Further model development for prediction of viscosity of...

Transcript of Further model development for prediction of viscosity of...

Full Terms & Conditions of access and use can be found athttp://www.tandfonline.com/action/journalInformation?journalCode=lpet20

Petroleum Science and Technology

ISSN: 1091-6466 (Print) 1532-2459 (Online) Journal homepage: http://www.tandfonline.com/loi/lpet20

Further model development for prediction ofviscosity of mixed oils

Saeed Ashtari Larki & Hooman Banashooshtari

To cite this article: Saeed Ashtari Larki & Hooman Banashooshtari (2017) Further modeldevelopment for prediction of viscosity of mixed oils, Petroleum Science and Technology, 35:23,2221-2228, DOI: 10.1080/10916466.2017.1399141

To link to this article: https://doi.org/10.1080/10916466.2017.1399141

Published online: 27 Nov 2017.

Submit your article to this journal

Article views: 22

View related articles

View Crossmark data

PETROLEUM SCIENCE AND TECHNOLOGY, VOL. , NO. , –https://doi.org/./..

Further model development for prediction of viscosity of mixed oils

Saeed Ashtari Larki and Hooman Banashooshtari

Department of Petroleum Engineering, Ahwaz Faculty of Petroleum, Petroleum University of Technology, Ahwaz, Iran

KEYWORDSmixed oil; viscosity; newmodel, prediction, mixingrule

ABSTRACTIn the present study a newmodel named adaptive neuron fuzzy inference sys-tem optimized by hybrid method (Hybrid-ANFIS) is developed for estimationof viscosity of mixed oils. The experimental data for development of the newmodel were gathered from literature. Various methods were taken into con-sideration to examine the accuracy and precision of the model. The outcomesof the developed model were also put into comparison with four well-knownliterature models. Results show that the Hybrid-ANFIS model provides accept-able and precise estimations and more satisfactory predictions in comparisonwith literature models. The model exhibits an overall AARD% value of 2.19%.

1. Introduction

Viscosity is an important property of crude oils which greatly effects on their production and trans-portation performance, especially for heavy oils. Most heavy oils are too viscous to be produced fromwellbore and transported in surface pipelines. Hence, in order to make these heavy compounds to bet-ter flow through wellbore and transportation pipelines, it is required to reduce their viscosity. To tacklethis issue, one can use two methods, one is heating up the heavy oil fractions to reduce their viscosityand the second method is to dilute and mix them with light oils. The second method is applicable insituations in which the reservoir fluid can flow through porous media but has not the adequate potentialto move upward within wellbore and being produced. In these situations the injection of light oil formixing with reservoir heavy oil is the most appropriate choice (Gao and Li 2012). However, the desiredfinal viscosity of mixed oil has an important role in determining the amount of light oil which should beinjected. Hence, in order to determine the optimummixing ratio of light and heavy oils and the amountof light oil which should be injected, the viscosity of mixed oil should be known. Different empirical andsemi-empiricalmethods are available for estimation of viscosity ofmixed oils (Beggs and Robinson 1975;Miadonye et al. 1992; Orbey and Sandler 1993). These methods are based on regression of experimentaldata (Gao and Li 2012). Arrhenius (Arrhenius 1887) developed a mode based on ideal solution conceptfor estimation of viscosity of liquid mixtures. The performance of this model for estimation of viscosityof pure hydrocarbon mixtures is accurate and acceptable. Next, different researchers tried to developedmore general and accurate models and correlations for estimation of mixed oil viscosity. Proposing newmodels with higher precision and generalization abilities for prediction of mixed oil viscosity is still anopen area for research. The purpose of this work is development of a new model called Hybrid-ANFISfor estimation of viscosity of mixed oils. The outcomes of the proposed method were also put into com-parison with some literature models.

CONTACT SaeedAshtari Larki [email protected] Department of PetroleumEngineering, Ahwaz Faculty of Petroleum,Petroleum University of Technology, Ahwaz, Iran.Color versions of one or more of the figures in the article can be found online at www.tandfonline.com/lpet.

© Taylor & Francis Group, LLC

2222 S. A. LARKI AND H. BANASHOOSHTARI

Table . Details of experimental data utilized in this work.

Parameter Min. Max. Average

Temperature (oC) .Volumetric ratio of lighter oil sample (VA) . . .Volumetric ratio of intermediate oil sample (VB) . .Volumetric ratio of heavier oil sample (VC) . . .Viscosity of lighter oil sample (µA)/mPa.s . . .Viscosity of intermediate oil sample (µB)/mPa.s . .Viscosity of heavier oil sample (µC)/mPa.s . .Viscosity of mixture (µm)/mPa.s . .

