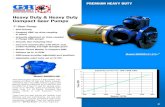

The large 12 station heavy duty turretfeatures a large 400 mm Curvic couplingdiameter and 213640 N of hydraulic clampforce. This heavy duty design providesunsurpassed rigidity for heavy stockremoval, fine surface finishes, and extendedtool life. The exceptionally stable turret has avery wide 150 mm turret plate to ensurelong boring bar over-hang ratios. Indexingrepeatability is ±0.0005 degrees. Turretindexing is non-stop bi-directional. Anextremely reliable high-torque hydraulicmotor provides for quick turret indexing. 32mm square tool holders are mounteddirectly to the turret. The boring bar capacityis 80 mm. The turret features a flexibledesign, allowing for left or right handed, IDor OD tool placement.

The turret features BMT styletooling in which the toolholders are mounted directiyto the turret’s periphery using4 large bolts. This type ofmounting system allows aextremely high degree ofrigidity.

Turret

TURRET SADDLEHeavy Duty Turret

5

Each axis is powered by a maintenance freedigital AC servo motor. These high torquedrive motors are connected to the ball screwswithout intermediate gears for quiet andresponsive slide movement with virtually nobacklash.

Asix Drives

The programmable tailstock body is mountedon the same guideway surface as theheadstock. The heavy casting, large 150 mmdiameter quill, and precision Morse Taper #6live center provide outstanding rigidity. The150 mm quill stroke is activated by either theprogram and foot switch. Auto lubrication isprovided to the quill and guideways.

Programmable TailstockDouble Pretensioned Ball Screw

Axis Drive Construction and Tail Stock

Both the X and Z axes feature doublepretension ed ball screw, supported on eachend by precision class P4 angular contactthrust bearings. Both axes are driven by largediameter, high precision ball screws. Each ballscrew has been carefully selected to achieve acombination of high accuracy, high rapidtraverse rates and high feed thrust. All ballscrews are fully supported on both ends.

Bed and Way Construction

Rapid Traverse

Doosan Infracore precision machine tools are internationally known for theirdurability, rigidity and high accuracy. Only well proven and time testedmanufacturing techniques can produce machines of this quality.

The PUMA 500 is a true 60 degree slant beddesign. The bed is a one piece casting with boththe saddle and tailstock guideways in the sameplane to eliminate thermal distortion. The heavilyribbed torque tube design prevents twisting anddeformation. Fine grain Meehanite processed castiron is used because of its excellent dampeningcharacteristics. This design ensures high rigiditywith no deformation during heavy cutting. Theslant angle allows for easy loading , changing andinspection of tools. All guide ways are groundwrap-around rectangular type for unsurpassedlong-term rigidity and accuracy. The guideways arewidely spaced to ensure stability and fully

protected. Each guideway is induction hardenedand precision ground. A fluroplastic resin, RulonⓇ

142, is bonded to the mating surfaces, for its wearand low friction characteristics and then handscraped for a perfect fit and center height.

6

•Scraping of Slideway •Outstanding rigidity for high feedrates

1100 m/min

X-axis

1122 m/min

Z-axis

Slant-design bed makes the work go smoother, chipremoval much easier. Tough tubular construction stands upto the hardest cutting jobs.

7

The coolant is kept clean and its life is extended with bed castingchannels from the Z axis to a separate reservoir. A belt oil skimmer picksup and removes waste oil from the coolant tank that is easily drained.

The high pressure flushes chips out of drilled holes, reduces theneed for peck drill cycles, exceeds the requirements of mostinsert drill manufactures and significantly increases tool life.

The separate, large 310L capacity coolant tank and chip pan areseparate from the machine bed to prevent heat transfer and easycleaning.

Eco-Friendly Design

Metered Way Lubrication

Hydraulic Power Unit

Oil Skimmer(Opt.)

Automatic lubrication is provided to all guideways, ball screws andthe tailstock quill. A maintenance free piston distributor delivers aprecise quantity of oil to each lubrication point. The 2.7L reservoirlasts up to 80 hours. A low level alarm prevents the machine fromrestarting without lubricant.

Automatic Tool Setter(Opt.)

Coolant System

The automatic tool setter reduces set-up time by minimizing theneed for skim cuts, measurements and entering tool offsets. The toolsetting arm is moved by an electric motor and can be controlledthrough the program.

unit : mm

unit : mm

Tooling System

Tool Interference Diagram

8

unit : mm

External Dimension

R57

4R597

R684

R649

R57

4R

594R570

R344

597

2455

560

R600

4930684

5579

3612

3150

4800

205 1445 130

1404

6204

1005

1165

650

2250

275 785 880 515

2202

38

7

2589

1394 10

950

980

TTOOPP VVIIEEWW

RRiigghhtt SSiiddee VVIIEEWW FFRROONNTT VVIIEEWW

9

Working Ranges

•Design and specifications are subject to change without prior notice.•We are not responsible for difference between the information in the catalog and the actual machine.

