guide to reinforced fill structure& slope design

-

Upload

shakirhamid6687 -

Category

Documents

-

view

20 -

download

1

description

Transcript of guide to reinforced fill structure& slope design

-

Guide to Reinforced Fill Guide to Reinforced Fill Structure and Slope DesignStructure and Slope Design

GeotechnicalGeotechnical Engineering OfficeEngineering OfficeCivil Engineering DepartmentCivil Engineering DepartmentThe Government of the Hong Kong The Government of the Hong Kong Special Administrative RegionSpecial Administrative Region

GEOGUIDE 6

Introductory Course (Lecture 1)Introductory Course (Lecture 1)

-

22

Historical DevelopmentHistorical Development Reinforced fill is an

established technology dating back to 4/5 BC

Examples include the Great Wall of China

GEOGUIDE 6GEOGUIDE 6

-

33

First Reinforced Fill Wall in Hong Kong 1981First Reinforced Fill Wall in Hong Kong 1981

-

44

Historical Development in Hong KongHistorical Development in Hong Kong

First used in 1981 Currently over 100 structures built

GEOGUIDE 6GEOGUIDE 6

Tuen Mun

Guangdong Sheng

Deep Bay

Hong KongInternationalAirport

Tolo Harbour

Kowloon

Tsing Yi

Hong KongIsland

LegendLocation of ReinforcedFill Feature

Lantau Island

2422201816141210

86420

0

-

5

5

-

1

0

1

0

-

1

5

2

0

-

2

5

2

5

-

3

0

>

3

0

1

5

-

2

0

Height (m)

Retaining WallFill Slope

N

u

m

b

e

r

Fill Slope

RetainingWall

Others RoadEmbankment

51%

14%

14%

9%

12%BridgeAbutment

-

55

North West North West TsingTsing Yi Yi 40m Reinforced Fill Wall40m Reinforced Fill Wall

-

66

ScopeScope

Geoguide 6 is a companion to Geoguide 1 Guide to Retaining Wall Design (1993)

Presents a recommended standard of good practice for design construction supervision of new permanent structures

Included are: Walls and slopes bridge abutments segmental block walls

(Does not cover soil nailing, reinforced fill dams, maritime structures or embankments on soft ground)

GEOGUIDE 6GEOGUIDE 6

-

77

Classification of Common Earth Retention Systems(Fig 13, P.145)

GEOGUIDE 6GEOGUIDE 6

-

88

Areas of ApplicationAreas of Application

Transportation Housing Slope

stabilisation and landslide mitigation

Others (industrial works, river walls)

GEOGUIDE 6GEOGUIDE 6

-

99

The Use of Reinforcement Fill in Highway and Railway Application(Fig 2, P.134)

GEOGUIDE 6GEOGUIDE 6

-

1010

Approach EmbankmentBridge Desk

Zone of Reinforced Fill

Levelling Strip

Bearing

Facing Panels

Highway Bridge AbutmentHighway Bridge AbutmentGEOGUIDE 6

-

1111

Zone ofReinforced Fill Levelling

Strip

11

Facing Panels

Retaining Wall and Embankment for RailwayRetaining Wall and Embankment for RailwayGEOGUIDE 6

-

1212

The Use of Reinforced Fill in Housing Development(Fig 3, P.135)

GEOGUIDE 6GEOGUIDE 6

-

1313

Segmental Block Facing GEOGUIDE 6

-

1414

Other Common Usage(Fig 5, P.137)

GEOGUIDE 6GEOGUIDE 6

-

1515

Examples of Reinforced Fill Structures

GEOGUIDE 6GEOGUIDE 6

-

1616

GEOGUIDE 6GEOGUIDE 6

Zone of Reinforced Fill

2.51

Reinforced Fill Blast Wall

1

2

-

1717

Rationale for the Use of Reinforced Fill

Reinforced fill structures can offer technical and economic advantages over conventional forms of construction

Savings of 20-50% of initial capital cost are possible

Particularly suited to sloping terrain Largely immune to earthquake Compatible with the concept of sustainable

development

GEOGUIDE 6GEOGUIDE 6

-

1818

Examples of Economic and Technical Advantages of Reinforced Fill(Fig 6, P.138)

GEOGUIDE 6GEOGUIDE 6

-

1919

Tsing Yi North Coastal Road

-

2020

Cyber Port Development

-

2121

Ecological Parameters for a 6m High Reinforced Fill Structure and an Equivalent Reinforced Concrete Structure(Fig 7, P.139)

GEOGUIDE 6GEOGUIDE 6

-

2222

Reinforced Fill WallReinforced Fill Wall Conventional ConcreteConventional ConcreteRetaining WallRetaining Wall

GEOGUIDE 6

-

2323

Embodied Energy (EE) of Construction Embodied Energy (EE) of Construction MaterialsMaterials

DefinitionEnergy used to extract and transport raw materials, refine and manufacture them, package, deliver and install them on site.

