Groundnut Agronomic and Post harvest practices TRAINING ...

Transcript of Groundnut Agronomic and Post harvest practices TRAINING ...

Groundnut Agronomic and Post harvest practices

TRAINING MANUAL

GROUNDNUT (arachis hypogaea L.):

A CROP FOOD AND INCOME SECURITY

Groundnut is widely grown in Uganda as a food and cash crop. It is one of the highest paying crops with

fairly stable prices. It is grown in nearly all parts of the country but especially in eastern Uganda and

Northern regions. Household consumption is quite high with preferences to the brown/red-kenneled

varieties because of their reputed taste. In addition, there is a huge informal trade at the borders. The

Kenyan market demands small-white and big-white varieties.

It is a useful rotation crop. Being a legume, it can fix atmospheric nitrogen. It has the advantage of

generating residual nitrogen in the soil which benefits subsequent crops, especially when groundnut

residues are incorporated into the soil during ploughing. Thus maintains soil fertility. It also controls soil

erosion.

All parts of the plant can be put to use. The plant stalks are fed to cattle in the form of green, dried and

silage. Groundnut shell, haulms and hay are good fodder. Groundnut cake is a good feed for livestock

and it is also used as manure

Because of the importance of groundnut, the demand far exceeds output. Thus the need to increase

yields and acreages. Well managed plots, and high yielding varieties could go a long way to achieve this.

This manual provides information on good agronomic and postharvest handling practices of the

groundnut. Adopting such practices would help increase groundnut crop production considerably

Some of the improved groundnuts varieties

The National Agricultural Research Organization (NARO), whose mandate institution is the serere

Agricultural and Animal Research Institute (SAARI) based in Soroti, released a number of groundnut

varieties.

Variety Description Seed rate Spacing Maturity Yield Pest control

Comment

Red Beauty-1968(SAARI)

BrightRedseedbedwith short pods, Bunch type

28-32kg/acre

40cm x 10cm on fine seedbed and weed free

90 days 800kg/acre(20 bags of 40kg)

Close plant population167,000 plants

Pests: Aphids Disease: Circums to rosette virus, spread by the aphids, cercospora leaf spot

IGOLA 1-1999(SAARI)

Large Brown kernels with white strips, bitter taste, spreading type, high oil content, podsare difficult to shell

40-48kg/acre

40cm x 15 cm on fine seedbed and weed free

130days 1200kg/acre(30 bags of 40 kg)

Highly resistant to rosette virus

Suitable for low-level management and cost of production

SERENUT 1 R-1999(SAARI)

Similar to red beauty but more red with slightly big kernels

32kg/acre 40cm x 10 cm on fine seedbed weed free

100-110 days

1120kg/acre(28 bags of 40kgs)

Moderately resistant to rosette

Drought resistant

SERENUT 11 (IGOLA11-1999)SAARI

Tan red seeded, High oil content, Spreading type

32kg/acre 40cm x 15cm on fine seedbed-weed free

100-110 days

1120kg/acre(28 bags of 40kgs)

Resistant to rosette and related pests

Drought resistant

SERENUT 3R-2002 SAARI

Red seeded like serenut 1 R

32kg/acre 45cm x 10cm on fine weed free seed bed

100 days 1080kg/acre(27 bags of 40kg)

Resistant to rosette

Drought resistant >40% oil content

SERENUT 4 – 2002 SAARI

Tony red seeded, Erect growth habit, high oil content, high shelling turn over (73% seed)

32kg/acre 40cm x 10cm on fine seed bed weed free

Short maturity period 90 – 100 days

960kg/acre(24 bags of 40kg)

Resistant to rosette

Drought resistant >40% oil content

RECOMMENDED AGRONOMIC PRACTICES

Practices Recommendations Variety selection

Acquire high yielding popular and improved varieties. The varieties are available at Research institutes, seed companies etc.

Site selection (soil type)

Groundnuts grow best in deep, well-drained, light-textured, loose, friable sandy – loam or sandy clay loam soils. Seed germination and seedling emergence are favored in loose, friable and sandy – loam soils. The pegs can penetrate the soil easily and pods can be harvested from such soils with minimum losses of comparatively clean produce. The soil does not adhere excessively to the freshly dug pods in these soils.