2. Data acquisition

For the purpose of this work, 266 experimental viscosity data for binary and ternary mixed oils wereused from published works in literature (Gao and Li 2012; Meng 2007; Shu 1984). The experimentaldata covers wide range of viscosity values and temperatures. The input parameters of the developedHybrid-ANFIS model were temperature (oC), viscosity of pure oil samples (mPa.s), volumetric ratio ofoil samples. Viscosity of mixed oil (mPa.s) was also the output parameter. The detailed analysis of thedata points which were utilized in the present work are shown in Table 1.

3. Adaptive Neuro Fuzzy Inference System (ANFIS)

ANFIS is a modeling technique which benefits from the combination capabilities of fuzzy logic (FL)and artificial neural networks (ANNs). A structure called fuzzy inference system (FIS) is the main partof ANFIS model for regression and modeling of a nonlinear problem. This structure contains differentrules known as fuzzy if-then rules (Lei et al. 2007). The FIS structure uses certain functions namelymembership functions (MFs) for construction of these rules. Two popular types of FIS structures areMamdani and Takagi-Sugeno-Kang (TSK) type FISs. Most of the time the TSK type FIS provides a betterperformance for the developed FIS. If one show the input vector of problem by X and the output vectorby Y, then the first order TSK if-then rules for the FIS are as follows (Safari et al. 2014):

Rule 1 : IFX is;P1; and Y is Q1 then z is g1(X,Y )Rule 2 : IFX is P2 and Y is Q2 then z is g2(X,Y ) (1)

In which Pi an Qi are fuzzy set statements and gi(X,Y) is first order TSK FIS. The structure of ANFISmodel with TSK type FIS have five layers. In the first layer specific terms called linguistic terms of inputparameters are evaluated. The second layer is responsible for determining a parameter which is called asfiring strengths of rules. This term shows the extent of influence of that rule on the final output of ANFIS

Figure . The AARD% value of train and test data in each iteration of PSO method for training of ANFIS model.

PETROLEUM SCIENCE AND TECHNOLOGY 2223

Figure . The structure of ANFIS model.

model. This term which is shown byWi is determined as below (Safari et al. 2014):

[Wi = μAi (X ).μBi (Y ) for i = 1, 2] (2)

Here, μAi and μBi are the MFs of ANFIS structure. The third layer normalizes this parameter. Thenormalization is carried out to better understand the contribution of different rules toward final outputvalue. The linguistic terms of the output layer are calculated in the fourth layer (Safari et al. 2014):

[O4 = Wi gi for i = 1, 2] (3)

Which O4 is the output of fourth layer andWi denotes the mean value of firing strength of individualrules. The mathematical formulation of gi is as below (Safari et al. 2014):

[gi(X,Y ) = ciX + diY + ei for i = 1, 2] (4)

Where ci, di and ei are optimization parameters related to internal calculation structure of ANFIS.The value of these parameters should be optimized by ANFIS model. The fifth layer evaluates the finaloutput of ANFIS model. In this layer the outputs of all linguistic terms are summed up as follows (Safariet al. 2014):

O5 =∑

i

Wi.gi (5)

Where O5 is the output of fifth layer (final output).

4. Development of Hybrid-ANFIS model

Before construction of themodel, rthe data points were randomly separated into two groups of train andtest data. About 80% of data points were allocated to train data and 20% were used for test data set. Next,the construction of the ANFIS model was started by using a first order TSK type FIS by utilizing thegenfis2 function of MATLAB based on train data. The Subtractive Clustering (SC) is the method whichis used by genfis 2 function for construction of the initial FIS. After construction of initial structurefor ANFIS model one important step is training of this structure to gain more reliable and accurate

2224 S. A. LARKI AND H. BANASHOOSHTARI

Figure . The related MFs of different input parameters.

