Final report 412

-

Upload

mohammed-julaidan -

Category

Documents

-

view

168 -

download

2

Transcript of Final report 412

KING FAHD UNIVERSITY OF

PETROLEUM & MINERALS

Mechanical Engineering Department

(152)

Senior Design Project Design Project

ME 412/416

Balancing of water VS Electricity generation (Rankine-MSF)

Name: Alkathiri, Ali Ahmed

ID# 201158730

Name: Julaidan, Mohammed

ID# 201168370

Name: Alhujaili, Amjad

ID# 201050560

Name:

ID#

Name:

ID#

Advisor Name:

MOHAMMED A. ANTAR Coordinator Name:

26/04/2016

ii

EVALUATION SHEET

Editorial

Structural

Criteria Evaluation Criteria Evaluation

Criteria Evaluation

Criteria Evaluation

Cover page*

Introduction

Overview

Final Design

Overall description Conclusion & Recommendation

Conclusion*

Title* Problem definition*

Detailed design description Recommendation*

Abstract* Objectives* Analysis & results*

Appendices

Decision matrix

Table of

contents*

Project

management* Material selection Gantt chart*

List of figures

Background

Existing product Cost analysis Final drawing

List of table Market research Drawings List of vendors, contact information and pricing

Heading Technical data*

Product Realization

Manufacturing processes Specification for supplied materials

Language Patent search Prototype verses planned design

Detailed supporting analysis

Figure/table

Design & Development

Conceptual design

Manufacturing processes

Captions

List of constraints*

Future manufacturing recommendation

Final Report Score

List of standards*

Figure/table citation

Concept selection

Design

verification

Test description

References

Preliminary analysis*

Detailed results

Proof of concept Specification verification list Items in (red) with asterisks (*) are mandatory.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

1

TableofContentsListoftables:.....................................................................................................................2

Listoffigures:....................................................................................................................2

Chapter1:.........................................................................................................................3

Introduction:.....................................................................................................................31.1 PowerPlant:....................................................................................................................3Classificationofpowerstation:...................................................................................................3

1.1.1 Byheatsource:[1]..........................................................................................................31.1.2 Byprimemover:.............................................................................................................31.1.3 Byduty(scheduled):.......................................................................................................4

1.2 DesalinationPlant:..........................................................................................................51.2.1 Typesofdistillationprocess:..........................................................................................51.2.2 Howitworks:..................................................................................................................61.2.3 Challenges:.....................................................................................................................7

1.3 Objective:........................................................................................................................7

Chapter2:.........................................................................................................................82.1 PowerPlant:....................................................................................................................8

2.1.1 Boiler:...........................................................................................................................102.1.2 HighPressureTurbine:.................................................................................................102.1.3 LowPressureTurbine:..................................................................................................112.1.4 Condenser:...................................................................................................................122.1.5 OpenFeedWaterHeater:............................................................................................122.1.6 ClosedFeedWaterHeater2:.......................................................................................132.1.7 ClosedFeedWaterHeater1:.......................................................................................14

2.2 DesalinationPlant:........................................................................................................152.1.1 Massbalancemodeling:...............................................................................................172.1.2 TemperatureDropModeling:......................................................................................182.1.3 TheTemperatureateachStage:..................................................................................182.1.4 Heattransferareas:......................................................................................................182.1.5 FlashingStageDimensionsModeling:..........................................................................202.1.6 PerformanceModeling:................................................................................................20

Chapter3:.......................................................................................................................21

Resultsanddiscussion:....................................................................................................213.1 Powerplant...................................................................................................................21

3.1.1 Theoptimumpressure:................................................................................................213.1.2 TheeffectofmassextractionfrompowerplanttoMSFplant....................................223.1.3 Theeffectoftheconditionoftheextractionmass......................................................243.1.4 Makeupwaterforthepowerplant:............................................................................253.1.5 Comparisonbetweendata:..........................................................................................26

3.2 MSFPlant......................................................................................................................293.2.1 Theeffectofconditionofthesteam............................................................................293.2.2 Extraction“b”frompowerplanttotheMSF...............................................................32

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

2

Chapter4:.......................................................................................................................33

Conclusion.......................................................................................................................33

References:.....................................................................................................................34

AppendixA:.....................................................................................................................35

AppendixB:.....................................................................................................................36

Listoftables:Table1:Reheatpressure......................................................................................................................21

Table2:optimumpressureforP[12]...................................................................................................22

Table3:Massextractionandeffectonefficiency................................................................................23

Table 4 :effectoftheconditionoftheextraction.................................................................................24

Table5:EfficiencywithreturningwaterfromMSF..............................................................................25

Table6:Efficiencywithreturningwater25C.......................................................................................26

Table7:pressureanditstemperatures................................................................................................29

Table8:steamtemperatureanditseffectonQandnumberofstages...............................................29

Table 9: table show how much “b” we need to satisfy the MSF at different top brine temperature....32

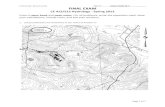

Listoffigures:Figure1:Schematicofa'once-through'multi-stageflashdesalinates:.................................................6

Figure2:PowerplantinSaudiArabia(Qurrayyah)[2]...........................................................................8

Figure3:PowerPlantschematicdiagram..............................................................................................9

Figure4:OncethroughMulti-StageFlashDistillationSystem............................................................16

Figure4:preheat/BoilerVseff....................................................................................................................21

Figure5:EffincyVsExtractionfraction.................................................................................................23

Figure6::T-Sdiagramshowshowhfgincreaseaspressuredecreases................................................24

Figure7:EfficiencyVsPbrine...................................................................................................................24

Figure9:theeffectofmakewaterinEfficiency...................................................................................27

Figure10:TheeffectofmakewaterinWorknet.................................................................................28

Figure11:numberofstageVsTopbrinetemperature........................................................................30

Figure12:MsteamVsTopbrinetemperature.........................................................................................31

Figure13:performanceratioVsTopbrinetemperature.....................................................................31

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

3

Chapter1:

Introduction:WaterdesalinationisoneofthemostimportantfacilitiesinSaudiArabiasince

SaudiArabiadoesnothaveanatural resource forwater. So,weneed to saveanyamountofenergywithincreasingtheefficiencyofthefactory.Ourproblemishowtoincreasetheefficiencyandconsumesomepower.

1.1 Power Plant: Powerplantisafacilitythatusedtogenerateelectricalpower.HereinSaudi

ArabiawehaveGazlanpowerplantthathaspowercapacityof2400MW.

Classification of power station: 1.1.1 Byheatsource:[1]

o Fossil-fuel power stations may also use a steam turbine

generator or in the case of natural gas-fired plants may use a

combustion turbine. The steam drives a steam turbine and

generator that then produces electricity

o Nuclear power plants use a nuclear reactor's heat that is

transferred to steam which then operates a steam turbine and

generator. About 20 percent of electric generation in the USA

is produced by nuclear power plants.

o Geothermal power plants use steam extracted from hot

underground rocks.

o Biomass-fuelled power plants may be fuelled by waste from

sugar cane, municipal solid waste, landfill methane, or other

forms of biomass.

o Waste heat from industrial processes is occasionally

concentrated enough to use for power generation, usually in a

steam boiler and turbine.

o Solar thermal electric plants use sunlight to boil water and

produce steam which turns the generator.

1.1.2 Byprimemover:o Steam turbine plants use the dynamic pressure generated by

expanding steam to turn the blades of a turbine. Almost all

large non-hydro plants use this system. About 90 percent of all

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

4

electric power produced in the world is through use of steam

turbines.

o Gas turbine plants use the dynamic pressure from flowing gases

(air and combustion products) to directly operate the turbine.

Natural-gas fuelled (and oil fueled) combustion turbine plants

can start rapidly and so are used to supply "peak" energy during

periods of high demand, though at higher cost than base-loaded

plants. These may be comparatively small units, and sometimes

completely unmanned, being remotely operated. This type was

pioneered by the UK, Princetown being the world's first,

commissioned in 1959.

o Combined cycle plants have both a gas turbine fired by natural

gas, and a steam boiler and steam turbine which use the hot

exhaust gas from the gas turbine to produce electricity. This

greatly increases the overall efficiency of the plant, and many

new baseload power plants are combined cycle plants fired by

natural gas.

o Internal combustion reciprocating engines are used to provide

power for isolated communities and are frequently used for

small cogeneration plants. Hospitals, office buildings, industrial

plants, and other critical facilities also use them to provide

backup power in case of a power outage. These are usually

fuelled by diesel oil, heavy oil, natural gas, and landfill gas.

o Microturbines, Stirling engine and internal combustion

reciprocating engines are low-cost solutions for using

opportunity fuels, such as landfill gas, digester gas from water

treatment plants and waste gas from oil production.

1.1.3 Byduty(scheduled):o Base load power plants run nearly continually to provide that

component of system load that doesn't vary during a day or

week. Baseload plants can be highly optimized for low fuel

cost, but may not start or stop quickly during changes in system

load. Examples of base-load plants would include large modern

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

5

coal-fired and nuclear generating stations, or hydro plants with

a predictable supply of water.

o Peaking power plants meet the daily peak load, which may only

be for one or two hours each day. While their incremental

operating cost is always higher than base load plants, they are

required to ensure security of the system during load peaks.

Peaking plants include simple cycle gas turbines and sometimes

reciprocating internal combustion engines, which can be started

up rapidly when system peaks are predicted. Hydroelectric

plants may also be designed for peaking use.

o Load following power plants can economically follow the

variations in the daily and weekly load, at lower cost than

peaking plants and with more flexibility than baseload plants.

1.2 Desalination Plant: Desalinationisaprocessthatremovesmineralsfromsalinewater.

Moregenerally,desalinationmayalsorefertotheremovalofsaltsandminerals,asinsoildesalination,whichalsohappenstobeamajorissueforagriculturalproduction.

1.2.1 Typesofdistillationprocess:a. Multi-Stageflashdistillation.b. Multiple-effectdistillation.c. Vapor-Compression.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

6

1.2.1 Multi-Stage flash distillation [1]:

Multi-stageflashdistillationisawaterdistillationprocessthatdistillsseawaterbyflashingaportionofthewaterintosteaminmultiplestagesofwhatareessentiallycountercurrentheatexchangers.

1.2.2 Howitworks:Theplanthasaseriesofspacescalledstages,eachcontainingaheat

exchangerandacondensatecollector.Thesequencehasacoldendandahotendwhileintermediatestageshaveintermediatetemperatures.Thestageshavedifferentpressurescorrespondingtotheboilingpointsofwateratthestagetemperatures.Afterthehotendthereisacontainercalledthebrineheater.

