FWH3 Thermal Printer Indicator User Manual - excell · PDF fileAppendix 3 7-Segment Display...

Transcript of FWH3 Thermal Printer Indicator User Manual - excell · PDF fileAppendix 3 7-Segment Display...

EXCELL PRECISION CO., LTD.

FWH3 Thermal Printer

Indicator User Manual

©EXCELL PRECISION CO., LTD. 2010. All rights reserved worldwide. The information contained herein is the property of EXCELL PRECISION CO., LTD. and is

supplied without liability for errors or omissions. No part may be reproduced or used except as

authorized by contract or other written permission. The copyright and the foregoing restriction on

reproduction and use extend to all media in which the information may be embodied.

FWH3 ZSME300000163

1

EXCELL PRECISION CO., LTD.

Table of Contents Instructions For Use ..................................................................................................................2

Preparations Before Using........................................................................................................2

Chapter 1 Install Thermal Paper.............................................................................................3

Chapter 2 General Introduction..............................................................................................5

2-1 Display Description .......................................................................................................5 2-2 Power Description .........................................................................................................6 2-3 Keypad Description .......................................................................................................7

Chapter 3 General Operation Description .............................................................................8

3-1 Totalizing (Print) ............................................................................................................8 3-2 Zero Function.................................................................................................................8 3-3 Tare Function.................................................................................................................9 3-4 Pretare Function ............................................................................................................9 3-5 Net/Gross Function .....................................................................................................10 3-6 Backlight Function ......................................................................................................10

Chapter 4 General Function Setting ....................................................................................11

4-1 Check Weighing Configuration ⇒ ....................................................................12 4-2 RS-232 Interface and Mini Printer Output Setting ⇒ ......................................14 4-3 Exit Setting Mode ⇒ ..........................................................................................22 4-4 Display Internal Value ⇒ ...................................................................................22 4-5 Weight Hold Mode setting ⇒ ............................................................................23 4-6 G value Calibration ⇒

..................................................................................25 4-7 ID Code Setting ⇒

........................................................................................26

4-8 Print Key ( ) Function Setting ⇒

...........................................................27

Chapter 5 Load Cell Pin Description..................................................................................28

Appendix 1 OP-1 RS232 & Printer board.............................................................................29

Appendix 2 OP-2 Relay Board..............................................................................................34

Appendix 3 7-Segment Display Characters ........................................................................38

Error Messages ........................................................................................................................39

FWH3 ZSME300000163

2

EXCELL PRECISION CO., LTD.

INSTRUCTIONS FOR USE 1. Washing with rain or water is prohibited. (If gets wet accidentally, please wipe it dry with

cloth. When the indicator does not work properly, please return it to our distributor for service.)

2. Please keep the indicator in a cool and dry place. Do not store at high temperature or damp places.

3. Please keep the indicator clean and away from insects entering the indicator. 4. Avoid heavy impact or overloading. (When over its maximum capacity, it might damage the

indicator) 5. When the indicator is not in use for some time, please clean and wrap the indicator well.

Recommend to store with desiccators. 6. For an accurate reading, please place objects near the center of the platter and within the

platter. 7. Any suggestion for product is warmly welcome.

PREPARATIONS BEFORE USING

1. Put the indicator on a firm level surface free from vibrations. Adjust the four leveling feet to get the leveling bubble at the centre of circle.

2. Avoid use under sunlight or near ventilation system. Please use in a stable temperature and air flow environment.

3. Use independent socket to avoid interference from other electrical appliances. 4. Remove any weight that might be on the platter before the indicator is switched on. 5. The indicator requires 15 ~ 20 minutes warm up before operation to ensure best accuracy. 6. Please note that when symbol appears on the screen, the indicator needs to replace

the dry batteries.

Thank you for purchasing Excell FWH3 Thermal Printer Indicator. To guide you to use our product correctly, please read the user manual carefully to avoid mis-operating this product.

FWH3 ZSME300000163

3

EXCELL PRECISION CO., LTD.

