Final Rate Analysis

-

Upload

sanjeev-shah -

Category

Documents

-

view

296 -

download

3

Transcript of Final Rate Analysis

ANALYSIS- The analysis has been presented in 16 nos. of spread sheets Worksheet- 1 : CHAPTER-1 CARRIAGE OF MATERIALSWorksheet- 2 : CHAPTER-2 SITE CLEARANCEWorksheet- 3 : CHAPTER-3 EARTH WORK, EROSION CONTROL AND DRAINAGEWorksheet- 4 : CHAPTER-4 SUB-BASES, BASES (NON- BITUMINOUS) AND SHOULDERSWorksheet- 5 : CHAPTER-5 BASES AND SURFACE COURSES (BITUMINOUS)Worksheet- 6 : CHAPTER-6 CEMENT CONCRETE PAVEMENTS Worksheet- 7 : CHAPTER-7 GEOSYNTHETICS AND REINFORCED EARTHWorksheet- 8 : CHAPTER-8 TRAFFIC SIGNS, MARKINGS & OTHER ROAD APPURTENANCESWorksheet- 9 : CHAPTER-9 PIPE CULVERTS Worksheet- 10 : CHAPTER-10 MAINTENANCE OF ROADSWorksheet- 11 : CHAPTER-11 HORTICULTUREWorksheet- 12 : CHAPTER-12 FOUNDATIONSWorksheet- 13 : CHAPTER-13 SUB-STRUCTUREWorksheet- 14 : CHAPTER-14 SUPER-STRUCTUREWorksheet- 15 : CHAPTER-15 RIVER TRAINING AND PROTECTION WORKSWorksheet- 16 : CHAPTER-16 REPAIR AND REHABILITATION

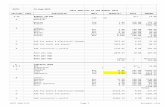

Name of the road materials Name of the quarry Lead in kms Cost of Carriage Basic cost Royalty

Dedn. for VAT @

4%

Other dedn. I.e. empty bags,

drumsTotal

Good laterite moorum Local 5.00 85.00 45.00 10.00 140.00

GSB Material 26.00 190.00 45.00 10.00 245.00

H.G. Stone (0.0015 - 0.003 cm) Bargaon/Adhamunda 9.00 105.00 148.00 36.00 289.00

30cm. and above size H.G. stone Bargaon/Adhamunda 9.00 105.00 148.00 36.00 289.00

Good course sand ( Filling ) Tel river 10.00 110.00 25.00 10.00 145.00

Good course sand ( Mortar ) Tel river 10.00 110.00 29.00 10.00 149.00

Cement. 43 grade Bhawanipatna 35.00 240.00 4160.00 4400.00

Steel Bhawanipatna 35.00 240.00 29662.00 29902.00

Emulision (SS-1) Vizag 491.00 2079.00 13166.00 15245.00

Bitumen S-65 (60/70) Vizag 491.00 2079.00 18449.00 20528.00

CRMB-55 Vizag 491.00 2079.00 18907.00 20986.00

Emulision (RS-1) Vizag 491.00 2079.00 13312.00 15391.00

Hume pipes (350 dia) Bhawanipatna 35.00 99.67 576.43 676.10

Hume pipes (450 dia) Bhawanipatna 35.00 99.67 724.22 823.89

Hume pipes (600 dia) Bhawanipatna 35.00 99.67 1026.99 1126.66

Hume pipes (750 dia) Bhawanipatna 35.00 149.50 1515.54 1665.04

Hume pipes (900 dia) Bhawanipatna 35.00 149.50 2032.61 2182.11

Hume pipes (1000 dia) Bhawanipatna 35.00 299.00 2505.09 2804.09

Hume pipes (1200 dia) Bhawanipatna 35.00 299.00 3434.71 3733.71

Bricks(WBCB)(25x12x8cm) Local 5.00 291.50 1568.00 1859.50

Enamel Paint Bhawanipatna 35.00 0.24 132.00 132.24

Angle Rod Bhawanipatna 35.00 0.17 30.64 30.81

Drainage pipe Bhawanipatna 35.00 240.00 350 590.00

Granite Spall Bargaon/Adhamunda 9.00 105.00 148 36.00 289.00

L E A D S T A T E M E N T

P&M-001 Air Compressor capacity in cum 170/250 hour 206

P&M-002 Batching and Mixing Plant (a) 30 cum capacity cum/hour 20 hour 1440

P&M-003 Batching and Mixing Plant (b) 15 - 20 cum capacity cum/hour 13 hour 1200

P&M-004 Bitumen Pressure Distributor sqm/hour 1750 hour 692

P&M-005 Bitumen Boiler oil fired capacity in litre 1500 hour 128

P&M-006 Concrete Paver Finisher with 40 HP Motor cum / hour 20 hour 1850

P&M-007 Concrete Pump of 45 & 30 cum capacity cum / hour 33 / 22 hour 165

P&M-008 Concrete Bucket capacity in cum 1 hour 10

P&M-009 Concrete Mixer (a) 0.4/0.28 cum cum/hour 2.5 hour 161

P&M-010 Concrete Mixer (b) 1 cum cum/hour 7.5 hour 161

P&M-011 Crane (a) 80 tonnes hour 825

P&M-012 Cranes (b) 35 tonnes hour 550

P&M-013 Cranes (c) 3 tonnes hour 230

P&M-014 Dozer D - 80 - A 12 cum/hour 300/ 150/250 hour 2190

P&M-015 Dozer D - 50 - A 15 cum/hour 200/ 100/150 hour 1592

P&M-016 Emulsion Pressure Distributor sqm/hour 1750 hour 516

P&M-017 Front End loader 1 cum bucket capacity cum/hour 60 /25 hour 520

P&M-018 Generator (a) 100/125 KVA KVA 100 hour 450

P&M-019 Generator( b) 33/63 KVA KVA 50 hour 240

P&M-020 GSB Plant 50 cum cum/hour 40 hour 670

P&M-021 Hotmix Plant - 120 TPH capacity cum/hour 40 hour 15100

P&M-022 Hotmix Plant - 100 TPH capacity cum/hour 30 hour 11167

P&M-023 Hotmix Plant - 60 to 90 TPH capacity cum/hour 25 hour 8930

P&M-024 Hotmix Plant - 40 to 60 TPH capacity cum/hour 17 hour 7150

P&M-025 Hydraulic Chip Spreader sqm/hour 1500 hour 1700

P&M-026 Hydraulic Excavator of 1 cum bucket cum/hour 60 /60 /60 hour 840

P&M-027 Integrated Stone Crusher 100THP TPH 100 hour 5590

P&M-028 Integrated Stone Crusher 200 HP TPH 200 hour 11760

P&M-029 Kerb Casting Machine Rm/hour 80 hour 200

P&M-030 Mastic Cooker capacity in tonne 1 hour 1442

P&M-031 Mechanical Broom Hydraulic sqm/hour 1250 hour 230

P&M-032 Motor Grader 3.35 mtr blade cum/hour 200/200/50/50 hour 1545

P&M-033 Mobile slurry seal equipment sqm/hour 2700 hour 650

P&M-034 Paver Finisher Hydrostatic with sensor control 100 TPH cum/hour 40 hour 1725

P&M-035 Paver Finisher Mechanical 100 TPH cum/hour 40/30 hour 739

P&M-036 Piling Rig with Bantonite Pump Rm/hour 2 to 3 hour 3525

P&M-037 Pneumatic Road Roller cum/hour 25 hour 802

P&M-038 Pneumatic Sinking Plant cum/hour 1.5 to 2.00 hour 2690

P&M-039 Pot Hole Repair Machine cum/hour 4 hour 585

P&M-040 Prestressing Jack with Pump & access hour 83

P&M-041 Ripper cum/hour 60 hour 18

P&M-042 Rotavator cum/hour 25 hour 11

P&M-043 Road marking machine Sqm/hour 100 hour 60

P&M-044 Smooth Wheeled Roller 8 tonne cum/hour 70/25 hour 269

Concrete Mixing

General Purpose

Paving of concrete surface

Bitumen Spraying

Applying bitumen tack coat

Concrete Mixing

Concrete Mixing

Concrete Mixing

For Pouring concrete

Pumping of concrete

Spreading /Cutting / Clearing

Lifting Purpose

Lifting Purpose

Lifting Purpose

Genration of electric Energy

Soil loading / Aggregate loading

Applying emulsion tack coat

Spreading /Cutting / Clearing

DBM/BM/SDC/ Premix

DBM/BM/SDC/ Premix

Producing GSB

Genration of electric Energy

Soil Ordinary/Soil Marshy / Soil Unsuitable

Surface Dressing

DBM/BM/SDC/ Premix

DBM/BM/SDC/ Premix

Mastic Wearing coat

Kerb Making

Crushing of Spalls

Crushing of Spalls

Paving of DBM/ BM/SDC/ Premix

Mixing and laying slurry seal

Clearing /Spreading /GSB /WBM

Surface Cleaning

Pneumatic Sinking of wells

Rolling of Asphalt Surface

0.75 m dia to 1.2 m dia Boring attachment

Paving of WMM /Paving of DLC

Scarifying

Scarifying

Stressing of steel wires/stands

Repair of potholes

Soil Compaction /BM Compaction

Road marking

(A) Usage Rates of Plant and Machinery

Sl. No. Description of Machine Rate Activity Output of Machine Output Unit

P&M-045 Tandem Road Roller cum/hour 30 hour 738

P&M-046 Tipper - 5 cum Capacity in cum 5.5 km 24

P&M-047 Tipper - 5 cum Capacity in cum 5.5 tonne.km 2

P&M-048 Tipper - 5 cum Capacity in cum 5.5 hour 506

P&M-049 Transit Mixer 4.0/4.5 cum cum/hour 4.5 hour 600

P&M-050 Transit Mixer 4/4.5 cum cum/hour 4.5 tonne.km 1.62

P&M-051 Transit Mixer 3.0 cum cum/hour 3 hour 550

P&M-052 Transit Mixer 3.0 cum cum/hour 3 tonne.km 1.46

P&M-053 Tractor capacity in HP 50 hour 231

P&M-054 Tractor with Rotevator hour 242

P&M-055 Tractor with Ripper hour 249

P&M-056 Truck 5.5 cum per 10 tonnes capacity/cum 4.5 km 20

P&M-057 Truck 5.5 cum per 10 tonnes capacity/cum 4.5 hour 506

P&M-058 Truck 5.5 cum per 10 tonnes capacity/cum 4.5 tonne.km 2

P&M-059 Vibratory Roller 8 tonne cum/hour 100/60/60 hour 994

P&M-060 Water Tanker capacity in KL 6 hour 506

P&M-061 Water Tanker capacity in KL 6 km 15.6

P&M-062 Wet Mix Plant 60 TPH cum/hour 25 hour 777

Sl. No. Unit Rate

P&M-063 hour 206

P&M-064 hour input

P&M-065 hour input

P&M-066 hour input

P&M-067 hour 5160

P&M-068 hour 2760

P&M-070 hour 230

P&M-075 hour 550

P&M-076 hour 500

P&M-078 hour 500

P&M-079 hour 240

P&M-080 hour 450

P&M-081 hour 1125

P&M-083 hour 300

P&M-085 hrs 3525

P&M-086 hour 100

P&M-088 hour 250

P&M-094 1036

P&M-095 Concrete Paver Finisher with 40 HP Motor cum / hour 175 hour 16188

Transportation of soil, GSB, WMM, Hotmix etc.

