GEAR TECHNOLOGY GEARTECHNOLOGY OCT12 BIG · PDF fileWITH EXTERNAL WAVE GENERATORS ... •...

Transcript of GEAR TECHNOLOGY GEARTECHNOLOGY OCT12 BIG · PDF fileWITH EXTERNAL WAVE GENERATORS ... •...

TakingBig Gears’Measure

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

JAN/FEB

1420

ASK THE EXPERT:PLANETARY GEAR DESIGN

OPTIMAL USE OF DOUBLE FLANK TESTING (PART I)NEW UPGRADES BOOST POWER SKIVINGTHE XL GEARS PROJECT: SOURCING NEW “BIG-GEAR” MATERIALS

www.geartechnology.com

TakingBig Gears’Measure

TakingBig Gears’MeasureTHERE’S NO SKILLS GAP IN KAUKAUNAQ&A WITHANTONIOMACCAFERRIAPPRENTICESHIPS: CAN THEY BE RELEVANT AGAIN?

Technical Articles• Ask the Expert • Distortion and Stress

Control in Heat Treating• PEEK vs. Steel Spur Gear

Performance

Addendum• Workforce

Sustainability

®

March/April 2012

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

PLASTIC GEARSMore Than An Alternative

BIG GEARHEAT TREATING

The Journal of Gear Manufacturing

GEAR TECHNOLOGYThe Journal of Gear ManufacturingNOVEMBER/DECEMBER 2005

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

LEAN MANUFACTURING• Getting Lean in the Gear Industry

• Inventory Control for Job Shops

PLASTIC GEARS• Smaller, Quieter Gears Take Center Stage

• Laminated Gearing

POWDER METAL GEARS• Shot Peening P/M Gears

GEAR TECHNOLOGYThe Journal of Gear ManufacturingSEPTEMBER/OCTOBER 2005

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

PLUS • Products, Events and News

GEAR EXPO• Gear Expo Product Showcase

• Map and Booth Listings

FEATURES• Power Losses in Helical Gears

• Gear Finishing with a Nylon Lap

• Bevel Gear Grinding

• Measuring Pitch Diameter?

GEAR TECHNOLOGYThe Journal of Gear ManufacturingSEPTEMBER/OCTOBER 2006

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

IMTS 2006• Booth Previews

TECHNICAL ARTICLES• The Effects of Pre-Rough Machine Processing• Optimization of Gear Shaving• Determining the Shaper Cut Helical Gear Fillet Profile

GEAR TECHNOLOGYThe Journal of Gear ManufacturingJULY/AUGUST 2004

THE GEAR INDUSTRY’S INFORMATION SOURCE

www.geartechnology.com

GREENER GEARS• Our Special Look at the Gear Industry

and the Environment

IMTS Pre-Show Issue• 18-page Sneak Preview

FEATURES• Profile: The Falk Corp.• Influence of Coatings on Gear Life• Screw Helicals: Steel Pinions & Plastic Wheels

Cover 6/10/04 10:35 AM Page C1

GEAR TECHNOLOGYThe Journal of Gear ManufacturingMARCH/APRIL 2006

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

TECHNICAL ARTICLES• Tip Relief Modification

• What’s the Right Tolerance?

• Detailed Computer Model of Gearbox Reduces Design Time

GROWING MARKETSFOR GEARMANUFACTURERS• Aerospace • Medical • Wind Energy

®

August 2012

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

The Journal of Gear Manufacturing

Technical Articles•AsktheExpert:ProfileShift• 10YearsofP/MR&D:Findings• SurfaceDurability/Improved

SurfaceFinish

Addendum•HowGearsandMind

ControlMesh

IMTS 2012SHOW PREVIEW

BOOTH LISTINGSBOOTH PREVIEWS

Powder Metal MagicFEATURE

THE JOURNAL OF GEAR MANUFACTURING

What We Learned at IMTS

TECHNICAL

ADDENDUM

OCT

1220

THE LATEST TECHNOLOGY

Pitting Resistance of Worm GearsBevel Gear SuperfinishingAsk the Expert:

Center Distance VariationAutomotive Differential Gears

GEARGRINDING

2012

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

www.geartechnology.com The Journal of Gear Manufacturing

March/April 2007

TECHNOLOGYGEAR

PLASTICS• Plastic Gear Standards: A Balancing Act

• Can’t Get No Respect?