Chapter 1 Install Thermal Paper 1. Please press the unlock button at the back case (see Figure 1) to release and open the case

(see Figure 2).

Figure 1: Unlock Button Figure 2: Open Case 2. Remove any wrappings from the thermal paper roll. 3. Insert drum into the paper roll (see Figure 3). 4. Place the paper roll in place (see Figure 4).

Figure 3: Insert Drum Into the Paper Roll Figure 4: Insert Paper Roll

FWH3 ZSME300000163

4

EXCELL PRECISION CO., LTD. 5. Pull enough paper out and press down the roller to fix paper in place (see Figure 5). 6. Then pass the paper through the opening on the upper cover (see Figure 5 and 6).

Figure 5: Press Down Roller Figure 6: Pass Paper Though Upper Cover

Opening 7. Close the case. 8. Press Print key to test (see Figure 7). 9. Tear the paper off along the cutting blade (see Figure 8). Figure 7: Print Figure 8: Tear Paper Off Note: If printer does not work properly, please follow step 1 to open the case and follow step 5-7 to reinstall the paper.

FWH3 ZSME300000163

5

EXCELL PRECISION CO., LTD.

Chapter 2 General Introduction 2-1 Display Description

: High limit value < As weighed value

: High limit value ≥ As weighed value ≥ Low limit value

: Low limit value > As weighed value

kg : “kg” unit lb : “lb” unit

: “Low battery power” indication % : “Percentage”

: “Stable” indication Zero : “Zero” indication Net : “Net weight” indication Gross : “Gross weight” indication Pretare : “Pre-tare” mode RANGE 2 : Division for the second range (refer to note1) RANGE 1 : Division for the first range (refer to note1)

Note 1: Only used when the indicator is set for multi-range.

RANGE 1

RANGE 2

FWH3 ZSME300000163

6

EXCELL PRECISION CO., LTD.

2-2 Power Description Power Selection

1. 240VAC~100VAC/7.5VDC/4A switching power

2. 6 × R20 battery

Power Consumption

State Power Consumption

System + Load cell About 27 mA System + Load cell + Backlight About 48 mA

With a load cell (350 Ω)

System + Load cell + Backlight + Printer card + Relay card About 92 mA

Low Power Alarm

Please note when the ( ) symbol displays, please replace battery.

FWH3 ZSME300000163

7

EXCELL PRECISION CO., LTD.

2-3 Keypad Description

:

Unit conversion and exit key. Press this key to select the required unit from the default units. At most, three units are available.

: Press this key to deduct tare weight (container weight), or increase value in

function setting mode.

:

Press this key to preset tare value.

:

Press this key to zero, or decrease value in function setting mode.

:

Press this key to print the total data and accumulate the weight value.

:

Press this key to advance the paper.

: Turn on or turn off the indicator.

: Net weight / gross weight switch key, or move cursor to the right for

confirmation when in function setting mode.

FWH3 ZSME300000163

8

EXCELL PRECISION CO., LTD.

Chapter 3 General Operation Description

3-1 Totalizing (Print) The totalizing function is valid when is set for , , , , .

1. Weight Totalizing

Place goods on the platter, after stable and press key to save the weight value.

Then the display shows the total number of additions and the totalized weight value.

The indicator will recover to show the weight value of the goods on the platter after 3

seconds.

The indicator allows the next totalizing operation, even when the weight value returns

back to zero. The key is functional, when the weight value changes by more than

10d. The indicator will save the totalized weight value after the weight is stable.

The indicator can totalize positive or negative weight but can’t do both at the same time.

The totalized weight data must be reset to zero before it is possible to select positive or

negative totalizing mode.

The totalizing function can be used up to a maximum of 999 times before it must be reset.

The totalizing display is limited to 6 digits maximum.

When totalizing, RS-232 and Mini Printer will also output. ( Refer to F5 setting)

2. Clear Totalized Weight Values

♦ When the indicator's reading shows zero, press key twice to clear all the weight

values from the memory. ♦ The indicators will automatically clear all the weight values from the memory after

turning off.