Rotation To avoid build up of pests and diseases, groundnut should not be grown continuously on the same land. A rotation of 3 years or longer can reduce disease, pest and weed problems. Because of the incidence of pests and soil-borne diseases, groundnut should not be grown after cotton, although cotton can be used in rotation after groundnut. Other legumes, tobacco, tomatoes and certain other vegetables may cause a build-up of nematodes and soil – borne diseases and, therefore, should be avoided in rotation with groundnuts. Cereals, such as maize, sorghum and millet are good rotational crops and other clean weeded crops such as cassava, sweet potato and sunflower can also be used.

Land preparation

Good land preparation provides suitable soil conditions for rapid and uniform germination, good root penetration and growth, and steady pod development. Land should be prepared early, before the rains start, so that sowing can take place early in the rains. All previous crop residues and weeds should be completely removed or buried, and seed beds should be smooth to provide good soil- to seed contact after sowing

Seed selection Pods should be shelled 1-2 weeks before sowing and only good quality seed should be discarded. It

Practices Recommendations is good practice to purchase certified seed at regular intervals, preferably, every 2-3 years.

Time of planting and soil moisture

Soil moisture is the most common limiting factor for better yields in groundnut production. Farmers should plant as soon as there is adequate moisture in the ground to ensure good germination. Planting early in the season helps to improve yields and seed quality, and reduce the incidence of rosette disease. There are three important periods for maintaining adequate moisture: At planting to encourage germination From 50-100 days after planting as the pegs enter the soil and the pod begins to develop. Pod filling until maturity of pods

Spacing Seeds should be sown at a depth of 5-6 cm and at the recommended spacing (45 x 7.5 – 10 cm for bunch type varieties and 45 x 10 – 15 cm for semi-erect type varieties). The soil should be pressed down to ensure good contact with the seeds, enabling them to extract moisture more effectively.

Weeding Groundnut cannot compete effectively with weeds, particularly 3-6 weeks after sowing. Therefore, early removal of weeds is important. Generally, 2-3 weeding are recommended, the first before flowering and at least one other during pegging. If early weeding is done well, and at least one other during pegging. If early weeding is done well, and crop spacing recommendations followed, and then the weeds that come up later are smothered with the vigorous growth of the crop. When weeding, it is very important to avoid covering the bottom of the plants with earth (including earthing up) as this can increase diseases (e.g. white mould), reduce flowering and pod development and, therefore, reduce pod yield. Once flowering and pod development and, therefore, reduce pod yield. Once flowering and pegging begins it is advisable to weed by hand pulling, rather than by using a hoe, as this is less likely to disturb any developing pods. Check for pests diseases and control where necessary

Soil fertility maintenance

Groundnut is energy rich crop, so its energy requirements need to be met with the application of optimum quantities of plant nutrients through application of manures and fertilizers. Groundnut requires adequate levels of phosphorus, potassium, magnesium and particularly calcium, which are required for maximizing yield and good quality seed. For farmers who can afford artificial fertilizers, application of Single Super Phosphate (SSP) at the rate of 100-125 kg/ha or Triple Super Phosphate (TSP) at 80-90 kg/ha will boost yield. SSP or TSP should be worked into the soil before planting. In areas where there is high incidence of empty pods (‘pops’), there could well be a shortage of calcium in the soil. To rectify this, a treatment of gypsum at the rate of 200-400 kg/ha (up to 500-1000kg/ha if the soil is particularly poor) at early flowering will reduce the incidence of pops.

Disease and pest control

Use rosette resistant varieties of groundnut e.g. Serenut 2, Igola 1 etc to eliminate the need for spraying insecticides to control the aphids. Avoid late planting and wide spacing to reduce incidences of rosette disease. If a high yielding non-rosette resistant variety is grown (e.g. Serenut 1) then insecticides will be needed. Systematic insecticides such as dimethoate (Rogor EC40) can be sprayed at 10-day intervals for a total of four sprays. Since the leaf spot pathogens survive mainly in crop debris, cultural practices such as crop rotation, burying crop debris during land preparation and early sowing can significantly reduce the incidence of the diseases. Avoid growing groundnut in fields that have history of termites.

Postharvest handling processing practices of groundnut

Timing for harvesting

It is very important to harvest groundnuts at the correct time. If harvested too early, the seeds will

shrink when drying which lowers the, oil content and quality of the seed. Delays in harvesting will result

in poor quality seed due to mould infections and subsequent aflatoxin contamination of the

seeds/pods.