Swing over bed mm 900

Swing over saddle mm 630

Recom. Turning diameter mm 450

Max. turning diameter mm 700

Max. turning length mm 1575

Bar working diameter mm 117

X-axis travel mm 370

Z-axis travel mm 1575

Spindle speed r/min 1500

Spindle nose ASA A2#15

Spindle bearing diameter mm 200

Spindle through hole diameter mm 152

No. of tool stations st 12

OD tool size mm 32

Boring bar diameter mm Ø80

Indexing time (1st. swivel) s 0.25

Quill diameter mm 150

Quill bore taper MT MT#6

Quill travel mm 150

Rapid traverse(X-axis) m/min 10

Rapid traverse(Z-axis) m/min 12

Main spindle motor(30min) kW 45

Feed motor(X/Z-axis) kW 4.0 / 7.0

Coolant pump motor kW 0.4

Electric power supply (Rated capacity) kVA 63.6

Machine height mm 2587

Machine dimensions (W × L) mm 2455 × 5009

Machine weight kg 14000

CCaappaacciittyy

IItteemm PPUUMMAA 550000

CCaarrrriiaaggee

MMaaiinn SSppiinnddllee

TTooooll PPoosstt

TTaaiill SSttoocckk

FFeeeeddrraattee

MMoottoorrss

PPoowweerr SSoouurrcceeMMaacchhiinneeSSiizzee

Machine Specifications

Standard Feature■ Coolant supply equipment■ Full enclosure chip and coolant shield■ Hand tool kit, including small hand tool

for operations

■ Hydraulic chuck & actuating cylinder■ Hydraulic power unit■ Leveling jack screw & plates■ Lubrication equipment

■ Programmable Tailstock & Live center■ Soft jaws (total 5sets)■ Standard tooling kit (tool holder & boring sleeve)■Work light (1set)

Optional Feature■ Air blast for chuck jaw cleaning■ Automatic door with safety device■ Automatic measuring system (in process touch probe)■ Automatic power off■ Bar feeder interface■ Chip conveyor ■ Chip bucket■ Controller : Fanuc 18i-TB

■ Tool monitoring system■ Dual chucking pressure■ Hardened & ground jaws■ High pressure coolant pump■ Oil skimmer■ Programmable Tailstock &

Built-in center (MT#5)■ Signal tower (yellow, red, green)