Rolling of Aspalt Surface

Transportation of Concrete Mix to site

Transportation of Concrete Mix to site

Transportation of soil, GSB, WMM, Hotmix etc.

Transportation of soil, GSB, WMM, Hotmix etc.

Rate of Tractor + Rotevator

Pulling

Transportation of Concrete Mix to site

Transportation of Concrete Mix to site

Material Transport

Material Transport

Material Transport

Rate of Tractor 6+ Ripper

Earth or soil / GSB / WBM

Air compressor with pneumatic chisel attachment for cutting hard clay.

Batch type cold mixing plant 100-120 TPH capacity producing an average output of 75 tonne per hour

Wet Mix

Description of Machine

Water Transport

Water Transport

Belt conveyor system

Boat to carry atleast 20 persons

Cement concrete batch mix plant @ 175 cum per hour (effective output)

Cement concrete batch mix plant @ 75 cum per hour

Crane 5 tonne capacity

Crane with grab 0.75 cum capacity

Compressor with guniting equipment along with accessories / shortcreteing equpiment

Epoxy Injection gun

Generator 33 KVA

Generator 100 KVA

Generator 250 KVA

Joint Cutting Machine with 2-3 blades (for rigid pavement)

Piling rig Including double acting pile driving hammer (Hydraulic rig)

Plate compactor

Texturing machine (for rigid pavement)

Wet Mix Plant 75 TPH

Paving of concrete surface

Sl. No. Unit Rate

L-01 day 90

L-02 day 100

L-03 day 100

L-04 day 100

L-05 day 100

L-06 day 100

L-07 day 185

L-08 day 90

L-09 day 90

L-10 day 90

L-11 day 100

L-12 day 80

L-13 day 70

L-14 day 90

L-15 day 100

L-18 day 100

M-001 cum 289.00

M-003 cum 289.00

M-004 cum 149.00

M-005 cum 149.00

M-006 cum 145.00

M-007 cum 140.00

M-008 Cum 289.00

M-009 Cum 140.00

M-012 Cum 609.00

Description

Filter media/Filter Material as per Table 300-3 (MoRT&H Specification)

Fitter

Painter I class

Mate / Supervisor

Mazdoor

Mazdoor/Dresser (Semi Skilled)

Mazdoor/Dresser/Sinker (Skilled)

Mali

Mason (IInd class)

Description of Labour

Mason (Ist class)

Chiseller (Head Mazdoor)

Driller (Jumper)

Diver

Blacksmith (IInd class)

Blacksmith (Ist class)/ Welder/ Plumber/ Electrician

Blaster (Stone cutter)

Carpenter I Class

(C) Materials

Sl. No. RateUnit

Stone Boulder of size 150 mm and below at Cruser Plant

Fine sand at Site

Moorum at Site

Gravel/Quarry spall at Site

Granular Material or hard murrum for GSB works at Site

Boulder with minimum size of 300 mm for Pitching at Site

Coarse sand at Mixing Plant

Coarse sand at Site

(B) Labour

UnitRate at Plant (HMP/Batchi

ng)Rate at Site

M-013 cum 561.50 561.50

M-014 cum 561.50 561.50

M-015 cum 587.50 587.50

M-016 cum 768.50 768.50

M-017 cum 768.50 768.50

M-018 cum 512.50 512.50

M-019 cum 512.50 512.50

M-020 cum 512.50 512.50

M-021 cum 395.85 395.85

M-022 cum 395.85 395.85

M-023 cum input 401.94

M-024 cum input 401.94

M-025 cum 609.00 609.00

M-026 cum 517.65 517.65

M-027 cum input 517.65

M-028 cum input 438.48

M-029 cum 414.12 414.12

M-030 cum 401.94 401.94

M-031 cum 517.65 517.65

M-032 cum 517.65 517.65

M-033 cum 438.48 438.48

M-034 cum 438.48 438.48

M-035 cum 414.12 414.12

M-036 cum 414.12 414.12

M-037 cum 408.03 408.03

M-038 cum 408.03 408.03

M-039 cum input 395.85

M-040 cum 468.93 468.93

M-041 cum 609.00 609.00

M-042 cum 609.00 609.00

M-043 cum 609.00 609.00

M-044 cum 609.00 609.00

M-045 cum 517.65 517.65

M-046 cum 517.65 517.65

M-047 cum input 517.65

M-048 cum input 438.48

M-049 cum 438.48 438.48

M-050 cum 468.93 468.93

M-051 cum 609.00 609.00

M-052 cum 609.00 609.00

M-053 cum 517.65 517.65

M-054 cum 517.65 517.65

M-055 cum 438.48 438.48

Stone crusher dust finer than 3mm with not more than 10% passing 0.075 sieve.

Description

Coarse graded Granular sub-base Material 2.36 mm & below

Coarse graded Granular sub-base Material 4.75 mm to 2.36 mm

Aggregates 20 mm nominal size

Aggregates 25 mm nominal size

Aggregates 40 mm nominal size

Aggregates 37.5 mm to 19 mm

Aggregates 19 mm to 6 mm

Aggregates 6 mm nominal size

Aggregates 10 mm nominal size

Aggregates 13.2/12.5 mm nominal size

Aggregates 37.5 mm to 25 mm

Close graded Granular sub-base Material 53 mm to 9.5 mm

Close graded Granular sub-base Material 26.5 mm to 9.5 mm

Close graded Granular sub-base Material 9.5 mm to 4.75 mm

Close graded Granular sub-base Material 9.5 mm to 2.36 mm

Close graded Granular sub-base Material 2.36 mm

Close graded Granular sub-base Material 4.75mm to 2.36 mm

Close graded Granular sub-base Material 4.75mm to 75 micron mm

Aggregates 25 mm to 10 mm

Aggregates 63 mm to 2.8 mm

Aggregates 13.2 mm to 10 mm

Aggregates 20 mm to 10 mm

Aggregates 13.2 mm to 5.6 mm

Aggregates 11.2 mm to 0.09 mm

Aggregates 13.2 mm to 0.09 mm

Aggregates 90 mm to 45 mm

Aggregates 63 mm to 45 mm

Aggregates 10 mm to 5 mm

Aggregates 22.4 mm to 5.6 mm

Aggregates 45 mm to 2.8 mm

Aggregates 53 mm to 2.8 mm

Coarse graded Granular sub-base Material 4.75mm to 75 micron mm

Coarse graded Granular sub-base Material 9.5 mm to 4.75 mm

Coarse graded Granular sub-base Material 26.5 mm to 9.5 mm

Coarse graded Granular sub-base Material 53 mm to 26 .5mm

Coarse graded Granular sub-base Material 26.5 mm to 4.75 mm

Close graded Granular sub-base Material 37.5 mm to 9.5 mm

Coarse graded Granular sub-base Material 37.5 mm to 9.5 mm

Aggregates 53 mm to 22.4 mm

Aggregates 45 mm to 22.4 mm

Aggregates 22.4 mm to 2.36 mm

Aggregates below 5.6 mm

Sl. No. Unit Rate

M-056 metre 60

M-058 litre 204

M-059 sqm 200

M-060 tonne 29902.00

M-061 sqm 6000

M-066 nos 23000

M-068 nos 120000

M-069 nos 30000

M-071 kg 2.06

M-072 kg 39

M-074 tonne 20528.00

M-075 tonne 20986.00

M-076 tonne 15245.00

M-077 tonne 15391.00

M-078 tonne 20986.00

M-079 each 1.86

M-080 kg 80

M-081 tonne 4400.00

M-082 tonne 29902.00

M-083 nos 1000

M-084 sqm 60

M-087 tonne 29902.00

M-089 cum 148

M-090 liter 20

M-091 each 600

M-092 cum 10

M-094 100 nos 1400

M-095 kg 200

M-097 kg 30

M-101 nos 10

M-103 kg 30.81

M-104 kg 100

M-110 nos 1.5

M-111 hour 230

M-118 litre 172

M-119 tonne 35000

M-120 kg 50

M-123 nos 4

M-124 kg 38

M-126 tonne 29902.00

M-130 kg 49

M-131 litre 132.24

M-132 litre 132.24

M-137 metre 590.00

Gelatin 80%

Binding wire

Epoxy compound with accessories for preparing epoxy mortar

AC pipe 100 mm dia

Compressible Fibre Board(20mm thick)

M.S. Clamps

Curing compound

Delineators from ISI certified firm as per the standard drawing given in IRC - 79

Electric Detonators @ 1 detonator for 1/2 gelatin stick of 125 gms each

Mild Steel bars

HTS strand

GI bolt 10 mm Dia

M.S. Clamps

Credit for excavated rock found suitable for use

Epoxy primer (Sealant Primer)

Brick(23X11X8Cm)

Bearing (PTFE sliding plate bearing assembly of 80 tonnes )