Figure 1: Schematic of a 'once-through' multi-stage flash desalinates:

A - Steam in

B - Seawater in

C - Potable water out

D - Waste out

E - Steam out

F - Heat exchange

G - Condensation collection

H - Brine heater

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

7

1. Thecoldwaterpumpedfromtheseathroughaheatexchangeranditwarmsitup.(witheachstage,thetemperatureofseawaterincrease).

2. Then,whenitreachesthebrineheater,italreadyhadgotnearlythemaximumtemperature.

3. Thewaterentersthebrineheaterandsomeheatisadded.

4. Aftertheheater,thewaterflowsthroughvalvesbackintothestagesthathaveeverlowerpressureandtemperature.Thewaternowcalledbrine.

5. Thebrineenterseachstageattemperaturehigherthantheboilingtemperature.Asaresult,smallfractionofbrineflashestosteamuntilitstemperaturereducetoequilibrium.Thenentersthenextstage.

6. Thesteamcoolsandcondenseagainsttheheatexchangertube,anditheatsupthewatercomingfromthesea.

7. Atthefinalstage,thetemperatureinnearlysameastheinlettemperature.

1.2.3 Challenges:Thereisamaximumtemperatureofbrineheaterthatthewatercan’t

beheatedabove120,becausethiswillresultincorrodetheheatexchangeraswellasscaleformation,whichisthesaltfromsea.ItcanbeavoidedbyaddingNanofilters,sothewaterisoutofMgandNa.

Also,anotherchallengeisabouthowtobalancetheheatusedinbrineheater,thatitgivesthebestperformancewithlowenergylost.

1.3 Objective: Ourobjectiveistofindabalancebetweenthepowerplantandthedesalinationplantsothatwegettheoptimumperformanceforbothsystems.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

8

Chapter2:Hereinthischapter,wearegoingtospecifythemodelforthepowerplantaswellasthedesalinationplant.

2.1 Power Plant: Wechoseapowerplant(SeeFig.2)basedonrealdata.Thepower

plantwechosehaveoneboiler,twoturbines,condenser,oneopen

feedwaterheater,twoclosedfeedwaterheater,andthreepumps.

Wedevelopthegeneralequationforthewholesystem.Next,wewill

developthegeneralequationforeachelement. Our objective is to

find the optimum extraction pressure with the maximum efficiency in

the power plant (See Appendix A for the EES code).

Figure 2: Power plant in Saudi Arabia (Qurrayyah)[2]

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

9

Figure 3: Power Plant schematic diagram

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

10

2.1.1 Boiler:intheboiler,weincreasethewatertemperatureupto500C

withpressureof6000KPa.Also,thereisareheatpartthatcomesoutfromthehighpressureturbine.HereistheenergybalanceequationrepresentingtheheataddedtothewateraswellastheheataddedtoZ-extraction(reheat):

!"# = &'() ℎ 11 − ℎ 10 + / ℎ 15 − ℎ 14 (1)

where:

§ h[11] represent the enthalpy for the whole steam coming out of

the boiler to the high pressure turbine.

§ h[10] represent the enthalpy for the whole water coming into of

the boiler.

§ h[15] represent the enthalpy for the Z- fraction of steam coming

out of the boiler to the low pressure turbine.

§ h[14] represent the enthalpy for the Z- fraction of steam coming

out of the high pressure turbine to the reheat.

§ mdot represent the mass flow rate for the whole system.

§ Z represent the fraction that is going to the reheat and the low

pressure turbine.

2.1.2 HighPressureTurbine:Inthehighpressureturbine,wehavethreefractionsbeing

extractedatdifferentpressureandthefirstoneisgoingtotheclosed

feedwaterheater1,andtheotheroneisgoingtotheclosedfeed

waterheater2,andthethirdoneisgoingtothereheat,andthento

thelowpressureturbine.Thehighpressureturbinehasisentropic

efficiencyof80%andhereistheenergybalanceequationforthehigh

pressureturbine:

2345 = &'() 6 ℎ 11 − ℎ 12 + 8 ℎ 11 − ℎ 13 +

/ ℎ 11 − ℎ 14 (2)

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

11

hereisthemassflowratefractionbalance:

1 = 6 + 8 + / (3)

where:

§ h[12]representstheenthalpyofX-fractionofsteamfromthe

highpressureturbineatP[12]andT[12].

§ h[13]representstheenthalpyofY-fractionofsteamfromthe

highpressureturbineatP[13]andT[13].

§ h[14]representstheenthalpyofZ-fractionofsteamfromthe

highpressureturbineatP[14]andT[14].

2.1.3 LowPressureTurbine:Inthelowpressureturbine,wehavethreefractionsbeing

extractedatdifferentpressureandthefirstoneisgoingtotheopenfeedwaterheater,andtheotheroneisgoingtotheMSF-OTplant,andthethirdoneisgoingtothecondenser.Thelowpressureturbinehasisentropicefficiencyof85%andhereistheenergybalanceequationforthelowpressureturbine:

2:45 = &'() /×ℎ 15 − &×ℎ 16 − =×ℎ 17 − ?×ℎ@A"#B[18] (4)

hereisthemassflowratefractionbalance:

/ = & + = + ? (5)

where:

§ h[15]representstheenthalpyofZ-fractionofsteamfromthe

reheatatP[15]andT[15]tothelowpressureturbine.

§ h[16] represent the enthalpy of m-fractionofsteamfromthe

low pressure turbine at P[16] and T[16] and going to the open

feed water heater.

§ h[17]representstheenthalpyofn-fractionofsteamfromthe

lowpressureturbineatPcondenserandT[17]goingtothe

condenser.

§ hbrine[18]representstheenthalpyofb-fractionofsteamfrom

thereheatatPbrine[18]andTbrine[18]andgoingtotheMSF.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

12

§ m represents the fraction of steam that is going to the open feed

water heater.

§ n represents the fraction of steam that is going to the condenser.

§ b represents the fraction of steam that is going to the MSF brine

heater.

2.1.4 Condenser:Inthecondenser,thewaterentersthecondenseratPcondenser

andthewatergetsoutwithzeroquality.Hereistheenergybalanceequationforthecondenser:

!(F) = &'() = ℎ 17 − ℎ 1 (7)

where:

§ h[1]representstheenthalpyofn-fractionofwaterfromthe

condenseratPcondenserandT[1]topump1.

2.1.5 OpenFeedWaterHeater:Intheopenfeedwaterheater,n-fractionafterpump1,m-

fractionfromlowpressureturbine,b-fractionfromMSF.Hereisthe

energybalanceequationfortheopenfeedwaterheater:

ℎ 2 × = + ℎ 16 ×& + ℎ 6 × 6 + 8 + ?×ℎ 20 = ℎ 3 (8)

hereisthemassflowratefractionbalanceequation:

? + 6 + 8 +& = 1 (9)

where:

§ h[2]representstheenthalpyofn-fractionofwaterfromthe

condenseratP[2]andT[2]andgoingtotheopenfeedwater

heater.

§ h[6]representstheenthalpyof(x&y)-fractionofsteamfrom

trap2atP[6]andT[6]andgoingtotheopenfeedwater

heater.

§ h[20]representstheenthalpyofb-fractionofsteamfromMSF

atPbrineandTbrine[18]andgoingtotheopenfeedwaterheater.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

13

§ h[3]representstheenthalpyofwholemassfractionofsteam

fromopenfeedwaterheaterandgoingtopump2,which

increasethewaterpressureuptoPboiler.

2.1.6 ClosedFeedWaterHeater2:Intheclosedfeedwaterheater2,wehavethreelinesentering

theheatexchanger:y-fractioncomingfromthehighpressureturbine,

wholemassfrompump2andx-fractionfromtrap1.Also,wehave

twolinesgoingoutfromtheheatexchanger:oneisgoingtothe

closedfeedwaterheater1andtheothergoingtrap2.Hereisthe

energybalanceequationfortheclosedfeedwaterheaterwith

effectivenessof0.8:

8×GH 13 × I 13 −IJK) 13 + 8×ℎLM 13 + ℎ 4 + ℎ 9 ×6 =

6 + 8 ×ℎ 5 + ℎ 7 (10)

where:

§ Cp[13]representsthespecificheatofy-fractionofwaterfrom

thehighpressureturbineatP[13]andT[13]andgoingtothe

closedfeedwaterheater2.

§ hfg[13]representsthevaporizationenthalpyofy-fractionof

steamfromhighpressureturbineatP[13]andT[13]andgoing

totheclosedfeedwaterheater2.

§ h[4]representstheenthalpyofwholemassfractionofwater

frompump2atP[4]andT[4]andgoingtotheclosedfeed

waterheater2.

§ h[9]representstheenthalpyofx-fractionofwaterfromtrap1

andgoingtotheclosedfeedwaterheater2.

§ h[7]representstheenthalpyofwholemassfractionofwater

fromclosedfeedwater2andgoingtotheclosedfeedwater

heater1.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

14

2.1.7 ClosedFeedWaterHeater1:Intheclosedfeedwaterheater1,wehavetwofractionsgoing

totheheatexchanger:onefromtheclosedfeedwater2andthe

otherfromthehighpressureturbine.Also,wehavetwofractions

goingoutfromtheheatexchanger:oneisgoingtotheboilerandthe

otherisgoingtotrap1.Hereistheenergybalanceequationforthe

closedfeedwaterheater1:

6×GH 12 × I 12 −IJK)[12] + 6×ℎLM[12] + ℎ 7 = ℎ 8 ×6 + ℎ 10

(11)

where:

§ Cp[12]representsthespecificheatofx-fractionofwaterfrom

thehighpressureturbineatP[12]andT[12]andgoingtothe

closedfeedwaterheater1.

§ hfg[12]representsthevaporizationenthalpyofx-fractionof

steamfromhighpressureturbineatP[12]andT[12]andgoing

totheclosedfeedwaterheater1.

§ h[8]representstheenthalpyofx-fractionofsteamfrom

closedfeedwater1andgoingtotrap1.

§ h[10]representstheenthalpyofwholemassfractionofwater

fromclosedfeedwater1andgoingtotheboiler.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

15

2.2 Desalination Plant:

We chose to work on a once through multi-stage flash distillation

system consists of two basic sections, a heat addition section and a heat

recovery section as can be seen in the Fig.4, in the next page. The heat

recovery section consists of a condenser, the distillate collection trays

and the flashing chamber. On the other hand, the heat addition section

consists mainly of a brine heater. (See Appendix B for the EES code)

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

16

Figure 4 : Once through Multi-Stage Flash Distillation System

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

17

TocarryoutthemathematicalmodelingoftheMSFplant,thefollowingassumptionsaremade:

a)Thetemperaturedropsacrosseachflashingstageaswellasthetemperatureriseineachcondenserstageisequal.

b)Theeffectofboilingpointriseandnon-equilibriumlossesonthestageenergybalanceisconsiderednegligible.

2.1.1 Massbalancemodeling:

AsseeninFigure2thereisoneinputwhichistheseawaterMfand

twooutputwhicharedistillatedwaterMdandbrineblowdownMb.So

themassflowratebalancewillbe:

(12)

Andifweaddedthesalinity:

(13)

Node:thedistillatedwaterhasazerosalinity.

