FDM July 2011

-

Upload

eastern-trade-media -

Category

Documents

-

view

274 -

download

0

description

Transcript of FDM July 2011

Adhesive-Free Has Never Felt So Weld

FDM

AS

IA M

ICA

(P) N

O. 045/11/2010 • P

PS

1204/06/2012 (022758) • ISS

N 0219-2284

July 2011 VO

L. 23 NO

. 5 C

over Price: U

S$10.00

Furniture Design And Manufacturing Asia Established Since 1986

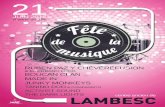

JULY 2011

CE: The Mark Of Entry For Exporters

CNC Machinery:The Right Road Ahead

OSB LINES:THEWOOD

BINDSBINDSTHAT

Cover_Jul 2011.indd 1 7/6/11 4:07:38 PM

ENQUIRY NO. 263

Even today, after more than 130 years, one thing above all drives us when we build complete lines for the wood panel industry: the development of concepts and technologies which not only satisfy but also delight our clients. To reduce material and energy costs, to boost productivity, or to ease the burden on the environment with intelligent solutions, for example. This is what we live for – now and in the future.

www.dieffenbacher.com ENQUIRY NO. 262

Innovation has been in our genes since 1873

me

die

nfo

rme

r.de

P A N E L P L A N T S

Innovation has been in our genes since 1873

me

die

nfo

rme

r.de

P A N E L P L A N T S

2 FDM AsiA JUly 2011 | www.fdmasia.com

JUly 2011 • VOL. 23 NO. 5

Contents

Furniture Design And Manufacturing Asia Established Since 1986

Market report16 Positive Outlook In Asian

Timber Markets According to insights on Asian markets provided by the ITTO Tropical Timber Market Report, demand continues to sustain timber prices at a high level. By International Tropical Timber Organization (ITTO)

Focus20 Getting Lean Without

Going TrimContrary to popular misconception, lean manufacturing practices are more about the reallocation of resources to avoid wastage, rather than the reduction of work force. By Roland Baumeister, department manager, FPInnovations

24 CNC Machinery Market: The Right Road AheadThe manufacturing of furniture involving critical operations has promoted the growth of computer-operated machines. CNC machinery providers must offer good after sale support and flexible payment models to entice potentical customers. By Shiv Kumar Shet, business development manager, Biesse Manufacturing India

34

38 Adhesive-free Has Never Felt So WeldWith rising adhesive costs, wood welding has presented itself as an alternative that gives better economic sense and mechanical strength. By Dr Antonio Pizzi, University Henri Poincare

28 Value Stream Mapping Points The Way To Lean Manufacturinglean manufacturing offers huge incentives in today’s competitive market by streamlining production operations to reduce waste and increase efficiency. Amongst the various methods for adoption, value stream mapping stands out due to the transparency it offers. By Chao Wang and Dr Henry Quesada-Pineda, Virginia Tech

32 Ready For Domestic ConsumptionDuring a stopover in Singapore, Mark Barford, executive director of the National Hardwood lumber Association, spoke to FDM Asia about the future of American hardwood in face of mounting competition and the changes in demand for the growing Asian market. By Wong Tsz Hin

technology34 The Wood That Binds

The use of methylene diphenyl diisocyanage (MDI) resin binders not only creates stronger bonds with wood strand and shorten press time, its application can also reduce formaldehyde emission and lower energy consumption. By Iain Stanton, composite wood panel marketing manager, Huntsman

24

panels42 CE: The Mark Of Entry

For ExportersThe CE mark is the symbol of confidence which assures consumers that the product is fit for its intended use. For wood-based panel manufacturers, this may be their ticket into the European market. By Mark Wilkinson, head of business development, Timber Research and Development Association

28

With the new ContiRoll® generation 8

Top technology for virtually isobaric operation.

Cut your costSave up to 15% in material!

www.siempelkamp.com

ENQU

IRY

NO.

261

4 FDM AsiA JUly 2011 | www.fdmasia.com

Contents

Regulars

72advertisers’ enquiry numbers.

Page

JUly 2011 • VOL. 23 NO. 5

Member of Business Publication Audit of Circulation, Inc.

Incorporating:

etm EasternTrade Media Pte Ltd

an Eastern Holdings Ltd company The Chinese Academyof Forestry

Associate of

The Chinese Academyof Forestry

Associate Of

Printer: Fabulous Printers Pte ltd

FDM Asia is published eight times a year (printed 2nd week of issue month) by

eastern trade Media pte ltd1100 lower Delta Road, EPl Building #02-05, Singapore 169206 Tel: (65) 6379-2888 • Fax: (65) 6379-2805/6379-2806 • Website: www.fdmasia.com

IMPORTANT NOTICEThe circulation of this publication is audited. The Advertiser's Association recommends that advertisers should place their advertisements only in audited publications.

Established in 1986, FDM Asia, formerly Asia Pacific Forest/Timber Industries, is a business magazine on sawmilling, woodworking, wood-based panels and furniture manufacturing. The Publisher reserves the right to accept or reject all editorial or advertising material and assumes no responsibility for the return of unsolicited artwork or manuscripts. All rights reserved. Reproduction of the magazine, in whole or in part, is prohibited without the prior written consent, not unreasonably withheld, of the publisher. Reprints of articles appearing in previous issues of the magazine are available on request, subject to a minimum quantity.

The views expressed in this journal are not necessarily those of the Publisher and while every attempt will be made to ensure the accuracy

and authenticity of information appearing in the magazine, the Publisher accepts no liability for damages caused by misinterpretation of information, expressed or implied, within the pages of the magazine. All correspondence regarding editorial, editorial contributions or editorial content should be directed to the Editor.

The magazine is available on subscription in Singapore at S$126.00 (GST applicable) per annum by surface mail. Subscription by airmail to readers in Asia Pacific costs S$160 per annum; Europe and the Americas, S$230 per annum. For further details, refer to the subscription card found within the pages of each issue. For more subscription information, please fax to: (65) 6379 2806 or email: [email protected].

MICA (P) NO. 045/11/2010 • PPS 1204/06/2012 (022758) • ISSN 0219-2284

46 Veneer Production At Your CommandHigh volume veneer production means that an enormous amount of data must be inputted for tracking and management purposes. Voice recording system can help improve efficiency and reduce possible errors. By Sophie Pothin, Metraplan Industries

surFaces & FloorIng50 Paint: Colourful

ResistanceSome paints used for floors are epoxy paints, oil-based paints and latex paints. Each type of paint has its own quality of durability, and is suited for different floor areas. By Tjut Rostina

FurnIture DesIgn & technology52 Staying Afloat In

Rising Tide Singaporean furniture manufacturers Falcon and Air Division share their views on staying ahead in the competitive market. By Wong Tsz Hin

WooDs & sustaInaBIlIty54 Sustainable

Plantation Forests: The Good And Bad While detractors may argue that plantation forests do more harm than good, careful planning and management can ensure they become a good solution to dwindling natural forest cover. Dr Jegatheswaran Ratnasingam, FIWSc

58 Certification Approach To SustainabilityWith growing concerns for forest degradation and deforestation particularly that of tropical forests, Malaysia has shown that forest certification can enhance forest management practices and biodiversity conservation. By the Malaysian Timber Certification Council

06 editorial08 Industry news70 calendar of events71 product highlights72a enquiry Form72b subscription Form

Events & ExhibitionsExhibition Review:62 Interzum 201164 Furnishing For The Future66 Ligna Hannover 201168 Going Green Is Serious Business 69 China Furniture & Woodworks

MALAYSIAN TIMBER INDUSTRY BOARD(Ministry of Plantation Industries and Commodities)

Level 13-17, Menara PGRM, No. 8, Jalan Pudu Ulu, Cheras, P.O. Box 10887, 50728 Kuala Lumpur, MalaysiaTel: 603-9282 2235 Fax: 603-9285 1477 / 9200 3769Email: [email protected] Website: www.mtib.gov.my

Endorse by

46

66

62

Promoting French Lumbers and Wood Products

6, rue François 1er 75008 PARISTél : + 33 (0)1 56 69 35 92 - Fax : + 33 (0)1 42 56 32 [email protected]

ENQUIRY NO. 083

Editorial

Published by:

EastErn tradE MEdia PtE Ltd(a fully owned subsidiary of Eastern Holdings Ltd)Registration No: 199908196C

managing director Kenneth Tan [email protected]

editor Tjut Rostina [email protected]

assistant editor Wong Tsz Hin [email protected]

editorial assistant Lena Chin [email protected]

senior graphic designer Agness Ng [email protected]

advertising sales manager Sim Eric [email protected]

business manager (China) Ding Yongmei [email protected]

assistant business manager (China) Yumi Gui [email protected]

senior circulation executive Brenda Tan [email protected]

contributors

Dr Antonio Pizzi Chao Wang Dr Henry Quesada-Pineda Iain Stanton Dr Jegatheswaran Ratnasingam Mark Wilkinson Roland Baumeister Shiv Kumar Shet Sophie Pothin

Demand for wood is expected to increase with concern over the security of

utilising nuclear generated power. Once considered as the power source

of the future, nations are beginning to question its stability when exposed

to unforeseen elements of catastrophe.