3-2 Zero Function

When indicator shows small reading without loading (zero drift phenomena), press

key to re-zero, zero indication " " is on.

FWH3 ZSME300000163

9

EXCELL PRECISION CO., LTD.

3-3 Tare Function

1. When the tare weight / container weight is unknown ( )

Place the container on the platter, after stable and press key, the weight value

returns to zero and net indication “” is on.

Place goods into the container, then the indicator shows the net weight of goods.

Clear tare value

When removing the container and goods, the display shows the negative weight value

of the container. Then press key to clear tare value. The indicator returns to zero

and net indication “” is off.

The total tare value (tare value + pre-set tare value) can equal the full capacity of the

indicator.

Multiple tare operation⇒ Users can continuously increase or decrease the tare value by

pressing the key.

3-4 Pretare Function

1. When the weight of the container is known ( )

• Press key and the display shows . . Use and

keys to input weight value of the container. After finishing the procedures, the net

indication “” and pretare indication “” is on.

• Place goods into the container, then the indicator shows the net weight of goods.

• Clear pretare value

Press key, input 00000 and then press key to clear pretare value. When the indicator returns to zero, net indication “” and pretare indication “”are off.

In Tare mode, the Preset tare function is disabled.

The indicators with two weighing ranges can NOT pre-set the tare value larger than

the first weighing range.

FWH3 ZSME300000163

10

EXCELL PRECISION CO., LTD.

3-5 Net/Gross Function When we set tare or pre-tare values, Net indication “” will be light on. At this time,

Press key to switch between Net / Gross weight and the indication behave accordingly.

All key are disable except and in gross indication mode. 3-6 Backlight Function

Press and hold key for over 2 seconds in weighing mode and the SWA1 is

connected to LOCK to enter into backlight function. Press key to select the three backlight modes: . 、 . 、 .

. ⇒ “Auto Backlight” mode. When the weight is over 10d or any key is pressed, the display backlight will be switched on. When the weight

returns to zero (the weight on platform is less than 10d), the display backlight will be switched off after 10 seconds.

. ⇒ Display backlight is on all the time. . ⇒ Display backlight is off.

FWH3 ZSME300000163

11

EXCELL PRECISION CO., LTD.

Chapter 4 General Function Setting ♦ Switch on the indicator. While the indicator is counting down to zero, press and hold key

until the display shows the software program version number.

Release the key, the indicator enters into the configuration setting mode and is

showed on the display.

⇒ Internal calibration (Reserved)

⇒ Internal calibration (Reserved)

⇒ Internal calibration (Reserved)

⇒ Internal calibration (Reserved)

⇒ Check weighing configuration

⇒ RS-232 or Mini Printer output setting

⇒ Exit setting mode

⇒ Display Internal value

⇒ Weight hold mode setting

⇒ Internal calibration (Reserved)

⇒ G value Calibration

⇒ ID setting

⇒ Print key function setting

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

Press key

FWH3 ZSME300000163

12

EXCELL PRECISION CO., LTD.

Press key

Press key

Press key

4-1 Check Weighing Configuration ⇒

When the indicator is in hold mode (F8), F4 will be disabled.

Press or key to select F4 function ⇒ the display shows

Preset “LO value” (LO value > 10d)

Press and keys to set “ LO value” E.g. LO value = 2 kg

Preset “HI value” (HI value ≥ LO value)

Press and keys to set “HI value” E.g. LO value = 2.5 kg

Preset “Beeper value”

Press and keys to set “HI value” E.g. Beeper value = 22

Press key for 5 times to clear HI, LO and beeper values

. kg

. kg

Press key

. kg

key = Increase the flash value by one (from 0 to 9)

key = Confirmation key

.

kg

Χ Χ A B A ⇒ 0 = After stable, the beeper beeps and the

indications are on 1 = After stable, the beeper beeps; whether

stable or not, the indications are on. 2 = whether stable or not, the beeper beeps

and the indications are on. B ⇒ 0 = No beep 1 = OK (when the weight is between Low limit

& High limit.), the beeper beeps. 2 = When the weight is under or equal to Low

limit (must be over 10d) & over or equal to High limit, the beeper beeps.