PETROLEUM SCIENCE AND TECHNOLOGY 2225

Figure . Predicted viscosity data by various literature models against experimental data: (a) PSO-ANFIS (b) Modified model I (Gao andLi ), (c) Walther model (Walther ), (d) Arrhenius model (Arrhenius ), (e) Cragoe model (Cragoe ).

predictions. In the present study, the hybrid method was used to train the initial structure of the ANFISmodel. The change in Average Absolute Relative Deviation (AARD%) of data in the process of trainingof the ANFIS model by hybrid method is shown in Figure 1. The formulation of the AARD% value is asbelow:

AARD% = 100N

N∑

i=1

∣∣∣∣(μm,Pr ed(i) − μm,Exp(i))

μm,Exp(i)

∣∣∣∣ (6)

As is shown in Figure 1, the AARD% value of data are lowered significantly after training with hybridmethod. The final structure of the Hybrid-ANFISmodel and relatedMFs of individual input parametersmethod are shown in Figure 2 and Figure 3 respectively. As is shown in Figure 2 the structure of theHybrid-ANFIS model has 6 rules and 6 MFs for each input parameter.

5. Evaluation of the developedmodel

In order to examine the reliability of estimation of the developed Hybrid-ANFIS model, first, graphicalmethods are utilized. Figure 4 shows the cross plot of predicted data versus experimental viscosity data.

2226 S. A. LARKI AND H. BANASHOOSHTARI

Figure . Relative error plot of different models: (a) Hybrid-ANFIS, (b) Modified model I (Gao and Li ), (c) Walther model (Walther), (d) Arrhenius model (Arrhenius ), (e) Cragoe model (Cragoe ).

As is clear from this figure there are a tight distribution of data points around the Y= X line which indi-cates that there is an acceptable agreement between experimental data and predicted data by developedmodel.

As mentioned before, the predictions of the developed model in the present work are compared withseveral literaturemodels. Thesemodels are listed in Table 2. The cross plot of predictions of thesemodelsagainst experimental data is shown in Figure 4. This figure shows that these models exhibit R2 valueslower than the developed Hybrid-ANFIS model in the present study. This reveals that the predictionsof the Hybrid-ANFIS model are more accurate and reliable than these models. However, the Modifiedmodel I (Gao and Li 2012) exhibits better accuracy in comparison with other literature models. The plotof relative errors of the developed Hybrid-ANFIS model against experimental data is shown in Figure 5.This figure shows that the relative deviations of the model are mostly distributed around zero deviationline which indicates the appropriate agreement between experimental and predicted data. This figureshows that, the relative errors of the developed model are mostly in the range of ± 10%. The modelexhibits amaximum error less than 30%. The plot of relative errors of the literaturemodels for predictionof the experimental data is shown in Figure 5. This figure indicates that these models represent relativeerrors higher than the developedHybrid-ANFISmodel whichmeans that, the developedHybrid-ANFISis able to estimate experimental viscosity data accurately with lower relative deviations compared toliterature models.

PETROLEUM SCIENCE AND TECHNOLOGY 2227

Table.

Listofliteraturecorrelations

utilizedinthepresentw

ork.

Correlation

Reference

lnμm

=V A

lnμA

+V B

lnμB

+V C

lnμC

∗Arrheniusm

odel

(Arrhenius

)

lnln

(μm

+C)=

V Alnln

(μA

+C)+V B

lnln

(μB

+C)+V C

lnln

(μC

+C)

C=.ford

atarepo

rted

byShu(Shu

)

C=.

×

−ford

atarepo

rted

Meng(M

eng)

C=.

ford

atarepo

rted

byGao

andLi(Gao

andLi)

Walterm

odel

(Walther)

1/ln

(200

0μm

)=

V A/ln

(200

0μA)+V B

/ln

(200

0μB)+V C

/ln

(200

0μC)

Cragoe

mod

el(Crago

e)

lnμm

=1 2(X

Aln

μA

+X B

lnμB

+X C

lnμC)+

1 2(

ln(200

0μA)ln

(200

0μB)ln

(200

0μC)

X Aln

(200

0μB)ln

(200

0μC)+

X Bln

(200

0μA)ln

(200

0μC)+

X Cln

(200

0μA)ln

(200

0μB)−

ln(200

0))

X A=

αV A

αV A

+VB+V

C,X B

=V B

αV A

+VB+V

C,X C

=1−

X A−

X BFord

atarepo

rted

byShu(Shu

)α

=.

at

oC,.

at

oCand.at

oC

Ford

atarepo

rted

byGao

andLi(Gao

andLi)and

datarepo

rted

byMeng(M

eng)the

values

ofαcanbe

foun

dinGao

andLi(Gao

andLi)

Mod

ified

mod

elI(Gao

andLi)

∗ µm

=viscosity

ofmixed

oil(mPa.s),V A

=volumefractio

noflighteroilsam

ple

V B=volumefractio

nofinterm

ediateoilsam

ple,V C

=volumefractio

nofheaviestoilsam

ple,µA

=viscosity

oflighteroilsam

ple(m

Pa.s),µB=viscosity

ofinterm

ediateoilsam

ple(m

Pa.s),µC=viscosity

ofheaviestoilsam

ple(m

Pa.s)

2228 S. A. LARKI AND H. BANASHOOSHTARI

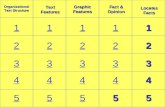

Table . Comparison between R and AARD% Values of different models.

