Farmakologi

-

Upload

izza-ayudia-hakim -

Category

Documents

-

view

16 -

download

5

description

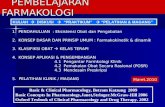

Transcript of Farmakologi

Research

Pap

er

RESEARCH PAPER New Biotechnology � Volume 32, Number 1 � January 2015

Use of three-carbon chain compounds asbiosynthesis precursors to enhancetacrolimus production in StreptomycestsukubaensisWanda Gajzlerska1, Justyna Kurkowiak2 and Jadwiga Turło1

1Medical University of Warsaw, Department of Drug Technology & Pharmaceutical Biotechnology, Banacha 1a, Warszawa 02-097, Poland2Medical University of Warsaw, Department of Physical Chemistry, Banacha 1a, Warszawa 02-097, Poland

Tacrolimus, a 23-membered polyketide macrolide, is isolated as a metabolite from the whole

fermentation broth of Streptomyces species. This potent immunosuppressive calcineurin inhibitor has

been widely used in various fields of medicine, including transplantology, dermatology and

pharmacotherapy of autoimmune diseases. The current study was focused on optimisation of tacrolimus

biosynthesis by Streptomyces tsukubaensis through the use of culture media supplements. Enrichment of

the fermentation medium with propionic acid, propylene glycol or propanol resulted in a 5.5-, 3.5- and

1.8-fold, respectively, increase in tacrolimus production. The optimal concentration of the precursors

was 0.25% for both propanol and propionic acid and 0.75% for propylene glycol. The mode of action of

each media supplement tested was unique. For instance, propionic acid acted as a tacrolimus

biosynthesis precursor while propylene glycol induced mycelial growth of S. tsukubaensis. Results from

the current study clearly demonstrate that a set of novel culture medium supplements considerably

increased tacrolimus production. Application of such promoters of tacrolimus biosynthesis may lead to a

substantial improvement in the production of tacrolimus by S. tsukubaensis in industrial fermentation

processes.

IntroductionSince first being isolated from a soil sample taken near mountain

Tsukuba in Japan as a product of fermentation of Streptomyces

tsukubaensis in 1984 [1], tacrolimus has attracted the attention of

scientists and clinicians as a potent immunosuppressant with

multiple applications. Tacrolimus (also referred to as FK-506) is

a 23-membered macrocyclic polyketide from the ‘limus’ family of

immunosuppressive macrolides [2]. The term ‘limus family’ refers

to a group of biologically active molecules with characteristic

macrocyclic structure obtained as isolates from Streptomyces sp.

strains or by chemical modification of the leading structure. It

includes tacrolimus (FK-506), sirolimus (rapamycin), everolimus,

biolimus A9, zotarolimus, pimecrolimus, temsirolimus and

ridaforolimus.

Corresponding author: Gajzlerska, W. ([email protected])

www.elsevier.com/locate/nbt

32

Specifically, FK-506 inhibits calcineurin – a calcium-dependent

serine–threonine phosphatase. In the process of T-cell activation

the level of intracellular calcium increases. Calmoduline binds

calcium ions for activation of calcineurin and this leads to de-

phosphorylation of transcription factor NF-AT (nuclear factor of

activated T-cells). This pathway results in activation of genes

responsible for T-cell activation and genes coding cytokines like

interleukin-2, interleukin 3, interleukin 4, interferon g and tu-

mour necrosis factor (TNF-a).

The complex of tacrolimus and FKBP (FK-506 binding protein)

binds with calcineurin and deactivates its function. Its major

therapeutic effects are exerted by the inhibition of T-cell prolifer-

ation and activation, as well as inhibition of cytokine production

and impairment of T cell-mediated cytotoxicity [3–5]. Due to its

powerful immunosuppressive activity, FK-506 has several applica-

tions in medicine. Research and clinical trials over the past two

decades have been promising for newer applications of tacrolimus,

http://dx.doi.org/10.1016/j.nbt.2014.07.006

1871-6784/� 2014 Elsevier B.V. All rights reserved.

New Biotechnology �Volume 32, Number 1 � January 2015 RESEARCH PAPER

FIGURE 1

The proposed utilisation of three-carbon chain compounds in the biosynthesis of FK-506 (tacrolimus). Methylmalonyl-CoA is derived from propionyl-CoA by

propionyl-CoA carboxylase (PCC). The macrolide ring of FK-506 is formed by cyclisation of a polyketide chain synthesised by PKS over ten elongation cycles using

two malonyl-CoAs, five methylmalonyl-CoAs, two methoxymalonyl-acyl carrier protein (-ACP) and allylmalonyl-CoA extender unit.Modified from Mo SJ and Goranovic D [15,19,24].