Technical Articles• Transmission Error Testing

• Rolling Contact Fatigue: Part II

• Asymmetric Tooth Bending Stress

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

AUG

1320

ASK THE EXPERT:Girth Gear Inspection

OIL-OFF AEROSPACE SPUR GEARSREDUCING STRESS ON PM GEARS

www.geartechnology.com

Gear Expo 2013AGMA Overview · Exhibitor Perspective · ASM

Titanium ShapingCustom Machine ToolsSME’s Knowledge EdgeWind Gearbox InspectionEMO 2013

BIG-GEARNDTToo Big to Fail?

Job Shop Lean Debuts

The Involute Curve

Agma Gear School's Basics and Beyond

On-Site and on the Air!

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

BACK TO BASICS

JAN/FEB

1320

Finding Harmony in Parts BalancingBig Gear Manufacturing and MetallurgyLarge Pinions for Open GearsAsk the Expert:

Taking the Measure of Involute Masters

www.geartechnology.com

NEW!

Cutting Tools

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

MAY

1320

OPTIMIZING HIGH-SPEED, NON-LUBRICATED LOW-CONTACT-PRESSURE SPUR GEARSLIGHT-WEIGHT ASSEMBLED GEARS: GREEN DESIGN SOLUTION FOR PASSENGER AND COMMERCIAL VEHICLESHYBRID GEAR PRELIMINARY RESULTS—APPLICATION OF COMPOSITES TO DYNAMIC MECHANICAL COMPONENTSASK THE EXPERT:

PRESSURE ANGLE/OPERATING PRESSURE ANGLE — WHAT’S THE DIFFERENCE?www.geartechnology.com

Repurposing Machine Tools Delivering Big Gears — FastThe Gear Research Institute:Removing Risk from Gear Design

Advanced Coating Technology

New Manufacturing Technologies Benefitting Gleason

HEAT TREATINGPPD TechnologyEldec Ramps Up ReproducibilityECM Furnace Powers PM Productivity

GRINDINGTesting the New, Advanced Grinding WheelsGrinding Technology Special Section

BORN TO BLOG

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

MAR/APR

1420

PRESS QUENCHING PRECISION COMPONENTSGEARS GROUND BY DRESSABLE CBN TOOLSDOUBLE-FLANK TESTING FOR MANUFACTURING CONTROL OF GEARING

www.geartechnology.com

ADDENDUM

Machining Gears without Gear MachiningGEAR PROFILE Jan KlingelnbergITAMCO Chips in for Youth Training

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

OCT

1320

ASK THE EXPERT:Worm Gears

THE NEXT STEPS FOR GEAR INSPECTION STANDARDSHARMONIC GEAR DRIVES WITH EXTERNAL WAVE GENERATORSMASTERING LUBRICATION BUYING

www.geartechnology.com

THE ART OF VERSATILITY

GEAR TECHNOLOGYThe Journal of Gear ManufacturingMARCH/APRIL 2004

THE GEAR INDUSTRY’S INFORMATION SOURCE

www.geartechnology.com

HEAT TREATING• Heat Treating News• Low Pressure Carburizing/High

Pressure Gas Quenching• Influence of Materials and Geometry• NEW! Heat Treating Classifieds

ALSO IN THIS ISSUE• Precise, Uniform End Chamfering• New ANSI/AGMA Accuracy Standard

Cover 3/3/04 1:15 PM Page C1

THE GEAR INDUSTRY’S INFORMATION SOURCE

IS ANYBODY

OUT THERE?

www.geartechnology.com The Journal of Gear Manufacturing

January/February 2007

TECHNOLOGYGEAR

IS ANYBODY OUT THERE?• Labor Pains in the Gear Industry

• AGMA’s Training Programs

• Manufacturing Education

Technical Articles• Rolling Contact Fatigue: Part I

• Face Gears: Geometry and Strength

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

JUN/JUL

1320

ASK THE EXPERT:Worn Gear Profile

NEW WAY TO CALCULATE LOAD CAPACITY OF BEVEL AND HYPOID GEARSPM GEARS: REDUCING STRESS FROM BENDING AND TRANSIENT LOADSBEVEL GEAR ASSEMBLY GUIDE

www.geartechnology.com

LEAN MACHINING CELLBEARINGS EDUCATION

OFF-HIGHWAYPICKING UP STEAM?