Bearing (Elastomeric bearing assembly consisting of 7 internal layers of elastomer bonded to 6 nos. internal reinforcing steel laminates by the process of vulcanisation,)

Bitumen (emulsion - SS1)

Bearing (Pot type bearing assembly consisting of a metal piston supported by a disc, PTFE pads providing sliding surfaces against stainless steel mating together with cast steel assemblies/fabricated structural steel assemblies duly painted with all components

Bitumen (emulsion-RS1)

Bentonite

C.I.shoes for the pile

Bitumen (60-70 grade)

Bitumen (modified graded)

CRMB-55

Cement

Cold twisted bars (HYSD Bars)

Galvanised structural steel plate 200 mm wide, 6 mm thick, 24 m long

Grouting pump with agitator

Joint Sealant Compound

Aluminium sheeting fixed with encapsulated lens type reflective sheeting including 2% towards lettering, cost of angle iron, cost of drilling holes, nuts, bolts etc.and signs as applicable

Aluminium alloy/galvanised steel

Pipes 200 mm dia, 2.5 m long for drainage

Coller for joints 300 mm dia

Earth Cost or compensation for earth taken from private land

Hot applied thermoplastic compound

Paint

Pavement Marking Paint

Aluminium alloy plate 2mm Thick

Description

Alluminium Paint

Corrosion resistant Structural steel

Galvanised MS flat clamp

Nuts and bolts

M-138 sqm 90

M-141 sqm 80.00

M-142 cum 4000.00

M-144 sqm 60.00

M-145 kg 200

M-147 kg 160

M-148 cum 289.00

M-149 metre 2804.09

M-150 metre 3733.71

M-151 metre 676.10

M-152 kg 200

M-159 nos 5.00

M-163 cum 140.00

M-164 sqm 3

M-165 metre 60

M-167 cum 50

M-169 cum 289.00

M-173 kg 120

M-174 metre input

M-175 metre 600

M-176 kg input

M-177 kg input

M-178 metre 8600

M-179 tonne 30640.00

M-180 kg 40

M-181 sqm 46

M-182 each 100

M-187 nos 322

M-188 tonne 11000

M-189 KL 10

M-190 litre 29

M-192 kg 52

Overheads for Road Works 8%

Contractors profit for Road Works 10%

Overheads for Bridge Works 20%

Overheads for Bridge Works (Rehabilitation) 30 %

Contractors profit for Bridge Works 10%

Lead from Mixing Plant to working site 17 km

Lead for E/W borrow area to site 5.00 km

Lead for fly ash from source to site input km

Pre-moulded asphalt filler board

Square Rubble Coursed Stone

Pre-packed cement based polymer concrete of strength 45 Mpa at 28 days

Unstaked lime

Through and bond stone

Sheathing duct

Steel wire rope 20 mm

Super plastisizer admixture IS marked as per 9103-1999

Synthetic Geogrids as per clause 3102.8 and approved design and specifications.

Structural Steel

Wire mesh 50mm x 50mm size of 3mm wire

Sludge / Farm yard manure @ 0.18 cum per 100 sqm at site of work for turfing

Separation Membrane of impermeable plastic sheeting 125 micron thick

Water

Water based cement paint

Tube anchorage set complete with bearing plate, permanent wedges etc

Strip seal expansion join

Steel wire rope 40 mm

Steel pipe 25 mm external dia as per IS:1239

Pre-coated stone chips of 13.2 mm nominal size

Random Rubble Stone

Quick setting compound

Reflectorising glass beads

RCC Pipe NP 4 heavy duty non presure pipe 1000 mm dia

Selected earth

Sand bags (Cost of sand and Empty cement bag)

RCC Pipe NP 4 heavy duty non presure pipe 1200 mm dia

Pre moulded Joint filler,25 mm thick for expansion joint.

RCC Pipe NP 4 heavy duty non presure pipe 300 mm dia

Plastic sheath, 1.25 mm thick for dowel bars

Steel pipe 50 mm external dia as per IS:1239

Steel helmet and cushion block on top of pile head during driving.

for input of Overheads or Contractors profit please type in collum C as like below

Type symble of apostrope(') then input value then one space then symble of percentage (%) for example '08 %

Items No. Unit Rate

Item 8.3 per cm height per letter 0.20

Item 8.8 sqm 32.00

Item 8.9 sqm 27.50

Item 12.6 (B) cum 3,162.00

Item 12.6 (A) cum 2,467.00

Item 12.6 (D) cum 1,512.00

Item 12.7 (A ) cum 2,698.80

Item 12.7 (Addl) B) cum 2,300.00

Item 12.8 (A) cum 2,715.70

Item 12.8 (A) cum 1,979.00

Item 12.8 (B) PCC cum 2,303.00

Item 12.8 (C) cum 2,362.50

Item 12.8 (C) RCC cum 3,266.60

Item 12.8 (C) cum 2,379.60

Item 12.8 (D) cum 2,546.30

Item 12.8 (D) cum 3,513.00

Item 12.8 (D) cum 2,565.30

Item 12.8 (E) cum 2,608.90

Item 12.8 (E) cum 2,626.00

Item 12.8 (F) cum 2,572.70

Item 12.8 (F) cum 2,589.10

Item 12.8 (G) cum 2,623.50

Item 12.8 (G) cum 2,641.40

Item 12.8 (H) cum 2,691.00

Item 12.8 (H) cum 2,859.60

Item 12.8 (H) cum 3,774.70

Item 12.8 (H) cum 2,776.40

Item 12.11 (C) i cum 2,559.10

Item 12.11 (C) i cum 2,529.70

Item 12.11 (C) ii cum 2,696.10

Item 12.11 (C) ii cum 2,665.30

Item 12.11 (C) iii cum 2,722.50

Item 12.11 (C) iii cum 2,693.10

Item 12.11 (C) iv cum 2,784.10

Item 12.11 (C) iv cum 3,798.00

Item 12.11 (C) iv cum 2,753.30

Item 12.11 (F) iv cum 3,682.90

Item No. 3.13 cum 69.60

Summary of Rates calculated and used for analysis of rates of other items

Excavation for Structures (Manual Means)

PCC Grade M35 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

PCC Grade M35 including OH & CP for Well Foundation (Bottom Plug) by Batching Plant

PCC Grade M35 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

PCC Grade M35 including OH & CP for Well Foundation (Well Cap) by Batching Plant

PCC Grade M25 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by MixerPCC Grade M25 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by Batching PlantPCC Grade M30 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by MixerPCC Grade M30 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

RCC Grade M35 excluding OH & CP for Open Foundation by Batching Plant

RCC Grade M35 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Batching PlantPCC Grade M20 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by MixerPCC Grade M20 for Open Foundation (Bottom Plug) Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

RCC Grade M30 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

RCC Grade M30 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

RCC Grade M35 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

RCC Grade M35 including OH & CP for Open Foundation by Batching Plant

RCC Grade M25 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

RCC Grade M25 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

PCC Grade M30 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

PCC Grade M30 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

RCC Grade M20 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

PCC Grade M25 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

PCC Grade M25 including OH & CP for Open Foundation by Batching Plant

PCC Grade M25 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Batching Plant

PCC Grade M15 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

PCC Grade M20 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

RCC Grade M20 for Open Foundation Per Cum Basic Cost of Labour, Material & Mechinery by Mixer

RCC Grade M20 including OH & CP for Open Foundation by Batching Plant

Cement mortor 1:3 (Excluding OH & CP)

Cement mortor 1:6 (Excluding OH & CP)

Random Rubble masonary in cement mortor 1:6 (including OH & CP)

PCC Grade M15 including OH & CP for Open Foundation by Mixer

Course Rubble masonary in cement mortor 1:3 (including OH & CP)

Printing new letter and figures of any shade (ii) English Roman

Painting Two Coats on New Concrete Surfaces

Painting angle iron post two coats

Cement mortor 1:2 (Excluding OH & CP)

Item No. 3.13 cum 22.30

Item 14.1(A) cum3,726.20

Item 14.1(B) cum4,134.90

Item 14.1(E) cum4,383.76

Item 14.1(C) cum3,170.80

Item 14.1(C) cum2,642.30

Item 14.2 A tonne 32,604.30

Item 13.6 tonne 29,902.00

Item 5.17 sqm 16.70

Item 5.15 Case-I sqm 27.50

Item 5.15 Case-II sqm 18.90

Item 5.15 Case-III sqm 12.10

Item 5.9 Case-I sqm 41.90

Item 5.9 Case-II sqm 35.60

Slurry Seal Case-II 3 mm thickness

Slurry Seal Case III 1.5 mm thickness

Surface Dressing Case-I 19 mm nominal chipping size

Surface Dressing Case-II 13 mm nominal size chipping

Slurry Seal Case-I 5 mm thickness

Supplying, fitting and placing HYSD including OH & CP for sub-structure

Fog Seal

RCC Grade M30 for super-structure excluding formwork and excluding OH & CP by Batching Plant

Supplying ,fitting and placing HYSD bar reinforcement in super-structure exncluding OH & CP

Excavation for Structures (Mechenical Meanse)

RCC Grade M20 for super-structure including OH & CP by Batching Plant

RCC Grade M20 for super-structure including OH & CP by Batching Plant

RCC Grade M20 for super-structure including OH & CP by Batching Plant

RCC Grade M30 for super-structure including formwork and excluding OH & CP by Batching Plant

Sr NoRef. to MoRTH Spec.

Description Unit Quantity Rate Rs Cost Rs Remarks/ Input ref.