Germany has already announced its intention to shut down all 17 of its

nuclear power facilities by 2022, while Switzerland pledged to do the same by 2034. One

of the three main renewable targets set by the European Union to be reached by 2020 is

to increase renewable energy use by 20 percent. Countries such as the US and UK have

already established initiatives to facilitate the installation of commercial and industrial-

scale biomass boilers.

Bioenergy will create business opportunities for the wood industry in areas such as

firewood extraction, combustion options, fuel conversion setup, transport systems, logistic

management and power optimisation. This is evident at Ligna Hannover 2011, where a

substantial portion of the show is dedicated to address the different aspects involved with

regard to bioenergy. (Page 68)

Over in the Asia Pacific region, wood consumption will continue to grow as the focus

shifts from products for export to goods for the domestic markets. The increasing income

level of the people in this area, particularly in countries like Indonesia and Vietnam, will

drive the appetite for high quality wood products. This will, to a certain extent, offset the

two major challenges of the export market.

The first is the more stringent standards imposed overseas. Europe and US are set

to toughen up import restrictions through the European Union Timber Regulation and the

United States Lacey Act. Both of these require proper documentation of wood products

before they can be approved for sale.

The weakening US dollar has significantly cut into the profit margins of countries

whose currency managed to remain strong. Australian woodchip exporters are finding it

difficult to compete with their overseas counterparts despite increasing demand for the

material in places like Japan as they negotiate in Australian dollars, unlike most of the

world that do it in US dollars. In similar fashion, the Malaysian Furniture Entrepreneurs

Association foresees a 15 percent decline that would bring export sales to about RM6.8

billion (US$2.26 billion).

Despite these setbacks, the forecast for the industry remains positive. While the general

opinion is that revenue is unlikely to hit pre-economic crisis level, the consensus is that the

market can sustain its recovery. After a good performance in the first half of 2011, there

are plenty of reasons to remain positive for the rest of the year.

ExEcutivE Boardchairman Stephen Taygroup executive director Kenneth Tanfinancial controller

Robbin Lim

etm EasternTrade Media Pte Ltd

an Eastern Holdings Ltd company

Head Office & Mailing address:Eastern Trade Media Pte Ltd1100 Lower Delta Road, EPL Building#02-05, Singapore 169206Tel: (65) 6379 2888 Fax: (65) 6379 2805

representative Office - shanghai, China Office:Shanghai New Eastern Media Co. Ltd15D Block B, Victoria Plaza, No. 1068, Xikang Road, Shanghai, P.R, China 200060 Tel: (86 21) 6276 8394Fax: (86 21) 6276 4170

Wong tsz Hin

Driven By

FutureA

Wood

6 FdM asia JULY 2011 | www.fdmasia.com

ENQUIRY NO. 239

8 FDM AsiA JULY 2011 | www.fdmasia.com

Industry NewsI N D U S T R YNews

SPS Group Gets Ikea ContractBangkok, Thailand: Thai furniture exporter, SPS Group, is targeting

5 billion baht (US$0.16 billion) worth of exports in three years

after being named a major supplier to Ikea, according to a report

from The Bangkok Post.

The company targets 20 percent export growth to 2 billion

baht this year. However, it has secured a six-year, 18 billion baht

contract with Ikea that will result in further growth.

To ensure production capacity meets the heightened demand,

the company built a factory to supply high-growth Asian markets

such as China and India, as well as established European markets

such as Germany, France and the UK.

The company has supplied Ikea in limited quantities since

1991. The Swedish company is embarking on an aggressive

five-year regional expansion to 20 branches from the current

figure of six.

Six branches will be opened in Japan, with others planned

for Singapore, Malaysia and South Korea, along with the first

Thai location in early November this year.

JULY 2011

Indonesia Warns Countries Against Receiving Illegal TimberJakarta, Indonesia: Indonesian president Susilo Bambang

Yudhoyono has warned foreign countries against receiving

illegal timber from the country to help safeguard its huge

rainforest to deal with global climate change, according

to The Jakarta Post.

He also reminded his ministers to seriously enforce

the law against forest and environment violators, including

forest companies reaping double benefits by illegally

cutting trees in their concessions.

Indonesia’s rainforest is the world’s third largest with

more than 120 million hectares. The country’s forest loss,

however, remains high due to among others illegal logging,

massive palm oil plantations and illegal mining.

A report on three provinces — Central, East and West

Kalimantan — showed that ‘non-procedural’ forest use cost

the state Rp311.4 trillion (US$36.38 billion) in losses.

Indonesia and the EU have signed the Voluntary

Partnership Agreement on Forest Law Enforcement

Governance and Trade (FLEGT–VPA) to reduce illegal

logging. The agreement is slated to be ratified in September

and expected to come into force by 2013.

Rog

er P

rice,

Ant

wer

p, B

elgi

um

Tane

nhau

s, B

rook

lyn,

US

ENQU

IRY

NO.

264

10 FDM AsiA JULY 2011 | www.fdmasia.com

Industry News

Wood Product Exporters Must Brace Themselves For Tougher StandardsHanoi, Vietnam: Vietnamese timber and wood product exporters

will have to develop an elaborate system to ensure the legality

of materials used to avoid the risk of losing their footholds in

key markets like the US and the EU, according to a report from

VietNamNet.

Manufacturers would need to show they have procured

wood from areas with approved forest management plans

and appropriate cutting permits. In addition, they would need

to ensure they are excluding illegal and other unwanted wood

both at the forest where materials are acquired as well as at

processing and manufacturing facilities.

These steps become necessary as the EU and US markets

are set to toughen up import restrictions through the European

Union Timber Regulation and the United States Lacey Act.

The US and Europe are the two biggest markets for Vietnamese

wood products, 38 and 44 percent respectively, and both have

adopted laws prohibiting the import of illegal timber.

Under the Lacey Act, all wood products must have certificates

proving they are made from legally exploited wood. Without a

certificate, the products could be seized or destroyed.

Under the EU Forest Law Enforcement, Governance and

Trade (FLEGT) that will take effect in 2013, companies exporting

wood products to Europe must provide documents proving

that the timber was legally logged. Documents must include

the timber’s scientific name, the quantity being exported, and

the country of harvest.

Companies found selling products made from illegally

sourced timber will face severe penalties, such as confiscation

of the goods, a possible jail term for those involved and a

heavy fine.

Hawa deputy chairman Huynh Van Hanh said the Vietnam and

EU are currently discussing a voluntary partnership agreement

on sourcing wood products to facilitate local wood product

exporters. The two sides hope to sign a voluntary partnership

agreement by the end of 2012.

Yun

Hua

ng Y

ong,

Har

bor

d, A

ustr

alia

Man Wah Sees Profit Soar In 2010Hong Kong: Man Wah Holdings, a Hong Kong-based

furniture manufacturer, has reported a 29.9 percent surge

in sales in fiscal year 2010, maintaining profits in the face

of rising costs.

Global revenue for the year was HKD$3.8 billion

(US$489.3 million) with net profit of HKD$621.3 million,

up 0.6 percent from the previous year.

The US remained the top market sales increasing by

55percent to US$266 million.

The company kept its gross profit margin stable at 42.5

percent, reflecting stringent cost controls and sales strategy

adjustments, despite increased production costs. The net

profit margin, however, declined to 16.3 percent from 21.1

percent the previous year, partly because of soaring ocean

freight costs.

The manufacturer, which raised funds last year by selling

about a 25 percent stake in the company in a public stock

offering, said it has a new factory under construction in

Wujiang, China, that is expected to open in the second half

of 2012. The company also plans another plant in Tianjin to

cope with expected increased demand over the next five to

eight years, and to take advantage of lower logistics costs

and shorter delivery time to northern China.

