Hazard Analysis — Filtrate Storage Tank/media/Documents/Subject Groups/Safety_Lo… · HAZARD...

Transcript of Hazard Analysis — Filtrate Storage Tank/media/Documents/Subject Groups/Safety_Lo… · HAZARD...

IChemE SYMPOSIUM SERIES NO. 153 # 2007 IChemE

HAZARD ANALYSIS – FILTRATE STORAGE TANK

Joseph Weber1 and Benjamin Sagiv2

1Safety Consultant, Weber Safety Engineering Ltd., Raoul Wallenberg 10, Haifa 34990 Israel; e-mail: [email protected] Manager, Rotem Amfert Negev Ltd. – ICL Group, Mishor Rotem Plants, M.P. Arava 80500 Israel;

e-mail: [email protected]

Plant design and changing in existing plants are relying on engineering approach focussing on the

technical design and production effectiveness. Process Safety issues have to be taken into account

in the various design stages. Process hazard analysis methods are use to determine possible

causes of an events or incidents issues in order to prevent hazardous states that might lead to

future incidents.

Changes and redesign in an exist plan, installing a new Filtrate Storage Tank, lead to perform a

detailed Process Hazard Analysis, as part of the Management of Change procedures. For the new

Filtrate Storage Tank design a Hazard and Operability (HAZOP) analysis was performed. Based on

the operation and safety expertise of the HAZOP team, it came out with a comprehensive list for

possible hazardous situation, which might lead.

KEYWORDS: hazard analysis, accident, root causes

INTRODUCTIONThe process industry has to maintain and improve thelevel of safety to its employees, the public and its stake-holders. Using Risk Assessment and Control methods forhazard identification are a way to improve the safety ofnew or revamp process plants. Hazard and OperabilityAnalysis studies are using the knowledge and experiencegained from successful approaches in other plants translat-ing it into practice, by improving the design of new units.Knowledge learned from accidents and near misses can betranslated into practice. Process Hazard Analysis studieswith a multi-discipline team can gain the knowledgeand implement it the new unit or plant design. A majorrole in safety operation and maintenance in the processindustry is performing of management of change foreach major change in the system, by analyzing the poten-tial hazards.

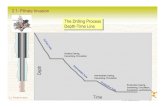

THE PROCESS INSTALLATIONThe process system consists of a phosphoric acid raffinatetank, which is fed from the solvent extraction (Liquid-Liquid Contact) section, a sulphuric acid tank, a mixerthat blends phosphoric acid (H3PO4) and sulphuric acids(H2SO4), and then fed to a reactor. The reactor isfeeding two filter presses, where calcium sulphate is fil-tered out. Having two filter presses, working on cycle.The acid liquor filtrate from the filters is passed to thefiltrate storage tank. Overflow line from the reactor isgoing into the filtrate storage tank. The sulphuric acidraffinate may include solvent remains from the previoussection.

After filtering, air is blown through the filters, to drythe filter cake. The air also passed to the storage tank, andleft it via 600 overflow line, being exhausted to atmospherein a pump sump alongside the thickener tank.

1

HAZARD ANALYSIS FOR POTENTIAL

ROOT CAUSESProcess Hazard analysis was performed for the unit, byusing the HAZOP method, in order to determine the rootcauses and consequences for an event or incident.

Here are some root causes for incident of overpres-sure and explosion, which might cause an incident.

OVER PRESSURING BY AIROverpressure could be derived from the blower air used fordrying the filter cake. The air compressor delivers air at 4.5bar (g). This is ample to cause damage.

The tank was designed with an overflow of the

tank, which was a fairly long 600 pipe, the tank

original vent nozzle is used for filtrate inflow.

The overflow pipe serves as a vent for the

airflow, although it is not designed as a vent.

There were low points in the pipe, so that

blockage with liquid or with slurry would not

only be possible, but might be inevitable at

some stage.

EXPLOSION OF HYDROGENHydrogen can be present in acid tanks, because of the reac-tion of acid with steel. The reaction is

Feþ H2SO4 ) FeSO4 þ H2 "

As can be seen, about 1/2 kg of hydrogen is sufficientto cause an explosion, which could project the tank to theobserved distance.