1.1 Loading and unloading of stone boulder / stoneaggregates / sand / kanker / moorum.Placing tipper at loading point, loading with front end loader,dumping, turning for return trip, excluding time for haulageand return tripUnit : cumTaking output = 5.5 cum Time required for

i) Positioning of tipper at loading point 1 Minii) Loading by front end loader 1 cum bucket capacity @ 25 cum per hour

13 Min

iii) Maneuvering, reversing, dumping and turning for return

2 Min

iv) Waiting time, unforeseen contingencies etc 4 MinTotal 20 Min

a) MachineryTipper 5.5 tonnes capacity hour 0.330 506.00 166.98 P&M-048Front end-loader 1 cum bucket capacity @ 25 cum/hour hour 0.330 520.00 171.60 P&M-017

b) Overheads @ 8% on (a) 27.09c) Contractors profit @ 10% on (a+b) 36.57Cost for 5.5 cum = a+b+c 402.23Rate per cum = (a+b+c)/ 5.5 73.13

Note Unloading will be by tipping. say 73.101.4 Cost of Haulage Excluding Loading and Unloading

Haulage of materials by tipper excluding cost of loading,unloading and stacking.Unit : t.kmTaking output 10 tonnes load and lead 10 km = 100 t.km

1.4(I) Case I Surfaced RoadSpeed with load : 25 km / hour.Speed while Returning empty : 35 km / hour.a) Machinery.i) Tipper 10 tonne capacity

Time taken for onward haulage with load hour 0.400 506.00 202.40 P&M-048Time taken for empty return trip. hour 0.290 506.00 146.74 P&M-048

b) Overheads @ 8% on (a) 27.93c) Contractors profit @ 10% on (a+b) 37.71cost for 100 t km = a+b+c 414.78Rate per t.km = (a+b+c)/100 4.15

say 4.10

1.4(II) Case II Unsurfaced Gravelled RoadSpeed with load : 20 km / hourSpeed for empty return trip : 30 km / houra)Machinery Tipper 10 tonnes capacity

Time taken for onward hanlage with load hour 0.500 506.00 253.00 P&M-048Time taken for empty return trip hour 0.330 506.00 166.98 P&M-048

b) Overheads @ 8% on (a) 33.60c) Contractors profit @ 10% on (a+b) 45.36Cost for 100 t .km = a+b+c 498.94Rate per t.Km = (a+b+c)/100 4.99

say 5.00

1.4(III) Case III Katcha Track and Track in river bed / nallah bed and choe bed.Speed with load : 10 km / hourSpeed while returning empty : 15 km / houra) MachineryI) Tipper 10 tonnes capacity

Time taken for onward haulage hour 1.000 506.00 506.00 P&M-048Time taken for empty return trip hour 0.670 506.00 339.02 P&M-048

b) Overheads @ 8% on (a) 67.60c) Contractors profit @ 10% on (a+b) 91.26Cost for 100 t .km = a+b+c 1003.88Rate per t.Km = (a+b+c)/100 10.04

say 10.001.5 Hand Broken Stone Aggregates 63 mm nominal size

Supply of quarried stone, hand breaking into coarseaggregate 63 mm nominal size (passing 80 mm and retainedon 50 mm sieve) and stacking as directedUnit : cumTaking output = 1 cuma) Labour

Mate day 0.060 80.00 4.80 L-12Mazdoor day 1.500 70.00 105.00 L-13

b) MaterialSupply of quarried stone 150 - 200 mm size cum 1.100 input #VALUE! M-002

c) Overheads @ 8% on (a+b) #VALUE!d) Contractors profit @ 10% on (a+b+c) #VALUE!Rate per cum = a+b+c+d #VALUE!

say #VALUE!1.6 Crushing of stone aggregates 13.2 mm nominal size.

Crushing of stone boulders of 150 mm size in an integratedstone crushing unit of 200 tonnes per hour capacitycomprising of primary and secondary crushing units, beltconveyor and vibrating screens to obtain stone aggregates of13 mm nominal size.Unit : cumTaking Output = 600 cum at crusher location.a) Labour

Mate day 0.760 80.00 60.80 L-12Mazdoor Skilled day 2.000 90.00 180.00 L-14Mazdoor including breaking of any oversize boulder. day 17.000 70.00 1190.00 L-13

b) MaterialStone Boulder of size 150 mm and below cum 800.000 289.00 231200.00 M-001

c) MachineryIntegrated stone crusher of 200 TPH including belt conveyor and vibrating screens

Hour 6.000 11760.00 70560.00 P&M-028

Front end loader 1 cum bucket capacity Hour 20.000 520.00 10400.00 P&M-017Tipper 5.5 cum capacity Hour 20.000 506.00 10120.00 P&M-048

d) Overheads @ 8% on (a+b+c) 25896.86e) Contractors profit @ 10% on (a+b+c+d) 34960.77Cost for 600 cum = ( a+b+c+d+e)*0.95 365340.01Rate per cum = (a+b+c+d+e)*0.95/600 578.46

say 578.50Note 1. 800 cum of stone boulders are needed to get 600 cum of

stone chips of size 13.2 mm.

2. 95% of above cost will be attributed to the production of600 cum of stone chips of 13.2 mm size and balance 5% tothe production of stone dust which comes out as a by-product.3. The integrated stone crusher includes primary andsecondary crushing units.

1.7 Crushing of stone aggregates 20 mm nominal sizeCrushing of stone boulders of 150 mm size in an integratedstone crushing unit of 200 tonnes per hour capacitycomprising of primary and secondary crushing units, beltconveyor and vibrating screens to obtain stone aggregates of20 mm nominal size.Unit : cumTaking Output = 670 cum at crusher location.a) Labour

Mate day 0.760 80.00 60.80 L-12Mazdoor Skilled day 2.000 90.00 180.00 L-14Mazdoor including breaking of any size boulder. day 17.000 70.00 1190.00 L-13

b) MaterialStone Boulder of size 150 mm and below cum 800.000 289.00 231200.00 M-001

c) MachineryIntegrated stone crusher of 200 TPH including belt conveyor and vibrating screens

Hour 6.000 11760.00 70560.00 P&M-028

Front end loader 1 cum bucket capacity Hour 20.000 520.00 10400.00 P&M-017Tipper 5.5 cum capacity Hour 20.000 506.00 10120.00 P&M-048

d) Overheads @ 8% on (a+b+c) 25896.86e) Contractors profit @ 10% on (a+b+c+d) 34960.77Cost for 670 cum = ( a+b+c+d+e)*.90 346111.59Rate per cum = (a+b+c+d+e)*0.90/670 464.93

say 464.90

Note 1. 800 cum of stone boulders are needed to get 600 cum ofstone chips of size 20 and 40 mm.2. 90% of above cost will be attributed to the production of670 cum of stone aggregates of 20mm size and balance 10% will be for smaller size aggregates and stone dust whichcomes out as a by-product.3. The integrated stone crusher includes primary andsecondary crushing units.

1.8 Crushing of stone aggregates 40 mm nominal sizeCrushing of stone boulders of 150 mm size in an integratedstone crushing unit of 200 tonnes per hour capacitycomprising of primary and secondary crushing units, beltconveyor and vibrating screens to obtain stone aggregates of40 mm nominal size.Unit : cumTaking Output = 750 cum at crusher location.a) Labour

Mate day 0.760 80.00 60.80 L-12Mazdoor Skilled day 2.000 90.00 180.00 L-14Mazdoor day 17.000 70.00 1190.00 L-13

b) MaterialStone Boulder of size 150 mm and below cum 800.000 289.00 231200.00 M-001

c) MachineryIntegrated stone crusher of 200 TPH including belt conveyor and vibrating screens

Hour 6.000 11760.00 70560.00 P&M-028

Front end loader 1 cum bucket capacity Hour 20.000 520.00 10400.00 P&M-017Tipper 5.5 cum capacity Hour 20.000 506.00 10120.00 P&M-048

d) Overheads @ 8% on (a+b+c) 25896.86

e) Contractors profit @ 10% on (a+b+c+d) 34960.77Cost for 750 cum = (a+b+c+d+e)x0.85 326883.17Rate per cum = (a+b+c+d+e)x0.85/750 435.84

say 435.80Note 1. 800 cum of stone boulders are needed to get 600 cum of

stone chips of size 13.2 mm.2. 85% of above cost will be attributed to the production of750 cum of stone aggregates of 40mm size and balance 15% will be for smaller size aggregates and stone dust whichcomes out as a by-product.3. The integrated stone crusher includes primary andsecondary crushing units.

5.9 510 Surface DressingProviding and laying surface dressing as wearing course insingle coat using crushed stone aggregates of specified sizeon a layer of bituminous binder laid on prepared surface androlling with 8-10 tonne smooth wheeled steel roller

Unit = sqmTaking output = 9000 sqmCase -1:-19 mm nominal chipping sizea) Labour

Mate day 0.440 80.00 35.20 L-12Mazdoor day 9.000 70.00 630.00 L-13Mazdoor skilled day 2.000 100.00 200.00 L-15

b) MachineryMechanical broom @ 1250 sqm per hour hour 7.200 230.00 1656.00 P&M-031Air compressor 250 cfm hour 7.200 206.00 1483.20 P&M-001Hydraulic self propelled chip spreader @ 1500 sqm per hour

hour 6.000 1700.00 10200.00 P&M-025

Tipper 10 tonne capacity for carriage of stone chips from stockpile on road side to chip spreader

hour 6.000 506.00 3036.00 P&M-048

Front end loader 1 cum bucket capacity hour 6.000 520.00 3120.00 P&M-017Bitumen pressure distributor hour 6.000 692.00 4152.00 P&M-004Smooth wheeled roller 8-10 tonne weight hour 6.000 269.00 1614.00 P&M-044

c) MaterialBitumen@ 1.20 kg per sqm tonne 10.800 20528.00 221702.40 M-074Crushed stone chipping,19 mm nominal size @ 0.015 cum per sqm

cum 135.000 517.65 69882.75 M-053

d) Overheads @ 8% on (a+b+c) 25416.92e) Contractors profit @ 10% on (a+b+c+d) 34312.85Cost for 9000 sqm= a+b+c+d+e 377441.32Rate per sqm = (a+b+c+d+e)/9000 41.94

say 41.90Case - II13 mm nominal size chippinga) Labour

Mate day 0.440 80.00 35.20 L-12Mazdoor day 9.000 70.00 630.00 L-13Mazdoor skilled day 2.000 100.00 200.00 L-15

b) MachineryMechanical broom @ 1250 sqm per hour hour 7.200 230.00 1656.00 P&M-031Air compressor 250 cfm hour 7.200 206.00 1483.20 P&M-001Hydraulic self propelled chip spreader @ 1500 sqm per hour

hour 6.000 1700.00 10200.00 P&M-025

Tipper 10 tonne capacity for carriage of stone chips from stockpile on road side to chip spreader

hour 6.000 506.00 3036.00 P&M-048

Front end loader 1 cum bucket capacity hour 6.000 520.00 3120.00 P&M-017Bitumen pressure distributor @ 1750 sqm per hour hour 6.000 692.00 4152.00 P&M-004Vibratory roller 8-10 tonne weight hour 6.000 994.00 5964.00 P&M-059

c) MaterialBitumen@ 1.00 kg per sqm tonne 9.000 20528.00 184752.00 M-074Crushed stone chipping,13 mm nominal size @ 0.01 cum per sqm

cum 90.000 609.00 54810.00 M-052

d) Overheads @ 8% on (a+b+c) 21603.07e) Contractors profit @ 10% on (a+b+c+d) 29164.15Cost for 9000 sqm= a+b+c+d+e 320805.62Rate per sqm = (a+b+c+d+e)/9000 35.65

say 35.60Note 1.Where the proposed aggregate fails to pass the stripping

test, an approved adhesion agent may be added to thebinder as per clause 510.2.4. Alternatively, chips may be pre-coated as per clause 510.2.52.Input for the second coat, where required, will be thesame as per the Ist coat mentioned above