Conventional RC Retaining WallConventional RC Retaining Wall

Concrete (ready mix) = 1.3 GJ/ton

Steel (virgin) = 32.0 GJ/ton

Fill = Nil

Formwork = 19.0 GJ/ton

Reinforced Fill Retaining WallReinforced Fill Retaining Wall

Concrete (precast) = 2.0 GJ/ton

Steel (galvanised) = 35.0 GJ/ton

Fill = 0.2 GJ/ton

GEOGUIDE 6

-

2424

Concrete Steel Fill Formwork0

20

40

60

80

100

120

140

E

n

e

r

g

y

p

e

r

m

(

G

J

/

m

)

Construction Materials

Concrete Steel Fill Formwork0

20

40

60

80

100

120

140

E

n

e

r

g

y

p

e

r

m

(

G

J

/

m

)

Construction Materials

for a 12 m High Wallfor a 12 m High Wallfor a 4 m High Wallfor a 4 m High Wall

RF WallRC Wall

Energy used by RF wall and RC wallEnergy used by RF wall and RC wallGEOGUIDE 6

-

2525

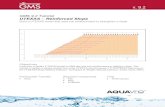

Quantity of Concrete used by RF wall and RC wallQuantity of Concrete used by RF wall and RC wall

0

20

40

60

80

100

0 2 4 6 8 10 12 14 16 18

Wall Height (m)

T

o

n

s

p

e

r

m

RC Wall

RF Wall

GEOGUIDE 6

-

2626

Quantity of Steel used by RF wall and RC wallQuantity of Steel used by RF wall and RC wall

0.0

1.0

2.0

3.0

4.0

5.0

0 2 4 6 8 10 12 14 16 18

Wall Height (m)

T

o

n

s

p

e

r

m

RC Wall

RF Wall

GEOGUIDE 6

-

2727

Quantity of Fill used by RF wall and RC wallQuantity of Fill used by RF wall and RC wall

0

50

100

150

200

250

0 2 4 6 8 10 12 14 16 18

Wall Height (m)

T

o

n

s

p

e

r

m

RC Wall

RF Wall

GEOGUIDE 6

-

2828

Energy used by RF wall and RC wallEnergy used by RF wall and RC wall

0

50

100

150

200

250

300

350

400

450

0 2 4 6 8 10 12 14 16 18

Wall Height (m)

E

n

e

r

g

y

p

e

r

m

(

G

J

/

m

)

RC Wall

RF Wall

GEOGUIDE 6

-

2929

Reinforced Fill SystemsReinforced Fill Systems

Elemental Full height Anchored earth Wrap-around Segmental blocks (hybrid)

GEOGUIDE 6GEOGUIDE 6

-

3030

Reinforced Fill Systems: ElementalReinforced Fill Systems: Elemental

GEOGUIDE 6GEOGUIDE 6

(Fig 8, P.140)

-

3131

Forms of ReinforcementForms of Reinforcement GEOGUIDE 6

-

3232

Reinforced Fill Systems: Full HeightReinforced Fill Systems: Full HeightGEOGUIDE 6GEOGUIDE 6

(Fig 9, P.141)

-

3333

Reinforced Fill Systems: Anchored EarthReinforced Fill Systems: Anchored Earth

GEOGUIDE 6GEOGUIDE 6

(Fig 12, P.144)

-

3434

Reinforced Fill Systems: WrapReinforced Fill Systems: Wrap--aroundaround

GEOGUIDE 6GEOGUIDE 6

(Fig 10, P.142)

-

3535

Reinforced Fill Systems: Segmental Reinforced Fill Systems: Segmental BlocksBlocks

GEOGUIDE 6GEOGUIDE 6

(Fig 11, P.143)

-

3636

Selection of SystemsSelection of Systems

Depends upon Use of the structure or slope Nature and size Life of structure Economy Available fill Aesthetics

GEOGUIDE 6GEOGUIDE 6

-

3737

Selection of Systems: Selection of Systems: ElementalElemental

Applications Bridge abutments Walls Construction on

slopes Industrial structures Containment dykes Building platforms

GEOGUIDE 6GEOGUIDE 6

-

3838

Selection of Systems: Selection of Systems: ElementalElemental

Advantages Proven technology Used with wide

range of reinforcement

Good aesthetics

GEOGUIDE 6GEOGUIDE 6

Limitations Initial cost of

shuttering for new units high

Need to test new units

-

3939

Selection of Systems: Full HeightSelection of Systems: Full Height Applications

Bridge abutments Retaining walls River training works Industrial structures

GEOGUIDE 6GEOGUIDE 6

-

4040

Advantages Rapid construction Very robust Eliminates failure

through the facing Good finishes

(pretensionedconcrete)