In order to confirm the possibility an inspectionshould be done to determine whether significant loss of

IChemE SYMPOSIUM SERIES NO. 153 # 2007 IChemE

steel could be found, sufficient to generate the necessaryhydrogen.

The hydrogen could in principle come from anothersource, but no obvious source was found, in the analysis.

Gradual accumulation of hydrogen in the tank is alsounlikely, because the air blowing of the filters provides goodventilation.

SOLVENT VAPOR EXPLOSIONA possibility for explosion is the ignition of solvent vapor inthe tank.

Solvent is necessarily present in solution in the acid,because of the use of the solvent in the raffinate sourceprocess section. Free solvent may be transferred if disturb-ances arise in the source process, leading to low level inthe vessel there. Under normal acid temperatures, thesolvent vapor pressure is sufficiently high to bring thevapor concentration above the upper explosion limit(UEL). With storage of acid alone, the tank would be fullof vapor. Air would enter the tank only when the tank wasdrawn down, (acid transferred out of the tank) and only ifthe draw down were rapid.

With the use of filter cake drying with air, the amountof air in the tank is increased significantly. With free flow, itis likely that a large part of the solvent vapor would be ven-tilated out of the tank. There would be an interval both at thestart and end of the blowing, when the concentration wasbetween LEL and UEL.

As the overflow line also served as a vent, whichmight be at least partially blocked, this may reduce thedegree of ventilation, and increased the explosion potential.

POSSIBLE SOURCES OF IGNITIONSome general potential sources of ignition were identified.This potential ignition sources might lead to an ignitionand explosion. This may happen in various systemsinvolved with flammable liquids, such as solvents and alco-hols. With these number of potential ignition sources,ignition is likely to propagate and explosive conditionsare allowed to arise.

(1) Blown droplets. Droplets blown by air during the filtercake drying could be charged electrostatically, andmight ignite vapor on discharging.Special design improvement should take electro staticdischarge (ESD) into account.

(2) Acid droplets in solvent. If a slug of solvent might betransferred into the tank, via the overflow line, dropletsof acid in the solvent could have become charged.This is a generally possible cause, this has to bechecked relatively to solvent conductivity and flowvelocity.

(3) Leyden charging of the tank. The tank is structured likea large Leyden jar (capacitor), with an outer conduc-tion layer (the tank shell) a resistive inner layer (therubber) and an inner conductive layer (acid).

2

Without a method of shorting, the acid could acquire avery large charge. The charge would be bled off byconduction through any cracks in the rubber lining,or slowly, through the rubber itself. The degree ofthe problem depends on the rate of charging versusthe actual rate of conduction. This cannot be predicted,and needs to be measured.

(4) Electrical failure. Electrical, control and instrumenta-tion accessories, with electrical power supplies, arefitted on tanks. On most tank level indication andswitched are installed. Electrical failure on either oftheses accessories might produce overheating or elec-trical sparking.The instruments should be designed and checkedperiodically for use in flammable zone.

(5) Chemical decomposition. Adding acid to with organicresidue may lead to organic material residuals thatmight collect on some surfaces, or that charring oforganic material, presumably solvent or organicimpurities.Mix of concentrated acid with solvent might formether by dehydrolisation. Higher degrees of charringto a tar may also occur. If ether is formed then thereis also a possibility of forming unstable peroxides,by oxidation with air.Although it is unlikely that such a reaction would takeplace with large yields, because of the rapid dilation ofthe acid, sufficient material might be produced due tothe large scale of the operation, and the materialwould tend to collect in the storage tank.

(6) Electrical discharge from other equipment. Electricalconduction from other equipment, such as the air com-pressor or pumps, is a possibility. Inductive currentfrom cables to piping could also, in principle lead toa discharge. In the actual circumstances this seemsextremely unlikely, in view of the fact that mostpiping are plastic, PE, PP or PVC.