5.15 516 Slurry SealProviding andlaying slurry seal consisting of a mixture of fineaggregates, portland cement filler, bituminous emulsion andwater on a road surface including cleaning of surface, mixingof slurry seal in a suitable mobile plant, laying andcompacting to provide even riding surface

Case I 5 mm thicknessUnit = sqmTaking output = 16000 sqm (80 cum)Taking density of 2.2 tonnes per cum, weight of mix =264 tonnesweight of mix = 176 tonnesa) Labour

Mate day 0.240 80.00 19.20 L-12Mazdoor day 6.000 70.00 420.00 L-13

b) MachineryMechanical broom hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfm hour 6.000 206.00 1236.00 P&M-001Mobile slurry seal equipment hour 6.000 650.00 3900.00 P&M-033Front end loader 1 cum bucket capacity hour 6.000 520.00 3120.00 P&M-017Tipper 5.5 cum capacity for carriage of aggregate from stockpile on road side to slurry equipment,bitumen emulsion and filler.

hour 6.000 506.00 3036.00 P&M-048

Pneumatic tyred roller with individual wheel load not exceeding 1.5 tonnes

hour 6.000 802.00 4812.00 P&M-037

Water tanker6 KL capacity hour 2.000 506.00 1012.00 P&M-060c) Material

Residual Binder @ 11 % of mix 80 x 2.2 x 0.11 tonne 19.360 15391.00 297969.76 M-077Fine aggregate 4.75 mm and below 87 % of total mix,80 x 2.2 x 0.87 = 153.12 tonnes. Taking density1.5,= 153.12/1.5 = 102.08 cum

cum 102.080 149.00 15209.92 M-005

Filler @ 2 % of total mix = 80 x 2.2 x 0.02 tonne 3.520 11000.00 38720.00 M-188Cost of water KL 12.000 10.00 120.00 M-189

d) Overheads @ 8% on (a+b+c) 29676.39

e) Contractors profit @ 10% on (a+b+c+d) 40063.13Cost for 16000 sqm= a+b+c+d+e 440694.40Rate per sqm = (a+b+c+d+e)/16000 27.54

say 27.50Case II 3 mm thickness

Unit = sqmTaking output = 20000 sqm (60 cum)a) Labour

Mate day 0.200 80.00 16.00 L-12Mazdoor day 5.000 70.00 350.00 L-13

b) MachineryMechanical broom hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfm hour 6.000 206.00 1236.00 P&M-001Mobile slurry seal equipment hour 6.000 650.00 3900.00 P&M-033Front end loader 1 cum bucket capacity hour 6.000 520.00 3120.00 P&M-017Tipper 5.5 cum capacity for carriage of aggregate from stockpile on road side to slurry equipment,bitumen emulsion and filler

hour 6.000 506.00 3036.00 P&M-048

Water tanker6 KL capacity hour 2.000 506.00 1012.00 P&M-060c) Material

Residual Binder @ 13 % of mix = 60 x 2.2 x 0.13 tonne 17.160 15391.00 264109.56 M-077Fine aggregate 3 mm and below 85 % of total mix, 60x 2.2 x 0.85 = 112.2 tonnes. Taking density 1.5,

cum 74.800 149.00 11145.20 M-005

Filler @ 2 % of total mix =60x 2.2 x 0.02 tonne 2.640 11000.00 29040.00 M-188Cost of water KL 12.000 10.00 120.00 M-189

d) Overheads @ 8% on (a+b+c) 25477.18e) Contractors profit @ 10% on (a+b+c+d) 34394.19Cost for 30000 sqm= a+b+c+d+e 378336.13Rate per sqm = (a+b+c+d+e)/20000 18.92

say 18.90Case III 1.5 mm thickness

Unit = sqmTaking output = 24000 sqm (36 cum)a) Labour

Mate day 0.200 80.00 16.00 L-12Mazdoor day 5.000 70.00 350.00 L-13

b) MachineryMechanical broom hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfm hour 6.000 206.00 1236.00 P&M-001Mobile slurry seal equipment hour 6.000 650.00 3900.00 P&M-033Front end loader 1 cum bucket capacity hour 6.000 520.00 3120.00 P&M-017Tipper 5.5 cum capacity for carriage of aggregate from stockpile on road side to slurry equipment,bitumen emulsion and filler.

hour 6.000 506.00 3036.00 P&M-048

Water tanker6 KL capacity hour 2.000 506.00 1012.00 P&M-060c) Material

Residual Binder @ 16 % of mix, 36 x 2.2 x 0.16 tonne 12.670 15391.00 195003.97 M-077Fine aggregate 2.36 mm and below,82 % of total mix,36x 2.2 x 0.82 = 64.94 tonnes. Taking density 1.5

cum 43.300 395.85 17140.31 M-022

Filler @ 2 % of total mix = 36x 2.2 x 0.02 tonne 1.580 11000.00 17380.00 M-188Cost of water KL 12.000 10.00 120.00 M-189

d) Overheads @ 8% on (a+b+c) 19495.54e) Contractors profit @ 10% on (a+b+c+d) 26318.98Cost for 24000 sqm= a+b+c+d+e 289508.80Rate per sqm = (a+b+c+d+e)/24000 12.06

say 12.10Note 1.Tack coat, if required to be provided, before laying slurry

seal may be measured and paid separately

5.17 518 Fog SprayProviding and applying low viscosity bitumen emulsion forsealing cracks less than 3 mm wide or incipient fretting ordisintegration in an existing bituminous surfacing.Unit = sqmTaking output = 10500 sqm a) Labour

Mate day 0.120 80.00 9.60 L-12Mazdoor day 3.000 70.00 210.00 L-13

b) MachineryMechanical broom @ 1250 sqm per hour hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfm hour 6.000 206.00 1236.00 P&M-001Bitumen emulsion pressure distributor @ 1750 sqm per hour

tonne 6.000 692.00 4152.00 P&M-004

c) MaterialBitumenemulsion @ 0.75 kg per sqm tonne 7.880 15391.00 121281.08 M-077

d) Overheads @ 8% on (a+b+c) 10261.49e) Contractors profit @ 10% on (a+b+c+d) 13853.02Cost for 10500 sqm= a+b+c+d+e 152383.19Rate per sqm = (a+b+c+d+e)/10500 14.51

say 14.501.In case it is decided by the engineer to blind the fog spray,the following may be addeda) Labour

Mate day 0.160 80.00 12.80 L-12Mazdoor for precoating of grit day 4.000 70.00 280.00 L-13

c) MaterialCrushed stone grit 3 mm size @ 3.75 kg per sqm cum 26.250 401.94 10550.93 M-024Bitumenemulsion for precoating grit @ 2 % of grit,39.38 x 0.02

tonne 0.790 15391.00 12158.89 M-077

23002.622.19

say 2.20

5.21 522 Crack Prevention CoursesCase - I Stress Absorbing Membrane (SAM) crack width less than

6 mmProviding and laying of a stress absorbing membrane over acracked road surface, with crack width below 6 mm aftercleaning with a mechanical broom, using modified bindercomplying with clause 521, sprayed at the rate of 9 kg per10 sqm and spreading 5.6 mm crushed stone aggregates @0.11 cum per 10 sqm with hydraulic chip spreader, sweepingthe surface for uniform spread of aggregates and surfacefinished to conform to clause 902.