Den

nis

Won

g, H

ong

Kon

g

www.fdmasia.com | FDM AsiA JULY 2011 11

Industry News

DNA Fingerprinting To Fight Against Illegal LoggingAdelaide, Australia: Advances in DNA ‘fingerprinting’ and other genetic techniques

are making it harder for illegal loggers to get away with destroying protected

rainforests.

DNA fingerprinting for timber products has grown in international recognition

due to research led by the University of Adelaide that traces individual logs or

wood products back to the forests where they came from.

An estimated 10 percent of wood imported into Australia consists of illegally

traded timber, which has been cut down outside designated logging areas or

outside agreed environmental controls. Australian companies have been the first

in the world to purchase timber products that use DNA fingerprinting, as part of

proof of legal origin starting back in 2007 — European and American importers

are now following suit.

The research is closely aligned with another major project, to develop a ‘DNA

barcode’ for every tree and grass species on earth.

Ran

den

Ped

erso

n

TimberWest Forest Acquired By BCIMC & PSPVancouver, Canada: TimberWest Forest has announced the

completion of the plan of arrangement under which British

Columbia Investment Management Corporation and the Public

Sector Pension Investment Board indirectly acquired all of the

company’s outstanding stapled units at a price of CAD$6.16

(US$6.39) in cash per stapled unit.

With the completion of the transaction, the company’s stapled

units will be delisted from the Toronto stock exchange.

Hak

an D

ahls

trom

, Hel

sing

bor

g, S

wed

en

Softwood Lumber Consumption To Continue Upward TrendSeattle, US: Global demand for softwood

lumber increased by over 10 percent

in 2010. This came after a year when

wood consumption worldwide was the

lowest it had been in almost 50 years.

This upward trend in consumption has

continued thus far in 2011, with total

volume consumed being more than 15

percent higher than the same period in

early 2010, according to Wood Resource

Quarterly.

China has been the major driver in the

higher demand for lumber. The country’s

sawmills are far from being able to meet

the increased demand, and as a result

there has been a substantial increase in

import volumes the past five year, from

just over two million cubic metres in

2006 to 9.4 million cubic metres in 2010.

This unprecedented rise in shipments

continued the first two months of 2011

when imports were as much as 32 percent

higher than in 2010.

Practically all major lumber markets in

Asia, Europe and North America experienced

stronger demand last year. This resulted

in higher production worldwide and

also increased global trade. The world’s

largest importer, the US, imported seven

percent more lumber in 2010 than the

previous year, while imports to the third

largest market, Japan, were up almost

15 percent. In Europe, shipments were

up between 10 and 35 percent to the

largest lumber-consuming countries on

the continent.

Lumber prices can be anticipated to

go up in many markets during 2011 for a

number of reasons, including expected

increased demand in China, somewhat

higher lumber imports to Japan for the

rebuilding after the earthquake, and continued

measured improvements in the US housing

market (mainly repair & remodeling and

multi-family residential housing).

12 FDM AsiA JULY 2011 | www.fdmasia.com

Industry News

Furniture Manufacturers Association Collaborates With NSF To Develop Standards

SCS Announces Indonesian SubsidiaryCalifornia, US: Scientific Certification Systems (SCS) has

announced the establishment of a new subsidiary to be

headquartered in Jakarta in response to growing demand

for certification and verification services from the Indonesian

forest products industry.

The subsidiary, PT Scientific Certification Systems Indonesia

(PT-SCS), offers Forest Stewardship Council (FSC) chain of custody

certification and forest management certification in Indonesia.

Indonesian timber exports grew from US$7.3 billion in 2005 to

US$9.7 billion in 2010, according to the European Union Delegation

to Indonesia. A 2007 United Nations report estimated that up to

88 percent of timber logged in Indonesia was illegally sourced,

putting timber importers at risk of unknowingly trafficking illegal

timber. In order to improve industry performance, a number of

initiatives are now seeking to increase independent third-party

certification of forests and verification of timber legality.

The Indonesian office also offers legal harvest verification,

and is in the process of becoming accredited to SVLK (Timber

Legality Assurance System), the Indonesian national standard

for legality that will become mandatory for all companies.

Loy Jones, a professional forester with 16 years of experience

in FSC certification, has been appointed the interim director,

with Thesis Budiarto assuming the role of Indonesia programme

coordinator.

Michigan, US: The Business and Institutional Furniture

Manufacturers Association International has collaborated

with NSF International, an ANSI-accredited developer of

more than 75 American national standards, to develop

product category rules (PCR) for the furniture industry.

The National Center for Sustainability Standards

(NCSS), founded by NSF, will serve as the programme

operator for developing the furniture PCR.

PCR help meet the growing demand for science-

based support to verify environmental product claims

and eliminate greenwashing. They define how to conduct

a life cycle assessment for a particular product group

and what to include in the resulting report.

A life cycle assessment measures inputs, outputs

and environmental impacts of a product across its

lifespan, from cradle to grave. An environmental product

declaration (EPD) is the ISO-compliant third-party-verified

report that functions like a nutrition label to explain the

data generated from a life cycle assessment.

Adopted by European countries and growing in

recognition in the US, PCR and EPDs provide an

international method of communication to compare and

report a product’s environmental impact throughout

its entire life cycle.

In addition to this collaboration, the centre is also

working with several flooring trade associations on the

first North American PCR for resilient, carpet, laminate,

tile, and wood flooring products.

Kat

ina

Rog

ers

International Paper Proposes To Acquire Temple-InlandTennessee, US: International Paper announced that it

has proposed to acquire all of the outstanding shares

of Temple-Inland for US$30.60 per share, about US$3.3

billion in total, in cash.

Under the terms of the proposal, the offer represents a

44 percent premium to Temple-Inland’s price. International

Paper’s offer, which is backed by committed financing

from UBS Investment Bank, is contingent on appropriate

documentation and regulatory approval, which the company

believes can be obtained.

The offer reflects the potential cyclical improvement in

Temple-Inland’s building products segment and International

Paper’s willingness to share a portion of the significant

synergies available from the transaction with Temple-

Inland shareholders.

www.fdmasia.com | FDM AsiA JULY 2011 13

Industry News

Canada’s Wood Products Industry To Remain Profitable In 2011

UK Forestry Returns Up For Fifth Year RunningBoston, US: Investors in UK commercial

forests have learnt that returns

exceeded other major markets,

such as commercial property, over

the past year, explained Alternative

Asset Analysis.

The IPD UK Forestry Index shows

that returns for 2010 reached 20

percent, which is the highest rate since

2007. Strong demand was behind the

growth in returns, according to the

analysts at IPD.

Timber prices were up by 38.5

percent in the year to March 2011 as

demand for timber from emerging

economies is quickly exceeding supply.

This level of demand is only expected

to rise even faster in the coming

years — leading to a widely held

expectation that timber prices will also

grow further, along with the need to

for sustainably produced timber.

Ottawa, Canada: Despite slower production

growth in 2011, Canada’s wood product

industry is expected to record a second

consecutive year of profitability, according

to The Conference Board of Canada.

Following a solid rebound last year,

the wood products industry is expected

to lose momentum in 2011. Ongoing

weakness in the US housing market and

a slowdown in residential construction

activity in Canada are limiting growth in

demand for wood products.

However, the industry is expected

remain in the black in 2011, thanks to

cost-cutting measures implemented in

previous years and industry efforts to

diversify away the US market.

Production growth will to slow to 3.9

percent this year, down from an increase

of 10.7 percent in 2010. Starting in 2012,

an improvement in residential construction

activity in Canada, rising exports to China

and the long-awaited recovery in the US

housing market should support stronger

production growth. However, industry

production is not expected to return to

its 2005 peak during the forecast period

through 2015.

After recording losses totaling CAD$1.6

billion (US$1.63 billion) between 2007 and

2009, the industry returned to profitability

last year. In 2011, pre-tax profits will increase

by 13.8 percent to CAD$694 million. Profit

margins will hover around 3.6 percent in

2011 and continue to rise over the next

four years.

inte

rnet

s_d

iary

FRA Supports Biomass InitiativeWashington, US: A new woody biomass procurement project, launched by The Nature

Conservancy (TNC) and the Sustainable Forestry Initiative (SFI), has attracted support

from Forestry Research Associates (FRA).