♦ LCD indication description:

10d Low limit value High limit value

. kg

kg

kg

Press key

FWH3 ZSME300000163

13

EXCELL PRECISION CO., LTD.

Preset Single point (preset low limit only): After “preset low limit” procedures is completed and the display shows

. kg, then press key five times, the display shows

. kg. This means that the “preset single point” procedure is completed.

Under Status in Preset Low Limit (preset single point only)

The BEEP, LCD mode should be fixed as follows:

When over “Low Limit”, is on, the beeper beeps and is off.

Whether stable or not, the beeper beeps and LCD indication is on.

FWH3 ZSME300000163

14

EXCELL PRECISION CO., LTD.

4-2 RS-232 Interface and Mini Printer Output Setting ⇒ Mini Printer interface is set as 9 600, N 8 1. The date and time can be printed.

Press or key to select F5 function ⇒ the display shows

Press key The display shows the default value of transmission mode

Press key Select transmission mode

Press key The display shows the default value of RS-232 baud rate

Press key Select RS-232 baud rate (1 200, 2 400,4 800,9 600)

Press key

Next Page

key = Press this key to choose desired baud rate. (1200, 2400, 4800, 9600)

key = Confirmation key

⇒ No transmission (none)

⇒ Stable transmission (RS-232)

⇒ Continuous transmission (RS-232)

⇒ Press key to transmit (simple mode) (RS-232, Mini Printer)

⇒ Press key to transmit (Complete mode) (RS-232, Mini Printer)

⇒ Stable transmission (totalizing mode).

The format is as same as (RS-232, Mini Printer)

⇒ Date and time printing mode

The format is as same as (RS-232, Mini Printer)

⇒ Date and time printing mode

The format is as same as (RS-232, Mini Printer)

⇒ Press key to transmit

The format is as same as

and . (RS-232)

(from 0 ~ 8 )

FWH3 ZSME300000163

15

EXCELL PRECISION CO., LTD.

Connect Mini Printer before continue

Last Page

Press key to select printing language

Please refer to DATA FORMAT for details

Press key

Mini Printer Printing Language

Chinese

English

Date Printing Order Setting

YY MM DD

MM DD YY

DD MM YY

Press key

Press keys to input the year.

Press keys to input the month.

Press keys to input the date.

Press keys to input the hour.

Press keys to input the minute.

Press key

Press key

Press key

Press key

Press key to complete the setting.

FWH3 ZSME300000163

16

EXCELL PRECISION CO., LTD.

RS-232 Interface Format I . Mode : UART Signal of EIA-RS0232 C

II . Format : 1. Baud rate : 1 200, 2 400, 4 800, 9 600 2. Data bits : 8 bits 3. Parity bit : None 4. Stop bits : 1 bit 5. Code : ASCII (Exchange code of American standard)

Start bit Data bits Stop bit

RS-232 Data Format Stable transmission (

), Continuous transmission (

),

Press key to transmit ( )

(1) Weight unit is g. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 g

HEAD , HEAD , ± DATA UNIT CR LF (2) Weight unit is kg or lb.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 kg/lb

HEAD , HEAD , ± DATA UNIT CR LF (3) Weight unit is twg, lb or oz.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 twg

HEAD , HEAD , ± DATA UNIT CR LF (4) Weight unit is hkg.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 hkg

HEAD , HEAD , ± DATA UNIT CR LF (5) Weight unit is viss.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 viss

HEAD , HEAD , ± DATA UNIT CR LF

FWH3 ZSME300000163

17

EXCELL PRECISION CO., LTD.

