Generic Exposure Scenarios: Their Development, …...industry groups in different supply chains,...

Transcript of Generic Exposure Scenarios: Their Development, …...industry groups in different supply chains,...

Ann. Occup. Hyg., Vol. 55, No. 5, pp. 451–464, 2011� The Author 2011. Published by Oxford University Press

on behalf of the British Occupational Hygiene Societydoi:10.1093/annhyg/mer022

Commentary

Generic Exposure Scenarios: Their Development,Application, and Interpretation under REACHCHRIS MONEY1*, ALISON MARGARY2, DOOK NOIJ3 andKEES HOMMES4

1ExxonMobil Petroleum and Chemical, Hermeslaan 2, Machelen 1831, Belgium; 2Shell InternationalLtd, Shell Centre, London, SE1 7NA, UK; 3Dow Benelux B.V., P.O. Box 48, 4530 Terneuzen,Netherlands; 4LyondellBasell Industries, Weena 737, 3013 Rotterdam, Netherlands

Received 15 December 2010; in final form 13 March 2011; published online 6 May 2011

The European Union Registration, Evaluation, Authorization, and Restriction of Chemicals(REACH) Regulation (EC 1907/2006) places significant new obligations on the manufacturersor importers (M/Is) of chemicals in Europe. It also places new responsibilities on downstreamusers (DUs) of these chemicals i.e. those that purchase and use chemical products. In partic-ular, for registered classified substances, the M/I is expected to communicate how any sub-stance can be safely used without risk to man or the environment. This communication is inthe form of an exposure scenario (ES), which is included in an Annex to the REACH extendedsafety data sheet. DUs then have certain obligations relating to adopting the control conditionsdescribed in the ES. The REACH Technical Guidance Documents lay down the expectationsfor the process of risk assessment that M/Is should adopt when developing ESs. But with manythousands of chemicals in daily commerce, it is also necessary to ensure that what is commu-nicated to DUs not only meets the requirements of REACH but is also understandable to thesegroups, as well as being consistent across different chemical suppliers and supply chains. Incooperation with relevant DU groups, the European solvents industry has developed genericapproaches for describing how solvents are commonly used, in order that these can subse-quently be used as the basis for REACH registrations and related safety data sheet communi-cations on health risk control. The utility of these approaches (termed ‘generic exposurescenarios’) is acknowledged under REACH and they are now publicly available for use bothby M/Is and DUs.

Keywords: exposure assessment; exposure scenario; REACH; risk communication

INTRODUCTION

The Registration, Evaluation, Authorization, andRestriction of Chemicals (REACH) Regulation(EU, 2006) was introduced by the European Union(EU) in response to the view that the previous systemof chemicals regulation was of limited success, aswitnessed by the rate at which regulatory risk assess-ments had been completed and subsequent interven-tions made on the marketing and use of these

chemicals (Christensen et al., 2003; Van der Wielen,2007). The previous system of chemicals regulationplaced the primary responsibility on Member Statesto identify chemical risks of concern. One of the fun-damental changes brought about by REACH is therequirement on industry to demonstrate that chemi-cals can be used safely (with respect to safety, health,and environment) across all their identified uses.These obligations are reflected in the broad registra-tion requirements for chemicals under REACH and,particularly so, for those substances classified ashazardous. The REACH Regulation is extensivein its expectations for industry, whether this be

*Author to whom correspondence should be addressed.Tel: þ32(0)2 722 4230; fax: þ32(0)2 722 3810;e-mail: [email protected]

451

manufacturers or suppliers of chemicals, or the ulti-mate users of these products [or downstream users(DUs) as they are described under REACH]. Thebroad requirements of REACH have been exten-sively described elsewhere (van Hemmen, 2009;Williams et al., 2009). However, for those groupswho are expected to assess and manage health risks,the most relevant provisions are those that relateto how a REACH registrant fulfills their substanceregistration obligations in health risks; notably, theregistrant [whether a manufacturer or importer (M/I)of a substance] has the responsibility to demonstratethe safe use of the substance throughout its life cycle,i.e. covering manufacture, distribution, formulation,and subsequent uses, including product recycling.The process that REACH lays down for demonstrat-ing safe use is the chemical safety assessment (CSA;for list of abbreviations, see Table 1). Within theCSA, the uses of the substance are described in a se-ries of exposure scenarios (ESs). The ES is themechanism used to characterize the nature of risks(whether health, environmental, or safety) withinany circumstance of use (Marquart et al., 2007). Al-though REACH does not specify how an ES is devel-oped, it is addressed within the supporting technicalguidance. However, the Regulation does require that,for substances with a hazard classification as ‘dan-gerous’, the ES is communicated in an Annex tothe safety data sheet (SDS) for the substance (whichis then subsequently described as the extended safetydata sheet, ext-SDS). The process of REACH regis-tration requires different M/Is with a common inter-est in a substance to come together to determine thehazards of the substance and how it ought subse-quently to be handled. For many substances, thereare likely to be lots of uses linked with a substanceand which can occur in a variety of sectors of indus-try. Within this context, there are clearly potentiallyhundreds of ESs associated with some commoditysubstances. Also, because the CSAs/ESs are ex-pected to be independently developed by differentindustry groups in different supply chains, there isfurther potential for the ESs to be different (in termsof how they evaluate and communicate risks) be-tween different supply chains.

The challenges that REACH has laid down forindustry have been widely discussed (Ruden andHansson, 2010; Schoeters, 2010). Most of this dis-cussion has addressed those issues that affect regis-trants under REACH, i.e. M/Is of chemicalsubstances. However, REACH also places signifi-cant new responsibilities on DUs of chemicals, i.e.those that purchase and use chemical products. Dur-ing the initial (pre-registration) phase of REACH,

DUs were encouraged to act with their suppliersand trade groups to ensure that the M/I’s of their sub-stances were aware of their uses and would committo continue to support the use of the chemical underREACH. However, once the (classified) substance isregistered, then the M/I is expected to communicate,in the form of an ES, the outcome of the CSA to theDU in the Annex of the REACH ext-SDS. ThisREACH SDS is both of a different format and con-tent to that which prevailed under the previous EUregulatory regime (EC, 1991). Perhaps of most note,DUs now have a legal obligation under REACH (un-der Article 37) to follow the advice contained withinthe ES or, if not, to either develop their own DU CSAor to request a revised ES from their supplier(ECHA, 2008a). This approach to the communica-tion of health risks differs to the previous regimewhere the information contained within the SDSwas advisory. Therefore, it is clearly in the interestsof the whole chemical supply chain that not onlyare chemical manufacturers aware of all the usesof their products but also that they evaluate the as-sociated risks in a manner that is not only compli-ant with REACH but also consistent betweensubstances across different supply chains. It isequally important that the outcome of this process,i.e. the SDS and its associated ES, is developedin a manner that is understandable and relevantfor any DU.