The research and advisory consultancy

provides fresh outlooks and consultancy

services on all matters surrounding forestry

investment, sustainability and forestry

management and has spoken out in support

of the new pilot scheme. The plan is to

support sustainable forestry management

by helping US-based bioenergy companies

to purchase woody biomass.

Both parties agree that bioenergy is a

major market for the forestry sector and

that in order to maintain the health of the

resource, appropriate steps should be in

place for the procurement of forest fibre.

“The focus is on developing a procurement

system that is fair and responsible,” explained

FRA’s analysis partner Peter Collins. His

view was backed by TNC’s Chief External

Officer, Glenn Prickett, who added, “Woody biomass can be a great source of renewable

energy and offers an excellent incentive so landowners can maintain their forests as

forests – as long the forest is managed responsibly.” SFI’s Fiber Sourcing requirements

will be imposed on the procurement processes.

FRA added that the initiative is intended to ensure that all sources of woody biomass

are responsible, which will help add legitimacy to the industry as a whole and will also

help to nurture it as a major source of income for forestry managers and investors.

She

hal J

osep

h, N

ugeg

oda,

Sri

Lank

a

14 FDM AsiA JULY 2011 | www.fdmasia.com

Industry News

Kior Appoints Condoleezza Rice As DirectorTexas, US: KiOR, a cellulosic fuels

producer, announced that former

secretary of state Condoleezza Rice

has agreed to join KiOR’s board of

directors.

Secretary Rice has a distinguished

career in the public, private, and

academic sectors. She served as

US secretary of state from January

2005 to 2009 after serving as the

chief national security advisor to the

president beginning in 2001. She is currently professor of political economy in

the Stanford Graduate School of Business, senior fellow of public policy at the

Hoover Institution, and professor of political science at Stanford University.

Secretary Rice has also served on the board of directors for the Chevron

Corporation, the Charles Schwab Corporation, the Transamerica Corporation

and the International Advisory Council of JP Morgan. She is currently on

the board of Makena Capital, a private endowment firm, and C3, an energy

software company.

Gob

iern

o d

e C

hile

German Pellets Acquires Blieninger GroupWismar, Germany: German Pellets has

acquired the Blieninger Group, headquartered

in Vilsbiburg, Germany, along with its

brands ‘FireStixx’ and ‘pelprotec’.

The subsidiary FireStixx Holzenergie is

one of the leading wood pellet retailers in

the German-speaking regions of Europe, and

its ‘FireStixx’ is a well-known wood pellet

brand in Germany, Austria and Italy.

The acquisition also include the patents

for ‘pelprotec’, a unique coating technology

that offers dust-free loading , a higher heat

value and improved flowability.

With this acquisition, the company

has also taken over the group’s divisions

for sawmill by-products and logistics, as

well as potting and garden soil.

Domotex Heading To Russia In 2012Hannover, Germany:

Deutsche Messe is

expanding its programme of

events abroad by expanding

Domotex to the reaches

of Russia in 2012.

The exhibition will be

held from September 26 –

28 and will comprise the

carpet, parquet flooring,

laminate flooring, natural

stone as well as textile and resilient flooring sections.

The show will be the only specialised flooring fair in Russia to date and the

targeted groups of visitors are mainly distributors and buyers in the wholesale

and retail trade.

The aim is to occupy a net exhibition area of approximately 4000 sq m in

the first year.

Appointments

Eacom Anounces Two New DirectorsQuebec, Canada: Eacom Timber has

announced at its annual general meeting

that it has elected two new directors to

its board, Joseph (Jay) Gurandiano and

Gilles Masson C.

Jay is the MD of Stone House

Investment Holdings and a director of

Xerium Technologies. He also served as

the chairman of the board of directors of

Ainsworth Lumber, a lumber and wood

products company, until May 2010. Jay

has been appointed the chair of the

corporate governance, nominating and

human resources committee.

Gilles is a corporate director of several

public companies including Malaga,

Royal Nickel and Semafo. Prior to his

retirement in 2005, he was a partner

of PricewaterhouseCoopers. Gilles has

been appointed the chair of the audit

committee.

Predictable suPPly. affordable Prices.That’s the way we do business at Weyerhaeuser each and every day. Our Northwest Hardwoods brand lumber is available in a wide range of grades that have been hand selected for maximum yield. This translates to more usable lumber and cost efficiency for you. And American hardwoods are in plentiful supply: the volume has more than doubled since 1953. USDA Forest Service 2007

Contact us for a quote today: [email protected] northwesthardwoods.com

Shanghai, China: 86.21.6249.9898 • Vietnam/Guangzhou, China: 86.20.3878.1570 • Hong Kong: 852.2865.5922

, and Northwest Hardwoods are registered trademarks of Weyerhaeuser. © 2011 Weyerhaeuser Company. All rights reserved.

540-522_Weyer_china ad_Final.indd 1 2/7/11 5:39 PM

ENQUIRY NO. 214

16 FDM AsiA july 2011 | www.fdmasia.com

Market Report

MalaysiaDomestic & Export Price Differentials ErodedPrices of Malaysian timber and timber products continue to rise sharply due to strong demand and higher fuel prices, which are driving up transportation and production costs.

Price differentials between domestic and export quality wood products are eroding fast. This is expected to have a spill-over effect on other building and construction material in the market. The increase in construction grade plywood prices is expected to increase construction cost by 10 to 30 percent for both commercial and housing projects.

Logging Area Reduced In 10th Malaysian PlanThe Malaysian National land Council has set aside 155,000 ha of forest to be harvested for timber annually under the 10th Malaysian Plan, a reduction of 15,000 ha from the previous 9th Malaysia Plan, which allowed for 170,000 ha of forest to be harvested annually.

According to insights on Asian markets provided by the ITTO Tropical Timber Market Report, demand continues to sustain timber prices at a

high level. By International Tropical Timber Organization (ITTO)

5 ITTO TTM Report 16:10 16 -31 May 2011

Malaysian Sawnwood, domestic Balau (25&50mm,100mm+) MerbauKempas 50mmx(75,100 & 125mm) Rubberwood 25x75x660mm up 50-75mm Sq. >75mm Sq.

US$ per m3

341-361472-524282-322

236-286275-307297-327

Plywood Prices Malaysia ply MR BB/CC, FOB 2.7mm3mm9mm & up

US$ per m3

440-500420-450372-442

Meranti ply BB/CC, domestic 3mm 12-18mm

US$ per m3

363-453346-375

Other Panel Prices Malaysia, Other Panels, FOB

Particleboard Export 12mm & up Domestic 12mm & up

MDF Export 15-19mm Domestic 12-18mm

US$ per m3

254-277244-259

307-338298-317

Added Value Product Prices Malaysia, Mouldings, FOB Selagan Batu Decking Red Meranti Mouldings 11x68/92mm x 7ft up Grade A Grade B

US$ per m3

565-575

580-593534-544

Furniture and Parts Prices Malaysia, Rubberwood, FOB

Semi-finished dining table solid laminated top 2.5'x4', extension leaf As above, Oak Veneer Windsor Chair Colonial Chair Queen Anne Chair (soft seat) without arm with arm Chair Seat 27x430x500mm

US$ per piece

76-9283-9775-7773-78

73-8273-8261-66

Rubberwood Tabletop 22x760x1220mm sanded & edge profiled Top Grade Standard

US$ per m3

622-652606-622

Report from Indonesia

More transparency on forest clearing moratorium The 2 year moratorium on primary forest clearing and logging provided guidance to the plantation, energy and construction industries concerning green house gas emissions, while offering various forms of exemptions and concessions. The moratorium outlines the following:

• The moratorium mandates ministers and government officials to suspend the processing of all permits for logging and forest conversion purposes, including those for timber and palm oil, in primary forests and peatlands in the following

government categories: conservation forest, protected forest and production forest. Permits however, are allowed for secondary forests, which have been affected by human and commercial activities.

• It will be enforced over two years and is open for extension. Its implementation will be overseen by a task force on Reducing Emissions from Deforestation and Forest Degradation (REDD).

• It covers up to 64.2 million ha. of primary forest and more than 30 million ha. of peatlands. No compensation will be offered under the moratorium to firms unable to expand in these areas, although the government has allocated another 35 million ha. of "degraded forest" for commercial development.

The moratorium provides the following exemptions:

• Firms with existing permits or have approval in principle from the forestry minister for permits to log and convert forest.

• Extension of existing permits.