Unit = sqmTaking output = 10500 sqm a) Labour

Mate day 0.240 80.00 19.20 L-12Mazdoor day 6.000 70.00 420.00 L-13

b) MachineryMechanical broom @ 1250 sqm per hour hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfm hour 6.000 206.00 1236.00 P&M-001Bitumen pressure distributor @ 1750 sqm per hour hour 6.000 692.00 4152.00 P&M-004Hydraulic Chip spreader hour 6.000 1700.00 10200.00 P&M-025Smooth wheeled road roller 8-10 tonne hour 6.000 269.00 1614.00 P&M-044

c) MaterialModified binder tonne 9.450 20986.00 198317.70 M-078Crushed stone aggregates 5.6 mm size cum 105.000 468.93 49237.65 M-050

d) Overheads @ 8% on (a+b+c) 21326.12e) Contractors profit @ 10% on (a+b+c+d) 28790.27Cost for 10500 sqm= a+b+c+d+e 316692.94Rate per sqm = (a+b+c+d+e)/10500 30.16

say 30.00

Case - II Stress Absorbing Membrane (SAM) with crack width 6mm to 9 mmProviding and laying of a stress absorbing membrane over acracked road surface, with crack width 6 to 9 mm aftercleaning with a mechanical broom, using modified bindercomplying with clause 521, sprayed at the rate of 11 kg per10 sqm and spreading 11.2 mm crushed stone aggregates@ 0.12 cum per 10 sqm, sweeping the surface for uniformspread of aggregates and surface finished to conform toclause 902.Unit = sqmTaking output = 10500 sqm a) Labour

Mate day 0.240 80.00 19.20 L-12Mazdoor day 6.000 70.00 420.00 L-13

b) MachineryMechanical broom @ 1250 sqm per hour hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfem capacity hour 6.000 206.00 1236.00 P&M-001Bitumen pressure distributor @ 1750 sqm per hour hour 6.000 692.00 4152.00 P&M-004Hydraulic Chip spreader hour 6.000 1700.00 10200.00 P&M-025Smooth wheeled road roller 8-10 tonne hour 6.000 269.00 1614.00 P&M-044

c) MaterialModified binder tonne 11.550 20986.00 242388.30 M-078Crushed stone chipping 11.2 mm size cum 105.000 609.00 63945.00 M-051

d) Overheads @ 8% on (a+b+c) 26028.36e) Contractors profit @ 10% on (a+b+c+d) 35138.29Cost for 10500 sqm= a+b+c+d+e 386521.15Rate per sqm = (a+b+c+d+e)/10500 36.81

say 37.00Case III Stress Absorbing Membrane (SAM) crack width above 9

mm and cracked area above 50 %

Providing and laying a single coatn of a stress absorbingmembrane over a cracked road surface, with crack widthabove 9 mm and cracked area above 50 % after cleaningwith a mechanical broom, using modified binder complyingwith clause 521, sprayed at the rate of 15 kg per 10 sqm andspreading 11.2 mm crushed stone aggregates @ 0.12 cumper 10 sqm, sweeping the surface for uniform spread ofaggregates and surface finished to conform to clause 902.

Unit = sqmTaking output = 10500 sqm a) Labour

Mate day 0.240 80.00 19.20 L-12Mazdoor day 6.000 70.00 420.00 L-13Mazdoor skilled day 2.000 100.00 200.00 L-15

b) MachineryMechanical broom @ 1250 sqm per hour hour 6.000 230.00 1380.00 P&M-031Air compressor 250 cfem capacity hour 6.000 206.00 1236.00 P&M-001Bitumen pressure distributor @ 1750 sqm per hour hour 6.000 692.00 4152.00 P&M-004Hydraulic Chip spreader hour 6.000 1700.00 10200.00 P&M-025Smooth wheeled road roller 8-10 tonne hour 6.000 269.00 1614.00 P&M-044

c) MaterialModified binder tonne 15.750 20986.00 330529.50 M-078Crushed stone aggregates 11.2 mm size cum 126.000 609.00 76734.00 M-051

d) Overheads @ 8% on (a+b+c) 34118.78e) Contractors profit @ 10% on (a+b+c+d) 46060.35Cost for 10500 sqm= a+b+c+d+e 506663.82Rate per sqm = (a+b+c+d+e)/10500 48.25

say 48.00Case IV Case - IV : Bitumen Impregnated Geotextile

Providing and laying a bitumen impregnated geotextile layerafter cleaning the road surface, geotextile conforming torequirements of clause 704.3, laid over a tack coat with 1.05kg per sqm of paving grade bitumen 80 - 100 penetration and constructed to the requirement of clause 704.4.5

Unit = sqmTaking output = 3500 sqm a) Labour

Mate day 0.560 80.00 44.80 L-12Mazdoor day 12.000 70.00 840.00 L-13Mazdoor skilled day 2.000 100.00 200.00 L-15

b) MachineryMechanical broom @ 1250 sqm per hour hour 2.800 230.00 644.00 P&M-031Air compressor 250 cfem capacity hour 2.800 206.00 576.80 P&M-001Bitumen pressure distributor @ 1750 sqm per hour tonne 2.000 692.00 1384.00 P&M-004Pneumatic roller hour 2.000 802.00 1604.00 P&M-037

c) MaterialPaving grade bitumen of 80 - 100 penetration @ 1.05 kg per sqm

tonne 3.680 20986.00 77228.48 M-075

Geotextile including 10 % for overlaps sqm 3850.000 input #VALUE! M-108d) Overheads @ 8% on (a+b+c) #VALUE!e) Contractors profit @ 10% on (a+b+c+d) #VALUE!

Cost for 10500 sqm= a+b+c+d+e #VALUE!Rate per sqm = (a+b+c+d+e)/3500 #VALUE!

say #VALUE!NOTE As bitumen overlay construction shallfollow closely the fabric

placement on the same day, an output of 3500 sqm only hasbeen considered for the analysis which will cover a length of500 m, of 7 m widecarriagway. This can be convenientlyoverlaid by a bitumenious course in a day

8.3 801 Printing new letter and figures of any shade Printing new letter and figures of any shade with syntheticenamel paint black or any other approved colour to give aneven shadeii) English and RomanHyphens and the like not to be measured and paid forDetail for 100 letters of 16 cm height. i.e.1600 cm Unit = per cm height per lettera) Labour

Mate day 0.07 80 5.60Painter Ist class day 1.25 100 125.00Mazdoor day 0.50 70 35.00

b) MaterialPaint Litre 0.50 132.24 66.12

c) Overheads @ 8% on (a+b) 18.54d) Contractors profit @ 10% on (a+b+c) 25.03Cost for 1600 cm = a+b+c+d 275.28Rate per cm height per letter = (a+b+c +d)/1600 0.17

say 0.208.8 803 Painting Two Coats on New Concrete Surfaces

Painting two coats after filling the surface with syntheticenamel paint in all shades on new plastered concretesurfacesUnit = sqmTaking output = 40 sqma) Labour

Mate day 0.12 80 9.60Painter day 2.00 100 200.00Mazdoor day 1.00 70 70.00

b) MaterialPaint conforming to requirement of clause 803.3. Litre 6.00 132.24 793.44

Add for scaffolding @ 1% of labour cost where required 2.80

c) Overheads @ 8% on (a+b) 86.07d) Contractors profit @ 10% on (a+b+c) 116.19Cost for 40 sqm = a+b+c+d 1278.09Rate per sqm = (a+b+c+d)/40 31.95

say 32.008.9 803 Painting on Steel Surfaces

Providing and applying two coats of ready mix paint ofapproved brand on steel surface after through cleaning ofsurface to give an even shadeUnit = sqmTaking output = 10 sqm

a) LabourMate day 0.03 80 2.40Painter day 0.45 100 45.00Mazdoor day 0.25 70 17.50

b) MaterialPaint ready mixed approved brand. Litre 1.25 132.24 165.30Add @ 1% on cost of material for scaffolding 1.65

c) Overheads @ 8% on (a+b) 18.55d) Contractors profit @ 10% on (a+b+c) 25.04Cost for 10 sqm = a+b+c+d 275.44Rate per sqm = (a+b+c+d)/10 27.54

say 27.5012.6 Sub-

analysis (A)

Cement mortar1:3 (1cement :3 sand)

Unit = 1 cumTaking output = 1 cuma) Materials

Cement MT 0.51 4400.00 2244.00Sand cum 1.05 149.00 156.45

b) LabourMate day 0.04 80.00 3.20Mazdoor day 0.90 70.00 63.00

Total Material and Labour = (a+b) 2467.00

Sub-analysis

(B)

Cement mortar1:2 (1cement :2 sand)

Unit = 1 cumTaking output = 1 cuma) Materials

Cement MT 0.67 4400.00 2956.80Sand cum 0.93 149.00 139.07

b) LabourMate day 0.04 80.00 3.20Mazdoor day 0.90 70.00 63.00

Total Material and Labour = (a+b) 3162.00

Sub-analysis

(D)

Cement mortar1:6 (1cement :6 sand)

Unit = 1 cumTaking output = 1 cuma) Materials

Cement MT 0.29 4400.00 1267.20Sand cum 1.20 149.00 178.80

b) LabourMate day 0.04 80.00 3.20Mazdoor day 0.90 70.00 63.00

Total Material and Labour = (a+b) 1512.0012.7 1400 Stone masonry work in cement mortar 1:3 in foundation

complete as drawing and Technical Specification

Unit = cumTaking output = 5 cum

(A) Square Rubble Coursed Rubble Masonry (first sort)

a) Material

Stone cum 5.50 289.00 1589.50 M-169Through and bond stone each 35.00 100.00 3500.00 M-182

(35no.x0.24mx0.24mx0.39m = 0.79 cu.m)Cement mortar 1:3 (Rate as in Item 12.6 A sub-analysis) cum 1.50 2467.00 3700.50 Item 12.6

(A) b) Labour

Mate day 0.66 80.00 52.80 L-12Mason day 7.50 100.00 750.00 L-11Mazdoor day 9.00 70.00 630.00 L-13

c) Overhead charges @ 20% on (a+b) 2044.56d) Contractor's profit @ 0.1 on (a+b+c) 1226.74Cost for 5 cum = a+b+c+d 13494.10Rate per cum (a+b+c+d)/5 2698.82

say 2698.801405.3 B) Random Rubble Masonry

( coursed/uncoursed )Unit = cumTaking output = 5 cuma) Material

Stone cum 5.50 289.00 1589.50Through and bond stone Nos 35.00 100.00 3500.00

(35nos.x0.24mx0.24mx0.39m = 0.79 cu.m)Cement mortar 1:3 (Rate as in item 12.6 A) cum 1.55 2467.00 3823.85

b) Labour Mate day 0.62 80.00 49.60Mason day 6.00 100.00 600.00Mazdoor day 9.00 70.00 630.00

c) Overheads @ 20% on (a+b) 2038.59d) Contractors profit @ 0.1 on (a+b+c) 1223.15Cost for 5 cum = a+b+c+d 13454.69Rate per cum (a+b+c+d)/5 2690.94

say 2690.90@ The labour already considered in cement mortar has been

taken into account while proposing labour for masonry works.

