FF-Automation AutoLog® OEM-M2M solutions · solutions for remote monitoring applications for...

Transcript of FF-Automation AutoLog® OEM-M2M solutions · solutions for remote monitoring applications for...

FF-Automation AutoLog® OEM-M2M solutions

FF-Automation has almost 40 years experience in designing and

manufacturing tailor-made OEM automation hardware and software

solutions for remote monitoring applications for machine builders

and equipment manufacturers. FF-Automation has own modern

Samsung production line and factory in Finland.

OEM = Original Equipment Manufacturer

Around the world, AutoLog has become the automatic choice for the

best and most affordable and very long term OEM products for

customer-specific AutoLog Controllers, Wireless I/Os, PLCs, data

loggers, Web-, Cloud and HMI interfaces, Internet of Things (IoT)

solutions, Machine to Machine (M2M) solutions and other automation

products. We have almost 40 years of specific experience in

analyzing and meeting end-user needs, in partnership with our

customers.

AutoLog®

Automation

System

FF-Automation Oy – quality products since 1976

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

•Based on well proven AutoLog technology. (Used by e.g. Grundfos, Metso, Sarlin,

Chiller, Saudi Aramco).

•Reliable Solution based on almost 40 years experience and 10.000+ supplied OEM-

Controllers and solutions.

•Complete solution directly from Finnish hardware manufacturer and software project

designer

•Reliable IoT (Internet of Things) Solutions - See machine measurements in Internet!

•Reliable and versatile GSM/GPRS/SMS/Internet communication.

•Can communicate with multiple medias like GSM, Radio, TETRA, RS-485, Fiber Optic,

TCP/IP, etc.

•Integrated graphical or character-keypad HMI solutions.

•Wireless I/O network solutions for OEM sensor manufacturers.

•Compact solution with many I/O, communication and other feature variants.

•Wide operating range -30...+70C.

•Long term and guaranteed life cycle for the product and complete solution

•Long term win-win partnerships

•Economically and competitively priced solution

•10 years spare part guarantee

AutoLog®

Automation

System

FF-Automation Oy – Benefits for OEM

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

AutoLog®

Equipment

AutoLog ® ControlMan AutoLog ® SCADA

AutoLog ® PLC

AutoLog ® HMI AutoLog ® OEM -M2M

AutoLog ® Radio Modem AutoLog ® Wireless

AutoLog ® TETRA AutoLog ® GSM

AutoLog ® RTU

FF-Automation’s AutoLog® Family Products

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

AutoLog®

Automation

System

Automation systems in equipment

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Integrated Machine-to-Machine PLC (Programmable Logical Controller)

May be used in equipment as a central “brain” with following

functionalities:

Digital Inputs from switches

Digital Outputs or relays for control

Analog Inputs from sensors (temperature, voltage, current etc.)

Analog Outputs for adjustment

Communication ports for third-party devices connection.

Main standard protocols support

Free shape of PCB (Printed Curcuit Board)

Displays, indicators, LEDs, buttons and other controls according to

customer needs

On board power supplies and converters from any power source

Battery power and non-volatile memory

Integrated Machine-to-Machine (M2M) PLC (Programmable Logical Controller)

May be used in equipment as a central “brain” with the following

functionalities:

Digital Inputs from switches

Digital Outputs or relays for controls

Analog Inputs from sensors (temperature, voltage, current etc.)

Analog Outputs for adjustment

Communication ports for third-party devices connection. The Main

standard protocols support: Modbus RTU M/S, Modbus TCP, etc.

Free shape of PCB (Printed Curcuit Board)

Displays, indicators, LEDs, buttons and other controls according to

customer needs

On board power supplies and converters from any power source

Battery power and non-volatile memory

AutoLog®

Automation

System

Automation systems in equipment

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Integrated Machine-to-Machine PLC (Programmable Logical Controller)

May be used in equipment as a central “brain” with following

functionalities:

Digital Inputs from switches

Digital Outputs or relays for control

Analog Inputs from sensors (temperature, voltage, current etc.)

Analog Outputs for adjustment

Communication ports for third-party devices connection.

Main standard protocols support

Free shape of PCB (Printed Curcuit Board)

Displays, indicators, LEDs, buttons and other controls according to

customer needs

On board power supplies and converters from any power source

Battery power and non-volatile memory

Implemented project applications: We are ready to supply similar devices for

customer’s projects

Medical equipment

Autoclaves

Sterilyzers

HVAC

Chiller for air conditioning

Air compressor plant optimizer

Industrial equipment

Pumps

Machinery

Pulp and paper production machines

AutoLog®

Automation

System

Automation systems in equipment

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Integrated Machine-to-Machine PLC (Programmable Logical Controller)

May be used in equipment as a central “brain” with following

functionalities:

Digital Inputs from switches

Digital Outputs or relays for control

Analog Inputs from sensors (temperature, voltage, current etc.)

Analog Outputs for adjustment

Communication ports for third-party devices connection.