■ Pressure switch for chucking pressure check■ Steady rest

- Hydraulic, or- Manual

■ Tool pre-setter- Hydraulic, or- Manual

10

CCoonnttrroollss

AAxxiissFFuunnccttiioonnss

OOppeerraattiioonn

IInntteerrppoollaattiioonn

FFeeeedd FFuunnccttiioonnss

AAxxuuiilliiaarryy &&SSppiinnddllee FFuunnccttiioonnss

PPrrooggrraammmmiinnggFFuunnccttiioonnss

EEddiittiinngg OOpp..FFuunnccttiioonnss

SSeettttiinngg && DDiissppllaayy

DDaattaa IInnppuutt &&OOuuttppuutt

TTooooll FFuunnccttiioonnss

OOtthheerr FFuunnccttiioonnss

IItteemm SSppeecc.. FFaannuucc 2211ii--TTBB FFaannuucc 1188ii--TTBB

Controlled axes X, Z X, ZSimultaneously controlled axes Std. 2 axes ○ ○Backlash compensation 0~±9999 pulses ○ ○Cs contouring control - -Follow-up / Chamfering on/off ○ ○HRV control ○ ○Least input increment 0.001mm / 0.0001″ ○ ○Stored stroke check1 Overtravel control ○ ○Automatic operation(memory) / Buffer register ○ ○Manual handle feed rate X1, X10, X100 ○ ○Search function Sequence NO. / Program NO. ○ ○1st, 2nd reference position check / return G27/G28, -/G30 ○ ○Circular interpolation G02, G03 ○ ○Continuous thread cutting ○ ○Dwell G04 ○ ○Linear interpolation G01 ○ ○Multiple threading /Thread cutting retract ○ ○Polar coordinate interpolation G12.1, G13.1 - -Thread cutting / Synchronous cutting ○ ○Feed per minute / Feed per revolution G98 / G99 ○ ○Feedrate override 0 - 200 % (10 % unit) ○ ○Jog feed override 0 - 2000 mm/min ○ ○Rapid traverse override F0/ 25 / 100 % ○ ○Tangential speed constant control ○ ○1st Spindle orientation ○ ○Constantant surface speed control G96, G97 ○ ○M-function M3 digit ○ ○Multi-spindle control - -Rigid tapping ○ ○Spindle speed override 0~150 % ○ ○Absolute / Incremental programming ○ ○Canned cycle for drilling G80 series ○ ○Custom macro B ○ ○Decimal point programming/pocket calculator type decimal point programming ○ ○Direct drawing dimension programming ○ ○eZ Guide i Conversational programming ○ ○Maximum program dimension ±99999.999mm/(±9999.9999 inch) ○ ○Multi repetitive canned cycle G70~G76 ○ ○Multi repetitive canned cycle 2 ○ ○Optional block skip(without hardware) Total 9(Only NC function) ○ ○Program number / Sequence number O4 digits / N5 digits ○ ○Programmable data input G10 ○ ○Sub program call Nested holds4 4 4Tape format for FANUC series 10/11 ○ -Tape format for FANUC series 15 - ○Work coordinate system selection G52, G53, G54~G59 ○ ○Auto tool offset ○ ○Tool monitoring system Opt. Opt.Direct input of tool offset value measured B ○ ○Tool geometry / wear compensation Geometry & wear data ○ ○Tool life management ○ ○Tool nose radius compensation G40~G42 ○ ○Tool number command(T-code function) T2+2 digits ○ ○Tool offset pairs 64 32Tool offset value counter input ○ ○Background editting ○ ○Expanded part program editting Copy, Move, Change of NC program ○ ○No. of Registered programs 200ea 125eaPart program editing / Program protect ○ ○Part program storage length*1 640m 640mDisplay of spindle speed and T-code at all screen ○ ○Help function Alarm&Operation display ○ ○Self diagnostic function ○ ○Servo setting screen / Spindle setting screen ○ ○Status display / Lock function ○ ○Tool path graphic display - -External key input / External data input ○ ○External work number search ○ ○I/O interface RS - 232C ○ ○Memory card input and output ○ ○Reader puncher control CH1 interface ○ ○Ethernet function Embedded ethernet function ○ ○MDI / DISPLAY unit 10.4″color LCD 10.4″color LCDPMC system ○ ○

◯ : Standard OPT : Option (!) : only M type *1 : Standard Part program length is different on export condition. On the addition of optional functions, its length can be reduced.

NC Unit Specifications

11

http://domss.doosaninfracore.com

Design and specifications are subject to change without prior notice. EU0804SPi-ser

Sales & Support Network

ARGENTINA/Rosario AUSTRALIA/Melbourne/Sydney AUSTRIA/Vienna BELGIUM/Gullegem BRAZIL/Sao paulo BULGARIA/Sofia CANADA/Edmonton/Montreal/Toronto

/Vancouver CHILE/Santiago CHINA/Beijing/Chongqing/Guangzhou/Shanghai/Shenyang COLOMBIA/Bogota CZECH/Brno DENMARK/Randers EGYPT/Cairo FINLAND/Tampere

FRANCE/Annecy GERMANY/Dusseldorf GREECE/Athens HONG KONG/Kowloon HUNGARY/Budapest INDIA/Bangalore/Pune INDONESIA/Jakarta ISRAEL/Herzlia

ITALY/Parma MALAYSIA/Puchong MEXICO/Guadalajara /Mexico City /Monterrey /Vera Cruz NETHERLANDS/Goorn NEW ZEALAND/Auckland NORWAY/Oslo PAKISTAN

/Islamabad POLAND/Krakow PORTUGAL/Lisbon ROMANIA/Bucharest RUSSIA/Moscow SINGAPORE/Singapore SLOVENIA/Ljubljana SOUTH AFRICA/Kempton Park

SPAIN/Barcelona SWEDEN/Stockholm SWITZERLAND/Zurich TURKEY/Istanbul THAILAND/Bangkok U.A.E/Sharjah U. K./Leamington U.S.A./Atlanta/Birmingham

/Charlotte/Chicago/Cincinnati/Cleveland/Dallas/Denver/Detroit/Houston/Indianapolis/Kansas City/Little Rock/Los Angeles/Milwaukee/Minneapolis/New Orleans/Norfolk/Philadelphia/Phoenix

/Pittsburgh/Portland/Rochester/Salt Lake City/San Diego/San Francisco/Seattle/Springfield/St. Louis/Tampa/Trenton/Tulsa VENEZUELA/Valencia VIETNAM/Hanoi

Head Office : Doosan Tower 22nd FL., 18-12, Euljiro-6Ga, Jung-Gu, Seoul, Korea 100-730Tel : ++82-2-3398-8651 Fax : ++82-2-3398-8699 E-mail : [email protected]

Doosan Infracore America Corp.: 8 York Avenue, West Caldwell, NJ 07006, U.S.A.Tel : ++1-973-618-2500 Fax : ++1-973-618-2501

Doosan Infracore Germany GmbH : Hans-Böckler-Strasse 29, D-40764 Langenfeld-Fuhrkamp, Germany.Tel : ++49-2173-8509-10 Fax : ++49-2173-8509-60

China Representative Office : 9-101 Xinmao Building, 99 Tianzhou Road, Caohejing Hi-Tech Development Shanghai, China 200233 Tel : ++86-21-5445-1155 (812,815) Fax : ++86-21-64403389