12.7 (Add) 1400 Stone masonry work in cement mortar 1:6 in foundationcomplete as drawing and Technical Specification

Unit = cumTaking output = 5 cum

1405.3 B) Random Rubble Masonry( coursed/uncoursed )Unit = cumTaking output = 5 cuma) Material

Stone cum 5.50 289.00 1589.50Through and bond stone Nos 35.00 100.00 3500.00

(35nos.x0.24mx0.24mx0.39m = 0.79 cu.m)Cement mortar 1:3 (Rate as in item 13.6 D) cum 1.55 1512.00 2343.60

b) Labour Mate day 0.62 80.00 49.60Mason day 6.00 100.00 600.00Mazdoor day 9.00 70.00 630.00

c) Overheads @ 20% on (a+b) 1742.54d) Contractors profit @ 0.1 on (a+b+c) 1045.52Cost for 5 cum = a+b+c+d 11500.76Rate per cum (a+b+c+d)/5 2300.15

say 2300.00@ The labour already considered in cement mortar has been

taken into account while proposing labour for masonry works.

12.8 1500, 1700 & 2100

Plain/Reinforced cement concrete in open foundationcomplete as per drawing and technical specifications

A PCC Grade M15 Unit = cumTaking output = 15 cuma) Material

Cement MT 4.13 4400.00 18172.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 8.10 438.48 3551.6920 mm Aggregate cum 4.05 517.65 2096.4810 mm Aggregate cum 1.35 609.00 822.15

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 63 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 1,979.00 d) Formwork @ 4% on cost of concrete i.e.cost of material, labour and machinery

1186.91

e) Overheads @ 20% on (a+b+c+d) 6171.96f) Contractors profit @ 0.1 on (a+b+c+d+e) 3703.17Cost for 15 cum = a+b+c+d+e+f 40734.92Rate per cum (a+b+c+d+e+f)/15 2715.66

say 2715.70Note Nedle Vibrator is an item of minor T & P which is already

included in overhead charges. Hence not added in rate analysis of cement concrete works.

12.8 B PCC Grade M20 Unit : cumTaking output = 15 cuma) Material

Cement MT 5.16 4400.00 22704.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,303.00 12.8 C RCC Grade M20

Unit = cumCase I Using concrete mixer

Taking output = 15 cuma) Material

Cement MT 5.21 4400.00 22924.00Coarse sand cum 6.75 149.00 1005.7520 mm Aggregate cum 8.10 517.65 4192.9710 mm Aggregate cum 5.40 609.00 3288.60

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,362.50 Case II With Batching Plant, Transit Mixer and Conrete Pump

Unit : cumTaking Output = 120 cuma) Material

Cement MT 41.66 4400.00 183304.00Coarse Sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Lead beyond 1 km, L-lead in km T-km 300L 1.62 8262.00 L= 17Concrete Pump hour 6 165.00 990.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,379.60 d) Formwork @ 4% on cost of concrete i.e.cost of material, labour and machinery

11421.67

e) Overheads @ 20% on (a+b+c+d) 59392.68f) Contractors profit @ 0.1 on (a+b+c+d+e) 35635.61Cost for 120 cum = a+b+c+d+e+f 391991.67Rate per cum = ( a+b+c+d+e+f )/120 3266.60

say 3266.6012.8 D PCC Grade M25

Unit = cumCase I Using concrete Mixer

Taking output = 15 cuma) Material

Cement MT 5.99 4400.00 26356.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,546.30 Case II With Batching Plant, Transit Mixer and Conrete Pump

Unit : cumTaking Output = 120 cuma) Material

Cement MT 47.95 4400.00 210980.00Coarse sand cum 54.00 149.00 8046.0040 mm Aggregate cum 43.20 438.48 18942.3420 mm Aggregate cum 43.20 517.65 22362.4810 mm Aggregate cum 21.60 609.00 13154.40

b) Labour

Mate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,565.30

d) Formwork @ 3.75% of cost of concrete i.e.cost of material,labour and machinery

11543.42

e) Overheads @ 20% on (a+b+c+d) 63873.57f) Contractors profit @ 0.1 on (a+b+c+d+e) 38324.14cost of 120 cum = a+b+c+d+e+f 421565.54Rate per cum (a+b+c+d+e+f)/120 3513.05

say 3513.0012.8 E RCC Grade M25

Unit = cumCase I Using concrete Mixer

Taking output = 15 cuma) Material

Cement MT 6.05 4400.00 26620.00Coarse sand cum 6.75 149.00 1005.7520 mm Aggregate cum 8.10 517.65 4192.9710 mm Aggregate cum 5.40 609.00 3288.60

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,608.90 Case II With Batching Plant, Transit Mixer and Conrete Pump

Unit : cumTaking Output = 120 cuma) Material

Cement MT 48.38 4400.00 212872.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80Admixer Kg 193.52 40.00 0.00

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity 1 cum hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,626.00

12.8 F PCC Grade M30 Unit = cum

Case I Using Concrete MixerTaking output = 15 cuma) Material

Cement MT 6.08 4400.00 26752.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,572.70 Case II Using Batching Plant, Transit Mixer and Conrete Pump

Unit : cumTaking Output = 120 cuma) Material

Cement MT 48.60 4400.00 213840.00Coarse sand cum 54.00 149.00 8046.0040 mm Aggregate cum 43.20 438.48 18942.3420 mm Aggregate cum 43.20 517.65 22362.4810 mm Aggregate cum 21.60 609.00 13154.40

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,589.10

12.8 G RCC Grade M30 Case I Using Concrete Mixer

Unit = cumTaking output = 15 cuma) Material

Cement MT 6.10 4400.00 26840.00Coarse sand cum 6.75 149.00 1005.7520 mm Aggregate cum 8.10 517.65 4192.9710 mm Aggregate cum 5.40 609.00 3288.60

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,623.50 Case II Using Batching Plant, Transit Mixer and Conrete Pump

Unit = cumTaking output = 120 cuma) Material

Cement MT 48.80 4400.00 214720.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,641.40

12.8 H RCC Grade M35 Case I Using Concrete Mixer

Unit = cumTaking output = 15 cuma) Material

Cement MT 6.33 4400.00 27852.00Coarse sand cum 6.75 149.00 1005.7520 mm Aggregate cum 8.10 517.65 4192.9710 mm Aggregate cum 5.40 609.00 3288.60

b) LabourMate day 0.86 80.00 68.80Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,691.00 Case II Using Batching Plant, Transit Mixer and Conrete Pump

Unit ; cumTaking Output = 120 cuma) Material

Cement MT 50.64 4400.00 222816.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80Admixer Kg 202.56 40.00 8102.40

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2,776.40

d) Formwork @ 3% on cost of concrete i.e.cost of material,labour and machinery

9994.68

e) Overheads @ 20% on (a+b+c+d) 68630.16f) Contractors profit @ 0.1 on (a+b+c+d+e) 41178.10

cost of 120 cum = a+b+c+d+e+f 452959.06Rate per cum (a+b+c+d+e+f)/120 3774.66

say 3774.70Rate per cum (a+b+c+d)/120 Excluding OH & CP 2859.60

Note: Where ever concrete is carried out using batching plant,transit mixer, concrete pump, admixers @ 0.4% of weight ofcement may be added for achieving desired slump ofconcrete.

12.11 1200, 1500 & 1700

Plain/Reinforced cement concrete, in well foundationcomplete as per drawing and technical specification

C Bottom Plug Concrete to be placed using tremie pipe

Case I Using Concrete Mixer(i) PCC Grade M20

Unit = cumTaking output = 15 cuma) Material

Cement MT 5.55 4400.00 24420.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30Admixer Kg 18.60 40.00 744.00

b) LabourMate day 0.90 80.00 72.00Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00Light Crane 3 tonnes capacity for handling tremie pipe hour 6.00 230.00 1380.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2559.10Note 10% extra cement may be added where under water

concreting is involved.Case II Using Batching Plant, Transit Mixer and Crane/concrete

pumpUnit ; cumTaking Output = 120 cuma) Material

Cement MT 44.40 4400.00 195360.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80Admixer Kg 148.80 40.00 5952.00

b) LabourMate day 0.88 80.00 70.40Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity, lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2529.70

(ii) PCC Grade M25

Case I Using Concrete MixerUnit = cumTaking output = 15 cuma) Material

Cement MT 5.99 4400.00 26356.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30Admixer Kg 21.60 40.00 864.00

b) LabourMate day 0.90 80.00 72.00Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00Light Crane of 3 tonnes capacity for handling tremie pipe hour 6.00 230.00 1380.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2696.10Case II Using Batching Plant, Transit Mixer and Crane/concrete

pumpUnit = cumTaking output = 120 cuma) Material

Cement MT 47.88 4400.00 210672.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80Admixer Kg 172.80 40.00 6912.00

b) LabourMate day 0.88 80.00 70.40Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity, lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2665.30

(iii) PCC Grade M30 Case I Using Concrete Mixer

Unit = 1 cumTaking output = 15 cuma) Material

Cement MT 6.08 4400.00 26752.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30Admixer Kg 21.60 40.00 864.00

b) LabourMate day 0.90 80.00 72.00Mason day 1.50 100.00 150.00

Mazdoor day 20.00 70.00 1400.00c) Machinery

Concrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00Light Crane of 3 tonnes capacity for handling tremie pipe hour 6.00 230.00 1380.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2722.50Case II Using Batching Plant, Transit Mixer and Crane/concrete

pumpUnit = cumTaking output = 120 cuma) Material

Cement MT 48.64 4400.00 214016.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80Admixer Kg 172.80 40.00 6912.00

b) LabourMate day 0.88 80.00 70.40Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity, lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2693.10

(iv) PCC Grade M35

Case I Using Concrete MixerUnit = 1 cumTaking output = 15 cuma) Material

Cement MT 6.29 4400.00 27676.00Coarse sand cum 6.75 149.00 1005.7540 mm Aggregate cum 5.40 438.48 2367.7920 mm Aggregate cum 5.40 517.65 2795.3110 mm Aggregate cum 2.70 609.00 1644.30Admixer Kg 21.60 40.00 864.00

b) LabourMate day 0.90 80.00 72.00Mason day 1.50 100.00 150.00Mazdoor day 20.00 70.00 1400.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00Light Crane of 3 tonnes capacity for handling tremie pipe hour 6.00 230.00 1380.00

Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2784.10Case II Using Batching Plant, Transit Mixer and Crane/concrete

pumpUnit = cumTaking output = 120 cuma) Material

Cement MT 50.28 4400.00 221232.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

Admixer Kg 172.80 40.00 6912.00b) Labour

Mate day 0.88 80.00 70.40Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader 1 cum capacity hour 6.00 520.00 3120.00Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Transit Mixer 4 cum capacity, lead beyond 1 Km, L - lead in Kilometer

T-Km 300L 1.62 8262.00 L= 17

Concrete Pump hour 6.00 165.00 990.00Per Cum Basic Cost of Labour, Material & Mechinery (a+b+c) 2753.30

Add 5% of cost of material and labour towards cost offorming sump, protective bunds, chiselling and makingarrangements for under water concreteing with tremie pipe..