Thetotaldistillatemassflowrateisobtainedby:

(14)

Where: (15)

Thesteammassflowrate:

(16)

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

18

2.1.2 TemperatureDropModeling:

Asweassumedthatthetemperaturedropineverystageisconstant,sotheequationwillbe:

(17)

Where:

To:Temperatureofseawaterleavingthebrineheater,thetopbrinetemperature.

Tn:Temperatureofbrineleavingthelaststageoftheflashingchamber.

n:thenumberofflashingstages.

2.1.3 TheTemperatureateachStage:

(18)

Whereirepresentsthestagenumber.

2.1.4 Heattransferareas:

TheequationofthebrineheattransferarearequiredAbis:

(19)WhereUbandTlmtd,bare:

Also,thecondenserheattransferareainthefirststageis:

(20)WhereTlmtd,candUcare:

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

19

WhereTv,1canbecalculatedasflow:

Andthetotalheattransferareacanbecalculatedisflows:

(21)

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

20

2.1.5 FlashingStageDimensionsModeling:

Thegateheightateachstage,GHis:

(22)

Andthebrinepoolheight,H:

(23)

Also,thewidthofeachchamberiscalculatedby:

(24)

2.1.6 PerformanceModeling:

Theperformanceofthedesalinationplantsisexpressedastheperformanceratio,PR,whichdefinedastheamountofdistillateproducedperunitofsteamconsumption.Andiscalculatedby:

(25)

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

21

Chapter3:

Resultsanddiscussion:

3.1 Power plant 3.1.1 Theoptimumpressure:

Theoptimumpressureinthepowerplantinboiler,reheatandextraction

linefromturbinestofeedwater.Allfollowingpressurecalculateatextraction

equal0.

3.1.1.1 Boiler pressure

Thepressureoftheboileristhemaximumpressureinthepowerplant.Thepressure set it tobe12MPaandall followingpressurewilldependson thispressure. We use 12 MPa. As we increase the pressure of the boiler, theefficiency of the cycle will increase but this increase should have someconstrain.

3.1.1.2 Reheat pressure

Thebestconditionofthereheatpressureistobe20-25%oftheboilerpressure,whichisequalto2400KPa.Wecanseethatfromthefollowinggraphandtable.

Table 1: Reheat pressure

Wnet (KW)

Efficiency (%)

Pressure (KPa)

711192 36.19 7000 717390 36.29 6500 723769 36.38 6000 730346 36.47 5500 737145 36.55 5000 744192 36.63 4500 751514 36.7 4000 759146 36.76 3500 767122 36.8 3000 775477 36.82 2500 777195 36.82 2400 784222 36.8 2000

Figure 5: preheat/Boiler Vs eff

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

22

3.1.1.3 Extraction pressure p [12]

The extraction pressure from the HPT to CFWH1. We can see P = 2500 KPa is the best condition. This pressure cannot be lower than the pressure of reheat.

3.1.2 TheeffectofmassextractionfrompowerplanttoMSFplant

Here in this part, we want to see the effect of the amount of mass that

extract form the power plant to the MSF plant. As we can see from the figure

and the table, the effect of the extraction is not going to effect the power plant.

If we say that we need to extract 10 % of the mass flow rate of the power plant,

we will loss 0.43% from the efficiency and if we compare this loss to how much

are we going to produce water, that loss will be nothing. The value of extraction

represent how much do we take from the power plant to the MSF. The following

table shows extraction value starts from 0% to 34% of the mass flow rate of the

power plant. The following data are at 700 KPa and we will discuss latter why

we choose this pressure for the extraction.

Wnet (KW)

Efficiency (%)

Pressure (KPa)

596780 31.71 5000 635627 33.04 4500 673348 34.21 4000 710418 35.25 3500 747347 36.17 3000 784749 36.97 2500

Table 2: optimum pressure for P [12]

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

23

Table 3: Mass extraction and effect on efficiency

Wnet (KW)

Efficiency (%)

Extraction fraction

777195 36.82 0 776298 36.78 0.01 775400 36.73 0.02 774502 36.69 0.03 773605 36.65 0.04 772707 36.61 0.05 771810 36.56 0.06 770912 36.52 0.07 770014 36.48 0.08 769117 36.44 0.09 768219 36.39 0.1 763731 36.18 0.15 759243 35.97 0.2 754755 35.76 0.25 750267 35.54 0.3 746676 35.37 0.34

Figure 6: Effincy Vs Extraction fraction

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

24

3.1.3 Theeffectoftheconditionoftheextractionmass

Here we are going to see, how the condition of the extraction can effect

on the power plant system. The following result is when we extract 10 % of

the mass flow rate of the power plant. As we can see, decreasing the pressure

will lead to decrease the value of hg . However, hfg will increase because as we

decrease the pressure hfg increase from the

T-S diagram. From here we can calculate the

amount of heat that will be delivered to the

MSF plant which equal to = m*hfg.. From

here, we can control the condition of the

pressure of extraction based on the needed

heat in the MSF plant.

Table 4 : effect of the condition of the extraction

QDesalination (KJ)

Wnet

(KW) Efficiency

(%) hg

(KJ/Kg) Pressure

(KPa) 158834 768577 36.41 2784 1200 159971 768475 36.41 2781 1100 161169 768385 36.4 2778 1000 162439 768310 36.4 2774 900 163796 768253 36.4 2769 800 165261 768219 36.39 2763 700 166863 768216 36.39 2757 600 168643 768255 36.4 2749 500 170674 768355 36.4 2739 400 173079 768551 36.41 2725 300 176124 768919 36.43 2707 200 180598 769698 36.46 2675 100

Figure 8: Efficiency Vs Pbrine

Figure 7: : T-S diagram shows how hfg increase

as pressure decreases

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

25

3.1.4 Makeupwaterforthepowerplant:

The losses in the mass flow rate from the power plant during the extraction

to the MSF plant should be compensating. Usually the makeup water that for the

power plant is water at 25 Co. in this project we tried to see how we could use the

same water that used in the MSF plant. Water that come back again will have less

energy than that delivered to MSF because the energy used to heat up the see

water temperature.

1- Using the water from the MSF: Steam that used in MSF plant will have hg at the extraction pressure. The

outlet of the brine heater will have hf at the extraction pressure. In this case, we

can use this water and pump it back to the open feed eater at the same pressure of

the OFWH. This water will be the makeup water for the power plant. We can see

from the table 5, how the efficiency will be if we return the water from MSF plant.

Table 5: Efficiency with returning water from MSF

Wnet (KW)

Efficiency (%) b

777195 36.82 0 776298 36.78 0.01 775400 36.73 0.02 774502 36.69 0.03 773605 36.65 0.04 772707 36.61 0.05 771810 36.56 0.06 770912 36.52 0.07 770014 36.48 0.08 769117 36.44 0.09

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

26

2- Using water at 25Co As we extract steam from power plant we should have make up water to

complete the cycle. In this case we will have makeup water in 25 C. we will pump this water to same pressure of OFWH. The flowing data are at 700 KPa for the make water and its efficiency.

Table 6: Efficiency with returning water 25 C

Wnet (KW)

Efficiency (%)

b

777195 36.82 0 775571 36.74 0.01 773946 36.65 0.02 772321 36.57 0.03 770697 36.49 0.04 769072 36.41 0.05 767447 36.32 0.06 765823 36.24 0.07 764198 36.16 0.08 762573 36.07 0.09

3.1.5 Comparisonbetweendata:

This table will show how much is the difference in efficiency and Wnet between make up water from MSF or at 25 C

Defiance (KW)

Wnet

(KW) Wnet

(KW) Defiance

(%) Efficiency

(%) Efficiency

(%) b

0 777195 777195 0 36.82 36.82 0 727 775571 776298 0.04 36.74 36.78 0.01 1454 773946 775400 0.08 36.65 36.73 0.02 2181 772321 774502 0.12 36.57 36.69 0.03 2908 770697 773605 0.16 36.49 36.65 0.04 3635 769072 772707 0.2 36.41 36.61 0.05 4363 767447 771810 0.24 36.32 36.56 0.06 5089 765823 770912 0.28 36.24 36.52 0.07 5816 764198 770014 0.32 36.16 36.48 0.08 6544 762573 769117 0.37 36.07 36.44 0.09

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

27

Figure 9: the effect of make water in Efficiency

3636.136.236.336.436.536.636.736.836.9

0 0.02 0.04 0.06 0.08 0.1

bVsEfficiency

BackfromMSF at25C

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

28

Figure 10: The effect of make water in Work net

760000762000764000766000768000770000772000774000776000778000

0 0.02 0.04 0.06 0.08 0.1

bVsWnet

BackfromMSF At25C

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

29

3.2 MSF Plant In MSF plant, we are going to see how much steam do we need from the

power plant to produce 378.8 Kg/s of desalt water. Also, how can the temperature of the steam can affect the performance ration of the MSF.

3.2.1 Theeffectofconditionofthesteam

As we see previously how the extraction condition can effect on the power plant.

It is also effect on MSF. As we increase the pressure of extraction, the temperature of

the steam will increase. Therefore, the temperature of top brine will increase also. We

can see how temperature will be difference with pressure in the following table.

Table 7: pressure and its temperatures

Tsat Pextraction

188 1200 184.1 1100 179.9 1000 175.4 900 170.4 800 165 700

158.9 600 151.9 500 143.6 400 133.6 300 120.2 200 99.63 100

Increasing the pressure of extraction will led to increase in performance ratio and increasing in number of stages. In addition, it will led to decrease the amount of steam that need in MSF plant. The following table shows how temperature will effect in the energy needed (Q) and number of stages.

Table 8: steam temperature and its effect on Q and number of stages

Msteam Q (KJ) PR ∆T (Co) n Tn (Co) To (Co) 95.7049 211837 3.958 2.75 24 40 106 90.83933 200025 4.17 2.8 25 40 110 80.81929 175690 4.687 2.758621 29 40 120 73.09919 156751 5.182 2.8125 32 40 130 66.99682 141611 5.654 2.777778 36 40 140 62.06784 129223 6.103 2.75 40 40 150 58.02696 118892 6.528 2.790698 43 40 160 54.69246 110155 6.926 2.765957 47 40 170

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

30

Tn: Brine Temperature in last stage

To: Top brine temperature

n: Total number of stages

∆T: The temperature drop per stage

PR: performance ratio

Q: heat need in brine heater

Infigure11,wecanseetherelationbetweenthetopbrinetemperature,whichis(Tsat–10),and the number of stages. Aswe increases number of stages the performance ratiowillincreases.