The solvents industry recognized that achievingthese aims required a partnership between chemicalmanufacturers and suppliers and DUs and initiateda series of activities. This process was led by themanufacturing trade group European Solvents In-dustry Group (ESIG) and supported by a platformof over 30 DU groups having major interests in theuse of solvents [termed European Solvents IndustryPlatform (ESVOC)]. The activities aimed to:

1. ensure that solvent manufacturers and supplierswould be able to meet their REACH obligationsin an efficient manner,

2. meet the specific expectations of DUs, i.e. con-sistency in the manner in which risks are evalu-ated and communicated across supply chains,and

3. ensure that the work products were understand-able and relevant for DUs and consistent withother current regulatory advice in these areas.

The activities were expected to cover the risksexperienced by workers, consumers, and the envi-ronment. This paper addresses only those activitiesaffecting workers.

452 C. Money et al.

Table 1. Selected list of REACH abbreviations and acronyms

Acronym Description and explanation

CE COSHH essentials: the UK Health and Safety Executive scheme for providing advice on the controlof chemical risks.

CEFIC European Chemical Industry Council: the trade group of the European chemical industry.

CHESAR Chemical safety assessment reporting: the ECHA tool for developing CSAs/ESs under REACH.

CMR Carcinogenic, mutagenic, or reprotoxic: the health drivers affecting whether a substance is consideredan SVHC (and which is a wider definition than used under the Carcinogens Directive).

CSA Chemical safety assessment: part of the registration process and which, for a classified substance,includes an assessment of exposure and characterization of risk.

CSR Chemical safety report: the document supporting the registration of a substance. Many elements ofthe CSR are published by the ECHA.

DNEL Derived no effect level: defined by REACH as the level of exposure above which humans should notbe exposed.

DMEL Derived minimum effect level: are applied to SVHCs and are intended to represent levels where theassociated risk (of contracting the disease) is considered to be very low.

DU Downstream user: the term used in REACH that refers to users of chemicals ‘downstream’ from thepoint at which the substance is manufactured or imported, e.g. a supplier’s customers.

ECETOC European Centre for Ecotoxicology and Toxicology of Chemicals: the scientific organization, fundedby industry, that addresses how chemical risks should be evaluated and controlled.

ECHA European Chemicals Agency: the Agency established in Helsinki to oversee REACH.

ES Exposure scenario: addresses the set of conditions (OCs and RMMs), covering the substance lifecycle, that describe how the substance should be safely handled to prevent unacceptable risks to manor the environment.

ESR Existing substances regulation: the regulation that applied to the marketing of chemicals prior to theintroduction of REACH.

ESIG European Solvents Industry Group: the European trade group for solvent manufacturers and suppliers.

ESVOC European Solvents Industry Platform: the organization established in Europe that brings togethersolvent manufacturers and users.

Ext-SDS Extended safety data sheet: a safety data sheet (most likely for a classified substance) where relevantESs are included an Annex to the SDS.

GES Generic exposure scenario: the termed applied to how broad uses of chemicals have been describedand grouped (by M/Is and DUs) in a manner that is relevant for REACH.

M/I Manufacturer or importer: the term used in REACH to describe those with the primary duty to registersubstances.

OC Operational condition: the UD that describes the boundary conditions on the use (if any) required toreduce exposures to acceptable levels, e.g. exposure duration.

PBT Persistent bioaccumulative and toxic: a term used within REACH to describe environmental propertiesthat would require the substance to be considered an SVHC.

PROC Process category: the UD that helps DUs better understand the scope of activities covered by anyidentified use of the substance.

REACH Registration, Evaluation, Authorization, and Restriction of Chemicals Regulation.

RCR Risk characterization ratio: the term applied by REACH to determine ‘safe use’ (RCR of ,1) anddefined as the ratio of the predicted exposure to the reference value (DNEL, etc.).

RMM Risk management measure: the UD that describes the form of control (if any) required to reduceexposures to acceptable levels (for the use).

SDS Safety data sheet: the form and content of the SDSs under REACH is laid out in Annex II of REACH.

SU Sector of use: the UD that describes the type of industry where a substance may be used.

SVHC Substance of very high concern: the REACH term applied to substances that are CMRs, PBTs,or vPvBs.

TGD Technical Guidance Document: the documentation developed by ECHA to describe how M/Is, ECHA,and the Member States are expected to be fulfill their various REACH obligations.

TRA Targeted risk assessment: the term used by ECETOC and REACH to describe the process fordetermining when ‘higher level’ (more detailed) CSAs are necessary to demonstrate safe use.

UD Use descriptor: the term applied to a series of different descriptors that are applied to ESs to helpDUs better understand them.

vPvB Very persistent very bioaccumulative: a term used within REACH to describe environmental propertiesthat would require the substance to be considered an SVHC.

Generic exposure scenarios 453

PROJECT AIMS

An extensive body of TGD has been developed bythe European Chemicals Agency (ECHA), in consul-tation with various stakeholders (member states, in-dustry, trade unions, and various non-governmentalorganizations) in order to ensure that the basic tech-nical expectations of the Regulation are applied withgood science (ECHA, 2010c). The TGD is compre-hensive and detailed. For example, the Guidance thatshapes how CSAs/ESs are developed and communi-cated (the Guidance on Information Requirementsand CSA) totals 25 sections and extends to 2200pages. The Guidance specifies terminology and laysout structures and processes which industry, as wellas other bodies, including regulatory agencies, areexpected to follow in order to meet their obligationswithin the many facets of REACH. Much of theguidance is an extension of that which prevailedunder the previous Existing Substances Regulation(ESR) as the inherent scientific structures that sup-ported that piece of legislation were felt to be robust,even though the rate at which ESR risk assessmentswere developed was considered slow (Munn andHansen, 2002; Bodar et al., 2003). If the ESR expe-riences were extrapolated to REACH, then the CSAand any supporting documentation could be ex-pected to extend to several hundred pages. Such anexpectation may be appropriate in a process requir-ing transparency, technical oversight, and scrutinyat the regulatory level. But communicating the out-come of that process in a manner that enables DUsto be in a position to identify key actions requiredon their part represents a challenge that was not di-rectly considered by the authors of REACH.