HEAD1 ( 2 BYTES ) HEAD2 ( 2 BYTES ) OL - Overload , Under load ST - Display is Stable NT - NET Mode US - Display is Unstable GS - GROSS Mode DATA ( 7 or 8 BYTE )

2D ( HEX ) = “ – ” ( MINUS ) 2B ( HEX ) = “ + ” 2E ( HEX ) = “ . ” ( DECIMAL POINT ) UNIT ( 2 or 4 BYTE )

kg = 6B ( HEX ) ; 67 ( HEX ) lb = 6C ( HEX ) ; 62 ( HEX ) tl.T = 74 ( HEX ) ; 6C ( HEX ) ; 2E ( HEX ) ; 54 ( HEX ) hkg = 68 ( HEX ) ; 6B ( HEX ) ; 67 ( HEX ) viss = 76 ( HEX ) ; 69 ( HEX ) ; 73 ( HEX ) ; 73 ( HEX ) Transmission example:

Data format for RS-232 continuous transmission are as below: 1. The gross weight (+0.876 kg) shows as below, after stable: (no tare or under pretare mode)

S T , G S , + 0 . 8 7 6 k g 0D 0A

HEAD , HEAD , DATA UNIT C LF

2. The net weight (-1.568 lb) shows as below without weight stability: (no tare or under pretare mode)

U S , N T , - 1 . 5 6 8 l b 0D 0A

HEAD , HEAD , DATA UNIT C LF

3. The net weight (+15 twg and 6.24 tl.T) shows as below, after stable:( under tare or pretare mode)

S T , N T , + 1 5 . 6 . 2 4 t l . T 0D 0A HEAD , HEAD , DATA UNIT C LF 4. The net weight (+1.245 viss) shows as below, after stable: (no tare or under pretare mode)

S T , N T , + 1 . 2 4 5 v i s s 0D 0A HEAD , HEAD , DATA UNIT C LF

FWH3 ZSME300000163

18

EXCELL PRECISION CO., LTD.

Press key to transmit (simple mode) English

S/N WT/UNIT ( kg / lb )

- - - - - - - - - - - - - -

0001 1.0000 Press key

0002 1.0000 Press key

0003 1.0000 Press key

0004 1.0000 Press key

0005 1.0000 Press key

- - - - - - - - - - - - - -

0005 5.0000 Press twice to print TOTAL

Stable Transmission (totalizing mode) English

S/N WT/UNIT ( kg / lb )

- - - - - - - - - - - - - -

0001 1.0000 The indicator is stable

0002 1.0000 The indicator is stable

0003 1.0000 The indicator is stable

0004 1.0000 The indicator is stable

0005 1.0000 The indicator is stable

- - - - - - - - - - - - - -

0005 5.0000 Press twice to print TOTAL

FWH3 ZSME300000163

19

EXCELL PRECISION CO., LTD.

Press key to transmit (complete mode) English

Press key

Press key

Press key

Press twice to print TOTAL

G = GROSS T = TARE PT = PRE-TARE N = NET

TICKET NO .0001G 1.000kgT 0.000kgPT 0.000kgN 1.000kg

( 3 blank lines) TICKET NO .0002G 1.000kgT 0.000kgPT 0.000kgN 1.000kg

( 3 blank lines)

TICKET NO .0003G 1.000kgT 0.000kgPT 0.000kgN 1.000kg

( 3 blank lines) TOTAL NUMBER OF TICKETS 0003TOTAL NET 3.000kg

( 3 blank lines)

FWH3 ZSME300000163

20

EXCELL PRECISION CO., LTD.

RTC setting , the form is the same with

Press key to transmit (simple mode)

English DATE:2008/02/25 TIME : 14:30:21 S/N WT/UNIT ( kg / lb )

- - - - - - - - - - - - - -

0001 1.0000 Press key

0002 1.0000 Press key

0003 1.0000 Press key

0004 1.0000 Press key

0005 1.0000 Press key

- - - - - - - - - - - - - -

0005 5.0000 Press twice to print TOTAL

FWH3 ZSME300000163

21

EXCELL PRECISION CO., LTD.