Figure 11: number of stage Vs Top brine temperature

y=0.3613x- 14.543

20

25

30

35

40

45

50

100 110 120 130 140 150 160 170

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

31

Thefollowingfigureshows,whatistherelationbetweenthetopbrinetemperatureandmassflowrateofthesteam.Asweincreasetemperatureofthesteamwewillneedlessmassflowratesolessamountofextractionfromthepowerplant.

Figure 12: Msteam Vs Top brine temperature

We can see from the following graph how performance ratio will effect by increasing the top

brine temperature. Actually increasing the temperature led to increase number of stage which

is going to increase the performance ratio.

Figure 13: performance ratio Vs Top brine temperature

40

50

60

70

80

90

100

100 110 120 130 140 150 160 170

y=0.0455x- 0.7828

1

2

3

4

5

6

7

8

100 110 120 130 140 150 160 170

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

32

3.2.2 Extraction“b”frompowerplanttotheMSF

b = ms / mp

ms: mass of steam required in MSF

mp: mass flow rate of water in power plant, which is 800 Kg/s

The following table show how much “b” we need to satisfy the MSF at different top brine temperature.

Table 9: table show how much “b” we need to satisfy the MSF at different top brine temperature

b msteam (Kg/s)

Q (KJ)

To (Co)

0.119631 95.7049 211837 106 0.113549 90.83933 200025 110 0.101024 80.81929 175690 120 0.091374 73.09919 156751 130 0.083746 66.99682 141611 140 0.077585 62.06784 129223 150 0.072534 58.02696 118892 160 0.068366 54.69246 110155 170

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

33

Chapter4:

ConclusionTosumup,wefocusedonthisprojecttofindtheoptimumperformanceratioby

combiningthesteampowerplantwiththeMSFdistillationplant.First,weworkedonthepowerplantandwefoundoutthebestreheatpressuretobe2400kPa.Then,welookedontheeffectoftheextraction,whichisgoingtosupplysteamtotheMSFplant,ontheefficiencyofthepowerplantandwefoundoutthatifwetake8%ofthemassinthepowerplanttheefficiencywilldecreaseby1%whichisverysmallcomparedtowhatwewillgetintheMSF.Afterthat,wefoundthatthebestpressureoftheextractiontobe700kPaandwelookedontheeffectofthemakeupmasstothepowerplant.Ifthemakeupwaswaterattemperatureof165Corwaterat25Candwefoundthattheefficiencywilldecreaseby0.36%ifweputamakeupwaterat25C.Then,welookedattheMSFandseetheeffectoftheincreasingthetemperatureofthesuppliedsteam.Asweincreasethesteamtemperature,thenumberofstagesincreasewhichwillleadustoanincreaseintheperformanceratio.Ifweincreasethesteamtemperaturefrom106Cto170C,theperformanceratiowillincreasebyalmost100%.ThesechangescausedbigimprovementonthecombinationofthepowerplantandMSFwhichwillsavealotofmoney.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

34

References:[1]Wikipedia

[2]acwapower.com

[3]HishamT.El-DessoukyandHishamM.Ettouney"FundamentalsofSaltWaterDesalination",Elsevier,2002.

[4]MOHAMMEDA.ANTARandSYEDM.ZUBAIR“AnalysisandAssessmentofPerformanceofaMSFEvaporationDesalinationPlant”,February2010.

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

35

AppendixA:

File

:pow

erpl

ant6

with

opt

imum

pre

suur

e.EE

S4/

25/2

016

9:30

:38

PM P

age

1EE

S Ve

r. 9.

901:

#16

96: D

epar

tmen

t of M

echa

nica

l Eng

inee

ring

King

Fah

d U

nive

rsity

Pet

role

um a

nd M

iner

als

Boi

ler

HPT

LPT

Con

dens

er

CFW

H 1

CFW

H 2

OPW

H

P2

P1

Trap

1Tr

ap 2

(11)

(10)

(12)

(13)

(14)

(15)

(16)

(17)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

P boi

ler =

*

****

T 11

= *

**

T 12

= *

**

P 12

= *

***

P reh

eat =

*

***

T 14

= *

****

x =

*

****

*

P 13

= *

***

T 13

= *

****

y =

*

****

*z

= *

****

*

T 15

= *

**P 1

6 =

*

**

T 16

= *

****

b =

*

****

**

m =

*

****

**

n =

*

****

*P c

ond

= *

**T 1

7 =

*

***

P 2 =

*

**

P 1 =

*

**

T 3 =

*

****

T 4 =

*

****

T 7 =

*

****

T 5 =

*

**T 6

= *

****

T 8 =

*

****

T 10

= *

**

P brin

e,18

= *

**

b =

*

****

**

T 2 =

*

****

K sys

,new

= *

****

P reh

eat =

*

***

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:25 PM Page 1EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Knowen information

Pboiler = 12000

P12 = 2600

P13 = 2500

Preheat = 2400

P16 = 900

Pcond = 7.5

T11 = 565

T15 = 550

KHPT = 0.8

KLPT = 0.85

b = 0.07254

Pbrine,18 = 700

rat = Preheat

Pboiler

Qdesel = b · M · hbrinefg,18

M = 800

HCFWH1 = HCFWH2

HCFWH2 = 0.4

massdes = M · b

Heat Transfer Coefficient of steam at Steam Temperature

hbrinefg,18 = Enthalpyvaporization SteamIAPWS , P = Pbrine,18

HPT

h11 = h Steam , T = T11 , P = Pboiler

s11 = s Steam , T = T11 , P = Pboiler

Isontropic turbine

s11 = s12

s11 = s13

s11 = s14

hiso,12 = h Steam , s = s12 , P = P12

hiso,13 = h Steam , s = s13 , P = P13

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:25 PM Page 2EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

hiso,14 = h Steam , s = s14 , P = Preheat

KHPT = h11 – h12

h11 – hiso,12

KHPT = h11 – h13

h11 – hiso,13

KHPT = h11 – h14

h11 – hiso,14

T12 = T Steam , s = s12 , P = P12

T13 = T Steam , s = s13 , P = P13

T14 = T Steam , s = s14 , P = Preheat

1

Mass balance

1 = z + x + y

WHPT = M · x · h11 – h12 + y · h11 – h13 + z · h11 – h14

LPT

h15 = h Steam , T = T15 , P = Preheat

s15 = s Steam , T = T15 , P = Preheat

Isontropic turbine

s15 = s16

s15 = s17

hiso,16 = h Steam , s = s16 , P = P16

hiso,17 = h Steam , s = s17 , P = Pcond

KLPT = h15 – h16

h15 – hiso,16

KLPT = h15 – h17

h15 – hiso,17

T16 = T Steam , s = s16 , P = P16

T17 = T Steam , s = s17 , P = Pcond

2

Mass Balance

z = m + n + b

hbrine,18 = h Steam , x = 1 , P = Pbrine,18

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:25 PM Page 3EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

WLPT = M · z · h15 – m · h16 – n · h17 – b · hbrine,18

Condencer

h1 = h water , P = Pcond , x = 0

To calculate the work in pump 1

v1 = v water , P = Pcond , x = 0

Qout = M · n · h17 – h1

Pump 1

P2 = P16

P1 = Pcond

Wp1 = M · n · v1 · P2 – P1

M · n · h2 – h1 = Wp1

OFWH

3

h2 · n + h16 · m + h6 · x + y + b · h20 = h3

Hrecovery = M · n · h2 + h16 · m + h6 · x + y + b · h20

hnew,3 = Hrecovery

M

h21 = h water , T = 25 , P = 101

h3 = h water , P = P16 , x = 0

To calculate the work in pump 2

v3 = v water , P = P16 , x = 0

T3 = T water , P = P16 , h = hnew,3

T2 = T water , P = P16 , h = h2

T6 = T water , P = P16 , h = h6

Pump 2

P4 = Pboiler

P3 = P16

Wp2 = M · v3 · P4 – P3

M · h4 – hnew,3 = Wp2

T4 = T3

pump 3

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 4EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

P16 = P20

v19 = v water , P = Pbrine,18 , x = 0

WP3 = M · b · P20 – Pbrine,18 · v19

WP3 = M · b · h20 – h19

h19 = h water , P = Pbrine,18 , x = 0

CFWH 2

4

y · Cp13 · T13 – Tsat,13 + y · hfg,13 + h4 + h9 · x = x + y · h5 + h7

Tsat,13 = Tsat water , P = P13

Tavg,13 = T13 + Tsat,13

2

Cp13 = Cp water , T = Tavg,13 , P = P13

hfg,13 = Enthalpyvaporization Steam , P = P13

T7 – T4

T13 – T4 = HCFWH2

T5 = T water , P = P13 , x = 0

h7 = h water , T = T7 , P = P4

Trap 2

h5 = h6

h5 = h water , P = P13 , x = 0

CFWH 1

5

x · Cp12 · T12 – Tsat,12 + x · hfg,12 + h7 = h8 · x + h10

Tsat,12 = Tsat water , P = P12

Tavg,12 = T12 + Tsat,12

2

Cp12 = Cp water , T = Tavg,12 , P = P12

hfg,12 = Enthalpyvaporization Steam , P = P12

h8 = h water , P = P12 , x = 0

T10 – T7

T12 – T7 = HCFWH1

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 5EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

T8 = T water , P = P12 , x = 0

h10 = h water , T = T10 , P = P4

Trap 1

h8 = h9

Boiler

Qin = M · h11 – h10 + z · h15 – h14

The System effecince

Wtotal,pump = Wp1 + Wp2 + WP3

Wnet = WLPT + WHPT – Wp1 – Wp2 – WP3

Ksys,new = Wnet

Qin · 100

HC,2 = M · n · h2

HC,4 = M · h4

HC,5 = M · x + y · h5

HC,6 = M · x + y · h6

HC,7 = M · h7

HC,8 = M · x · h8

HC,9 = M · x · h9

HC,10 = M · h10

HC,11 = M · h11

HC,12 = M · x · h12

HC,13 = M · y · h13

HC,14 = M · z · h14

HC,15 = M · z · h15

HC,16 = M · m · h16

HC,17 = M · n · h17

HC,18 = M · b · hbrine,18

SOLUTIONUnit Settings: SI C kPa kJ mass degb = 0.07254 HCFWH1 = 0.4 HCFWH2 = 0.4 KHPT = 0.8

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 6EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

KLPT = 0.85 Ksys,new = 36.51 Ksys,new = 36.51 Hrecovery = 594343 m = 0.07824 massdes = 58.03 M = 800 n = 0.4825 Pboiler = 12000 Pcond = 7.5 Preheat = 2400 Qdesel = 119881 Qin = 2.111E+06 Qout = 907519 rat = 0.2 WHPT = 309122 WLPT = 471878 Wnet = 770684 Wp1 = 347.3 Wp2 = 9956 WP3 = 12.86 Wtotal,pump = 10316 x = 0.1523 y = 0.2144 z = 0.6333

38 potential unit problems were detected.