To make REACH a success, a number of poten-tially competing interests need to be balanced andfulfilled. Industry must successfully register its sub-stances for all the types of uses that have been iden-tified, consistent with the expectations that REACHlays down for M/Is, so that industry can legitimatelycontinue supply. And DUs must be in a position torespond to any new information contained withinREACH ext-SDSs when these have been received.Moreover, when seen across the tens of thousandsof chemical substances that are expected to be regu-lated under REACH, there is a need to foster effi-cient work processes that serve to benefit chemicalsuppliers, their customers and the other REACHstakeholders. Recognizing that this objective wouldprobably not be achieved unless an appropriate ac-tivity was initiated before the registration of affectedchemical substances, ESIG established a small taskgroup with the following aims:

1. to describe common uses of solvents in a mannerthat is consistent with the expectations ofREACH, that is understandable for DUs of sol-vent products and which aligns with current in-dustry practice and regulatory advice in the area,

2. to test the approach to ensure it meets the expect-ations of DUs of solvent products and the expec-tation of regulatory agencies, as well as theobligations of chemical manufacturers,

3. to structure the descriptions so that they commu-nicate clearly what was intended when the sol-vent was registered, and

4. to describe the approach using standard phrases,in order that the guidance can not only be incor-porated into SDS systems but such phrases canalso be used and applied by other sectors ofindustry.

While REACH places an obligation on thechemical manufacturer to undertake a CSA for anyclassified substance as part of its registration, under-taking a health risk assessment is not a new conceptfor health professionals. Indeed, the requirements toundertake workplace health risk assessments extendback over many years. For example, occupationalexposure limits (OELs) of various forms have nowbeen available for over 50 years (Henschler, 1984;Rappaport, 1993) and their derivation is a sort ofCSA. More recently, generic systems of risk assess-ment such as those associated with control bandingconcepts have been developed and are now being ac-tively applied (Money, 2003; Zalk and Nelson,2008). These approaches use also risk-based ap-proaches to propose controls and the experiencecan inform the CSA process under REACH.

STRUCTURE AND CONTENT OF GESs

The REACH guidance is both extensive and de-tailed in its requirements for how any CSA is under-taken (ECHA, 2010c). In essence, any use ofa substance is expected to be described in a mannerconsistent with the nomenclature contained withinthe REACH use descriptor (UD) system, the likelyexposures associated with the use must then be de-termined, and any necessary exposure controls(whether procedural or engineering) identified com-mensurate with the need to reduce exposures to be-low the relevant exposure control value [which isdefined within REACH as the derived no effect level(DNEL)]. Conceptually, this process is straightfor-ward and will be familiar to workplace health profes-sionals; job or task-related exposures are comparedagainst an appropriate health-based Reference Value

454 C. Money et al.

in order to judge the acceptability of the risk. How-ever, there are lots of uses of many chemicals, result-ing in the potential for several hundred permutationsof UDs, which could be applied to these. Such an ap-proach could be heavily bureaucratic, and a DUwould most likely find it difficult to readily identifyand understand the relevant use among the hundredspotentially listed in the ext-SDS. It was therefore ap-parent that a more efficient approach was required ifthe nature of the information on safe use that is in-tended to be contained within the ext-SDS was tobe available for use by chemicals M/Is in their Phase1 (2010) registrations.

Benefiting from some of the sector-based discus-sions that have taken place in the development ofthe UK Control of substances hazardous to health(COSHH) Essentials control banding scheme onhow uses are described and communicated, such asthe COSHH Essentials schemes for silica, welding,agrochemicals printing, etc. (HSE, 2010), ESIGworked with DU trade associations within ESVOCto identify and describe the broad uses of solventsin a manner that is relevant for REACH. A total of22 uses have been identified covering a total of 32areas of use (describing either industrial and/orprofessional applications). Some of these generic ex-posure scenarios (GESs) are listed in Table 2. Eachtitle describes a common area of use of solventswithin industry. The title is described in layman’sterms (including colloquial terms for certain industrysectors) as well as reflecting a consensus amongstthe supplier and user groups concerning the applica-tion of relevant associated REACH UDs. As de-scribed earlier, in order to meet the objectives ofREACH, it is necessary for the chemical’s M/I todemonstrate as part of the CSA that the substancecan be safely used in each identified use. To accom-plish this, REACH requires that a CSA is undertakenfor affected substances and that the safe use (whichis determined by reference to the risk characteriza-tion ratio, RCR, for the use) is communicated inan ES.

The process for the development of each GES,therefore, follows the expectations of the REACHTGD, i.e. it characterizes the use in the terms re-quired under REACH, including likely associated(inhalation and dermal) exposures and then identifiesthe necessary exposure control conditions [which aredescribed under REACH as either operating condi-tions (OCs) or risk management measures (RMMs)]required to successfully control exposures to withindefined exposure bands. However, contrary to usinga starting assumption that no exposure controls (be-yond those described by the relevant UDs) are imple-

mented during the use of chemicals, the GESs usethe nature of typical existing controls for the use astheir start point. This then enables, as a key outputof the CSA, a distinction to be made between thosecontrols which are apparently a direct requirementof REACH (i.e. those necessary to reduce exposuresto less then any DNEL) and those that constitutegood exposure control practice for the sector. Thus,this step enables an M/I not only to meet theirREACH obligations but also to supplement thesevia appropriate product stewardship activities.

Many of the key elements of the GESs representan extension of previous industry initiatives (CIA,1993; ABPI, 1995; RSC, 1996). That is, the GES de-scribes a defined set of exposure control conditionsthat are appropriate for a certain risk range or band(which is, in turn, described by a combination ofthe substance’s volatility and DNEL/OEL range).Thus, the approach is applicable not only for differ-ent uses of solvents but also for different classes ofsolvents, e.g. hydrocarbon, oxygenated, haloge-nated, etc. Two aspects, however, represent a signifi-cant departure from previous initiatives in this area:

1. The development of the GESs represents a part-nership of chemical suppliers and their custom-ers. This is intended to ensure that thedescriptions of the chemical risks and the requi-site controls solutions are understandable to DUsand the manner of communication is likely to beconsistent across different solvent supply chains.Clearly, the need for consistency in the manner inwhich risks are evaluated and communicated bysolvent suppliers is of paramount importance forDUs. It not only provides an assurance regardingthe provenance of the information received but isalso in a language that is likely to be understand-able, including reference to control terminologythat is familiar to the sector.