• Projects to develop geothermal and other power plants, oil and gas fields, sugar and rice plantations.

• Ecosystem restoration

• The government will regularly update a map of its forests in a bid to correct overlapping permits in the sector. The map will be published to help investors clarify which forest areas are still on offer and which are not.

Log Prices (domestic) Indonesia logs, domestic prices Plywood logs Face Logs Core logs Sawlogs (Meranti) Falcata logs Rubberwood PineMahoni (plantation mahogany)

US$ per m3

217-260202-231211-271179-21490-94

189-230 494-524

Sawnwood Prices Indonesia, construction material, domestic Kampar (Ex-mill) AD 3x12-15x400cm KD AD 3x20x400cm KD

Keruing (Ex-mill) AD 3x12-15x400cm AD 2x20x400cm AD 3x30x400cm

US$ per m3

202-221217-252238-261240-269

253-267241-259224-243

5 ITTO TTM Report 16:10 16 -31 May 2011

Malaysian Sawnwood, domestic Balau (25&50mm,100mm+) MerbauKempas 50mmx(75,100 & 125mm) Rubberwood 25x75x660mm up 50-75mm Sq. >75mm Sq.

US$ per m3

341-361472-524282-322

236-286275-307297-327

Plywood Prices Malaysia ply MR BB/CC, FOB 2.7mm3mm9mm & up

US$ per m3

440-500420-450372-442

Meranti ply BB/CC, domestic 3mm 12-18mm

US$ per m3

363-453346-375

Other Panel Prices Malaysia, Other Panels, FOB

Particleboard Export 12mm & up Domestic 12mm & up

MDF Export 15-19mm Domestic 12-18mm

US$ per m3

254-277244-259

307-338298-317

Added Value Product Prices Malaysia, Mouldings, FOB Selagan Batu Decking Red Meranti Mouldings 11x68/92mm x 7ft up Grade A Grade B

US$ per m3

565-575

580-593534-544

Furniture and Parts Prices Malaysia, Rubberwood, FOB

Semi-finished dining table solid laminated top 2.5'x4', extension leaf As above, Oak Veneer Windsor Chair Colonial Chair Queen Anne Chair (soft seat) without arm with arm Chair Seat 27x430x500mm

US$ per piece

76-9283-9775-7773-78

73-8273-8261-66

Rubberwood Tabletop 22x760x1220mm sanded & edge profiled Top Grade Standard

US$ per m3

622-652606-622

Report from Indonesia

More transparency on forest clearing moratorium The 2 year moratorium on primary forest clearing and logging provided guidance to the plantation, energy and construction industries concerning green house gas emissions, while offering various forms of exemptions and concessions. The moratorium outlines the following:

• The moratorium mandates ministers and government officials to suspend the processing of all permits for logging and forest conversion purposes, including those for timber and palm oil, in primary forests and peatlands in the following

government categories: conservation forest, protected forest and production forest. Permits however, are allowed for secondary forests, which have been affected by human and commercial activities.

• It will be enforced over two years and is open for extension. Its implementation will be overseen by a task force on Reducing Emissions from Deforestation and Forest Degradation (REDD).

• It covers up to 64.2 million ha. of primary forest and more than 30 million ha. of peatlands. No compensation will be offered under the moratorium to firms unable to expand in these areas, although the government has allocated another 35 million ha. of "degraded forest" for commercial development.

The moratorium provides the following exemptions:

• Firms with existing permits or have approval in principle from the forestry minister for permits to log and convert forest.

• Extension of existing permits.

• Projects to develop geothermal and other power plants, oil and gas fields, sugar and rice plantations.

• Ecosystem restoration

• The government will regularly update a map of its forests in a bid to correct overlapping permits in the sector. The map will be published to help investors clarify which forest areas are still on offer and which are not.

Log Prices (domestic) Indonesia logs, domestic prices Plywood logs Face Logs Core logs Sawlogs (Meranti) Falcata logs Rubberwood PineMahoni (plantation mahogany)

US$ per m3

217-260202-231211-271179-21490-94

189-230 494-524

Sawnwood Prices Indonesia, construction material, domestic Kampar (Ex-mill) AD 3x12-15x400cm KD AD 3x20x400cm KD

Keruing (Ex-mill) AD 3x12-15x400cm AD 2x20x400cm AD 3x30x400cm

US$ per m3

202-221217-252238-261240-269

253-267241-259224-243

Asian Timber Markets

Positive Outlook In

Rob

and

Ste

pha

nie

levy

, Tow

nsvi

lle, A

ustr

alia

www.fdmasia.com | FDM AsiA july 2011 17

Market Report

According to the Malaysian Natural Resources and Environment Ministry, the annual allowable cut was adjusted to meet criteria set up to determine proper and effective forestry management.

The ministry added that up to 2008, Sarawak had 6 million ha of forest reserve out of 14.43 million ha for the entire country. However, in terms of forested areas, Sarawak had up to 8.23 million ha, which constituted 66.9 percent of the state land area, compared to 4.4 million ha (56.7 percent) for Sabah and 5.85 million ha. (44.7 percent) for Peninsular Malaysia.

New Green Material For Industrial ApplicationsThe Malaysian Agricultural Research and Development Institute (MARDI) has succeeded in developing Kenaf Polymer Composite (KPC) as a green material for construction and industrial applications.

This came as a result of intensive research and development over a six year period.

Kenaf is regarded as a suitable substitute for timber products as it is a short term fibre crop, thus mitigating the need to harvest timber for wood-based product applications. The initial market potential for KPC products is estimated at RM3 billion (uS$0.99 billion) annually.

Presently, samples of KPC have been sent to the Eu for further testing and certification of its durability and properties. KPC is regarded as outstanding reinforcing filler in thermo-plastic composites when combined with certain plastic resins.

indonesiaMore Transparency On Forest Clearing MoratoriumThe two-year moratorium on primary forest clearing and logging provided guidance to the plantation, energy and construction industries concerning green house gas emissions, while offering various forms of exemptions and concessions.

The moratorium outlines the following:• The moratorium mandates ministers and government

officials to suspend the processing of all permits for logging and forest conversion purposes, including those for timber and palm oil, in primary forests and peatlands in the following government categories: conservation forest, protected forest and production forest. Permits however, are allowed for secondary forests, which have been affected by human and commercial activities.

• It will be enforced over two years and is open forextension. Its implementation will be overseen by a task force on Reducing Emissions from Deforestation and Forest Degradation (REDD).

• It covers up to 64.2 million ha of primary forest and

6 ITTO TTM Report 16:10 16 -31 May 2011

Plywood Prices Indonesia ply MR BB/CC, export FOB 2.7mm3mm6mm

US$ per m3

426-482384-425363-405

MR Plywood (Jakarta), domestic 9mm 12mm 15mm

US$ per m3

281-292273-283263-277

Other Panel Prices Indonesia, Other Panels, FOB

Particleboard Export 9-18mm Domestic 9mm 12-15mm 18mm MDF Export 12-18mm Domestic 12-18mm

US$ per m3

240-249220-232214-226210-221270-285254-266

Added Value Product Prices Indonesia, Mouldings, FOB Laminated Boards Falcata wood

US$ per m3

322-335Red Meranti Mouldings 11x68/92mm x 7ft up Grade A Grade B

515-546470-493

Report from Myanmar

Early monsoon strands logs in the forest Myanmar’s annual monsoon usually begins around the last week of May or early June but this year the rains started in April which caught loggers by surprise and they had to leave a huge quantity of logs in the forest as conditions did not permit transportation.

The drop in supply of logs triggered an upward swing in log prices in Yangon and also resulted in some short shipping.

Importers in Bangladesh steady buyers of Gurjan Hardwood buyers report that while Gurjan prices are on the rise the prices of Pyinkado are rather soft as trading is slow.

The reason for the good Gurjan market is said to be because of active purchases by buyers for the markets in China and Bangladesh. Importers in Bangladesh have always been steady buyers and the logs are used mainly for sawnwood production.

Will firm April prices be sustained? The market outlook for teak and other hardwoods has picked up, one analyst said. It could be seen in the April hardwood tender sales that export quality Pyinkado fetched US$ 716 (cf. MTE list price US$ 642 to 678). Export rejection quality Pyinkado fetched US$ 694 (cf. MTE list price US$ 578).