14883.65

d) Overheads @ 20% on (a+b+c) 69053.71e) Contractors profit @ 0.1 on (a+b+c+d) 41432.23cost of 120 cum = a+b+c+d+e 455754.51Rate per cum (a+b+c+d+e)/120 3797.95

Say 3798.00F Well cap

iv) RCC Grade M35 Case II Using Batching Plant, Transit Mixer and Conrete Pump

Unit = cumTaking output = 120 cuma) Material

Cement MT 50.64 4400.00 222816.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader(capacity 1 cum) hour 6.00 520.00 3120.00

Transit Mixer ( capacity 4.0 cu.m )Transit Mixer 4 cum capacity for lead upto 1 km. hour 15.00 600.00 9000.00Lead beyond 1 Km, L - lead in Kilometer T-Km 300L 1.62 8262.00 L= 17Concrete Pump hour 6.00 165.00 990.00

Formwork @ 3% of (a+b+c) 9751.61d) Overheads @ 20% on (a+b+c) 66961.07e) Contractors profit @ 0.1 on (a+b+c+d) 40176.64cost of 120 cum = a+b+c+d+e 441943.04Rate per cum (a+b+c+d+e)/120 3682.86

Say 3682.90Note Where ever concrete is carried out using batching plant,

transit mixer, concrete pump, admixers @ 0.4% of weight ofcement may be added for achieving desired slump ofconcrete.

3.13 304 Excavation for Structures

Earth work in excavation of foundation of structures as per drawing and technical specification, including setting out, construction of shoring and bracing, removal of stumps and other deleterious matter, dressing of sides and bottom, backfilling the excavation earth to the extent required and utilising the remaning earth locally for road work. I) Ordinary soilUnit = cumTaking output = 10 cum

A Manual Means(i) Depth upto 3 ma) Labour

Mate day 0.320 80.00 25.60 L-12Mazdoor day 8.000 70.00 560.00 L-13

b) Overheads @ 8% on (a) 46.85c) Contractors profit @ 10% on (a+b) 63.24Cost for 10 cum = a+b+c 695.69Rate per cum = (a+b+c)/10 69.57

say 69.60Note Cost of dewatering may be added where required upto 10 %

of labour cost Assessment for dewatering shall be made asper site conditions..

B Mechanical Means(i) Depth upto 3 m Unit = cumTaking output = 300 cuma) Labour

Mate day 0.32 80 25.60Mazdoor day 8.00 70 560.00

b) MachineryHydraulic excavator 1.0 cum bucket capacity hour 6.00 840 5040.00

c) Overheads @ 8% on (a+b) 450.05d) Contractors profit @ 10% on (a+b+c) 607.56Cost for 300 cum = a+b+c+d 6683.21Rate per cum = (a+b+c+d)/300 22.28

say 22.30Note Cost of dewatering upto 5% of (a+b) may be added, where

required. Assessment for dewatering shall be made as persite conditions..

13.6 Section 1600 & 2200

Supplying, fitting and placing HYSD bar reinforcement insub-structure complete as per drawing and technicalspecifications Output : MTTaking output = 1 MTa) Material

HYSD bars including 5% overlaps and wastage MT 1.05 29902.00 31397.10Binding wire kg 6.00 39.00 234.00

b) Labour for cutting, bending, shifting to site, tying andplacing in position

Mate day 0.34 80.00 27.20Blacksmith day 2.00 100.00 200.00Mazdoor day 6.50 70.00 455.00

c) Overheads @ 20% on (a+b) 6462.66

d) Contractors profit @ 0.1 on (a+b+c) 3877.60Rate for per MT (a+b+c+d) 42653.56

say 42653.6014.1 1500

&1600 1700

Furnishing and Placing Reinforced/Prestressed cementconcrete in super-structure as per drawing andTechnical Specification

A RCC Grade M20Case II Using Batching Plant, Transit Mixer and Concrete Pump

Unit = cumTaking output = 120 cuma) Material

Cement MT 40.92 4400.00 180048.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader hour 6.00 520.00 3120.00

Transit Mixer ( capacity 4.0 cu.m )Transit Mixer 4 cum capacity lead upto 1 Km hour 15.00 600.00 9000.00Lead beyond 1 Km, L - lead in Kilometer T-Km 300L 1.62 8262.00 L= 17Concrete Pump hour 6.00 165.00 990.00

Basic Cost of Labour, Material & Mechinery (a+b+c) for 120 cum 282285.80

(i) For solid slab super-structure, 20-30% of (a+b+c)(p) Height upto 5m

Basic Cost of Labour, Material & Mechinery (a+b+c) for 120cum

282285.80

d) Formwork and staging 20 % of (a+b+c) 20.00 56457.16e) Overheads @ 20% on (a+b+c+d) 67748.59f) Contractors profit @ 0.1 on (a+b+c+d+e) 40649.16Cost for 15 cum = a+b+c+d+e+f 447140.71Rate per cum (a+b+c+d+e+f)/120 3726.17

say 3726.20B RCC Grade M25

Case II Using Batching Plant, Transit Mixer and Concrete Pump

Unit = cumTaking output = 120 cuma) Material

Cement MT 47.95 4400.00 210980.00Coarse sand cum 54.20 149.00 8075.8020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

b) LabourMate day 0.84 80.00 67.20Mason day 3.00 100.00 300.00Mazdoor day 18.00 70.00 1260.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader hour 6.00 520.00 3120.00

Transit Mixer ( capacity 4.0 cu.m )Transit Mixer 4 cum capacity lead upto 1 Km hour 15.00 600.00 9000.00

Lead beyond 1 Km, L - lead in Kilometer T-Km 300L 1.62 8262.00 L= 17Concrete Pump hour 6.00 165.00 990.00

Basic Cost of Labour, Material & Mechinery (a+b+c) for 120 cum 313247.60For formwork and staging add the following:

(i) For solid slab super-structure, 20-30% of (a+b+c) (p) Height upto 5m

Basic Cost of Labour, Material & Mechinery (a+b+c) for120 cum

313247.60

d) Formwork and staging 20 % of (a+b+c) 20.00 62649.52e) Overheads @ 20% on (a+b+c+d) 75179.42f) Contractors profit @ 0.1 on (a+b+c+d+e) 45107.65Cost for 15 cum= a+b+c+d+e+f 496184.20Rate per cum (a+b+c+d+e+f)/120 4134.87

say 4134.90

C RCC Grade M 30

Case II Using Batching Plant, Transit Mixer and Concrete Pump.

Unit = cumTaking output = 120 cuma) Material

Cement MT 48.79 4400.00 214676.00Coarse sand cum 54.60 149.00 8135.4020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80

b) LabourMate day 0.88 80.00 70.40Mason day 3.00 100.00 300.00Mazdoor day 19.00 70.00 1330.00

c) MachineryBatching Plant @ 20 cum/hour hour 6.00 1440.00 8640.00Generator 100 KVA hour 6.00 450.00 2700.00Loader hour 6.00 520.00 3120.00

Transit Mixer ( capacity 4.0 cu.m )Transit Mixer 4 cum capacity lead upto 1 Km hour 15.00 600.00 9000.00Lead beyond 1 Km, L - lead in Kilometer T-Km 300L 1.62 8262.00 L= 17Concrete Pump hour 6.00 165.00 990.00

Basic Cost of Labour, Material & Mechinery (a+b+c) for 120 cum 317076.40For formwork and staging add the following:

(i) For solid slab super-structure, 20-30% of (a+b+c)(p) Height upto 5m

Basic Cost of Labour, Material & Mechinery (a+b+c) for 120cum

317076.40

d) Formwork and staging 20 % of (a+b+c) 20.00 63415.28e) Overheads @ 20% on (a+b+c+d) 76098.34f) Contractors profit @ 0.1 on (a+b+c+d+e) 45659.00Cost for 15 cum = a+b+c+d+e+f 502249.02Rate per cum (a+b+c+d+e+f)/120 4185.41

say 4185.40Rate per cum (a+b+c+d)/120 ( including formwork and excluding OH & CP) 3170.80Rate per cum (a+b+c+d)/120 ( excluding formwork and Excluding OH & CP) 2642.30

E PSC Grade M-40Case 1 Using concret mixer.

Unit = 1 cum

Taking output = 15 cuma) Material

Cement MT 6.45 4400.00 28380.00Coarse sand cum 6.75 149.00 1005.7520 mm Aggregate cum 8.10 517.65 4192.9710 mm Aggregate cum 5.40 609.00 3288.60Admixture @ 0.4% of cement kg 25.80 40.00 1032.00

b) LabourMate day 0.96 80.00 76.80Mason day 2.00 100.00 200.00Mazdoor day 22.00 70.00 1540.00

c) MachineryConcrete mixer (cap. 0.40/0.28 cum) hour 6.00 161.00 966.00Generator 33 KVA hour 6.00 240.00 1440.00

Basic Cost of Labour, Material & Mechinery (a+b+c) for 15 cum 42122.20

Case II Using Batching Plant, Transit Mixer and Concrete Pump

Unit = cumTaking output = 120 cuma) Material

Cement MT 51.60 4400.00 227040.00Coarse sand cum 54.00 149.00 8046.0020 mm Aggregate cum 64.80 517.65 33543.7210 mm Aggregate cum 43.20 609.00 26308.80Admixture @ 0.4% of cement kg 206.40 40.00 8256.00

b) LabourMate day 0.94 80.00 75.20Mason day 3.50 100.00 350.00Mazdoor day 20.00 70.00 1400.00