Late harvesting also reduces yield because higher proportions of pods are left in the ground due to the

pegs being weak and the pods breaking off. If harvested late, some non – dormant varieties will begin

to sprout in the field resulting in yield losses.

Indicators for harvesting time

A proper time to commence the harvest is when a good number of pods are

fully developed and are fairly intact.

Maturity of pods is normally achieved when the vine begins to turn yellow and

leaf shedding starts. It is recommended that a few plants (3 - 5) should be pulled

up and the pods removed and shelled. The insides of the shells should be

examined. If the majority of pods (70% upwards) have dark markings inside the

shell and the seeds are plump and the correct colour for that variety, then the

groundnuts are mature and ready for harvest. The estimated period of maturity

for each variety can be used as a rough guide.

Groundnut plant ready for harvest

Other consideration for harvesting:

If leaf spot or other diseases are problem in the field, do not

delay harvest.

If there is a weather forecast that would delay the harvest, this

must be taken into account.

Harvest must be done when sufficient labour and adequate

equipment are available.

Failure of peg strength and well filled pods with pink seed coat

indicate maturity in large seeded Virginia type

Shells with dark interior which indicates harvest maturity

Signs of weakening peg strength indicate immediate need for harvest if excessive

losses are to be avoided.

Check groundnut crop closely as the average number of days to maturity approaches.

shells with dark interior which indicates harvest maturity

Harvesting

The actual method of harvest employed depends upon the type of groundnut grown. Harvesting by

hand only is more suitable for the erect groundnut varieties in sandy, loam soils which are well drained.

Hand pulling of groundnut plants Bunch type

In bunch types, pod development is confined to the base of the plant and the pegs carrying the pods

into the soil are thick and strong. Almost all the pods are recovered with the plants when they are

pulled out of the soil. That is why the bunch type of groundnut is mostly harvested by pulling out the

plants with manual labour.

The spreading or semi – spreading groundnut types produce pods all Along the running stem.

This type of groundnut is harvested either manual or by using a blade harrow or ox-plough. The soil

should be sufficiently moist for easy harvesting and without loosing pods in the soil.

When harvesting care should be taken not to damage the pods with the hoe as damage makes the

pods susceptible to fungal attack. A hoe fork lessens the likelihood of such

damage

Spreading type

Cleaning

It is important to shake the plant after lifting to remove excess soil from the pods, particularly when the

soil is wet or heavy. Soil stuck to the pods will lengthen drying times and produce better conditions for

the development of unwanted fungal growth.

Harvesting groundnuts using blade harrow

Drying

The correct drying or curing of the harvested groundnuts is very important as poor curing can help

induce fungal growth (producing aflatoxin contamination) and reduce seed quality for consumption,

marketing and germination for the following seasons planting. For good storage and germination, the

moisture content of the pods should be reduced to 6-8%. There are different ways of drying the pods,

some of which are better than other. It is particularly important to note that if the pods are exposed to

the sun for too long the seed quality can deteriorate considerably and germination can be affected.

Drying in windows

If the harvested groundnut plant are left to dry on the soil surface where they have been lifted, the pod

are likely to be in contact with the soil, which can contain moisture and be at a higher temperature.

This method can easily affect the quality of the seed, particularly if there is rain during the drying

period. If field drying is used, it is better to use windows, where plants are laid in rows to catch the

wind and dry more quickly. The drying of pods in windows (3-5 days) should produce the required level

of moisture before the pods are picked or stripped. Excessive exposure to the sun can affect the quality

of the seed.

Drying in windows

Drying on mats

The plants can be picked/plucked from the window and then laid out in a thin layer in the sun on dry

ground, matting or other dry surfaces for a further 2-5 days which would normally dry the pods to the

required moisture content for storing. Pods should be covered or taken indoors during wet weather.

They can also be picked immediately after lifting and then dried in the sun as above for 6-8 days. Once

again excessive exposure to the sun can affect the quality of the seed.

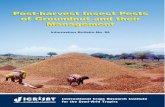

Groundnut spread on the ground

Drying so that the pods are shaded

Ideally pods should be dried with plenty of air circulation and and in the shade. Two principal methods

are used elsewhere in Africa, both of which can produce good quality seed with reduced levels of

fungal infection. After 2-3 days of wilting in the field in windows, the plants should be dried using one

of the following.