Export quality Gurjan (Kanyin) logs fetched US$ 445 (cf. MTE list price from US$ 375 to 390) Demand for Teak, especially Sawing Grade 7 (ER1) is very strong but this quality log is in short supply so demand is expected to remain high.

Myanmar log prices (natural forest logs) Teak Logs, FOB € Avg per Hoppus Tonne

(traded volume)

Veneer Quality 2nd Quality

3rd Quality

4th Quality

Sawing Quality Grade 1 (SG-1)

Grade 2 (SG-2)

Grade 4 (SG-4)

Grade 5 (SG-5) Assorted

Grade 6 (SG-6) Domestic

Grade 7 (ER-1)

Aprnil

nil

4,658(11 tons)

3,198(44 tons)

2,846(41 tons)

2,019(200 tons)

1,313(139 tons)

1,196(78 tons)

936(92 tons)

Maynil

nil

4,250(11 tons)

3,180(34 tons)

2,773(44 tons)

2,143(219 tons)

1,362(180 tons)

1,357(72 tons)

991(61 tons)

Hoppus ton=1.8m3; All grades, except SG-3/5/6, are length 8’ x girth 5’ &up. SG-3/4/6 are girth 4’ &up. SG-3 grade is higher than SG-4 but with lower girth and price. Prices differ due to quality or girth at the time of the transaction.

Hardwood log prices Pyinkado export quality Euro517 (261 tons) Pyinkado export reject Euro500 (39 tons) Gurjan export quality Euro345 (404 tons)

Prices are in Euro per hoppus ton FOB

Report from India

India sets high export target As the flow of exports from India improves, the government of India has set an export target of US$500 billion for 2013-14, almost doubling the US$246 billion achieved during 2010-11.

The current export policies, diversification of markets and technological advances have helped the government project such an optimistic future. Processed wood product exporters have also been quite active and expect to contribute to enhancing the export performance.

Log sales brisk and prices firm In Western India, the current schedule of log auctions, which began on the 22nd of May in forest depots in north and south Gujarat, will continue until the 5th of June. Thereafter auctions will begin in forest depots of central Gujarat notably the Vyara, Rajpipala and Tapti regions.

These auctions will run until the third week of June. Approximately 6,500 cubic metres of Teak and about 4,200 cubic metres of other hardwoods put up for sales are of newly harvested logs, sales are expected to be brisk and prices firm.

more than 30 million ha of peatlands. No compensation will be offered under the moratorium to firms unable to expand in these areas, although the government has allocated another 35 million ha of ‘degraded forest’ for commercial development.

The moratorium provides the following exemptions:• Firmswithexistingpermitsorhaveapprovalinprinciple

from the forestry minister for permits to log and convert forest.

• Extensionofexistingpermits.• Projectstodevelopgeothermalandotherpowerplants,

oil and gas fields, sugar and rice plantations.• Ecosystemrestoration• Thegovernmentwillregularlyupdateamapofitsforests

in a bid to correct overlapping permits in the sector. The map will be published to help investors clarify which forest areas are still on offer and which are not.

MyanmarEarly Monsoon Strands Logs In ForestMyanmar’s annual monsoon usually begins around the last week of May or early june, but this year, the rains started in April, which caught loggers by surprise and they had to leave a huge quantity of logs in the forest as conditions did not permit transportation.

The drop in supply of logs triggered an upward swing in log prices in yangon and also resulted in some short shipping.

Importers In Bangladesh Steady Buyers Of GurjanHardwood buyers report that while Gurjan prices are on the rise, the prices of Pyinkado are rather soft as trading is slow.

The reason for the good Gurjan market is said to be because of active purchases by buyers for the markets in China and Bangladesh. Importers in Bangladesh have always been steady buyers and the logs are used mainly for sawnwood production.

18 FDM AsiA july 2011 | www.fdmasia.com

Market Report

Hardwood Prices Expected To Remain HighThe market outlook for teak and other hardwoods has picked up. It could be seen in the April hardwood tender sales that export quality Pyinkado fetched uS$716. Export rejection quality Pyinkado fetched uS$694. Export quality Gurjan (Kanyin) logs fetched uS$445.

Demand for Teak, especially Sawing Grade 7 (ER1) is very strong, but this quality log is in short supply so demand is expected to remain high.

indiaIndia Sets High Export TargetAs the flow of exports from India improves, the government of the country has set an export target of uS$500 billion for 2013-14, almost doubling the uS$246 billion achieved during 2010-11.

The current export policies, diversification of markets and technological advances have helped the government project such an optimistic future. Processed wood product exporters have also been quite active and expect to contribute to enhancing the export performance.

Optimism In Building Sector Driving DemandSales of teak and hardwoods in forest depots of Central India, for example Madhya Pradesh, have seen active bidding. Reports indicate that approximately 20,000 cubic metres have been sold and that newly harvested logs, felled in the current season, continue to arrive.

There is a positive attitude in the Indian building and construction sectors and this is driving demand for locally grown hardwoods as well as Teak. Prices secured in the central as well as in the western forest depots tend to be similar as the final market is the same.

JapanImproving Sarawak Log Supply Takes Heat Out Of Log MarketImproved weather conditions allowing uninterrupted forest harvesting and the slowing of orders for plywood from japan has resulted in an easing of the critical log supply in Sarawak, reports the japan lumber Reports (jlP).

Another factor which is stabilising the South East Asian log market is the slowing of orders from Indian importers who found that the Indian market could not bear the high log prices.

under these circumstances, log supply and demand in the domestic market and for export is better balanced, so log prices, while remaining firm, are not moving higher.

Sarawak regular Meranti log prices are currently around uS$350-360 per cubic metre, unchanged from last month, but suppliers in Sarawak are still seeking prices of uS$370 per cubic metre.

Meranti small log prices are holding at uS$320-330 while super small logs are at uS$300-310 per cubic metre, which is about the upper level for these logs.

Wooden Building Design Standard DraftedThe Ministry of land Infrastructure and Transport has released the new building standard for wooden public buildings to facilitate construction under the recently enacted law to promote the use of more wood in public buildings.

This new standard sets out the requirements for building life expectations, fire resistance and structural limits which, says jlP, have not been available until now.

Wood products used for the construction of public buildings are required to be manufactured from forest thinnings and certified legal timbers. It is required that the buildings have a life of at least 50 years so the standards on decay prevention and use of treated or naturally durable wood are specified in detail.

Industrial Material DistributionMaterials needed for the construction of temporary homes in east japan are now moving steadily. Products such as panels, piling, structural steel framing and household fittings

12 ITTO TTM Report 16:10 16 -31 May 2011

Plywood mills in Japan having to pay Yen 9-10,000 per koku for logs find it very hard to pass on these prices to plywood consumers.

Orders for new homes holding up There was deep concern amongst house builders in Japan that there would be a sharp drop in demand for new homes because of the unease felt by consumers over the East Japan earthquake and the ongoing nuclear crisis.

However, the major house builders are reporting that orders in April did not drop as much as expected but there was a noticeable drop in visits to model homes by prospective buyers so the future remains uncertain.

Wooden building design standard drafted The Ministry of Land Infrastructure and Transport has released the new building standard for wooden public buildings to facilitate construction under the recently enacted law to promote the use of more wood in public buildings.

This new standard sets out the requirements for building life expectations, fire resistance and structural limits which, says the Japan Lumber Reports (JLR), have not been available until now.

Wood products used for the construction of public buildings are required to be manufactured from forest thinnings and certified legal timbers. It is required that the buildings have a life of at least 50 years so the standards on decay prevention and use of treated or naturally durable wood are specified in detail.

Industrial material distribution Materials needed for the construction of temporary homes in east Japan are now moving steadily. Products such as panels, piling, structural steel framing and household fittings such as kitchens and bathrooms are all flowing well to the disaster hit areas.

Because there is so much debris to remove engineering works to rebuild the infrastructure have yet to get underway. When this work begins there will be a second surge in demand for industrial products and construction materials.

Radiata pine log price doubled in two years New Zealand radiata pine export log prices continue to rise reports the JLR. This is opening opportunities for exporters of alternative timbers and it is possible the softwood log market in Japan will undergo a change.

The rise in Radiata log prices is put down mainly to the aggressive purchasing by buyers in China. The JLR reports that exports of Radiata logs from New Zealand to China in December alone exceeded 700,000 cu.m for the first time this is in comparison to imports by Japan which were only 760,000 cu.m for the whole of 2010.