2. The GESs are described using standard phrases.The reason for this is simple; ESs are requiredto be incorporated within SDSs, and SDSs mustbe available in all 27 of the European communitylanguages. Therefore, any system, which is reli-ant on free text descriptions, is not amenable tomanipulation within current SDS technologies.What is different between the standard phrasesused to characterize much of the GES, and thosethat typically are used elsewhere in the SDS, isthat the GES phrase is a reflection of the ex-pected exposure reduction that the identifiedRMM would be expected to deliver. The ESIGGESs use the European Centre for Ecotoxicol-ogy and Toxicology of Chemicals Targeted Risk

Generic exposure scenarios 455

Assessment (ECETOC TRA model (ECETOC,2009) as the basis for the underlying exposurepredictions. This is consistent with the advicegiven within the REACH Guidance (ECHA,2010b). For solvents, the TRA exposure predic-tions align well with actual exposure data on sol-

vents, i.e. they are generally over predictive ofand rarely under predictive of current exposureexperiences within the industry (TNO, (unpub-lished report)). As the ECETOC TRA is a modelwhich is dependent on only comparatively fewexposure variables for its operation, then it has

Table 2. Indicative GES titles for solvents

Title of GESa Principle areasof application

Scope of the GESb Relevant REACH UDs

Sector ofuse (SU)

Processcategory (PROC)

Manufacture Industrial Manufacture of the substance or useas an intermediate or process chemicalor extraction agent. Includes recycling/recovery, material transfers, storage,maintenance, and loading (includingmarine vessel/barge, road/rail car, andbulk container).

3 1, 2, 3, 4, 8a, 8b, 15

Formulation andre-packing

Industrial Formulation, packing, and re-packingof the substance and its mixtures inbatch or continuous operations,including storage, materials transfers,mixing, large and small scale packing,equipment cleaning, and maintenance.

3 1, 2, 3, 4, 5, 8a,8b, 9, 15

Use in coatings Industrial,professional

Covers the use as a component ofcleaning products including transferfrom storage, pouring/unloading fromdrums, or containers. Exposures duringmixing/diluting in the preparatoryphase and cleaning activities (includingspraying, brushing, dipping, wiping,automated, and by hand), relatedequipment cleaning, and maintenance.

3, 22 1, 2, 3, 4, 5, 7,8a, 8b, 10, 13

Use in oil and gasfield drilling andproduction operations

Industrial,professional

Oil and gas field well drilling andproduction operations (including drillingmuds and well cleaning) includingmaterial transfers, on-site formulation,well head operations, shaker roomactivities, and related maintenance.

3, 22 1, 2, 3, 4, 8b, 9, 10

Lubricants Industrial,professional

Covers the use in lubricants in closedand open systems including transferoperations, operation of machinery/engines and similar articles, reworkingon reject articles, equipment maintenance,and disposal of wastes.

3, 22 1, 2, 3, 4, 5, 7, 8a, 8b,9, 10, 13, 17, 18

Metal working fluidsand rolling oils

Industrial,professional

Covers the use in metal working fluids/rolling oils including transfer operations,rolling and annealing activities, cutting/machining activities, automated andmanual application of corrosionprotections (including brushing, dipping,and spraying), equipment maintenance,draining, and disposal managementof waste.

3, 22 1, 2, 3, 5, 7, 8a, 8b,9, 10, 13, 17, 18

Road and constructionapplications

Professional Application of surface coatings andbinders in road and construction activities,including paving uses, manual mastic,and in the application of roofing andwater-proofing membranes.

22 5, 8a, 8b, 9, 10, 11, 13

Use in laboratories Industrial,professional

Use of the substance within laboratorysettings, including material transfersand equipment cleaning.

3, 22 10, 15

aTitles may be abbreviations of full title. Refer to web page of supplier trade group for full list of titles.bScope statement only refer to industrial uses, unless GES only available for professionals. Statements for professional uses maydiffer slightly.

456 C. Money et al.

been possible to develop phrases that are consis-tent with the exposure control conditions de-scribed within the TRA, but which, moreimportantly, are in a language that is under-standable to DUs of solvents. Table 3 givesexamples of some of these phrases together withtheir relationship to TRA exposure determi-nants. Over 130 phrases have now been devel-oped within industry in order to effectivelycommunicate the required exposure controlconditions (RMMs and OCs) for the varioususes of solvents and different forms of exposurecontrols encountered in these situations. Thiscatalog of standard phrases, together with theirassociated exposure reduction efficiencies hasnow been incorporated into European phase cat-alogue of the library of REACH SDS standardphrases administered by the Bundesverbandder Deutschen Industrie, Federation of GermanIndustries (BDI, 2010). The phrases addressboth inhalation and dermal risks (ingestionis not considered a relevant exposure route forsolvents). They also extend to circumstancesof use that exist within consumer uses of sol-vents (although this aspect is not addressed inthis paper).

PROCESS FOR THE USE OF GESs

The overall value and role that GESs play in help-ing to communicate REACH required informationwithin supply chains has been acknowledged not on-ly within the chemical industry (CEFIC, 2009) butalso by ECHA (ECHA, 2008b). Specifically, theEuropean Chemical Industry Council (CEFIC) guid-ance for CSA development foresees the GES occu-pying a central role for different substance tradegroups as it serves to facilitate efficient and consis-tent communication on risks for similar substancetypes to different DU groups. For this reason, furtherGESs (beyond those listed in Table 2) have now beendeveloped by various industry groups, and a ‘webportal’ exists at CEFIC to facilitate entry to these(CEFIC, 2010). Although this is essentially aimedat companies needing to register their substances,the portal is also a useful resource for DUs (suchas formulators of preparations) wishing to accessand apply the information.