RTC setting , the form is the same with

Press key to transmit (complete mode) English

Press key

Press key

Press key

Press twice to print TOTAL

DATE: 2009 / 12 / 25 TIME: 14 : 30 : 00 TICKET NO .0001G 1.000kgT 0.000kgPT 0.000kgN 1.000kg

(3 blank lines)

DATE: 2009 / 12 / 25 TIME: 14 : 31 : 00 TICKET NO .0002G 1.000kgT 0.000kgPT 0.000kgN 1.000kg

(3 blank lines)

DATE: 2009 / 12 / 25 TIME: 14 : 32 : 00 TICKET NO .0003G 1.000kgT 0.000kgPT 0.000kgN 1.000kg

(3 blank lines)

DATE: 2009 / 12 / 25 TIME: 14 : 33 : 00 TOTAL NUMBER OF TICKETS 0003TOTAL NET 3.000kg

(3 blank lines)

FWH3 ZSME300000163

22

EXCELL PRECISION CO., LTD.

(3) RS-232 and Mini Printer Output Format in Hold condition

Please is set for . eg. For 1.000kg model, the format is as follow.

1 . 0 0 0 k g 0D 0A 0D 0A 0D 0A 0D 0A

4-3 Exit Setting Mode ⇒ Press or key to select F6 function ⇒ the display shows

Press key

4-4 Display Internal Value ⇒

Press or key to select F7 function ⇒ the display shows

Press key

Press key

Counting down to zero and exit setting

mode

Display Internal Value

FWH3 ZSME300000163

23

EXCELL PRECISION CO., LTD.

4-5 Weight Hold Mode setting ⇒ Under hold mode, press key to print the hold value showed.

(Select proper baud rate according to receiver and F5 transmission mode does not affect)

(Refer to F5 for details of transmission rate)

♦ Please make sure MINI JUMPER of SWA1 is connected to ADJ on PC board before setting.

Please make sure MINI JUMPER of SWA1 is connected to LOCK on PC board after setting.

Press or key to select F8 function ⇒ the display shows

Press key in order and the display shows accordingly

~ Select required hold mode and then press

key to finish setting.

Press key

Press key

Press key

Press key

Press key

Press key

FWH3 ZSME300000163

24

EXCELL PRECISION CO., LTD.

Animal scale hold mode setting

Choose hold 4

Press key

Setting Error Range

Press and keys to set error range from 1% ~ 100% Default setting: 10%

%

Average Trade Count Setting

Press and keys to set from 1.2.4. 8.16.32.64. Default setting: 8

%

⇒ Hold function Disable ⇒ When the weight keeps changing, the indicator will automatically hold

and display the largest value.

Press any key except and key to clear the hold value. ⇒ When the indicator becomes stable, the display shows and holds the

weight value, which can not be changed.

Press any key except and key to clear the hold value. ⇒ When the indicator becomes stable, the display shows and holds the

weight value, which can not be changed. When the indicator is re-zeroed (weight less than 10d), the hold value is automatically cleared.

⇒ Animal scale. When the animal is on the platter, the display shows the weight value, which can not be changed.

When the animal leaves the platter (weight less than 10d), the indicator is re-zeroed automatically.

Press key

Press key

Press key

FWH3 ZSME300000163

25

EXCELL PRECISION CO., LTD.

4-6 G value Calibration ⇒

Press or key to select F10 function ⇒ the display shows

When SWA1 is connected to LOCK location, the indicator can be input 9 times of G value

data in F10 function. These historical data can’t be revised and only be read. When SWA1 is connected to ADJ location, G value data is fixed in the “00” time and clear

all the data. After doing the weight calibration “F0”, the last G value data is saved automatically and

other historical data is cleared.

.

.

.

.

.

.

.

Press key Press key

After 1 sec

The display shows the present number and after 1 sec. shows the local G value.