ResearchPap

er

resulting in many clinical indications for this drug. For instance, it

has been licensed as an immunosuppressive drug for use in trans-

plantology, primarily for subsequent immunosuppression and

rescue therapy following solid organ or bone marrow rejection,

but also for pharmacotherapy of numerous autoimmune diseases

[3,5,6]. Currently, for large-scale industrial production, tacrolimus

can only be synthesised and isolated as a metabolite from the

whole fermentation broth of various Streptomyces sp. cultivated in

submerged cultures [7–9]. Due to high production cost and low

yield, the cost of tacrolimus pharmacotherapy is very high [10–12].

Methods to increase the production of FK-506 in different

strains of Streptomyces have been of great interest to scientists

for many years. To date, efforts have included attempts to isolate

mutants that over-produce tacrolimus, as well as the use of meta-

bolic regulation through supplementation of cultivation medium

with various compounds [13–16]. The current study describes

optimisation of tacrolimus biosynthesis in S. tsukubaensis and

development of a novel fermentation process for more efficient

and economical industrial production of tacrolimus. Biosynthesis

of tacrolimus in Streptomyces sp. has been the subject of structural,

enzymological and genetic researches [17–19]. Production of sec-

ondary metabolites in Streptomyces is mainly determined by the

availability of biosynthetic precursors, such as acetyl-CoA and

malonyl-CoA [20]. In the case of tacrolimus, malonyl-CoA and

methylmalonyl-CoA are the main blocks (along with methoxy-

malonyl-acyl carrier protein (-ACP) and allylmalonyl-CoA which

are biosynthesised). Synthesis of tacrolimus in S. tsukubaensis

requires complex type I polyketide synthases (PKSS) and additional

modification enzymes [17,18]. According to literature describing

macrolide biosynthesis [21–23], the macrolide ring is a product of

enzymatic head-to-tail condensation of acetate and propionate,

resembling the fatty acid biosynthesis pathway. Previous studies

on macrolide biosynthesis have shown that shorter chain mole-

cules containing 2, 3 or 4 carbon units, such as acetate or propio-

nate, may be used as precursors for the macrolide ring.

Furthermore, for the biosynthesis of numerous macrolides, such

as candicin, nystatin, amphotericin B and lucensomycin, propio-

nate has been shown to be a more potent precursor [21]. According

to Mo et al. [15,24], extension of the polyketide chain requires

malonyl-CoAs, methylmalonyl-CoA and allylmalonyl-CoA (bio-

synthesised from propionylmalonyl-CoA). Propionate and acetate

play the main role in that process as substrates for the biosynthesis.

When propanol and propionic acid are used as precursors to enrich

fermentation medium, biosynthesis of many macrolides can be

enhanced. Three-carbon chain compounds are directly trans-

formed into malonyl-CoA and accumulate, whereas acetyl needs

to undergo a carboxylation reaction to be converted to propio-

nate. Thus, three-carbon chain compounds appear to be more

effective. Analysis of metabolic flux of tacrolimus biosynthesis

(Fig. 1) reveals great potential to enhance production of FK-506

biosynthesis by using three-carbon chain compounds as precur-

sors for polyketide chain extension units. Glycerol and three-

carbon molecules with free hydroxylic group have been reported

to induce stimulation of various polyene and non-polyene macro-

lides by various mechanisms [15,21,25]. However, to date there

has been limited research on the effect of propanol, propionic

acid and propylene glycol on the biosynthesis of FK-506 in S.

tsukubaensis.

Based on findings from previous studies, we hypothesised that

propanol, propionic acid and propylene glycol would be potent

precursors of tacrolimus biosynthesis. In the current study, we

evaluated FK-506 biosynthesis parameters in submerged cultures

of S. tsukubaensis using three different effectors with a three-carbon

chain as the leading structure: propanol, propylene glycol and

propionic acid.

Materials and methodsMicroorganism, media and inoculum preparationS. tsukubaensis (FERM BP-927) was obtained from the International

Patent Organism Depositary of National Institute of Advanced

Industrial Science and Technology (AIST) in Tsukuba, Ibaraki,

Japan. The S. tsukubaensis strain (FERM BP-927) used in this study

is a wild-type strain with relatively low FK-506 yields of FK-506.

The seed culture was grown in a 500 mL flask containing 200 mL

of basal medium (Malt Extract Broth; Biocorp Polska Co., Warsaw,

Poland) composed of 0.6% (w/v) malt extract, 0.6% glucose, 0.6%

maltose and 0.12% yeast extract. The pH of the medium was

adjusted to 7.3, the optimal value for mycelial growth observed

in previous studies. The pH of the culture broth was measured

using a digital pH meter (intoLab pH Level 1, WWT, Germany).

The fermentation was performed at 308C on a rotary shaker (New

Brunswick Scientific, Edison, NY, USA) at 110 rev/min for 10 days.

www.elsevier.com/locate/nbt 33

RESEARCH PAPER New Biotechnology � Volume 32, Number 1 � January 2015

Research

Pap

er

The seed culture used was stored at 48C before the inoculation of

cultivation media.