GEAR TECHNOLOGYThe Journal of Gear ManufacturingJULY/AUGUST 2006

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

GEAR TECHNOLOGYThe Journal of Gear ManufacturingMARCH/APRIL 2005

THE GEAR INDUSTRY’S INFORMATION SOURCE

www.geartechnology.com

HEAT TREATING• Advances in Quenching• The Heat Goes On: Gear Up for Induction Hardening• Hot Stuff

FEATURES • Environmentally Friendly Cutting Fluids • Gear Data Exchange Format

NEWS • Expanded Coverage of Products, Events and Industry News

Technical Articles• Super-Reduction Hypoid Gears

• Psychoacoustic Analysis of Gear Noise

• Cutting Spiral Bevels on a Machining

Center

Plus• Addendum: Doodling with Metal

®

August 2011

TECHNOLOGYGEARwww.geartechnology.com The Journal of Gear Manufacturing

FeatureArticles• Gear Noise

• Raw Materials

• State-of-the-Art Broaching

THE GEAR INDUSTRY’S INFORMATION SOURCE

THE GEAR INDUSTRY’S INFORMATION SOURCE

www.geartechnology.com The Journal of Gear Manufacturing

September/October 2008

TECHNOLOGYGEARFeatures• IMTS—The Global Marketplace Gathers in Real Time

• AGMA’s Technical Committees Remain Workhorse

• NASA’s SARJ Problem— Root Cause Remains Elusive

Technical Articles• Induction-Hardening of Gears

• Digital Photography Aids Test for Pitting Failure

• Lapping, Superfi nishing Effects on Hypoid Gears

Plus• Voices: Vacuum Carburizing a Green Upgrade

• Addendum: Gears on Mt. Baldy—Who Knew ??

GT 9-10-08 covers 1.indd 1 8/15/2008 3:13:15 PM

FLIER, FLIER, PANTS ON FIRE?

AutomationTechnology

Hired A Vet Lately?

HSSvs.

IndexableHobbing

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

MAY

1420

ASK THE EXPERT: MACHINE MARKS ON GEAR FLANKS

LOAD DISTRIBUTION ANALYSIS OF SPLINE JOINTS

APPLICATION AND IMPROVEMENT OF FACE LOAD FACTOR DETERMINATION BASED ON AGMA 927

METALLURGICAL INVESTIGATION OF “TIGER STRIPES” ON A CARBURIZED HIGH-SPEED PINION

TOPOLOGICAL GEARING MODIFICATIONS: OPTIMIZATION OF COMPLEX SYSTEMS CAPABLE OF OSCILLATION

www.geartechnology.com

ADDENDUM

GEAR TECHNOLOGYThe Journal of Gear ManufacturingMAY/JUNE 2004

THE GEAR INDUSTRY’S INFORMATION SOURCE

www.geartechnology.comGEAR DESIGN• The Pumping Action Between Gear Teeth• Rating Trends in ISO & AGMA

GRINDING & ABRASIVES• 11-Page Special Section

Anniversary Issue• 20 Years of Gear Technology

• Flashback to 1984: Single-Flank Testing of Gears

ALSO IN THIS ISSUE • Globalization and Gear Standards • Bending Strength of Carburized Gears • Gear Horoscopes

Cover 4/22/04 2:59 PM Page C1

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

MAR/APR

1320

INDUCTION HEAT INNOVATION UPDATEHEAT TREAT AUDIT? NO SWEAT!DUAL-CLUTCH GEARBOX SHAFT — OPTIMALLY PROCESSEDASK THE EXPERT:

WORKHOLDING MULTI-TASK MACHINING: LARGE SKEW BEVEL PINIONwww.geartechnology.com

Heat Treat2013

Automotive GettingSincerely Plastic

My Gears Are Bigger than Your Gears

THE OSU GearLab:Still Making a Joyful Noise

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

SEP

1320

ASK THE EXPERT:Lubrication Education

NEW-FORMULA ACETYLENE ENHANCES LPCPLANETARY GEAR TRANSMISSIONS GO LITE

www.geartechnology.com

Gear Expo2013 Issue

• Gear/ASM Exhibitor Interviews• Showstoppers Advertising Section• Show Map/All Booth Listings

STEM: The New 3 Rs?How to Inspect a Gearbox

GEAR TECHNOLOGYThe Journal of Gear ManufacturingJANUARY/FEBRUARY 2006

www.geartechnology.com

THE OTHER SIDEOF THE WORLD• Strategic Partnerships & Overseas Ventures

• Gear Manufacturing in the Far East

TECHNICAL ARTICLES• Simulation of Face Hobbing

• Hypoid and Spiral Bevel Assembly

• Noise & Vibration of Planetary Gear Drives

THE GEAR INDUSTRY’S INFORMATION SOURCE

GEAR TECHNOLOGYThe Journal of Gear ManufacturingMAY/JUNE 2005

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

GEAR INSPECTION• High Accuracy Gear Calibration• New Approaches in Spiral Bevel Roll Testing