After 1 sec

The display shows the last time number and after 1 sec. shows the local G value.

The display shows the last 2 times number and after 1 sec. shows the local G value.

After 1 sec

Time no. is “01” ⇒ Local G value used in the weight calibration

Press key to enter into G value setting mode

After 1 sec

After 1 sec

Time no. is “00” ⇒ Manufacture G value used in the weight

Input the local G value Press and keys to input the numbers.

Press key to shift the flashing digit one space to right.

Press key to save the data.

Press key show the historical data

Press key Press key

Press key Press key

Press key Press key

FWH3 ZSME300000163

26

EXCELL PRECISION CO., LTD.

4-7 ID Code Setting ⇒

(Use must be in coordination with rnP 1, 2, 8 of F5)

Press or key to select F11 function ⇒ the display shows

Press key

Press key

RS232 DATA FORMAT Stable transmission (

), Continuous transmission (

),

Press key to transmit ( )

1. eg. Local ID code is 10. The gross weight (+0.876 kg) shows as below, after stable: (no tare or under pretare mode)

1 0 S T , G S , + 0 . 8 7 6 k g 0D 0A

ID HEAD1 , HEAD2 , DATA UNIT C LF

2. eg. Local ID code is 00. (Not using local ID function.) The net weight (-1.568 lb) shows as below without weight stability: (under tare or pretare mode)

U S , N T , - 1 . 5 6 8 l b 0D 0A

HEAD1 , HEAD2 , DATA UNIT C LF

Local ID code setting:

Press and to set 01 ~ 99. Default setting: 00

Local ID code setting: (1) “00”: RS-232 transmits data not including local code. (2) “01~99”: RS-232 transmits data including local code.

FWH3 ZSME300000163

27

EXCELL PRECISION CO., LTD.

4-8 Print Key ( ) Function Setting ⇒

Press or key to select F12 function ⇒ the display shows

Press key

Press key

⇒ Press key, it is accumulation function if weight variation range is over ±10d ~ ±1d. It can print the weight if weight variation range is less than ±10d ~ ±1d.

⇒ Press key to print the weight at once and no accumulation function.

⇒ Press key to print the weight which is between the high limit and the low limit and no accumulation function.

Local ID code setting:

Press and to set 0 ~ 2.

Default setting: 0

FWH3 ZSME300000163

28

EXCELL PRECISION CO., LTD.

Chapter 5 Load Cell Pin Description (1) For 4 wire cable, SEN+ and SEN- do not need to be connected, and J3 and J4 on PCB board need to be shorted. (2) J3 and J4 are open in circuit board with 6 load cell cable.

FWH3 ZSME300000163

29

EXCELL PRECISION CO., LTD.

Appendix 1 OP-1 RS232 & Printer board PCB programme version: 0908G Two devices can output:

RS232 serial output /input Printer serial output (FUJITSU FTP-628MCL103#70-R)

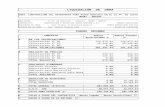

RS232 serial output / input 1. Hardenite assembly method

Item No. Specification QuantityA PCB: 0908G 1 B 10 pin winding displacement ×270mm 2 C 6 pin winding displacement × 30mm 1 D Be fixed in 0908G screw 3 E Connecting line ( 7pin double end) (JST+5PIN metal head) 1

Connecting method of 10 pin connecting line

Make sure that CN5 in 09082 main board is connected to CN5 in 0908G RS232 & printer board.

Make sure that CN8 in 09082 main board is connected to CN8 in 0908G RS232 & printer board.

Connecting method of 6 pin connecting line Make sure that CN2 in 09084 power board is connected to CN3 in 0908G RS232

& printer board.

Connecting line which has 7pin double end and JST+5PIN metal head is connected to round hole in the right corner of lower cover.