Model R AARD%

Modified model I (Gao and Li ) . .Walther (Walther ) . .Arrhenius (Arrhenius ) . .Cragoe (Cragoe ) . .Newmodel Train data . .

Test data . .All data . .

Table 3 shows the values of R2 and AARD% for the developed Hybrid-ANFIS model and literaturemodels. According to this table the R2 value of the developed model is higher than the literature mod-els and the AARD% value of Hybrid-ANFIS model is lower than these models. In another word, thedeveloped model is more accurate and dependable than literature models for prediction of the experi-mental viscosity data. Despite the effectiveness and accuracy of the proposedmodel, thismodel has somedisadvantages that should be taken into consideration.

6. Conclusions

This work highlights the application of a newly developed model namely Hybrid-ANFIS model for esti-mation of viscosity of mixed oils by utilizing experimental data from literature. Different statistical andgraphical approaches were taken into consideration to examine the precision and reliability of themodel.A comparison was also conducted between predictions of the developed model and several literaturemodels. The obtained results revealed that the developed model exhibits acceptable and precise perfor-mance for estimation of experimental viscosity data. Comparison between predictions of the developedmodel and outcomes of literaturemodels revealed the reliability and superiority of the developedHybrid-ANFIS model. The developed model in the present work can be effectively utilized in areas were rapidand accurate predictions of mixed oil viscosity values are needed.

ORCID

Saeed Ashtari Larki http://orcid.org/0000-0002-5834-8160

References

Arrhenius, S.A. 1887. Uber die Dissociation der in Wasser gelosten Stoffe. Z. Phys. Chem. 1, 631–48.Beggs, H.D., and J. Robinson. 1975. Estimating the viscosity of crude oil systems. Journal of Petroleum technology 27 (1):

140–41.Cragoe, C. 1933. Changes in the Viscosity of Liquids with Temperature, Pressure and Composition, 1st World Petroleum

Congress. World Petroleum Congress.Gao, Y., and K. Li. 2012. New models for calculating the viscosity of mixed oil. Fuel 95:431–37.Lei, Y., Z. He, Y. Zi, and Q. Hu. 2007. Fault diagnosis of rotating machinery based on multiple ANFIS combination with

GAs.Mechanical systems and signal processing 21:2280–94.Meng, Q. 2007. An available viscosity calculation model for mixed crude oil. Oil Gas Storage Transport 26:22–24.Miadonye, A., B. Singh, and V.R. Puttagunta. 1992. One-parameter correlation in the estimation of crude oil viscosity.

Society of Petroleum Engineers, SPE-26206-MS.Orbey, H., and S.I. Sandler. 1993. The prediction of the viscosity of liquid hydrocarbons and their mixtures as a function

of temperature and pressure. The Canadian Journal of Chemical Engineering 71:437–46.Safari, H., S. Nekoeian, M.R. Shirdel, H. Ahmadi, A. Bahadori, and S. Zendehboudi. 2014. Assessing the dynamic viscosity

of Na–K–Ca–Cl–H2O aqueous solutions at high-pressure and high-temperature conditions. Industrial & EngineeringChemistry Research 53:11488–500.

Shu, W. 1984. A viscosity correlation for mixtures of heavy oil, bitumen, and petroleum fractions. Society of PetroleumEngineers Journal 24:277–82.

Walther, C. 1931. The evaluation of viscosity data. Erdol Teer 7:382–84.

本文献由“学霸图书馆-文献云下载”收集自网络,仅供学习交流使用。

学霸图书馆(www.xuebalib.com)是一个“整合众多图书馆数据库资源,

提供一站式文献检索和下载服务”的24 小时在线不限IP

图书馆。

图书馆致力于便利、促进学习与科研,提供最强文献下载服务。

图书馆导航:

图书馆首页 文献云下载 图书馆入口 外文数据库大全 疑难文献辅助工具