The most comprehensive activity, however, re-mains that initiated by the solvents sector (ESIG,2010). Its work products reflect those outlined inTable 2, i.e. a listing of available GES titles, their de-scription in REACH UD terms, a mapping of use and

Table 3. Examples of standard phrases for use in developing and describing ESs

Standard phrase European phasecatalogue code

Assigned exposurereduction efficiency (%)

Comments

Emission

Avoid carrying out activitiesinvolving exposure for .1 h

OC27 80 Only applies to exposures to substancesexhibiting chronic (time-weighted) effects

Limit the substance contentin the product to 25%

OC18 40 Phrase aimed at formulators and whereexposure reduction linked to ECETOCTRA

Transmission

Provide a good standard ofgeneral ventilation (not ,3–5air changes per hour)

E11 30 Exposure reduction consistent withpublished values (e.g. HSE, 2008)

Fill containers/cans atdedicated fill points suppliedwith local extract ventilation

E51 80/90 Assigned exposure reduction differsdependent on sector of use (and alignswith TRA defaults for professional andindustrial use, respectively)

Handle within a fumecupboard or implement suitableequivalent methods to minimizeexposure

E12 90 Exposure reduction consistent withpublished values (e.g. HSE, 2008)

Sample via a closed loop orother system to avoid exposure

E8 95 Only intended to be applied to industrialsettings

Immission

Wear a respirator conformingto EN140 with Type A filteror better

PPE22 90 Exposure reduction intended to reflectlikely actual protection factor (APF)

Wear chemically resistant gloves(tested to EN374) in combinationwith ‘basic’ employee training

PPE16 90 Exposure reduction intended to reflectcombined effects of likely APF andtraining

Generic exposure scenarios 457

control conditions typically encountered in the sec-tor, generic CSAs for different volatility ranges,and resulting ESs for each use that differentiate theexposure controls/RMMs likely to be required underREACH, from those measures that might also beconveyed as part of a supplier’s broader productstewardship communications. All the major workproducts are then made available via a GES ‘library’.In the first instance, the libraries have been aimed atREACH registrants in that they serve as an informa-tion source that enables ’ready made’ CSAs to beidentified and evaluated with respect to their ade-quacy for REACH registration purposes. Hence,their primary purpose is to serve as an efficient startpoint when seen across registrants and supply chainsthat also provides the basis for consistent CSA eval-uations and subsequent SDS communications. How-ever, the libraries also serve as a resource for othergroups with an interest in the management of work-place chemical health risks, e.g. formulators, DUs,and workers themselves.

Figure 1 outlines the process that is intended to beapplied within industry for using GESs:

1. The start point is to determine the volatility andrelevant DNELs for any substance. The volatilityis defined in a manner consistent with the ECE-TOC TRA (ECETOC, 2009). Any DNEL islikely to have been derived as an outcome ofthe hazard assessment for the substance and ina manner consistent with the guidance offeredin chapter R8 of the TGD.

2. The uses of the substance must be identified.This will be a process that uses both market in-formation available to the supplier, together withresponses from customers and other DUs result-ing from supply chain communication activities.

3. Based upon 1 and 2, the relevant GESs are cho-sen that best describe the known uses of thesubstance. The availability of GESs is shownwithin the library index.

4. For each use, the relevant (inhalation and dermal)DNELs for the substance are then inserted intothe CSA template sheet (which is written inMicrosoft� Excel�). Once this step is completed,the sheet will auto-calculate the RCR for each ofthe contributing scenarios that describe thesituations associated with handling the materialthat potentially gives rise to exposure.

5. Where the RCR remains ,1, then the narrativestatements (and which address the OCs andRMMs) associated with the GES remain valid,i.e. because the GES already represents a set ofconditions that manage risk to an acceptablelevel, then providing the RCR remains ,1,the suitability of the assigned phrases can beconsidered to have been verified. Since theGES is developed using DNEL bands, it is alsoadvisable to determine whether it is appropriateto select alternative (and possibly less stringent)OCs and/or RMMs for the scenario, while ensur-ing the RCR still remains ,1.

6. In those circumstances where the RCR is .1,then the user will need to implement additionalRMMs (or more stringent OCs) to ensure that as-sociated exposures are reduced such that theRCR is ,1. In those instances, the associatedES will also need to be (manually) amended toensure that any additional RMM or OC changesare also reflected in the narrative ES.

7. On completion of steps 1 to 6, users can considerthat the GESs have been applied to the CSA pro-cess in a manner consistent with REACH, i.e. theGES serves a start point, but where, in line withthe REACH Guidance (ECHA, 2008b, 2010a)the resulting CSA/ES has been refined and cus-tomized by reference to the specific characteris-tics of the substance being evaluated. Theassociated revised files then also form the basisfor information that is be required to be con-tained within Sections 9 and 10 of any ChemicalSafety Report for the substance.

DISCUSSION

Although an extensive number of GESs have nowbeen developed, it is important to understand theirlimitations. First, they have been developed asa mechanism that aims to ensure that the obligationsthat chemical manufacturers and suppliers have un-der REACH to undertake an assessment of relevant

Fig. 1. How chemical manufacturers and suppliers should useGES libraries.

458 C. Money et al.

uses can be executed in a manner aligned with theexpectations of the REACH guidance and communi-cated in an understandable manner to DUs. Asa consequence, by their very nature, the GESs are‘generic’; they paint a picture of how solvents (orother materials) should be handled within an as-sumed typical workplace. The extensive consultationthat has taken place with DUs during their develop-ment helps ensure that the GES will be practicallyvalid across a wide range of workplaces. But therewill always be exceptions.

Second, the approach uses the ECETOC TRA toolas the basis of the exposure predictions within theCSAs that are at the heart of each GES. The ECE-TOC TRA is based on an extension to the EASEmodel (ECETOC, 2004; Money et al., 2007). Thelimitations of EASE have been well documented(Creely et al., 2005). However, the updated TRA(ECETOC, 2009) has extensively revised the associ-ated EASE predictions in order to develop exposureestimates that both better align with the expectationsof REACH and represent more accurate exposure es-timates for any scenario described by the REACHUD system. Furthermore, the revised TRA now ap-plies EASE within the broader context of the sourcereceptor approach to exposure modeling (Cherrie;Schneider, 1999), that is account can now also betaken of imission pathways as well as the emissionand transfer pathways included in the original ver-sion. Any resulting exposure estimates are only asaccurate as the extent to which the base model (inthis case the TRA) has been validated. Beyond thework undertaken by ECETOC in refining the EASEestimates, only one (limited) independent compari-son of the TRA has been undertaken, although forsolvent-like materials the outcome demonstrateda generally good correlation with ‘real exposures’and a clear tendency toward estimated exposureshigher than those observed (TNO, [unpublished re-port]). The TRA has not been validated for gasesor aerosols, however. Therefore, where co-exposuresof this type exist, then other approaches to exposuresestimation may be useful to consider such as the ap-plication of the prediction models of the EMKG(BAuA, 2010), COSHH essentials (HSE, 2009),StoffenManager (Marquart et al., 2008; Arbo Unie,2010), or the Advanced REACH Tool (Fransmanet al., 2009).