1-1 Working drawing

FWH3 ZSME300000163

30

EXCELL PRECISION CO., LTD. 2. Signal Table

0908GCN4 Pin

Signal name 5PIN metal head Summery

1 TXD 1 RS-232C 2 Reserved Blank 3 Reserved Blank 4 SG 2 RS-232C 5 Reserved Blank 6 RXD 3 RS-232C 7 FG 4 RS-232C 5 Blank

5 PIN metal head The indicator

Outboard end

3. RS-232C internal current

FWH3 ZSME300000163

32

EXCELL PRECISION CO., LTD.

Printer serial output 1. PRINTER model name: FTP-628MCL103#70-R( TB09NT03-628)

Hardenite assembly method Item No. Specification Quantity

A Be fixed in Printer screw 4

B FTP-628MCL103#70-R contains of TB09NT03-628 controlling board 1

C 4 PIN 150mm double-end connecting line P=1.25 mm 2

D 2 PIN printer connecting line 1

1-1 Working drawing 1-1-1 TB09NT03-628 controlling board

JS is connected to 0908G CN2 J2 is connected to 0908G CN7 => The red line is connected to 2(+) and the black one is connected to 1(-) J1 is connected to 0908G CN1

1-1-2

FWH3 ZSME300000163

33

EXCELL PRECISION CO., LTD.

1-2 FUJITSU Printer Hardenite setting

Printer type FTP-628MCL103#70-R Buad 9600 bits/second Parity bit NONE Data bits 8 bits Stop bit 1 bit

1-3

D0 D1 D2 D3 D4 D5 D6 D7 LSB MSB

Start bit Data bits Stop bit

FWH3 ZSME300000163

34

EXCELL PRECISION CO., LTD.

Appendix 2 OP-2 Relay Board PCB programme version: 0908N Relay output & input signal

3 output (L/OK/H) Relay

The largest endurance: 50/60HZ 10A 120VAC or 28VDC 5A 240VAC

The output signal and LCD LO/OK/HI in step 1. Hardenite assembly method

Item No. Specification QuantityI 0908N 1 J 8 pin winding displacement 170mm p=2.5 1 K Be fixed in 0908N screw 3

L 6pin double-end connecting line (JST+6PIN metal head)

1

Connecting method of 8 pin connecting line Make sure that CN7 in 09082 main board is connected to CN7 in 0908N Relay board.

Connecting line which has 6pin double-end and JST+6PIN metal head is connected to round hole in the right corner of lower cover.

1-1 Working drawing

FWH3 ZSME300000163

35

EXCELL PRECISION CO., LTD.

2. Signal Table PIN Signal Name 1 LO 2 OK 3 HI 4 COM

6 PIN metal head

The indicator

Outboard end

3. Internal current

FWH3 ZSME300000163

36

EXCELL PRECISION CO., LTD.

Input signal Input signal is tare key function

1. Signal Table PIN Signal Name Summery 5 INPUT 6 INPUT(GND)

NORMAL OPEN

6 PIN metal head The indicator

Outboard end

2 Internal current

FWH3 ZSME300000163

38

EXCELL PRECISION CO., LTD.

Appendix 3 7-Segment Display Characters Number Display Letter Display Letter Display

0

A

N

1

B

O

2

C

P

3

D

Q

4

E

R

5

F

S

6

G

T

7

H

U

8

I

V

9

J

W

K

X

L

Y

M

Z

FWH3 ZSME300000163

39

EXCELL PRECISION CO., LTD.

Error Messages

OL⇒ The indicator is over full scale +9d. E1 ⇒ Zero value after power on is over 10% FS.

E2 ⇒ Zero value after power on is less than 10% FS.

E4 ⇒ Re-zero is unstable. When it is over 10 seconds, press to exit E4.

E6 ⇒ Zero is over 550 000 when calibrating.

E7 ⇒ Zero is less than 150 000 when calibrating.

E10⇒ LEVEL Switch function:When PCB J1 is open, the signal is connected to CN3. When CN3 is open, the display disappears 2 seconds and shows E10. When CN3 is short, the display will work. J1 is short if the level switch is not be used.