Cocks used for plant/pod drying

(a) Cock

Plants are laid, with foliage, directly on the ground in a circle 1-2 m in diameter, the pods placed

towards the inner part of the circle. Layers of plants are built up, gradually reducing the diameter of the

circles as the cock gets higher, until there is a small opening left at the top of the cock. Foliage (e.g.

banana leave) can be used to cover the top of the cock. The cock should be built on raised ground so

that the lower parts do not get waterlogged if it rains during drying. Polythene should not be used for

the base of the cock as this reduces drainage in the case of rain, and also should not be as a cover as a

built up of condensation can occur.

(b) A – Frame

The wilted plants are gathered and stacked on an A-frame with the pods facing inwards and away from

the soil. A – frame are easy to construct using three thick poles as a base with thin poles attached to

either side of the main poles of the A-frame forming shelves on to which the wilted plants can be

placed. The lowest shelf should be about 30cm above the ground. Excellent air circulation occurs and, if

constructed properly, the drying foliage of the plants protects the pods from rainfall.

A-frame used for plant/pod drying

In both cases the groundnut should normally be left to dry for 3-4 weeks before the pods are picked.

After picking do not dry further by putting the pods into the sun as this could result in over-drying or a

reduction in seed quality.

Plucking/stripping

After proper curing and drying, the pods are separated from the plants. This operation is called

stripping or plucking. Stripping of pods is done manually by the small farmers. Also, groundnuts meant

for seed purpose are stripped manually.

Stripping of pods manually

The hand removal of pods from the plants (plucking) can be labour intensive. A simple frame of wood,

built at a height convenient for plucking, covered with a stretched piece of chicken netting, can speed

up the process considerably and reduce drudgery. The dried/wilted plants are held by the leaves and

the roots/pods drawn across the stretched chicken wire. The pods get caught in the wire and are pulled

off, dropping below the frame.

Simple plucking machine Stripping of pods with a stripper

STORAGE

It is best to store groundnuts in their shell. Good drying of the pods to 7-8% moisture content will help

to ensure that the seeds remain in good condition during storage. Never bag groundnuts for storage

when the pods are still dump. Before storing, poor, damaged shriveled, rotten, or fungus-infected pods

should be removed. Whatever the storage container, it is important to ensure that the store is dry and

that there is good ventilation so that the pods/seeds do not increase in moisture content, which would

encourage fungal growth. Ideally the store should be cool as this is prolonged the storage life of the

pods.

In bags

Bags should be made of material which allows the air to circulate, therefore, gunny bags are

recommended. Do not use polythene or polypropylene bags as these restrict air flow and fungal growth

could occur. For the same reason, do not cover bags with plastic or tarpaulin (canvas) which may also

restrict ventilation and increase condensation. Bags should be stored away from the ground on

wooden slats to avoid damage from dampness. If bags are stacked, a gap should be left between stacks

to allow ventilation. Do not stack bags more than ten bags high.

Groundnuts in shell

Other methods

If bags cannot be used, storage in clay pots, woven baskets, or storing loose may be used. In all cases it

is important to ensure good ventilation by keeping the storage vessel off the ground and ensuring that

the storage place used is dry. When storing the pods loose, a platform made of local material (e.g.

bamboo) should be made to keep the pods off the ground.

Pests

When pests damage the pods/seeds, they create the condition for the build up of fungal infection.

Insect storage pests can be controlled using pirimiphosmethyl (Actellic super) applied as a dust to the

pods before bagging.

SHELLING Shelling should be done as and when groundnut seeds ar required for consumption, marketing or for

planting as the storage life of the seed outside the shell is short and the quality can reduce rapidly.

With both hands and mechanical shelling, the seeds should be checked and any discoloured, mouldy or

shriveled seeds should be thrown away.

By hand

Hand shelling is labour intensive but is effective for small quantities of groundnuts. It is particularly

good for the selection of seed for planting the following season as there is less damage to the seeds,

thus avoiding fungal infections.

Hand shelling

The practice of putting pods into sacks and beating the to break them up is not recommended as this

can produce a high level of damaged seeds.

Mechanical shellers

There are a number of mechanical hand shellers on the market that can shell groundnuts at a rate of up

to six bags an hour. The rotary types have the advantage of continuous operation (rather than shelling

in batches) and new designs produce very little wastage in terms of damaged seed.

