Heat transfer by conduction

Transcript of Heat transfer by conduction

Heat

• Heat is a form of Energy

• A material becomes hotter when it gains sensible heat energy

• Gain in heat energy can lead to a change of phase

• Heat energy can transfer from one point to another in space

• The SI unit is Joules [J]

• Commonly used symbol is 𝑄

𝑄 =𝑑𝑄

𝑑𝑡Heat Flow Rate

𝑄 = 𝑆

𝑞. 𝑑 𝑠Heat Flux is given as

[W]

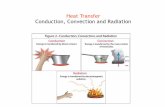

Heat Transfer

Where Heat flux is 𝑞 [W.m-2]

[W]

Heat energy is effectively transferred from one point in space to

another under a temperature gradient.

Heat Transfer: First Law of Thermodynamics

• Principle of Conservation of Energy

𝐸𝑖𝑛 − 𝐸𝑜𝑢𝑡 = ∆𝐸𝑠𝑦𝑠𝑡𝑒𝑚

Steady State of Heat Transfer:

𝑄𝑖𝑛 = 𝑄𝑜𝑢𝑡

Energy balance in a closed system with constant mass and only

involving heat transfer (no work):

𝑄 = 𝑚𝐶𝑣∆𝑇

Energy balance in a closed system with steady flow and only

involving heat transfer (no work):

𝑄 = 𝑚𝐶𝑝∆𝑇

Heat Transfer by Conduction

Thermal Conduction is the transfer of Heat energy from the more energeticparticles of a substance or material medium to adjacent less energetic ones as aresult of interactions between the particles.

Fourier’s Law of Heat Conduction

𝑞𝑐𝑜𝑛𝑑 = −λ𝛻𝑇

In one dimensional form:

𝑞𝑐𝑜𝑛𝑑 = −λ𝑑𝑇

𝑑𝑥

Thermal Conductivity

• Thermal conductivity is the property of the material medium’s

ability to conduct heat. It is expressed in SI units as [Wm-1K-1].

• It is also defined as the rate of heat transfer through a unit

thickness of the material per unit area per unit temperature

difference.

• A high value of λ indicates good thermal conductor and a low

value indicates thermal insulator.

Thermal Resistance

𝑅 =∆𝑥

λ[m2KW-1]

Using above relation, Fourier’s heat conduction equation can be

written as

𝑞 =∆𝑇

𝑅

Analogy with Ohm’s Law of electrical conduction

Fourier’s Law Ohm’s Law

∆𝑇 = 𝑞𝑅 𝑉 = 𝐼𝑅

Network of Thermal Resistances

∆𝑥1 ∆𝑥2

𝑞

𝑇1 𝑇2 𝑇3

λ1 λ2

𝐴𝑠

∆𝑥

𝐴1

𝐴2

λ1

λ2

𝑞1

𝑞2

𝑇1 𝑇3

𝑅1 𝑅2

𝑅1

𝑅2

𝑅𝑡𝑠 =

𝑖=1

𝑛

𝑅𝑖

𝑅𝑡𝑝 =1

𝑖=1𝑛 1

𝑅𝑖

Calculation of Thermal Resistances

Example #1: Thermal Resistance of a circular cylinder

𝑟1

𝑟2 𝑄 = λ 2𝜋𝑟𝐿𝑑𝑇

𝑑𝑟

1

2𝜋𝐿λ

𝑟1

𝑟2 𝑄

𝑟𝑑𝑟 =

𝑇1

𝑇2

𝑑𝑇

𝑄 =2𝜋𝐿λ∆𝑇

ln𝑟2𝑟1

𝑅𝑐𝑦𝑙 =ln

𝑟2𝑟1

2𝜋𝐿λ

Transient Heat Conduction

One dimensional transient heat conduction equation:-

Variable Conductivity:

Constant Conductivity:

𝜕

𝜕𝑥λ𝜕𝑇

𝜕𝑥+ 𝜀𝑔𝑒𝑛 = 𝜌𝐶

𝜕𝑇

𝜕𝑡

𝜕2𝑇

𝜕𝑥2+

𝜀𝑔𝑒𝑛

λ=1

𝛼

𝜕𝑇

𝜕𝑡

where𝛼 =

λ

𝜌𝐶

Thermal Diffusivity

• It is the property of the material medium which indicates how

fast the heat diffuses through that material.

• It can also be explained as the ratio of heat conducted to the

heat stored in that material per unit volume.

• The higher thermal diffusivity means faster propagation of

heat through the material.

• It’s unit is [m2s-1]

Thermal Effusivity or Thermal Absorptivity

𝑏 = λ𝜌𝐶

Thermal absorptivity of textile materials indicates the warm-cool feeling to touch by human fingers. A higher value indicates cooler feeling.

ALAM-

BETA

EFFECT OF FABRIC STRUCTURE, COMPOSITION AND TREATMENT ON THE LEVEL OF

THERMAL ABSORPTIVITY b [Ws1/2/m2K], contact pressure 200 kPa

20 - 40 Micro-fibre or fine PES fibre non-woven insulation webs

30 - 50 Low density raised PES knits, needled and thermally bonded PES light webs

40 - 90 Light knits from synthetic fibres (PAN) or textured filaments, raised tufted carpets

70 - 120 Light or rib cotton RS knits, raised light wool/PES fabrics, brushed micro-fibre weaves

100 - 150 Light cotton or VS knits, rib cotton woven fabrics

130 - 180 Light finished cotton knits, raised light wool woven fabrics

150 - 200 Plain wool or PES/wool fabrics with rough surface

180 - 250 Permanent press treated cotton/VS fabrics with rough surface, dense micro-fibre knits

250 - 350 Dry cotton shirt fabrics with resin treatment, heavy smooth wool woven fabrics

300 - 400 Dry VS or Lyocell or silk weaves, smooth dry resin-free heavy cotton weaves (denims)

330 - 500 Close to skin surface of wetted (0,5 ml of water) cotton/PP or cotton/spec. PES knits

450 - 650 Heavy cotton weaves (denims) or wetted knits from special PES Fibres (COOLMAX)

600 - 750 Rib knits from cotton or PES/cotton or knits from micro-fibres, if superficially wetted

750 Other woven and knitted fabrics in wet state

1600 Liquid water (evaporation effect not considered)

• It is the rate at which a material can absorb heat.

• It is the property that determines the contact temperature of

two bodies that touch each other.