The experiences of using the GESs to date havebeen very positive. Currently, over 150 GESs areavailable for different workplace uses of differenttypes of solvents (CEFIC, 2010). GESs are alsoavailable from other sector organizations that de-scribe uses of other solvent-like materials, e.g. poly-

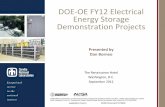

merization processes, use of blowing agents, andresin-based adhesives. The experience has alsohelped shape the manner in which supporting prod-uct stewardship information on the products andtheir uses can be better targeted to users of the sub-stances. Figure 2 highlights this capability. It showsthat:

1. GESs (such as those listed in Table 2) can be ex-pected to be available for different classes (vola-

tility ranges) of solvents. Within ESIG, three

volatility ranges have been applied reflecting

those described in the ECETOC TRA model

(and covering high, moderate, and low volatil-

ities). For solid substances, the classes are likely

to reflect their dustiness, e.g. as described in the

TRA or by COSHH Essentials.2. GESs are likely to have been developed for dif-

ferent DNEL combinations that reflect relevantexposure routes (inhalation and/or dermal) forthe use. For visual simplicity, Figure 2 onlyrefers to inhalation exposures.

3. Generally, the GES will have been developed forexposure to the ‘pure’ (100%) substance. But forsome uses, GESs may have also been further re-fined to account for the likely presence of thesubstance within simple formulations. In certaininstances (as indicated by the GES referencenumbers), the exposure control conditions (OCsand RMMs) required to manage the risks arisingfrom the presence of a hazardous substance ata certain concentration level within a preparationmight also be expected to reflect those necessaryto manage the risks from exposures to higherconcentration levels of a less hazardous solventof a similar volatility.

4. The GESs can differ between industrial and pro-fessional uses. This is largely a function of theassumption contained within the REACH Guid-ance that exposures and exposure controls innon-industrial situations are likely to be differentto those in industrial settings.

Figure 2 also demonstrates that for some solvent/use combinations, a GES may be unavailable. Forexample, the use of some classes of solvents for cer-tain applications may either not be credible (e.g.a low volatility material being used as a propellantor a high volatility material as a binder) or generallyunsupported across the industry (e.g. due to consid-erations of flammability or toxicity). In such instan-ces, if a solvent of that type to be considered for thatuse, then there would be a need for a specific risk as-sessment that extended beyond the capabilities of

Generic exposure scenarios 459

the GES and for which additional targeted productstewardship information is likely to be advisable,e.g. detailing monitoring and control methods, han-dling precautions, etc. Furthermore, these useswould also expect to be identified in the ext-SDSfor the substance.

Although the elements underpinning GESs wereinitially developed for solvents, they are also likelyto be applicable to other substances. For example,the manner in which key uses have been describedthrough dialogue with DUs and their representativessuggests how other groups wishing to evaluate therisks presented from the use of their substancesmight proceed. In these situations, however, userswill as a minimum need to (i) determine whetherthe volatility ranges are relevant to such materials,e.g. if the material were a solid, then users wouldneed to substitute the exposure predictions containedwithin the Excel�-files within the library withthose resulting from the application of the ECETOCTRA (or other suitable REACH endorsed exposuremodel) for the substance properties of interest and(ii) to develop suitable exposure control bandsconsistent with the DNEL ranges used within theESIG activity. Consideration will also need to begiven to the extent to which any GES adequately de-

scribes the circumstances of use of the substanceand where it is insufficient or inappropriate, thenthe content within the Excel� file will need to berefined accordingly.

One important attribute of the GES is the mannerin which the outputs are presented as these are re-quired to be communicated (for classified substan-ces) as an Annex to the REACH SDSs. Figure 3shows how the ES derived from the GES is likelyto be communicated to DUs as an outcome of theCSA contained within the registration dossier forthe substance.

The following characteristics should be noted:

1. As the GES is intended to represent the output ofa generic CSA for a defined set of substance con-ditions, it is written in format consistent with theexpectations of REACH using standard senten-ces (in order to facilitate ready translation intoother languages).

2. The GES describes the range of activities or tasksthat are typically associated with the use intoa consolidated ES for the use. The associatedrisks for each of these ‘contributing scenarios’are evaluated and, based upon the stated OCs,the required RMMs are identified. Dependingupon the use, there may be up to a 15 different

Fig. 2. The structure of GES libraries.

460 C. Money et al.

contributing scenarios, e.g. covering materialtransfers, different application techniques, stor-age, and maintenance.

3. Broad information that explains the UDs coveredby the ES, together with a simple explanation thatis more likely to be understandable by the user/customer (and which in turn relates to informationrequired to be contained in Section 1 of the SDS).

4. Basic information that states the assumptions(termed OCs) behind the ES, e.g. detail of thekey physicochemical properties and that it coversdaily exposures to 100% of the product.

5. Specific RMMs and/or further OCs that are con-sidered necessary to manage the risks for partic-ular activities associated with its area of use, e.g.the use of specific types of extract ventilation or

personal protection when transferring or spray-ing the material, the need for specific forms ofsampling when this activity is undertaken, etc.This information covers both the controls neces-sary to manage both human health and environ-mental risks.

6. Information that enables the DU to obtain an ideaof the likely exposures associated with the useconditions described in the ES. Where the useconditions differ to those described in the ES, in-formation that enables the DU to be able to‘scale’ from the ES, i.e. how any DU may be ableto determine whether the controls encountered atthe local level might be considered to representsomething that is equivalent to, better, or worsethan those described in the ES.

Fig. 3. Structure and content of the ES.

Generic exposure scenarios 461

The net implication of this activity is that theprocess is now more straightforward and far moreefficient then would otherwise be the case. For atypical classified solvent, the SDS under REACHis likely to be �50–100 pages, when the variousESs associated with the use of that solvent areconsidered. This compares with ext-SDSs of sev-eral hundred pages that would otherwise be thecase if the original draft REACH guidance hadbeen followed. Limited testing by industry hasshown that, perhaps unsurprisingly, ESs that arecommunicated in a language that is straightfor-ward and written in a form that aligns with thelanguage commonly encountered within a sectorare more likely to be understood and imple-mented than ESs written to fulfill the needs ofregulatory risk assessments. DUs should, there-fore, be able to better understand the (technicaland procedural) measures necessary to managethe health risks associated with the use of the sub-stance, as these are now described. This is not tosay, however, that some users of chemicals willrequire access to detailed information on the na-ture of exposures and use. For example, formula-tors of substances may need to have recourse tothis type of information when assessing the natureof the hazards and risks presented by the use ofhazardous preparations.