PLUS• Additive Chemistry and Gear Micropitting• Expanded Coverage of Products, News and Events

GEAR TECHNOLOGYThe Journal of Gear ManufacturingMAY/JUNE 2006

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

HIGHPERFORMANCE• Racing Gears• Marine Gears

TECHNICAL ARTICLES• Surface Roughness and Gear Pitting• Dry Bevel Cutting

GEAR TECHNOLOGYThe Journal of Gear ManufacturingNOVEMBER/DECEMBER 2006

www.geartechnology.com

THE GEAR INDUSTRY’S INFORMATION SOURCE

STATE OF THEGEAR INDUSTRY• Results of our Research

TECHNICAL ARTICLES• Characteristics of Master Gears• Optimization of Profile Grinding• Selecting Thermoplastic Materials

©2012 Google - Help - Terms of Service - Privacy - Disclaimer - Discuss

Public Data

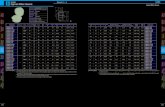

Unemployment in the U.S.EmploymentLabor forceUnemploymentUnemployment rate

Compare by

United StatesAlabamaAlaskaArizonaArkansasCaliforniaColoradoConnecticutDelawareDistrict of ColumbiaFloridaGeorgiaHawaiiIdahoIllinoisIndianaIowaKansasKentucky

Seasonality Seasonally AdjustedAgeSex

Unemployment rate - Seasonally Adjusted

Illinois

Indiana

Wisconsin

1990 1992 1994 1996 1998 2000 2002 2004 2006 2008 2010 Sep 20120%

1%

2%

3%

4%

5%

6%

7%

8%

9%

10%

11%

12%

1990 1992 1994 1996 1998 2000 2002 2004 2006 2008 2010 2012

Data from U.S. Bureau of Labor Statistics Last updated: Nov 13, 2012

Search public data or change visualization Sign in

+You Search Images Maps Play YouTube News Gmail Drive Calendar More

Unemployment in the U.S. - Google Public Data Explorer http://www.google.com/publicdata/explore?ds=z1ebjpgk2654c1_&met_y...

1 of 1 11/28/2012 11:48 AM

THE JOURNAL OF GEAR MANUFACTURING

Paper+

Scissors(No Rock)

=Gears!

TECHNICAL

ADDENDUM

NOV/DEC

1220

GEAR INDUSTRY TRENDS

Predicting Scuffing to Spur/Helical Gears in Commercial Vehicle TransmissionsMorphology of MicropittingAsk the Expert:

Gleason Machinery Setup

www.geartechnology.com

STATEINDUSTRY

OF THE

OUR ANNUAL GEAR INDUSTRY SURVEYTHE “MANUFACTURING MIDDLE CLASS”

— WHAT HAPPENED?

STATEOF THE

GEARINDUSTRY

Survey Reveals Current Trends and

Future Expectations

2013 BUYERS GUIDEGear Manufacturing Machines,

Tooling and ServicesLOOKING BEYOND THE NUMBERSA NEW DAY FOR U.S. RAIL?FLEXIBLE AND LEAN: EDUCATIONAL RESOURCES

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

NOV/DEC

1320

ASK THE EXPERT:High-Temp Gears

DESIGN AND OPTIMIZATION OF PLANETARY GEARSOIL ANALYSIS AND RELIABILITY OF WIND TURBINE GEARBOXES

www.geartechnology.com

®

THE JOURNAL OF GEAR MANUFACTURING

Clayton's Clockswww.geartechnology.com

TECHNICAL

ADDENDUM

SEP

1220IMTS 2012

EVENTS, CONFERENCES, FUN STUFFPREVIEW: CUTTING TOOLS, WORKHOLDING, ETC.

EXHIBITORS OF NOTE

Cutting Power Losses in Transmissions, Axles, Steering SystemsBearings Improve Gearbox By DesignAsk the Expert:

Refurbishing a Ball MillBevel Gears: Backlash/ContactPattern Optimization

1984 REDUX

1984 – 2014

THE JOURNAL OF GEAR MANUFACTURING

TECHNICAL

20

ASK THE EXPERT: MEASURING BACKLASH

CALCULATION OF TOOTH ROOT LOAD-CARRYING CAPACITY OF BEVELOID GEARS

HIGH GEAR RATIO EPICYCLIC DRIVES ANALYSIS

www.geartechnology.com

30 YEARS OF MECHANICAL ENGINEERING SOFTWARE

ADDENDUM

JUN

14

ANNIVERSARY

ECM’s HistoryToday – ECM continues innovative R&D vacuum

and high pressure gas quenching furnace applications bringing our total installed cells worldwide to 1000.