Log and Sawnwood Prices in JapanLogs for Ply Manufacture, CIF Meranti (Hill, Sarawak) Medium Mixed Standard Mixed Small Log (SM60%, SSM40%) Taun, Calophyllum, others (PNG) Mixed light hardwood, G3/4 grade (PNG)Keruing MQ & up (Sarawak) Kapur MQ & up (Sarawak)

Yen per Koku (Koku=0.278 m3)

8,6008,8008,7008,000

-11,500

10,400

Logs for Sawmilling, CIF Melapi (Sarawak) High Select Agathis (Sarawak) High Select

Yen per Koku 12,000

-

Lumber, FOB White Seraya (Sabah) 24x150mm, 4m, Grade 1 Mixed Seraya, Sangi 24x48mm, 1.8-4m, S2S

Yen per m3

145,00056,000

Wholesale prices (Tokyo)

Report from China

Timber Protection Industry Association formed Recently, China’s Ministry of Civil Affairs approved the registration of a new association, the China Timber Protection Industry Association. The association will be supervised and guided by the Ministries of Civil Affairs and the Ministry of Industry and Information Technology.

The aim of the new association is to improve timber utilization, to extend timber life in-use, to promote standardization and to expand markets.

The products in the association mandate include wooden frame houses and wooden structures, wooden outdoor products, treated and fire resistant wood, modified wood, wood preservatives, composite materials, engineered bamboo and wood coatings.

The new association will also promote timber recycling and waste utilisation.

Expanded transit port for wood chips It has been reported by the Fujian Quanzhou City Inspection and Quarantine Bureau that in the first four months of 2011 large quantity of woodchips were imported through Xiaocuo Port of Quanzhou City.

Indonesian & Malaysian Plywood Size (mm)

2.4mm (thin plywood, F 4star, type 2 ) 920 X 1830 340 380-410

12mm for foundation (F 4star, special) 910 X 1820 1010 1300

12mm concrete-form ply (JAS) 900 X 1800 970 1220

12mm coated concrete-form ply (JAS) 900 X 1800 1090 1300

11.5mm flooring board 945 X 1840 1280 1350-1400

3.6mm baseboard for overlays (OVL)1230 X 2440 740 880

5.2mm (med. Thickness, F 4star, type 2) 910 X 1820 570 640-720

Apr May

(¥ per sheet)

3.7mm (med. Thickness, F 4star, type2) 910 X 1820 460 540-600

7 ITTO TTM Report 16:10 16 -31 May 2011

Optimism in building sector driving demand Sales of teak and hardwoods in forest depots of Central India for example Madhya Pradesh have also seen active bidding. Reports indicate that approximately 20,000 cubic metres have been sold and that newly harvested logs, felled in the current season, continue to arrive.

There is a positive attitude in the Indian building and construction sectors and this is driving demand for locally grown hardwoods as well as Teak. Prices secured in the central as well as in the western forest depots tend to be similar as the final market is the same. At present teak prices per cubic foot Hoppus are as below:

Shipbuilding quality Teak logs Rs.2100~2300 First quality Teak Saw-logs Rs.1700~2000 Long length high girth Teak logs Rs.1500~1800 Average Sawmill quality15ft & up Rs.1000~1200 “ “ 12ft & up Rs.900~1000 “ “ 8ft - 10ft Rs.800~ 900

CNF Plantation Teak

Tanzania Teak sawn Côte d'Ivoire logs PNG logs El-Salvador logs Guatemala logs Nigeria squares Ghana logs Guyana logs Benin logs Benin sawn Brazil squares Burkina Faso logs Columbia logs Togo logs Ecuador logs Costa Rica logs Panama logs Sudan logs Venezuela logs

US$ per m3

450-800�550-750�500-600�475-550400-500

375-475�350-600350-450500-650475-600500-600 350-450

400-600�350-500450-500350-500

350-450�500-700�460-500

Variations exist based on lengths and average girths of logs in a parcel. Prices also vary with measurement allowances given for bark and sap in different countries of origin.

India Sawnwood Prices (domestic) Myanmar Teak (imports)

Sawnwood (Ex-mill) Myanmar Teak (AD) Export Grade F.E.Q. Plantation Teak A grade Plantation Teak B grade Plantation Teak C grade

Rs. per ft3

6500-9000 3000-3800 2500-2800 1800-2000

India Sawnwood Prices (imports)Sawnwood, (Ex-mill) (AD)

MerbauBalauKapurRed Meranti BilingaRadiata Pine (AD)

Rs. per ft3

145015501000850750

400-450

Sawnwood, (Ex-warehouse) (KD) BeechSycamore Red OakAmerican Walnut Hemlock clear grade Hemlock AB grade Western Red Cedar Douglas fir

Rs. Per ft311001200130021501000850

13501000

India Plywood Prices Plywood, (Ex-warehouse) (MR Quality) 4 mm6 mm 12 mm 15 mm 18 mm

Rs. per sq.ft 36.25�51.00�66.50�79.60�95.00�

Locally Manufactured Plywood “Commercial Grade”

Rs. per sq.ft

4mm6mm8mm12mm19mm

5mm Flexible ply

Rubberwood Rs.12.10�Rs.17.70�Rs.22.10�Rs.26.50�RS.34.60�

Rs.21.50�

Hardwood Rs.21.00�Rs.30.50�Rs.34.00�Rs.36.50� Rs.49.10�

Rs.26.00

Report from Brazil

Exports of tropical sawnwood and plywood fall In April the value of exports of timber products (except pulp and paper) declined 5% to US$ 191 million compared to the level of US$ 201 million in April 2010.

Pine sawnwood exports dropped 2.2% in value in April compared to the level in the same month of 2010, from US$ 13.5 million to US$ 13.2 million. In term of volume, April 2011 exports were down 9.3% from 62,400 cu.m in April 2010 to 56,600 cu.m in April this year.

Exports of tropical sawnwood fell both in volume and in value, from 46,500 cu.m in April 2010 to 33,700 cu.m in April 2011 and from US$ 22.7 million to US$ 17 million in the same period. This corresponds to a 25% decline in value and a 28% decline in volume.

On the other hand, pine plywood exports increased 7.4% in value in April 2011 compared to the same month in 2010, from US$29.8 million to US$32 million. The volume of exports increased 2% from 84,000 cu.m to 85,700 cu.m.

Exports of tropical plywood dropped from 9,600 cu.m in April 2010 to 6,500 cu.m in April 2011, representing a 32% fall. In terms of value a 22.2% decrease was registered

April was also not a good month for wooden furniture exports. Export earnings dropped from US$ 42.4 million in April 2010 to US$ 40.2 million in April 2011 (-5%).

www.fdmasia.com | FDM AsiA july 2011 19

Market Report

ENQUIRY NO. 5001

such as kitchens and bathrooms are all flowing well to the disaster hit areas.

Because there is so much debris to remove engineering works to rebuild the infrastructure have yet to get underway. When this work begins there will be a second surge in demand for industrial products and construction materials.

Radiata Pine Log Price Doubled In Two YearsNew Zealand radiata pine export log prices continue to rise, reports the jlR. This is opening opportunities for exporters of alternative timbers and it is possible the softwood log market in japan will undergo a change.

The rise in Radiata log prices is put down mainly to the aggressive purchasing by buyers in China. The exports of Radiata logs from New Zealand to China in December alone exceeded 700,000 cubic metres for the first time this is in comparison to imports by japan which were only 760,000 cubic metres for the whole of 2010.

ChinaTimber Protection Industry Association FormedRecently, China’s Ministry of Civil Affairs approved the registration of a new association, the China Timber Protection Industry Association.

The association will be supervised and guided by the Ministries of Civil Affairs and the Ministry of Industry and Information Technology.

The aim of the new association is to improve timber utilisation, to extend timber life in-use, to promote standardisation and to expand markets.

The products in the association mandate include wooden frame houses and wooden structures, wooden outdoor products, treated and fire resistant wood, modified wood, wood preservatives, composite materials, engineered bamboo and wood coatings.

The new association will also promote timber recycling and waste utilisation.

Expanded Transit Port For Wood ChipsIt has been reported by the Fujian Quanzhou City Inspection and Quarantine Bureau that in the first four months of 2011, large quantity of woodchips was imported through Xiaocuo Port of Quanzhou City.

Imports through the port have increased in value and volume, and the range of supply countries has expanded in recent months. FDM

ENQU

IRY

NO.

266

The new innovative resource-saving feature comes without added charge for almost all HOMAG Group products.