Main standard protocols support

Free shape of PCB (Printed Curcuit Board)

Displays, indicators, LEDs, buttons and other controls according to

customer needs

On board power supplies and converters from any power source

Battery power and non-volatile memory

Other examples of existing project

applications:

Cathodic protection rectifiers:

Embedded PLC with various

communication systems

Building industry:

Heating, water distibution and ventilation

equipment may be automated with

embedded PLC

Production industry:

Pumps, machinery and other equipment

became “smarter” with

AutoLog® M2M solutions

AutoLog®

Automation

System

Automation system advantages

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Integrated Machine-to-Machine PLC (Programmable Logical Controller)

May be used in equipment as a central “brain” with following

functionalities:

Digital Inputs from switches

Digital Outputs or relays for control

Analog Inputs from sensors (temperature, voltage, current etc.)

Analog Outputs for adjustment

Communication ports for third-party devices connection.

Main standard protocols support

Free shape of PCB (Printed Curcuit Board)

Displays, indicators, LEDs, buttons and other controls according to

customer needs

On board power supplies and converters from any power source

Battery power and non-volatile memory

Water treatment, wastewater and

environmental applications

Other AutoLog® M2M advantages:

Energy saving and efficiency

Wireless sensor measurements and controls

Severe operation conditions, both in cold (-40°C)

and hot (+70°C) environment

Data acquisition both in local Intranets and global

Internet networks, buid-in GSM commmunication

Optionally battery operation

AutoLog®

Automation

System

AutoLog® M2M PLCs

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Measurements of voltage,

current, temperature.

Controls over GSM, TETRA,

Radio-modem

Measurements of temperature,

flow, pressure.

Controls over wired networks,

GSM, TETRA

Measurements from various

sensors. Embedded control

screens with SCADA

AutoLog®

Automation

System

Customer’s

equipment

OEM-M2M automation solution development process flow

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

?

Set of

measurements

Set of controls

Communications

?

?

?

Sensor

specifications

Input signal

specifications

Control tools

specifications

Output signal

specifications

HMI display

specifications

Communication

system requirements

Ports and protocols

specifications

SCADA

specifications

AutoLog®

OEM-M2M

Equipment

and

solution developement

!

AutoLog®

Automation

System

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Sensor specifications

Input signal specifications

• Current, voltage, potential, magnetic

• Chemical measurements

• Temperature, weather, moisture, humidity

• Flow, fluid velocity

• Navigation instruments

• Position, angle, displacement, distance

• Optical, light, imaging, photon

• Pressure

• Force, density, level

• Acoustic, sound, vibration

• Proximity, presence

• Other sensors

• Input signal examples:

• 4 .. 20 mA

• 0 .. +5 VDC

• -10…+10VDC

Measurements and inputs for OEM-M2M PLC

Control tools specifications

AutoLog®

Automation

System

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Control tools examples:

• Relays

• Controllable switches and breakers

• Actuators

• Motors and pneumatic control tools

Output signal specifications

HMI display specifications

Output signal examples:

Analog outputs

• 12 bit, 0-5VDC

• 12 bit, 0-10VDC

Digital outputs

• 12-24VDC, max 2A

• 5A /250VAC 1A/30VDC

LCD screens, LED indicators, buttons

Touch screens with embedded SCADA

applications.

Controls and interfaces system for OEM-M2M PLC

AutoLog®

Automation

System

Communication system for OEM-M2M PLC

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

Communication system

requirements

Ports and protocols

specifications

SCADA specifications

Available networks and communication systems

• GSM / GPRS

• TETRA

• Radio-modem communication

• Wireless sensors

• Local wired and optical fiber networks

Supported data ports and protocols:

Physical ports:

• RS232

• RS485

• Ethernet

Communication protocols:

• ModBus RTU, ModBus TCP/IP

• I2C expansion and HMI

• DNP 3.0 (under development)

• Local SCADA server

• CloudSCADA Internet service

• Embedded Touch-screens with SCADA applications,

AutoLog® M2M

Inputs and Outputs

PLC (Programmable Logical Controller)

Communication system

Power supply

HMI (Human Machine Interface)

Auxiliary equipment

May be integrated in PLC

May be partially integrated in PLC

Optional

1

2

3

4

5

6

1

2

4

5

6

OEM-M2M PLC

Optional

AutoLog® OEM-M2M PLC content

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

!

3

AutoLog® M2M

List of needed measurements and controls

Equipment description, operation flow, schemes and drawings

Communication system requirements and availability*

Data acquisition method and software application suggestions

Auxiliary equipment requiremnts

1

2

3

4

5

For OEM-M2M PLC development we

requesting following information:

AutoLog® M2M PLC development

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

!

* Optional

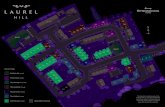

Iran

FF-Automation has a worldwide network of AutoLog system

integrators and distributors. We are also constantly seeking more new

co-operation partners, representatives and software partners.

Korea

India

Pakistan

Philippines

Iran

China

Indonesia

Singapore

North America

Brazil

England

Sweden

Latvia

South Africa

Finland Russia

Ukraine

Malaysia

Thailand

Saudi-

Arabia U.A.E

AutoLog®

Connections

FF-Automation Oy partners

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N

.

FF-AUTOMATION OY

Head Office:

Eräkuja 2, 01600 Vantaa,

Finland

tel: +358 10 2190 500

fax: +358 3 5846 711 e-mail: [email protected]

Factory:

Valkeakoski, Finland

For more information

about FF-Automation

and the AutoLog® range

of control products and

automation solutions,

please open

www.ff-automation.com

Contact

information

FF-Automation Oy contact details

S O P H I S T I C A T E D A U T O M A T I O N S O P H I S T I C A T E D A U T O M A T I O N