Arrays Table: MainCpi hi hbrine,i HC,i hfg,i hiso,i hnew,i Pi Pbrine,i si

1 168.8 7.5 2 169.7 65487 900 3 742.9 742.9 900 4 755.4 604299 12000 5 962 282218 6 962 282218 7 995.3 796218 8 971.7 118388 9 971.7 118388 10 1163 930464 11 3519 2.815E+06 6.699 12 2.612 3145 383111 1831 3051 2600 6.699 13 2.605 3137 538036 1840 3041 2500 6.699 14 3128 1.585E+06 3031 6.699 15 3575 1.811E+06 7.483 16 3294 206156 3244 900 7.483 17 2520 972659 2334 7.483 18 2763 160361 700 19 697.4 20 697.6 900 21 104.8

Arrays Table: MainTi Tavg,i Tsat,i vi hbrinefg,i

1 0.001008 2 40.33 3 175.4 0.001121 4 175.4 5 224 6 175.4 7 230.7 8 226.1 9 10 266 11 565 12 319 272.6 226.1 13 313.7 268.8 224 14 308.2 15 550

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 7EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Arrays Table: MainTi Tavg,i Tsat,i vi hbrinefg,i

16 389.9 17 40.3 18 2066 19 0.001108 20 21

There are a total of 114 equations in the Main program.Block Rel. Res. Abs. Res. Units Calls Time(ms) Equations 0 0.000E+00 0.000E+00 OK 1 0 P_boiler=12000 0 0.000E+00 0.000E+00 OK 1 0 P[12]=2600 0 0.000E+00 0.000E+00 OK 1 0 P[13]=2500 0 0.000E+00 0.000E+00 OK 1 0 P_reheat=2400 0 0.000E+00 0.000E+00 OK 1 0 P[16]=900 0 0.000E+00 0.000E+00 OK 1 0 P_cond=7.5 0 0.000E+00 0.000E+00 OK 1 0 T[11]=565 0 0.000E+00 0.000E+00 OK 1 0 T[15]=550 0 0.000E+00 0.000E+00 OK 1 0 Eta_HPT=0.8 0 0.000E+00 0.000E+00 OK 1 0 Eta_LPT=0.85 0 0.000E+00 0.000E+00 OK 1 0 b=.07254 0 0.000E+00 0.000E+00 OK 1 0 P_brine[18]=700 0 0.000E+00 0.000E+00 OK 1 0 M_dot=800 0 0.000E+00 0.000E+00 OK 1 0 epsilon_CFWH2=0.4 0 0.000E+00 0.000E+00 OK 4 0 rat=P_reheat/P_boiler 0 0.000E+00 0.000E+00 OK 4 0 mass_des=M_dot*b 0 0.000E+00 0.000E+00 ? 4 0 h_brinefg[18]=Enthalpy_vaporization(Steam_IAPWS,P=P_brine[18]) 0 0.000E+00 0.000E+00 ? 4 0 h[11]=Enthalpy(Steam,T=T[11],P=P_boiler) 0 0.000E+00 0.000E+00 ? 4 0 s[11]=Entropy(Steam,T=T[11],P=P_boiler) 0 0.000E+00 0.000E+00 OK 4 0 s[11]=s[12] 0 0.000E+00 0.000E+00 OK 4 0 s[11]=s[13] 0 0.000E+00 0.000E+00 OK 4 0 s[11]=s[14] 0 0.000E+00 0.000E+00 ? 4 0 h_iso[12]=Enthalpy(Steam,S=S[12],P=P[12]) 0 0.000E+00 0.000E+00 ? 4 0 h_iso[13]=Enthalpy(Steam,S=S[13],P=P[13]) 0 0.000E+00 0.000E+00 ? 4 0 h_iso[14]=Enthalpy(Steam,S=S[14],P=P_reheat) 0 1.355E-19 -5.073E-17 OK 4 0 Eta_HPT=(h[11]-h[12])/(h[11]-h_iso[12]) 0 1.355E-19 5.182E-17 OK 4 0 Eta_HPT=(h[11]-h[13])/(h[11]-h_iso[13]) 0 2.033E-19 -7.942E-17 OK 4 0 Eta_HPT=(h[11]-h[14])/(h[11]-h_iso[14]) 0 0.000E+00 0.000E+00 ? 4 0 T[12]=Temperature(Steam,S=S[12],P=P[12]) 0 0.000E+00 0.000E+00 ? 4 0 T[13]=Temperature(Steam,S=S[13],P=P[13]) 0 0.000E+00 0.000E+00 ? 4 0 T[14]=Temperature(Steam,S=S[14],P=P_reheat) 0 0.000E+00 0.000E+00 ? 4 0 h[15]=Enthalpy(Steam,T=T[15],P=P_reheat) 0 0.000E+00 0.000E+00 ? 4 0 s[15]=Entropy(Steam,T=T[15],P=P_reheat) 0 0.000E+00 0.000E+00 OK 4 0 s[15]=s[16] 0 0.000E+00 0.000E+00 OK 4 0 s[15]=s[17] 0 0.000E+00 0.000E+00 ? 4 0 h_iso[16]=Enthalpy(Steam,S=s[16],P=P[16]) 0 0.000E+00 0.000E+00 ? 4 0 h_iso[17]=Enthalpy(Steam,S=s[17],P=P_cond) 0 1.276E-19 3.587E-17 OK 4 0 Eta_LPT=(h[15]-h[16])/(h[15]-h_iso[16]) 0 1.276E-19 1.346E-16 OK 4 0 Eta_LPT=(h[15]-h[17])/(h[15]-h_iso[17]) 0 0.000E+00 0.000E+00 ? 4 0 T[16]=Temperature(Steam,S=s[16],P=P[16]) 0 0.000E+00 0.000E+00 ? 4 0 T[17]=Temperature(Steam,S=s[17],P=P_cond) 0 0.000E+00 0.000E+00 ? 4 0 h_brine[18]=Enthalpy(Steam,x=1,P=P_brine[18]) 0 0.000E+00 0.000E+00 ? 4 0 h[1]=Enthalpy(Water,P=P_cond,x=0) 0 0.000E+00 0.000E+00 ? 4 0 v[1]=Volume(Water,P=P_cond,x=0) 0 0.000E+00 0.000E+00 OK 4 0 P[2]=P[16] 0 0.000E+00 0.000E+00 OK 4 0 P[1]=P_cond 0 0.000E+00 0.000E+00 ? 4 0 h[21]=Enthalpy(Water,T=25,P=101)

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 8EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

0 0.000E+00 0.000E+00 ? 4 0 h[3]=Enthalpy(Water,P=P[16],x=0) 0 0.000E+00 0.000E+00 ? 4 0 v[3]=Volume(Water,P=P[16],x=0) 0 0.000E+00 0.000E+00 OK 4 0 P[4]=P_boiler 0 0.000E+00 0.000E+00 OK 4 0 P[3]=P[16] 0 0.000E+00 0.000E+00 OK 4 0 W_p2=m_dot*v[3]*(P[4]-P[3]) 0 0.000E+00 0.000E+00 OK 4 0 P[16]=P[20] 0 0.000E+00 0.000E+00 ? 4 0 v[19]=Volume(Water,P=P_brine[18],x=0) 0 0.000E+00 0.000E+00 OK 4 0 W_P3=m_dot*b*(P[20]-P_brine[18])*v[19] 0 0.000E+00 0.000E+00 ? 4 0 h[19]=Enthalpy(Water,P=P_brine[18],x=0) 0 0.000E+00 0.000E+00 ? 4 0 T_sat[13]=T_sat(Water,P=P[13]) 0 0.000E+00 0.000E+00 OK 4 0 T_avg[13]=((T[13]+T_sat[13])/2) 0 0.000E+00 0.000E+00 ? 4 0 Cp[13]=Cp(Water,T=T_avg[13],P=P[13]) 0 0.000E+00 0.000E+00 ? 4 15 h_fg[13]=Enthalpy_vaporization(Steam,P=P[13]) 0 0.000E+00 0.000E+00 ? 4 0 T[5]=Temperature(Water,P=P[13],x=0) 0 0.000E+00 0.000E+00 ? 4 0 h[5]=Enthalpy(Water,P=P[13],x=0) 0 0.000E+00 0.000E+00 ? 4 0 T_sat[12]=T_sat(Water,P=P[12]) 0 0.000E+00 0.000E+00 OK 4 0 T_avg[12]=((T[12]+T_sat[12])/2) 0 0.000E+00 0.000E+00 ? 4 0 Cp[12]=Cp(Water,T=T_avg[12],P=P[12]) 0 0.000E+00 0.000E+00 ? 4 16 h_fg[12]=Enthalpy_vaporization(Steam,P=P[12]) 0 0.000E+00 0.000E+00 ? 4 0 h[8]=Enthalpy(Water,P=P[12],x=0) 0 0.000E+00 0.000E+00 ? 4 0 T[8]=Temperature(Water,P=P[12],x=0) 0 0.000E+00 0.000E+00 OK 4 0 h[8]=h[9] 0 0.000E+00 0.000E+00 OK 4 0 H_C[11]=m_dot*h[11] 0 0.000E+00 0.000E+00 OK 4 0 H_C[18]=m_dot*(b)*h_brine[18] 0 0.000E+00 0.000E+00 OK 4 0 Q_desel=b*M_dot*h_brinefg[18] 0 0.000E+00 0.000E+00 OK 4 0 epsilon_CFWH1=epsilon_CFWH2 0 1.087E-16 -1.398E-15 OK 4 0 W_P3=m_dot*b*(h[20]-h[19]) 0 0.000E+00 0.000E+00 OK 4 0 h[5]=h[6] 0 0.000E+00 0.000E+00 ? 4 0 T[6]=Temperature(Water,P=P[16],h=h[6]) 1 0.000E+00 0.000E+00 OK 48 0 1=(z+x+y) 1 0.000E+00 0.000E+00 OK 48 0 z=(m+n+b) 1 0.000E+00 0.000E+00 OK 40 0 W_p1=m_dot*(n*v[1]*(P[2]-P[1])) 1 1.919E-08 -6.663E-06 OK 48 0 m_dot*(n)*(h[2]-h[1])=W_p1 1 1.121E-11 -8.325E-09 OK 64 0 h[2]*(n)+h[16]*m+h[6]*(x+y)+b*h[20]=h[3] 1 1.121E-11 6.662E-06 OK 72 0 H_recovery=m_dot*(n*h[2]+h[16]*m+h[6]*(x+y)+b*h[20]) 1 0.000E+00 0.000E+00 OK 40 0 h_new[3]=H_recovery/m_dot 1 2.002E-14 3.512E-12 ? 82 109 T[3]=Temperature(Water,P=P[16],h=h_new[3]) 1 6.245E-19 -6.217E-15 OK 40 0 m_dot*(h[4]-h_new[3])=W_p2 1 0.000E+00 0.000E+00 OK 40 0 T[4]=T[3] 1 0.000E+00 0.000E+00 OK 56 0 y*Cp[13]*(T[13]-T_sat[13])+y*h_fg[13]+h[4]+h[9]*x=(x+y)*h[5]+h[7] 1 1.152E-18 4.608E-19 OK 40 0 (T[7]-T[4])/(T[13]-T[4])=epsilon_CFWH2 1 1.104E-16 -1.099E-13 ? 40 0 h[7]=Enthalpy(Water,T=T[7],P=P[4]) 1 8.468E-20 1.110E-16 OK 48 0 x*Cp[12]*(T[12]-T_sat[12])+x*h_fg[12]+h[7]=h[8]*x+h[10] 1 1.897E-18 7.589E-19 OK 40 0 (T[10]-T[7])/(T[12]-T[7])=epsilon_CFWH1 1 2.148E-17 -2.498E-14 ? 40 0 h[10]=Enthalpy(Water,T=T[10],P=P[4]) 2 3.174E-10 -9.812E-05 OK 3 0 W_HPT=m_dot*(x*(h[11]-h[12])+y*(h[11]-h[13])+z*(h[11]-h[14])) 3 3.174E-10 -1.498E-04 OK 3 0 W_LPT=m_dot*(z*h[15]-m*h[16]-n*h[17]-b*h_brine[18]) 4 2.525E-09 2.291E-03 OK 3 0 Q_out=m_dot*(n*(h[17]-h[1])) 5 4.229E-14 1.705E-12 ? 3 16 T[2]=Temperature(Water,P=P[16],h=h[2]) 6 2.525E-09 5.329E-03 OK 3 0 Q_in=m_dot*(h[11]-h[10]+z*(h[15]-h[14])) 7 3.786E-11 3.905E-07 OK 3 0 W_total_pump=W_p1+W_p2+W_p3 8 2.525E-09 1.946E-03 OK 3 0 W_net=W_LPT+W_HPT-W_p1-W_p2-W_p3 9 4.218E-14 1.540E-12 OK 3 0 Eta_sys_new=(W_net/q_in)*100 10 3.786E-11 2.479E-06 OK 3 0 H_C[2]=m_dot*n*h[2] 11 2.525E-09 1.526E-03 OK 3 0 H_C[4]=m_dot*h[4] 12 3.174E-10 -8.958E-05 OK 3 0 H_C[5]=m_dot*(x+y)*h[5] 13 3.174E-10 -8.958E-05 OK 3 0 H_C[6]=m_dot*(x+y)*h[6] 14 2.525E-09 2.010E-03 OK 3 0 H_C[7]=m_dot*h[7] 15 3.174E-10 -3.758E-05 OK 3 0 H_C[8]=m_dot*(x)*h[8]