The value of different aspects of GESs is recog-nized. For example, the Guidance on ES develop-ment (ECHA, 2008b) discusses the merits ofGESs within the context of the need for coher-ency and alignment of supply chain communica-tions to ensure that the downstream uses ofa substance are effectively addressed within itsregistration dossier. CEFIC advocates GESs asthe preferred basis for the development of theCSAs/ESs for substances in dispersive use(CEFIC, 2009). Finally, the CSA tool now devel-oped by ECHA (and termed CHESAR) also ap-plies many of the core ideas behind the GES(ECHA, 2010a). However, the key test of whetherGESs are able to deliver many of their claimed at-tributes will only become evident following theintroduction of REACH ext-SDSs by chemicalsuppliers and the ECHA/Member State activitiesaimed at evaluating substance registrations. Ifext-SDSs are inconsistent in their form and con-tent across major supply chains, then the potentialof GESs will not have been realized. This willalso be the case if the level of detail of GES-based CSAs is considered insufficient to reliablydescribe the risks for associated uses of thesubstance.

CONCLUSIONS

The introduction of the REACH Regulation willresult in a marked increase in the amount of informa-tion that is communicated to users of chemicals inorder that they are better able to safely use these ma-terials. Specifically, REACH foresees the ES as themechanism via which safe use information can becommunicated to the users of chemicals (as an An-nex to the SDSs of classified substances). But thecommunication of information alone will not neces-sarily lead to improvements in standards of work-place health and safety. Indeed, the communicationof forms of information that are perceived as not rel-evant or are difficult to understand may be disre-garded by the very groups the information isintended to assist (Briggs and Crumbie, 2000). Inorder to try to minimize the likelihood of this unde-sirable outcome, industry has sought to identifyapproaches for assessing and communicating work-place health risks that ensure that the informationthat is contained in ESs that are likely to be under-standable and considered as relevant by DUs. Theapproach comprises a series of linked activities that,taken together, enable manufacturers and suppliersof chemicals to develop the CSA for their substancesand communicate the outcomes (ESs) to their cus-tomers in a manner likely to be understood andcapable of being processes by IT systems. Together,these are now referred to as GESs. This work hasbeen accomplished through a close cooperation be-tween the manufacturers/suppliers of solvents (whoare responsible for many of the main duties underREACH) and representatives of the major DU asso-ciations for the affected product types and has nowresulted the development of GES libraries for differ-ent substance supply chains (such as solvents).

The content of these libraries deliver significantbenefits for industry and users of chemicals, not onlydo they provide an efficient and reliable basis bywhich the workplace health risks can be consistentlyevaluated and communicated but because they havebeen developed in conjunction with DUs, they arewritten in a manner that is likely most relevant forusers of these chemicals. They also serve as a re-source for those groups seeking further advice onthe control of workplace health risks, e.g. for thosesubstances with later phase-in dates under REACH.Moreover, because the approaches have similaritiesto existing schemes for evaluating workplace healthrisks (such as COSHH Essentials and the EMKGscheme of the BAuA) then the advice that is commu-nicated as part of the supplier’s SDS may also be ex-pected to complement that which is already be

462 C. Money et al.

available from certain regulatory agencies. This isnot to say that the introduction of ESs into ext-SDSswill be straightforward. For example, a commercialsolvent may typically be associated with between10 and 15 different industrial uses. This means thatthere will be a marked increase in the amount of in-formation that is contained within SDSs over histor-ical levels. Current indications are that SDS arelikely to increase in size from 10 pages to .50 pa-ges. This step change in the amount of informationprovided by chemical suppliers will create chal-lenges not only for DUs but also for everyone withan interest in the control of workplace health risks,including occupational hygienists. However, withoutGESs, which enable consistency in health risk com-munications both within and across supply chains,the picture would be even more challenging.

FUNDING

The work described has received no research fund-ing but has been developed with secretarial supportfrom ESIG, CEFIC and CONCAWE.

Acknowledgements—The authors wish to thank TonyNewbould, European Council of Producers and Importers ofPaints, Printing Inks and Artists’ Colours; Sylvie Lemoine,International Association for Soaps, Detergents and Mainte-nance Products; Johannes Tolls, Association of EuropeanAdhesive and Sealant Industries; Marianne Lyngsae, EuropeanAssociation of Chemical Distributors; Reinhard Jacobi, DHCSolvents; Alain D’Haese, European Aerosol Federation, andJan Urbanus, Shell, for their contributions to the developmentof many of the concepts and the subsequent population of theESIG GES library.

REFERENCES

ABPI. (1995) Guidance for setting in-house occupational ex-posure limits for airborne therapeutic substances and theirintermediates. London: Association of the British Pharma-ceutical Industry.

Arbo Unie. (2010) Welcome to the Stoffenmanager. Utrecht,Netherlands. Available at: https://www.stoffenmanager.nl/default.aspx. Accessed 16 April 2011.

BAuA. (2010) EMKG EMKG-EXPO-TOOL is part of the‘Easy-to-use workplace control scheme for hazardoussubstances’ (EMKG ‘Einfaches Maßnahmenkonzept furGefahrstoffe’). Available at: http://www.emkg.de/. Ac-cessed 16 April 2011.

BDI. (2010) European standard phrase catalogue. Berlin, Ger-many: Bundesverband der Deutschen Industrie. Availableat: http://reach.bdi.info/380.htm. Accessed 16 April 2011.

Bodar CW, Berthault F, de Bruijn JH et al. (2003) Evaluationof EU risk assessments existing chemicals (EC Regulation793/93). Chemosphere; 53: 1039–47.

Briggs D, Crumbie N. (2000) Characteristics of people work-ing with chemical products in small firms, Health & SafetyExecutive contract research report 278. Norwich, UK: HerMajesty’s Stationery Office.

CEFIC. (2009) Developing generic exposure scenarios underREACH. Brussels, Belgium: European Chemical IndustryCouncil. Available at: http://cefic.org/Industry-support/Implementing-reach/Documents-and-Tools1/. Accessed 16April 2011.

CEFIC. (2010) Activities relevant to the REACH Libraries car-ried out by industry associations. Brussels, Belgium: Euro-pean Chemical Industry Council. Available at: http://cefic.org/Industry-support/Implementing-reach/Libraries/.Accessed 16 April 2011.

Cherrie JW, Schneider T. (1999) Validation of a new methodfor structured subjective assessment of past concentrations.Ann Occup Hyg; 43: 235–245.