Because we care

... up to 30% energy savings

... lower operating cost due to standby mode

...higherefficiencywiththeecoPlus calculator

for more information visit us online at www.homag-group.com or e-mail to [email protected]

20 FDM AsiA july 2011 | www.fdmasia.com

Focus

growth by improving productivity and quality, reducing lead times and freeing huge amounts of resources.

For example, lean manufacturing frees office and plant space, and can increase capacity, enabling companies to add product lines, in-source component production and increase output of existing products, without acquiring new facilities. Companies implementing lean will be able to take advantage of renewed growth by increasing sales without increasing costs.

Many think that lean means a reduction of the work force, but lean really means how to utilise your work force so you get even more done. Companies who have implemented lean as a system have seen benefits that have included:

• Decreased lead times

• Improved margins and improvedquality

• Lessemployeeturnoverandbettercommunication

• Increasedfloorspaceandimprovedinventory management

lean is a systematic approach to identifying and eliminating non-value-added activities, and is focused on customer demand and customer value. It isachievedbysimplifyingandcontinuously improving all processes and relationships in an environment of trust, respectandfullemployeeinvolvement.Itisaboutpeople,simplicity,flow,visibility,partnerships and true value as perceived by the customer.

Lean ImplementationA great number of wood products manufacturers today are already sold

lean manufacturing is front and center in the news these days. Around the world, thousands

of manufacturing companies are optimising their manufacturing process by implementing lean tools and principles within their factories.

The lean approach is the most comprehensive business management improvement initiative because it simultaneously addresses customers, products, processes, and human-related issues in the production system.

Small and large companies are using lean techniques to increase the value and quality of their products, with the end result of improving their bottom line. lean manufacturing techniques quickly cut production costs and inventories to free cash, which is critical to businesses in a slow economy. It also supports

Contrary to popular misconception, lean manufacturing practices are more about the reallocation of resources to avoid wastage, rather than the reduction of work force. By Roland Baumeister, department manager, FPInnovations

Getting

Going TRIMWithoutLEAN

Mar

k H

unte

r

www.fdmasia.com | FDM AsiA july 2011 21

Focus

on the potential benefits offered by the lean manufacturing approach.

low inventories, technology to produce on demand, and relocation to smaller premises are proven lean manufacturing solutions and have been implemented by many over the last years. However, companies are frequently facing the challenge on how to put the smart theory intopracticeon theplantfloor.

Many well-intended continuous improvement initiatives start with enthusiasm, but quickly faltered as time progressed and new issues need to be addressed. Some best practices and techniques have been observed that can help a company first focus on the most important issues, and then work with employees to ensure that lean initiatives do not get sidelined.

Strategy SessionItisoftenhelpfulforcompanymanagementto first outline a strategy that takes a system-wide view. The objective of this approach is to identify the required level of output (goods or service) that meets the company’s expectations and those of their customers for productivity, quality, cost, delivery time, safety and environment, and morale.

In lean, supervisors and businessowners must manage the five Ms: manpower, machines, material, methods, and measurements. Visual techniques such as the use of display boards that present information on product quality, absenteeism, training matrices, job standards, machine maintenance schedules, and other indicators are very helpful in focusing employees on what is important in their area.

Value Stream MappingOne of the tools used by companies to identify areas of improvement is called ‘Value Stream Mapping’ (VSM). This tool is used to describe steps that include the arrival of the material through the production process, shipping, to receiving

feedback from customers. Mapping this process is key to analysing and then refining each step to take full advantage of the lean concepts.

A company that applied VSM to its wood window and cladding production area reduced its lead time from 14 weeks to 8 weeks, dropped its production time

from over five days to two days, and reconfigured its production line from 14,000 to 10,000 square feet.

With a relatively small investment in time and equipment to implement these changes, the return on the investment through productivity gains was achieved within two weeks.

ENQU

IRY

NO.

272

Excellent opportunity to immediately acquire a complete Rubberwood unit capable of processing 1200 Cbm of Rubberwood logs per month. Ideally located in Tellicherry, Kerala, India.

The State of Kerala produces 95% of India’s rubber output. The total land area available is 20700 sq.mtr including 7150 sq.mtr built up area. The factory has all modern machinery like Vaccum dryer (Moldrup, Singapore), Finger Jointing line (Howard, Taiwan), Rotary Composer (Howard), UV Lacquering (Elmag, Italy), 4 side planer (Weing, Germany), Spindle Moulder (Felder, Austria), Copy Shaper (Fulpow, Taiwan), Double End Tennoner (Ital Press, Italy) etc. and has been producing Finger Jointed Edge Glued Panel, Furniture, Modular Kitchen cabinets. The unit has a skilled manpower of 131 heads. The unit will be sold without any financial liability of any kind.

RUBBERWOOD

IN INDIA FOR SALEPROCESSING UNIT

Interested parties may contact Mr Rajesh Nair at ATI Limited, “Circular Court”, 7th floor, 8 A.J.C Bose Road, Kolkata-700 017, India Tel: +91 9679522522 +91 9830072945 Email: [email protected]

22 FDM AsiA july 2011 | www.fdmasia.com

Focus

VSM also helped a kitchen cabinet manufacturer free up floor space andinstitute changes to their plant layout. After implementing these changes, the company postponed its move, saved money, and increased its output inside the existing production area.

Kaizen Events Kaizen events are an extremely efficient way to quickly improve a process with maximum results in a short time period — usually three days.

The true intent of a Kaizen event is to hold small events attended by the owners and operators of a process to make improvements to that process which are within the scope of the process participants. Such events rapidly implement work cells, improve setups or streamline processes.

Kaizen events are commonly referred to as tools that:

• Areusedas incrementalimprovements on specific processes

• EmployVSMtomap theexisting process

• Improveon theexistingprocess• Solicitbuy-in fromallparties

related to the process

Encouraging Employee Involvement Most businesses are constantly on the lookout for ways to cut costs, improve customer service and drive performance. yet many ignore the untapped resource of their employees who have cost savings ideas and know their jobs better than any expert.

There are a variety of ways to capture these cost savings ideas quickly and easily. For example, some companies have installed suggestions boxes, while others conduct weekly group or departmental meetings.

These initiatives, done individually or in conjunction with one another can help continuous improvement efforts.

However, many companies find that their suggestion box programmes produce results that are sporadic and slow. They also find that many good ideas get screened out, lay dormant, or are overlooked and ignored by management.

One strategy that some companies are finding some success with is called the ‘5-Minute Huddle Board’. The idea behind this approach is to capture ideas, drive involvement and identify cost savings ideas from the bottom of the organisation to the top.

During a Huddle Board session, afive-minute meeting is conducted every day within each group to discuss their keyperformance indicators (KPIs).TheKPIs are very specific to each groupand usually focus around areas such as safety, quality, daily production status, and status of the ideas being generated.

For one company, applying the Huddle Board system provided the structure to implement change and support their lean manufacturing initiative. This large millwork company used the huddle board system to quickly form groups and begin implementing ideas that originated from their employees. Once installed, the company was effectively dealing with dozens of valuable suggestions from its employees, and was implementing an idea from each person each month.

5S The 5S system provides a foundation that allows a manufacturer to deliver high quality products in the right quantity at the right time to satisfy customer needs. 5S is the name that describes the following functions: sorting, straightening, systematic cleaning, standardising, and sustaining.

The implementation of the 5S system is the starting point in the development of improvement activities to ensure any company’s survival. The 5S system is designed to create a visual workplace and a work environment that is self-explaining, self-ordering, and self-improving. Out of standard situations should be obvious at a glance and easily corrected.

Companies who have implemented the 5S system have seen benefits that include:

•Improvedworkingconditionsandwork team performance

•Established operating proceduresand reduced training cycles

•Increased adherence to standardoperating procedures (SOPs)

•Improvedcustomersatisfaction•Improveddatabasemanagement

Single-Minute Exchange Of Die (SMED) Single-MinuteExchangeofDie(SMED)is a lean manufacturing method that

Mar

cin

Wic

hary

, San

Fra

ncis

co, U

S

www.fdmasia.com | FDM AsiA july 2011 23

Focus

focuses on reducing the time it takes to change over from one manufacturing process to another or from running the current product to the next one.

Many companies believe that their set-up times are reasonable when in fact, they really are not certain how long they take. Studies have shown that implementing lean practices has reduced changeover time by as much as 50 to 90 percent.