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 9EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

16 3.174E-10 -3.758E-05 OK 3 0 H_C[9]=m_dot*(x)*h[9] 17 2.525E-09 2.349E-03 OK 3 0 H_C[10]=m_dot*h[10] 18 3.174E-10 -1.216E-04 OK 3 0 H_C[12]=m_dot*x*h[12] 19 2.525E-09 1.358E-03 OK 3 0 H_C[13]=m_dot*(y)*h[13] 20 2.525E-09 4.001E-03 OK 3 0 H_C[14]=m_dot*(z)*h[14] 21 2.525E-09 4.572E-03 OK 3 0 H_C[15]=m_dot*(z)*h[15] 22 3.174E-10 -6.544E-05 OK 3 0 H_C[16]=m_dot*(m)*h[16] 23 2.525E-09 2.456E-03 OK 3 0 H_C[17]=m_dot*(n)*h[17]

Parametric Table: overall viwe b T10 Ksys,new Wnet T3 hnew,3 x y z n

Run 1 0 266 36.82 777195 175.4 742.9 0.1523 0.2144 0.6333 0.5428 Run 2 0.01 266 36.78 776298 175.4 742.9 0.1523 0.2144 0.6333 0.5345 Run 3 0.02 266 36.73 775400 175.4 742.9 0.1523 0.2144 0.6333 0.5262 Run 4 0.03 266 36.69 774502 175.4 742.9 0.1523 0.2144 0.6333 0.5179 Run 5 0.04 266 36.65 773605 175.4 742.9 0.1523 0.2144 0.6333 0.5095 Run 6 0.05 266 36.61 772707 175.4 742.9 0.1523 0.2144 0.6333 0.5012 Run 7 0.06 266 36.56 771810 175.4 742.9 0.1523 0.2144 0.6333 0.4929 Run 8 0.07 266 36.52 770912 175.4 742.9 0.1523 0.2144 0.6333 0.4846 Run 9 0.08 266 36.48 770014 175.4 742.9 0.1523 0.2144 0.6333 0.4763 Run 10 0.09 266 36.44 769117 175.4 742.9 0.1523 0.2144 0.6333 0.468 Run 11 0.1 266 36.39 768219 175.4 742.9 0.1523 0.2144 0.6333 0.4597 Run 12 0.11 266 36.35 767321 175.4 742.9 0.1523 0.2144 0.6333 0.4514 Run 13 0.12 266 36.31 766424 175.4 742.9 0.1523 0.2144 0.6333 0.4431 Run 14 0.13 266 36.27 765526 175.4 742.9 0.1523 0.2144 0.6333 0.4347 Run 15 0.14 266 36.22 764629 175.4 742.9 0.1523 0.2144 0.6333 0.4264 Run 16 0.15 266 36.18 763731 175.4 742.9 0.1523 0.2144 0.6333 0.4181 Run 17 0.16 266 36.14 762833 175.4 742.9 0.1523 0.2144 0.6333 0.4098 Run 18 0.17 266 36.1 761936 175.4 742.9 0.1523 0.2144 0.6333 0.4015 Run 19 0.18 266 36.05 761038 175.4 742.9 0.1523 0.2144 0.6333 0.3932 Run 20 0.19 266 36.01 760140 175.4 742.9 0.1523 0.2144 0.6333 0.3849 Run 21 0.2 266 35.97 759243 175.4 742.9 0.1523 0.2144 0.6333 0.3766 Run 22 0.21 266 35.93 758345 175.4 742.9 0.1523 0.2144 0.6333 0.3683 Run 23 0.22 266 35.88 757448 175.4 742.9 0.1523 0.2144 0.6333 0.36 Run 24 0.23 266 35.84 756550 175.4 742.9 0.1523 0.2144 0.6333 0.3516 Run 25 0.24 266 35.8 755652 175.4 742.9 0.1523 0.2144 0.6333 0.3433 Run 26 0.25 266 35.76 754755 175.4 742.9 0.1523 0.2144 0.6333 0.335 Run 27 0.26 266 35.71 753857 175.4 742.9 0.1523 0.2144 0.6333 0.3267 Run 28 0.27 266 35.67 752959 175.4 742.9 0.1523 0.2144 0.6333 0.3184 Run 29 0.28 266 35.63 752062 175.4 742.9 0.1523 0.2144 0.6333 0.3101 Run 30 0.29 266 35.59 751164 175.4 742.9 0.1523 0.2144 0.6333 0.3018 Run 31 0.3 266 35.54 750267 175.4 742.9 0.1523 0.2144 0.6333 0.2935 Run 32 0.31 266 35.5 749369 175.4 742.9 0.1523 0.2144 0.6333 0.2852 Run 33 0.32 266 35.46 748471 175.4 742.9 0.1523 0.2144 0.6333 0.2769 Run 34 0.33 266 35.42 747574 175.4 742.9 0.1523 0.2144 0.6333 0.2685 Run 35 0.34 266 35.37 746676 175.4 742.9 0.1523 0.2144 0.6333 0.2602

Parametric Table: overall viwe m

Run 1 0.0905 Run 2 0.08881 Run 3 0.08712 Run 4 0.08543 Run 5 0.08374 Run 6 0.08205

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 10EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Parametric Table: overall viwe m

Run 7 0.08036 Run 8 0.07867 Run 9 0.07698 Run 10 0.07529 Run 11 0.0736 Run 12 0.07191 Run 13 0.07022 Run 14 0.06853 Run 15 0.06684 Run 16 0.06515 Run 17 0.06346 Run 18 0.06177 Run 19 0.06008 Run 20 0.05839 Run 21 0.0567 Run 22 0.05501 Run 23 0.05332 Run 24 0.05163 Run 25 0.04994 Run 26 0.04825 Run 27 0.04656 Run 28 0.04487 Run 29 0.04318 Run 30 0.04149 Run 31 0.0398 Run 32 0.03811 Run 33 0.03642 Run 34 0.03473 Run 35 0.03304

Parametric Table: O.P for P_12P12 Ksys,new Wnet x z y m n

Run 1 5000 31.71 596780 0.4112 0.4441 0.1447 0.04252 0.4016 Run 2 4500 33.04 635627 0.3552 0.4801 0.1647 0.05165 0.4285 Run 3 4000 34.21 673348 0.301 0.5171 0.1819 0.06104 0.4561 Run 4 3500 35.25 710418 0.2479 0.5559 0.1962 0.07088 0.485 Run 5 3000 36.17 747347 0.195 0.5973 0.2076 0.08139 0.516 Run 6 2500 36.97 784749 0.1415 0.6428 0.2158 0.09291 0.5499

Parametric Table: O.P for P_13P13 Ksys,new Wnet x z y m n

Run 1 2000 36.88 796997 0.2084 0.6563 0.1353 0.09147 0.4923 Run 2 1900 37.01 803773 0.2123 0.6664 0.1213 0.09493 0.4989 Run 3 1800 37.14 810485 0.2163 0.6766 0.1071 0.09839 0.5057 Run 4 1700 37.25 817126 0.2205 0.687 0.09246 0.1019 0.5126 Run 5 1600 37.35 823694 0.2249 0.6976 0.07744 0.1054 0.5198 Run 6 1500 37.44 830179 0.2295 0.7085 0.06195 0.1089 0.5271 Run 7 1400 37.51 836574 0.2343 0.7197 0.04595 0.1124 0.5348 Run 8 1300 37.57 842866 0.2394 0.7312 0.02936 0.116 0.5427

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 11EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Parametric Table: O.P for P_reheat Preheat rat Ksys,new Wnet x z y m n