2012 ECM launches the JUMBO furnace

2012 ECM India founded

2008 140th ECM ICBP low pressure furnace sold worldwide

2008 ECM launches LPC continuous furnace

2005 ECM processes patented:• low pressure carbonitriding• STOPGQ• STEPGQ

2001 ECM acetylene processes patented

1999 Gas quench cell patented

1998 ECM USA and ECM China founded

1991 ECM processes patented; low pressure carburizing infracarb

1990 ECM equipment patented; ICBP vertical

1984 1st photovoltaic furnace delivered

1980 Initial tests of low pressure carburizing & gas quenching

1960 ECM begins development of vacuum furnace technology

1928 ECM founded (France)

A journey of 1000 cells began with one installation...Low Pressure Vacuum Carburizing Systems

RUF US, Inc.OFFERS GEAR GRINDERS VALUE IN BRIQUETTING SYSTEMS

Gear and other grinding operations are finding the value they thought was lost in their grinding sludge. The bonuses of increased operational efficiencies and safer working conditions are realized once companies start using a briquetting system.

Corrugated Replacements, Inc., a developer of machine replacement parts for the corrugated board, steel, poultry and satellite industries, and Horsburgh-Scott, a provider of industrial gears and custom gear drives for steel, aluminum, tire, rubber plants and wind turbines, are just two of the many companies who looked to RUF Briquetting Systems to help squeeze value out of product they previously viewed as lost.

Just one year ago, managing monthly expenses of time, money and resourc-es dealing with swarf produced in the grinding process was a reality for Corrugated Replacements. Before pur-chasing a briquetting system, dirty swarf was stored in barrels on the production floor, and then disposed of by a cost-ly hazardous waste removal company. With the briquetting system, things have changed. “We were able to turn some-thing that was a 100 percent expendi-ture process into a profitable revenue stream and reuse reclaimed coolant,” said Corrugated Replacements plant and engineering manager Scott Wallis. “It has been a win-win for our business.”

Similarly, the Horsburgh-Scott pro-duction process was positively impacted after the installation of a briquetting sys-tem in February of this year. “The bri-quetter has helped our operation reclaim more than 1,650 gallons of oil from our swarf,” said Horsburgh-Scott manufac-turing engineer Luciana Talpa. “The RUF machine works amazingly; it sim-plified the business and will pay for itself in less than a year.”

Horsburgh-Scott’s grinding sludge contained 63 percent oil by weight. The briquetting process is able to reclaim nearly all of the oil from this saturat-ed grinding sludge. The reclaimed oil is then reused, reducing the amount of new oil purchases needed for their gear grinding process.

Reducing oil and coolant loss is just part of the added efficiency of the bri-quetting system. Both companies have also reduced or eliminated hazardous waste costs, turning it into a revenue stream by selling the briquettes as scrap to steel mills. Although it was not part of the initial goal, by improving opera-tion efficiency and reducing expenses for

wasted material and swarf, briquetting and reclaiming product has made for a safer work environment.

“The barrels where swarf was previ-ously stored, waiting for disposal, cre-ated a heat safety issue,” said Wallis. “Not only did we regain a significant amount of floor space, but we also eliminated the need to store hazardous waste.”

17June 2014 | GEAR TECHNOLOGY

These two companies, along with oth-ers in the metal grinding industry, have improved efficiency, safety, productiv-ity and developed a new revenue stream, simply by recycling their own product through the briquetting process.

For more information:RUF US, Inc.Phone: (440) 779-2747www.ruf-briquetter.com

Burka-KosmosOFFERS NEW GEAR GRINDING WHEEL

The Mira Ice product line of gear grinding wheels was developed in order to meet the requirements of profile grinding larger gears. A new approach in the development of this grinding wheel enables results to be achieved in terms of econom-ic efficiency and cool grinding that were previously unheard of in the profile grinding of gears. The Mira Ice grinding wheel has been further optimized on the basis of the lead-ing product line from Burka-Kosmos. The use of new grain qualities and the new high-strength bond system guarantees particularly cool grinding. Longer cycle times between dress-ing and shorter grinding times sig-nificantly reduce the processing costs per gear. During testing against the Burka-Kosmos SK23 ceramic grind-ing wheel stock removal volume was increased by almost 400 percent on a 3.6 diametral pitch gear. This increase, along with the need for fewer dressing cycles, resulted in a 30 percent reduction in total machining time.

For more information:JRM International, Inc.Phone: (815) 282-9330www.jrminternational.com

18 GEAR TECHNOLOGY | June 2014[www.geartechnology.com]

product news