GEOGUIDE 6GEOGUIDE 6

Limitations Limited to 10m

height Needs propping Good compaction

required

Selection of Systems: Full HeightSelection of Systems: Full Height

-

4141

Selection of Systems: WrapSelection of Systems: Wrap--aroundaround

Applications Steep slopes Slope repairs Tall embankments Blast walls Rock fall protection

GEOGUIDE 6GEOGUIDE 6

-

4242

Advantages Use of indigenous

fill Economic Green structures Composite

reinforcement/ drainage used with fine fill

GEOGUIDE 6GEOGUIDE 6

Limitations Facing susceptible

to fire/vandalism Must protect

against UV light

Selection of Systems: WrapSelection of Systems: Wrap--aroundaround

-

4343

Selection of Systems:Selection of Systems:Anchored EarthAnchored Earth

Applications Bridge abutments Walls Slope repairs Noise barriers Blast barriers

GEOGUIDE 6GEOGUIDE 6

-

4444

Advantages Improved pullout Use of waste

materials (tyres) produces economic structures

GEOGUIDE 6GEOGUIDE 6

Limitations Not used with

wrap-around systems

Selection of Systems:Selection of Systems:Anchored EarthAnchored Earth

-

4545

Selection of Systems:Selection of Systems:Segmental BlockSegmental Block Applications

Housing Low/medium walls Bridge abutments Superimposed

structures

GEOGUIDE 6GEOGUIDE 6

-

4646

Advantages Proven technology Rapid construction Minimal

construction plant (Used with

indigenous fill) Wide range of

facings

GEOGUIDE 6GEOGUIDE 6

Limitations Usually no provision

for differential settlement between facing/fill

Little adaptability to differential settlement

Selection of Systems:Selection of Systems:Segmental BlockSegmental Block

-

4747

Proprietary Systems and Proprietary Systems and ProductsProducts

Proprietary products/systems often restricted to specific applications

Some proprietary products only suitable for use with proprietary systems

Some systems are covered by Patents

GEOGUIDE 6GEOGUIDE 6

-

4848

Certification of Reinforcing Certification of Reinforcing ProductsProducts

Ensure safe long-term design strength Ensure adequate quality assurance of

products Eliminate repetitive checking

Objectives of Certification

GEOGUIDE 6

-

4949

Certification Procedure

Certification of Reinforcing Certification of Reinforcing ProductsProducts

z Manufacturer submits product details to GEOz Reinforced Fill Advisory Panel (RFAP) assesses

the submissionz RFAP submits draft certificate to Endorsement

Committee for review and agreementz Director of Civil Engineering (DCE) signs the

certificate

GEOGUIDE 6

-

5050

Types of Reinforcing Products

Certification of Reinforcing Certification of Reinforcing ProductsProducts

Metallic reinforcing products do not require certification

Reinforcing products, the strength and stress-strain characteristics are temperature and time dependent require certification

GEOGUIDE 6

-

5151

GEOGUIDE 6(Fig 23, P.155)

-

5252

Viscoelastic Behaviour Viscoelastic Behaviour of Polymerof Polymer

Strain (%)

L

o

a

d

(

k

N

/

m

) IncreasingStrain Rate

-

5353

Viscoelastic Behaviour Viscoelastic Behaviour of Polymerof Polymer

IncreasingTemperature

Strain (%)

L

o

a

d

(

k

N

/

m

)

-

5454

Viscoelastic Behaviour Viscoelastic Behaviour of Polymerof Polymer

Strain Rate (%/min)

(

P

e

a

k

L

o

a

d

)

/

(

I

n

d

e

x

V

a

l

u

e

)

x

1

0

0

%

IncreasingTemperature

-

5555

Assessment Details

Certification of Reinforcing Certification of Reinforcing ProductsProducts

Creep and stress rupture

GEOGUIDE 6

-

5656

Sustained Load Creep TestSustained Load Creep Test GEOGUIDE 6

-

5757

Interpretation of Sustained Load Creep TestInterpretation of Sustained Load Creep Test

S

t

r

a

i

n

(

%

)

Time (hr)

Creep Curves

-

5858

Interpretation of Sustained Load Creep TestInterpretation of Sustained Load Creep Test

Strain (%)

L

o

a

d

(

k

N

/

m

)

Isochronous Curves

-

5959

Assessment Details Creep and stress rupture

Certification of Reinforcing Certification of Reinforcing ProductsProducts

Oxidation and hydrolysis

CED Homepage (www.info.gov.hk/ced) provides details of the certification system and submission requirements

Installation damage

GEOGUIDE 6

-

6060

END OF LECTURE 1END OF LECTURE 1