Run 1 7000 0.5833 36.19 711192 0.1523 0.6333 0.2144 0.09917 0.5341 Run 2 6500 0.5417 36.29 717390 0.1523 0.6333 0.2144 0.09855 0.5347 Run 3 6000 0.5 36.38 723769 0.1523 0.6333 0.2144 0.09789 0.5354 Run 4 5500 0.4583 36.47 730346 0.1523 0.6333 0.2144 0.09717 0.5361 Run 5 5000 0.4167 36.55 737145 0.1523 0.6333 0.2144 0.09639 0.5369 Run 6 4500 0.375 36.63 744192 0.1523 0.6333 0.2144 0.09554 0.5377 Run 7 4000 0.3333 36.7 751514 0.1523 0.6333 0.2144 0.09459 0.5387 Run 8 3500 0.2917 36.76 759146 0.1523 0.6333 0.2144 0.09351 0.5398 Run 9 3000 0.25 36.8 767122 0.1523 0.6333 0.2144 0.09228 0.541 Run 10 2500 0.2083 36.82 775477 0.1523 0.6333 0.2144 0.09083 0.5425 Run 11 2400 0.2 36.82 777195 0.1523 0.6333 0.2144 0.0905 0.5428 Run 12 2000 0.1667 36.8 784222 0.1523 0.6333 0.2144 0.08905 0.5442

Parametric Table: P_brinePbrine,18 hbrine,18 b Wnet Ksys,new T3 Qdesel T10

Run 1 1200 2784 0.1 768577 36.41 175.4 158834 266 Run 2 1100 2781 0.1 768475 36.41 175.4 159971 266 Run 3 1000 2778 0.1 768385 36.4 175.4 161169 266 Run 4 900 2774 0.1 768310 36.4 175.4 162439 266 Run 5 800 2769 0.1 768253 36.4 175.4 163796 266 Run 6 700 2763 0.1 768219 36.39 175.4 165261 266 Run 7 600 2757 0.1 768216 36.39 175.4 166863 266 Run 8 500 2749 0.1 768255 36.4 175.4 168643 266 Run 9 400 2739 0.1 768355 36.4 175.4 170674 266 Run 10 300 2725 0.1 768551 36.41 175.4 173079 266 Run 11 200 2707 0.1 768919 36.43 175.4 176124 266 Run 12 100 2675 0.1 769698 36.46 175.4 180598 266

Parametric Table: 1234b T10 Ksys,new Wnet T3 hnew,3 x y z n

Run 1 0 263.4 37.14 822747 179.9 762.9 0.2505 0.04243 0.7071 0.586 Run 2 0.01 263.4 37.13 822602 179.9 762.9 0.2505 0.04243 0.7071 0.5776 Run 3 0.02 263.4 37.12 822456 179.9 762.9 0.2505 0.04243 0.7071 0.5692 Run 4 0.03 263.4 37.12 822311 179.9 762.9 0.2505 0.04243 0.7071 0.5608 Run 5 0.04 263.4 37.11 822165 179.9 762.9 0.2505 0.04243 0.7071 0.5524 Run 6 0.05 263.4 37.1 822019 179.9 762.9 0.2505 0.04243 0.7071 0.5439 Run 7 0.06 263.4 37.1 821874 179.9 762.9 0.2505 0.04243 0.7071 0.5355 Run 8 0.07 263.4 37.09 821728 179.9 762.9 0.2505 0.04243 0.7071 0.5271 Run 9 0.08 263.4 37.08 821583 179.9 762.9 0.2505 0.04243 0.7071 0.5187 Run 10 0.09 263.4 37.08 821437 179.9 762.9 0.2505 0.04243 0.7071 0.5103 Run 11 0.1 263.4 37.07 821291 179.9 762.9 0.2505 0.04243 0.7071 0.5018 Run 12 0.11 263.4 37.06 821146 179.9 762.9 0.2505 0.04243 0.7071 0.4934 Run 13 0.12 263.4 37.06 821000 179.9 762.9 0.2505 0.04243 0.7071 0.485 Run 14 0.13 263.4 37.05 820854 179.9 762.9 0.2505 0.04243 0.7071 0.4766 Run 15 0.14 263.4 37.04 820709 179.9 762.9 0.2505 0.04243 0.7071 0.4682 Run 16 0.15 263.4 37.04 820563 179.9 762.9 0.2505 0.04243 0.7071 0.4598 Run 17 0.16 263.4 37.03 820418 179.9 762.9 0.2505 0.04243 0.7071 0.4513 Run 18 0.17 263.4 37.02 820272 179.9 762.9 0.2505 0.04243 0.7071 0.4429 Run 19 0.18 263.4 37.02 820126 179.9 762.9 0.2505 0.04243 0.7071 0.4345 Run 20 0.19 263.4 37.01 819981 179.9 762.9 0.2505 0.04243 0.7071 0.4261

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 12EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Parametric Table: 1234m

Run 1 0.1211 Run 2 0.1195 Run 3 0.1179 Run 4 0.1163 Run 5 0.1147 Run 6 0.1132 Run 7 0.1116 Run 8 0.11 Run 9 0.1084 Run 10 0.1068 Run 11 0.1053 Run 12 0.1037 Run 13 0.1021 Run 14 0.1005 Run 15 0.09893 Run 16 0.09735 Run 17 0.09576 Run 18 0.09418 Run 19 0.0926 Run 20 0.09102

0.1 0.2 0.3 0.4 0.5 0.636

36.5

37

Preheat/P,boiler

K sys

,new

File:powerplant6 with optimum presuure.EES 4/25/2016 9:34:26 PM Page 13EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

0 0.05 0.1 0.15 0.2 0.25 0.3 0.3535

35.5

36

36.5

37

37.5

38

b

K sys

,new

0 200 400 600 800 1000 120036.3

36.4

36.5

Pbrine[18]

K sys

,new

ME412|BalancingofwaterVSElectricitygeneration(Rankine-MSF)

36

AppendixB:

File:C:\Users\Ali Alkathiri\Desktop\SDP\Final\MSF_32 (1).EES 4/25/2016 9:26:31 PM Page 1EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Inputs

Md = 378.8 Total Distillate Flow Rate

n = 42 Total Number of Stages

Tf = 25 [C] Feed Seawater Temperature

To = 160 [C] Top Brine Temperature

Tsteam = 170 [C] Steam Temperature

Tn = 40 [C] Brine Temperature In Last Stage

Xf = 42000 [ppm] Salinity of Feed Seawater

Cp = Cp water , T = Tf , x = 0 Heat Capacity of Liquid Streams

Cd = 0.5 Weir Friction Cofficient

Vvn = 6 [m/s] Vapor Velocity in the last Stage

Vb = 180 [Kg/ms] Brine Mass Flow Rate Per Stage Width

Temprutres Calcution

Tavg = To + Tn

2 Avrege Temperature of Brine Seawater

hfg,av = Enthalpyvaporization SteamIAPWS , T = Tavg Heat Transfer Coefficient of Braine at Avrege Temperature

hfg,steam = Enthalpyvaporization SteamIAPWS , T = Tsteam Heat Transfer Coefficient of steam at Steam Temperature

'T = To – Tn

n The Temperature Drop Per Stage

Ti = To – 'T Temperature at i Stage

Tii,DELTA,T = To – 'T · i for i = 1 to n

T1 = Tf + n · 'T Seawater Temperature leavs the first stage of the condenser

T2 = T1 – 'T Seawater Temperature leavs the second stage of the condenser

[ i = Tf + n – i – 1 · 'T for i = 1 to n xi=Ti

flow rate

for first stage

y = Cp · 'T

hfg,avspecific ratio of Sensible Heat

Md = Mf · 1 – 1 – y n

Mb = Mf – Md Rejected Brine Mass Flow Rate

Xf · Mf = Xb · Mb X is Salt Concentration

File:C:\Users\Ali Alkathiri\Desktop\SDP\Final\MSF_32 (1).EES 4/25/2016 9:26:31 PM Page 2EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Msteam = Mf · Cp · To – T1

hfg,steamSteam Flow Rate

Heat transfer Area

Ab = Msteam · hfg,steam

Ub · Tlmtd,bArea of Brine Preheater

Ub = 1.7194 + 3.2063 · 10 – 3 · Tsteam + 1.5971 · 10 – 5 · Tsteam2 – 1.9918 · 10 – 7 · Tsteam

3

Tlmtd,b = Tsteam – To – Tsteam – T1

ln Tsteam – To

Tsteam – T1

Logarithmic Mean Temperature

Ac = Mf · Cp · T1 – T2

Uc · Tlmtd,cArea of Condenser

Uc = 1.7194 + 3.2063 · 10 – 3 · Tv,1 + 1.5971 · 10 – 5 · Tv,12 – 1.9918 · 10 – 7 · Tv,1

3

Tv,1 = Ti – BPE1 – NEA1 – 'T1 Vapor Temperature

BPE1 = X1 · B + X1 · C · 10 – 3 Boiling Point Elevation

X1 = Mf · Xf

B1

B1 = Mf – D1

D1 = y · Mf Amount of Flashing Vapor Formed in First Stage

B = 6.71 + 6.34 · 10 – 2 · Ti + 9.74 · 10 – 5 · Ti2 · 10 – 3

C = 22.238 + 9.59 · 10 – 3 · Ti + 9.42 · 10 – 5 · Ti2 · 10 – 8

NEA1 = 0.9784 T o · 15.7378 H 1 · 1.3777V b · 10 – 6

Non-Equilibrium Allawnce

'T1 = 0

Tlmtd,c = Tv,1 – T1 – Tv,1 – T2

ln Tv,1 – T1

Tv,1 – T2

A = n · Ac + Ab

Dii = Mf · 1 – 1 – y i for i = 1 to n Md in each stage + all stages before

Mb,i = Mf – Mf · 1 – 1 – y i for i = 1 to n R = Mb

Xi = Mf · Xf

Bi for i = 1 to n

Bi = Mf – Dii for i = 1 to n

stage Diamentions

GH1 = Mf · 2 · 'bi · 'Pi

– 0.5

Cd · WGate Height

'bi = 1002

File:C:\Users\Ali Alkathiri\Desktop\SDP\Final\MSF_32 (1).EES 4/25/2016 9:26:31 PM Page 3EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

'Pi = 10490 Presure in each Stage

GH : gate heightdP : stage pressure drop db : brine densityCd : weir friction coeff.W : stage width

H1 = 0.2 + GH1

W = Mf

VbWidth of the Stage

PR = Md

MsteamPerformance

Q = Msteam · hfg,steam

Msteam = 800 · bex Bex : the extraxtion fraction of mass flow rate

SOLUTIONUnit Settings: SI C kPa kJ mass degA = 46290 [m2] Ab = 4156 [m2]Ac = 1003 [m2] B = 0.01908 BPE1 = 1.27 [C] B1 = 1885 [Kg/s]bex = 0.07253 C = 2.607E-07 Cd = 0.5 Cp = 4.183 [Kj/Kg-C]'bi = 1002 'Pi = 10490 'T = 2.857 [C] 'T1 = 0 [C]D1 = 10.04 [Kg/s] GH1 = 0.07852 [m]H1 = 0.2785 [m] hfg,av = 2256 [Kj/Kg]hfg,steam = 2049 [Kj/Kg] Mb = 1516 [Kg/s]Md = 378.8 [Kg/s] Mf = 1895 [Kg/s]Msteam = 58.03 [Kg/s] n = 42 NEA1 = 0.06547 [C] PR = 6.528 Q = 118885 T1 = 145 [C]T2 = 142.1 [C] Tavg = 100 [C]Tf = 25 [C] Ti = 157.1 [C]Tlmtd,b = 16.37 [C] Tlmtd,c = 12.18 [C]Tn = 40 [C] To = 160 [C]Tsteam = 170 [C] Tv,1 = 155.8 [C]Ub = 1.747 [Kw/m2-C] Uc = 1.853 [Kw/m2-C]Vb = 180 [Kg/ms] Vvn = 6 [m/s]W = 10.53 [m] X1 = 42224 Xb = 52496 [ppm] Xf = 42000 [ppm]y = 0.005297

264 potential unit problems were detected.