(7) Lightning. Induction from lightning could in principlecause an explosion. In the actual case, the weather situ-ation at the site has to be checked for possibility oflightning. In a more general context, lightning couldcause ignition.

(8) Electrical charging from the filter press. The filter clothof the filter press is a synthetic fiber, and could presum-ably cause charging of liquid droplets during filter cakedrying. This cause may be checked and measurementshould be taken.

(9) Ignition from electrical equipment in the sump. Thedischarge location of the tank overflow line shouldbe carefully examined. With discharge of an air/solvent vapor mixture into the sump, there would bea frequent or regular presence of explosive atmospherein the sump. Electrical equipments in the sump are notdesigned as explosion safe, so ignition might been apossibility. This potential for accidents has impli-cations for any plant, where sumps exist which cancontain a flammable atmosphere.

Figure 1. Plan of process system feeding filtrate storage tank

IChemE SYMPOSIUM SERIES NO. 153 # 2007 IChemE

GENERAL LESSONS LEARNEDYet again we learn that all plant changes require a ProcessHazard Analysis (such as HAZOP – Hazard and OperabilityAnalysis). On the basis of cost alone, savings on HAZOP area bad form of saving. Safety analysis may be regarded ascostly, but accidents cost hundreds of times more.

It should be considered whether an actual accidentcould be prevented by a prior HAZOP study. A safetydesign review process should be added to the HAZOPstudies. The actual procedure and knowledge base forHAZOP studies is probably not good enough for preventionof all accidents.

A HAZOP and a pre-startup safety review arerecommended step for Management of Change in theplant. Prior to each new unit or equipment startup safetyconsideration and studies has to take place. Process SafetyManagement guidelines are including this methodology.Plant management has to take care for implying goodcompany standards and procedures, in order to keep ahigh safety level at each of the plant units.

CONCLUSIONThe following are the main Hazard Analysis conclusion:

– Overpressuring might be caused by acid overflow intothe overflow pipe, or to collection of splashed dropletsat a low point in the overflow line.

– Vapour explosion might be caused by alcohol vapour,mixed with air.

– The possibility of an explosion with hydrogen mixedwith air is less likely, but there is a possibility for hydro-gen accumulation.

– Several design weaknesses were found, which need to beeliminated and approved in the tank design, as well inany future design.

3

– There were many potential sources of ignition, whichmight be removed or reduced before unit start-up.

Each of the possible causes of the incident may lead tobe depended on technical issues and human factor aspects.

(a) Detail design.(b) Management of Change.(c) Process Hazard Analysis.(d) Operation procedures and Safety instructions.

The evidence of a potential accident in an acid storagetank should lead for deep safety analysis of the system. Afull Process Hazard Analysis, as part of Management ofChange, should be done on each system, even if ignitionor explosion in an acid tank might be overseen.

The system was regarded as non flammable and islocated in the inorganic section of the plant.

The system was introduced as a full scale pilot, inexperimental mode, as for these a lot of changes were per-formed with no related safety overview.

For each design or mechanical changes in a plantsafety analysis should be performed.

Management of Change procedure should beimplemented for changes in an experimental plant as wellas in process plant. Even change of tank overflow linelocation might cause a hazard.

There were many potential sources of ignition. Asafety analysis should be done, prior to plant operation, toidentify potential ignition sources. The analysis shouldinclude survey of ignition source and potential causes forexplosion, especially when operating with flammable sub-stance, even when dissoluble in inorganic material.

No explosions occur at the operation of the FiltrateStorage Tank, either due to a special combination of ignitioncircumstances, or to the time needed for overflow line block-age to accumulate.

![[XLS]dep.ky.govdep.ky.gov/formslibrary/Documents/TankSpreadsheetv6a.xls · Web viewHints Glossary Tank#10 Tank#9 Tank#8 Tank#7 Tank#6 Tank#5 Tank#4 Tank#3 Tank#2 Tank#1 Summary Instructions](https://static.fdocuments.in/doc/165x107/5ab43ede7f8b9a1a048ba1de/xlsdepky-viewhints-glossary-tank10-tank9-tank8-tank7-tank6-tank5-tank4.jpg)