Christensen FM, de Bruijn JHM, Hansen BG et al. (2003) As-sessment tools under the new European Union ChemicalsPolicy. Green Manag Int; 41: 5–19.

CIA. (1993) Safe handling of Colorants 2. London: ChemicalIndustries Association.

Creely KS, Tickner J, Soutar AJ et al. (2005) Evaluation andfurther development of EASE Model 2.0. Ann OccupHyg; 49: 135–45.

EC. (1991) COMMISSION DIRECTIVE of 5 March 1991 de-fining and laying down the detailed arrangements for thesystem of specific information relating to dangerous prepa-rations in implementation of Article 10 of Directive 88/379/EEC (91/155/EEC) (Official Journal L76/91) as amendedby Commission Directive 93/112/EC of 10 December1993 (Official Journal L314/93).

ECETOC. (2004) Targeted risk assessment. Brussels, Bel-gium: European Centre for the Ecotoxicology and Toxicol-ogy of Chemicals Technical Report No. 93.

ECETOC. (2009) Addendum to ECETOC targeted risk assess-ment report no. 93. Technical Report No. 107. Brussels, Bel-gium: European Centre for the Ecotoxicology andToxicology of Chemicals.

ECHA. (2008a) Guidance for downstream users. Helsinki,Finland: European Chemicals Agency. Available at: http://guidance.echa.europa.eu/docs/guidance_document/du_en.pdf?vers=29_01_08. Accessed 16 April 2011.

ECHA. (2008b) Guidance on information requirementsand chemical safety assessment: part D exposure scenariobuilding. Helsinki, Finland: European Chemicals Agency.Available at: http://guidance.echa.europa.eu/docs/guidance_document/information_requirements_part_d_en.pdf.

ECHA. (2010a) CHEmical Safety Assessment and Reportingtool. Available at: http://chesar.eu/. Accessed 16 April 2011.

ECHA. (2010b) Guidance on the different processes and meth-ods under REACH. Helsinki, Finland: European ChemicalsAgency. Available at: http://guidance.echa.europa.eu/guidance_en.htm. Accessed 16 April 2011.

ECHA. (2010c) Guidance on information requirements andchemical safety assessment chapter R14 occupational expo-sure estimation. Helsinki, Finland: European ChemicalsAgency. Available at: http://guidance.echa.europa.eu/docs/guidance_document/information_requirements_r14_en.pdf?vers527_05_10. Accessed 16 April 2011.

ESIG. (2010) Guidance on the use of GESs. Brussels, Bel-gium: European Solvents Industry Group. Available at:http://www.esig.org/en/regulatory-information/reach/ges-library/ges-library-3. Accessed 16 April 2011.

EU. (2006) Regulation (EC) No 1907/2006 of the European Par-liament and of the Council of 18 December 2006 concerningthe Registration, Evaluation, Authorisation and Restrictionof Chemicals (REACH), establishing a European ChemicalsAgency, amending Directive 1999/45/EC and repealingCouncil Regulation (EEC) No 793/93 and Commission

Generic exposure scenarios 463

Regulation (EC) No 1488/94 as well as Council Directive 76/769/EEC and Commission Directives 91/155/EEC, 93/67/EEC, 93/105/EC and 2000/21/EC. Official Journal L 396,30.12.2006, 1–849. Available at: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri5OJ:L:2006:396:0001:0849:EN:PDF. Accessed 16 April 2011.

Fransman W, Cherrie J, van Tongeren M et al. (2009) Devel-opment of a mechanistic model for the Advanced Tool,REACH Tool (ART). Report V8667. Zeist, The Nether-lands: TNO. Available at: http://www.advancedreachtool.com/. Accessed 16 April 2011.

Henschler D. (1984) Exposure limits: history, philosophy, fu-ture developments. Ann Occup Hyg; 28: 79–92.

HSE. (2008) Controlling airborne contaminants at work: a guideto local exhaust ventilation (LEV), HSG258. London: Health& Safety Executive. Available at: http://www.hse.gov.uk/pubns/priced/hsg258.pdf. Accessed 16 April 2011.

HSE. (2009) The technical basis for COSHH essentials: easysteps to control chemicals. London: Health & Safety Exec-utive. Available at: http://www.coshh-essentials.org.uk/assets/live/CETB.pdf. Accessed 16 April 2011.

HSE. (2010) Control of substances hazardous to health(COSHH) essentials guidance publications. Available at:http://www.hse.gov.uk/pubns/guidance/index.htm. Accessed16 April 2011.

Marquart H, Heussen H, Le Feber M et al. (2008) ‘Stoffen-manager’, a web-based control banding tool using an expo-sure process model. Ann Occup Hyg; 52: 429–41.

Marquart H, Northage C, Money C. (2007) Exposure scenariosfor workers. J Expo Sci Environ Epidemiol; 17: S16–25.

Money C. (2003) European approaches in the development ofapproaches for the successful control of workplace healthrisks. Ann Occup Hyg; 47: 533–40.

Money CD, Jacobi S, Penman M et al. (2007) The ECETOC ap-proach to targeted risk assessment; lessons and experiences rel-evant to REACH. J Expo Sci Environ Epidemiol; 17: S67–71.

Munn SJ, Hansen BG. (2002) EU risk assessment: science andpolicy. Toxicology; 27: 181–281–5.

Rappaport SM. (1993) Threshold limit values, permissible ex-posure limits, and feasibility: the bases for exposure limits inthe United States. Am J Ind Med 23: 683–94.

RSC. (1996) COSHH in laboratories. 2nd edn. London: RoyalSociety of Chemistry.

Ruden C, Hansson SO. (2010) Registration, Evaluation, and Au-thorization of Chemicals (REACH) is but the first step-howfar will it take us? Six further steps to improve the Europeanchemicals legislation. Environ Health Perspect; 118: 6–10.

Schoeters G. (2010) The REACH perspective: toward a newconcept of toxicity testing. J Toxicol Environ Health B CritRev; 13: 232–41.

Van der Wielen A. (2007) REACH: next steps to soundchemicals management. J Expo Sci Environ Epidemiol;17: S2–6.

van Hemmen JJ. (2009) REACH and the obligations of thechemical industry. Occup Environ Med; 66: 560–8.

Williams ES, Panko J, Paustenbach DJ. (2009) The EuropeanUnion’s REACH regulation: a review of its history and re-quirements. Crit Rev Toxicol; 39: 553–75.

Zalk DM, Nelson DI. (2008) History and evolution of controlbanding: a review. J Occup Environ Hyg; 5: 330–46.

464 C. Money et al.