Arrays Table: Main[i Dii Bi Xi Mb,i Tii,3

1 145 10.04 1885 42224 1885 157.1 2 142.1 20.02 1875 42449 1875 154.3 3 139.3 29.95 1865 42675 1865 151.4

File:C:\Users\Ali Alkathiri\Desktop\SDP\Final\MSF_32 (1).EES 4/25/2016 9:26:31 PM Page 4EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

Arrays Table: Main[i Dii Bi Xi Mb,i Tii,3

4 136.4 39.82 1855 42902 1855 148.6 5 133.6 49.65 1845 43130 1845 145.7 6 130.7 59.42 1835 43360 1835 142.9 7 127.9 69.14 1825 43591 1825 140 8 125 78.81 1816 43823 1816 137.1 9 122.1 88.43 1806 44056 1806 134.3 10 119.3 98 1797 44291 1797 131.4 11 116.4 107.5 1787 44527 1787 128.6 12 113.6 117 1778 44764 1778 125.7 13 110.7 126.4 1768 45002 1768 122.9 14 107.9 135.8 1759 45242 1759 120 15 105 145.1 1749 45483 1749 117.1 16 102.1 154.3 1740 45725 1740 114.3 17 99.29 163.6 1731 45969 1731 111.4 18 96.43 172.7 1722 46213 1722 108.6 19 93.57 181.9 1713 46460 1713 105.7 20 90.71 190.9 1704 46707 1704 102.9 21 87.86 200 1695 46956 1695 100 22 85 208.9 1686 47206 1686 97.14 23 82.14 217.9 1677 47457 1677 94.29 24 79.29 226.7 1668 47710 1668 91.43 25 76.43 235.6 1659 47964 1659 88.57 26 73.57 244.4 1650 48219 1650 85.71 27 70.71 253.1 1641 48476 1641 82.86 28 67.86 261.8 1633 48734 1633 80 29 65 270.4 1624 48994 1624 77.14 30 62.14 279 1616 49255 1616 74.29 31 59.29 287.6 1607 49517 1607 71.43 32 56.43 296.1 1598 49781 1598 68.57 33 53.57 304.6 1590 50046 1590 65.71 34 50.71 313 1582 50312 1582 62.86 35 47.86 321.4 1573 50580 1573 60 36 45 329.7 1565 50850 1565 57.14 37 42.14 338 1557 51120 1557 54.29 38 39.29 346.3 1548 51393 1548 51.43 39 36.43 354.5 1540 51666 1540 48.57 40 33.57 362.6 1532 51941 1532 45.71 41 30.71 370.7 1524 52218 1524 42.86 42 27.86 378.8 1516 52496 1516 40

There are a total of 299 equations in the Main program.Block Rel. Res. Abs. Res. Units Calls Time(ms) Equations 0 0.000E+00 0.000E+00 OK 1 0 M_d=378.8 0 0.000E+00 0.000E+00 OK 1 0 n=42 0 0.000E+00 0.000E+00 OK 1 0 T_f=25[C] 0 0.000E+00 0.000E+00 OK 1 0 T_o=160[C] 0 0.000E+00 0.000E+00 OK 1 0 T_steam=170[C] 0 0.000E+00 0.000E+00 OK 1 0 T_n=40[C] 0 0.000E+00 0.000E+00 OK 1 0 X_f=42000[ppm] 0 0.000E+00 0.000E+00 OK 1 0 C_d=0.5 0 0.000E+00 0.000E+00 OK 1 0 V_vn=6[m/s] 0 0.000E+00 0.000E+00 OK 1 0 V_b=180[Kg/ms] 0 0.000E+00 0.000E+00 OK 1 0 DELTA_T1=0 0 0.000E+00 0.000E+00 OK 1 0 DELTA_bi=1002 0 0.000E+00 0.000E+00 OK 1 0 DELTA_Pi=10490 0 0.000E+00 0.000E+00 OK 4 0 C_p=Cp(Water,T=T_f,x=0)

File:C:\Users\Ali Alkathiri\Desktop\SDP\Final\MSF_32 (1).EES 4/25/2016 9:26:31 PM Page 5EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals

0 0.000E+00 0.000E+00 OK 4 0 T_avg=(T_o+T_n)/2 0 0.000E+00 0.000E+00 OK 4 0 h_fg_av=Enthalpy_vaporization(Steam_IAPWS,T=T_avg) 0 0.000E+00 0.000E+00 OK 4 0 h_fg_steam=Enthalpy_vaporization(Steam_IAPWS,T=T_steam) 0 0.000E+00 0.000E+00 OK 4 0 DELTA_T=(T_o-T_n)/n 0 0.000E+00 0.000E+00 OK 4 0 T_i=T_o-DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 Ti[1,3]=T_o-DELTA_T*1 0 0.000E+00 0.000E+00 ? 4 0 Ti[2,3]=T_o-DELTA_T*2 0 0.000E+00 0.000E+00 ? 4 0 Ti[3,3]=T_o-DELTA_T*3 0 0.000E+00 0.000E+00 ? 4 0 Ti[4,3]=T_o-DELTA_T*4 0 0.000E+00 0.000E+00 ? 4 0 Ti[5,3]=T_o-DELTA_T*5 0 0.000E+00 0.000E+00 ? 4 0 Ti[6,3]=T_o-DELTA_T*6 0 0.000E+00 0.000E+00 ? 4 0 Ti[7,3]=T_o-DELTA_T*7 0 0.000E+00 0.000E+00 ? 4 0 Ti[8,3]=T_o-DELTA_T*8 0 0.000E+00 0.000E+00 ? 4 0 Ti[9,3]=T_o-DELTA_T*9 0 0.000E+00 0.000E+00 ? 4 0 Ti[10,3]=T_o-DELTA_T*10 0 0.000E+00 0.000E+00 ? 4 0 Ti[11,3]=T_o-DELTA_T*11 0 0.000E+00 0.000E+00 ? 4 0 Ti[12,3]=T_o-DELTA_T*12 0 0.000E+00 0.000E+00 ? 4 0 Ti[13,3]=T_o-DELTA_T*13 0 0.000E+00 0.000E+00 ? 4 0 Ti[14,3]=T_o-DELTA_T*14 0 0.000E+00 0.000E+00 ? 4 0 Ti[15,3]=T_o-DELTA_T*15 0 0.000E+00 0.000E+00 ? 4 0 Ti[16,3]=T_o-DELTA_T*16 0 0.000E+00 0.000E+00 ? 4 0 Ti[17,3]=T_o-DELTA_T*17 0 0.000E+00 0.000E+00 ? 4 0 Ti[18,3]=T_o-DELTA_T*18 0 0.000E+00 0.000E+00 ? 4 0 Ti[19,3]=T_o-DELTA_T*19 0 0.000E+00 0.000E+00 ? 4 0 Ti[20,3]=T_o-DELTA_T*20 0 0.000E+00 0.000E+00 ? 4 0 Ti[21,3]=T_o-DELTA_T*21 0 0.000E+00 0.000E+00 ? 4 0 Ti[22,3]=T_o-DELTA_T*22 0 0.000E+00 0.000E+00 ? 4 0 Ti[23,3]=T_o-DELTA_T*23 0 0.000E+00 0.000E+00 ? 4 0 Ti[24,3]=T_o-DELTA_T*24 0 0.000E+00 0.000E+00 ? 4 0 Ti[25,3]=T_o-DELTA_T*25 0 0.000E+00 0.000E+00 ? 4 0 Ti[26,3]=T_o-DELTA_T*26 0 0.000E+00 0.000E+00 ? 4 0 Ti[27,3]=T_o-DELTA_T*27 0 0.000E+00 0.000E+00 ? 4 0 Ti[28,3]=T_o-DELTA_T*28 0 0.000E+00 0.000E+00 ? 4 0 Ti[29,3]=T_o-DELTA_T*29 0 0.000E+00 0.000E+00 ? 4 0 Ti[30,3]=T_o-DELTA_T*30 0 0.000E+00 0.000E+00 ? 4 0 Ti[31,3]=T_o-DELTA_T*31 0 0.000E+00 0.000E+00 ? 4 0 Ti[32,3]=T_o-DELTA_T*32 0 0.000E+00 0.000E+00 ? 4 0 Ti[33,3]=T_o-DELTA_T*33 0 0.000E+00 0.000E+00 ? 4 0 Ti[34,3]=T_o-DELTA_T*34 0 0.000E+00 0.000E+00 ? 4 0 Ti[35,3]=T_o-DELTA_T*35 0 0.000E+00 0.000E+00 ? 4 0 Ti[36,3]=T_o-DELTA_T*36 0 0.000E+00 0.000E+00 ? 4 0 Ti[37,3]=T_o-DELTA_T*37 0 0.000E+00 0.000E+00 ? 4 0 Ti[38,3]=T_o-DELTA_T*38 0 0.000E+00 0.000E+00 ? 4 0 Ti[39,3]=T_o-DELTA_T*39 0 0.000E+00 0.000E+00 ? 4 0 Ti[40,3]=T_o-DELTA_T*40 0 0.000E+00 0.000E+00 ? 4 0 Ti[41,3]=T_o-DELTA_T*41 0 0.000E+00 0.000E+00 ? 4 0 Ti[42,3]=T_o-DELTA_T*42 0 0.000E+00 0.000E+00 OK 4 0 T_1=T_f+n*DELTA_T 0 0.000E+00 0.000E+00 OK 4 0 T_2=T_1-DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[1]=T_f+(n-(1-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[2]=T_f+(n-(2-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[3]=T_f+(n-(3-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[4]=T_f+(n-(4-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[5]=T_f+(n-(5-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[6]=T_f+(n-(6-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[7]=T_f+(n-(7-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[8]=T_f+(n-(8-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[9]=T_f+(n-(9-1))*DELTA_T 0 0.000E+00 0.000E+00 ? 4 0 xi[10]=T_f+(n-(10-1))*DELTA_T

File:C:\Users\Ali Alkathiri\Desktop\SDP\Final\MSF_32 (1).EES 4/25/2016 9:26:31 PM Page 6EES Ver. 9.901: #1696: Department of Mechanical Engineering King Fahd University Petroleum and Minerals