Groundnuts Sample Shellers

Aflatoxin problem in groundnut

What are aflatoxins?

Aflatoxins are toxic substances produced by certain fungi called Aspergillus

flavus and Apergillus, parasiticus. The word “ aflatoxin” derived as:

A stands for aspergillus,

Fla for flavus and

Toxin for poison

This fungus is present normally in air, soil and water and is associated with

living or dead plants and animals throughout the world.

A very small amount of aflatoxin in feed (10-20parts per billion) can produce fatal liver cancer in young

animals. Aflatoxin contamination is a serious quality problem in groundnut.

Factors contributing to contamination

Pre-harvest

End of season moisture stress to the crop for more than 20 days.

Growth cracks and mechanical injury to the pod

Insects damage to pods by termites or pod borers

Death caused by diseases (stem, root, and pod rots) at pod maturity stage.

Nematodes damage to the pod.

Post-harvest

Harvesting over mature crop. Mechanical damage to the pod at the time of harvest.

Stacking the harvest when pod moisture is more than 10% or under humidity

conditions.

Growth Cracks

on groundnut

pods

Pod Damage during harvesting pod damage from insects lead to aflotoxin

Damage of the pods by insects during storage.

Storing haulms with immature or small pods (they tend to contain more aflatoxins).

Wetting of stored pods due to high ground-moisture or roof leakage.

Effects of aflatoxin contamination

Causes marked deterioration in pod and kernel quality because of fugal growth. Contaminated kernels are unfit for consumption. If eaten insufficient quantities

aflatoxin can cause sickness, hepatitis and/or liver cancer. It is, therefore, extremely important

to ensure good management of ground nut crops and suspect seed should be destroyed rather

than used for human or animal consumption.

Reduce price for the produce

Causes decay in both seeds and non-emerged seedlings.

Severely affects the export of groundnut and its products

Deterioration in pod and kernel quality

Practices for minimizing aflatoxin contamination Harvest the crops as soon as it is mature, any delay will encourage the development of

fungus.

Avoid damaging pods during cropping.

Remove soil from the pods before leaving to dry.

Ensure that the correct drying procedures are used and that damaged, shriveled, or

rotten pods are removed before storage.

Store the pods under dry, well ventilated conditions to ensure the moisture content

remains low, thus discouraging fungal growth.

Avoid damaging the seed during shelling and destroy any discolored, shriveled or

mould seed.

Avoid pod damage by insects as this can leave the pods / seeds susceptible to fungal

infection.

Pre – harvest contamination is severe during drought and extra care should be taken

to clean the seed, especially the smaller seed.

Important points to remember about aflatoxin

Groundnuts at farm level generally contain low level of aflatoxin. The contaminated groundnuts are

those exposed to the rain during harvesting, stripping, or drying. Introduction of appropriate

mechanization can help lessen the problem of aflatoxin through a reduction in operation time to avoid

harvesting, stripping, and drying during the rain.

Some splitted groundnut and groundnut powder produced by village processors are highly

contaminated due to the products being exposed to an open air for a long period of time. Proper

techniques for handling and packaging of the products should be introduced to these processors.

Quality and marketing

The quality of ground nut is determined very much at the level. Good growing, harvesting, drying and

storage on-farm will ensure that the pods/seeds are marketable.

A buyer will in particular, be looking for varietal purity (at least 95%), low moisture content (7-8%), high

shelling percentage (above 55%), low level of damage pods/kernels (less than 17%) and no aflatoxin

contamination.

Consumption of groundnut

Groundnut consumed in many ways and various forms.

Primarily used as a vegetable cooking oil

Kernels are used directly as food or snacks for human.

A large number of food products are prepare from groundnut – Boiled nuts,

groundnut butter, groundnut cheese, bakery products etc.

Nutritive value

Content/100

Calories(g) Raw Roasted Defatted flour

564.0 582.0 371.0

Protein(g) 26.0 26.0 45.0

Fat(g) 47.5 48.7 5.8

Carbohydrates(g) 18.6 20.6 30.0

Calcium(g) 69.0 72.0 127.0

Phosphorus(mg) 401.0 401.0 800.0

Iron(mg) 2.1 2.2 33.5

Thiamine(B1)(mg) 1.14 0.32 0.75

Riboflavin(B2)(mg) 0.13 0.13 0.35

Niacin(mg) 17.2 17.2 2.5

Source: Burn and Huffman (1975)