Propanol, propylene glycol and propionic acid-enriched culturesThe fermentation medium chosen has been previously reported to

promote optimal mycelial growth and tacrolimus production

[26,27]. The cultures were grown in 500 mL flasks containing

200 mL of medium composed of 2% (w/v) maltose, 3% soy pep-

tone, 1% corn steep liquor, 0.05% MgSO4, 0.2% KH2PO4, 0.4%

Na2HPO4 and 0.3% CaCO3 at 308C on a rotary shaker at 110 rev/

min for 10 days.

Culture medium was enriched with multiple concentrations of

either propanol, propylene glycol or propionic acid. The tested

concentrations of each compound were 0, 0.25, 0.5, 0.75 or 1%.

The initial pH of the medium was adjusted to 7.3 with 0.1 N NaOH

solution. Mycelia were grown in 500 mL flasks containing 200 mL

of medium. Fermentation media were autoclaved at 1218C for

20 min, cooled to room temperature and inoculated with 10% (v/

v) of the seed culture. Cultures were incubated at 308C on a rotary

shaker at 110 rev/min for 10 days. Afterwards, the cultivation was

terminated, biomass was filtered and mycelial dry mass and tacro-

limus concentration were determined. The hypothesis regarding

the mechanisms of action of tested compounds was examined by

an alternative method. The amount of tacrolimus synthesised by

1 g of S. tsukubaensis biomass in each cultures was calculated and

expressed in mg/mycelial dry weight in g, isolated from 1 L of

cultivation broth, after 10 days of cultivation. All experiments

were conducted five times to ensure reproducibility.

The medium additives were tested independently. The experi-

ments were conducted at different times. To show the results

clearly and to be able to compare them, the control was cultivated

for each series of the experiments. The obtained results were

normalised – expressed in relation to the control which is assumed

as 100%.

Batch fermentations in a 5-L jar fermenterFermentation medium in a 5-L working volume bioreactor (Biotec,

UK) was inoculated with 10% (v/v) seed culture. Propylene glycol

at 0.25% (v/v) was then added to culture medium. The control

culture was also cultivated. At an initial pH of 7.3, fermentation

was performed at 308C, 2 vvm and 100 rev/min for 150 hours.

Eighty millilitre test samples were collected at regular intervals for

determination of FK-506 concentration and dry biomass weight.

Analytical methodsFor determination of mycelial growth, dry cell weight (DCW) was

monitored. Mycelia were harvested by filtration and dried at 608C.

The dry mass percent of the filtered biomass was determined by the

use of moisture analyzer (Sartorius, Germany).

Preparation of a sample for FK-506 high-performance liquidchromatography (HPLC) detectionExtraction of tacrolimus from the fermentation broth was carried

out according to a modified method previously described by Kino

and Hatanaka [27,28]. FK-506 is produced intracellularly, but is also

excreted into the culture medium. As such, the whole fermentation

broth can be used for effective extraction. Eighty millilitre

test samples (whole fermentation broth) were homogenised in an

34 www.elsevier.com/locate/nbt

ultrasonic bath for 10 min then extracted with 80 mL acetone while

being stirred for 1 hour. Extracts were filtered through Whatman

No. 5 filter paper, purified by chromatography on silica gel (0.2–

0.5 mm), evaporated to dryness and dissolved in 40 mL methanol.

HPLC tacrolimus determinationFK-506 concentration was determined by RP-HPLC (reversed phase

HPLC) using combined methods of Akashi et al. [29] and Nishi-

kawa et al. [30]. For preparation of external standards, FK-506

standard (Sigma, St. Louis, USA) was used. The calibration curve of

FK-506 was linear within the range of the concentrations mea-

sured. RP-HPLC was carried out using a Shimadzu LC-10AT gradi-

ent system (Shimadzu USA Manufacturing Inc., Calby, Oregon

City, USA) equipped with a UV–vis SPD-10A detector, a SCL-10-A

system controller and a CTO-10AC column oven. The column

used was a RP-18, 5 mm particle size, 25/4-mm Supelcosil DB

(Supelco, Sigma Aldrich Co., Bellefonte, USA). The methanol

extracts obtained as described above were injected into an HPLC

column. The eluent was acetonitrile/water 75:25 (v/v). The tem-

perature was 608C, the injection volume was 20 mL and the flow

rate was set to 1 mL/min. The wavelength of detection was

214 nm. All measurements were performed in triplicate. Tacroli-

mus retention time was 6.8 min. The content of FK-506 was

calculated based on the standard curve.

Statistical analysisA Dixon test was used to test for single outliers (at a 95% confi-

dence level) in the data. All data in groups were first tested for

normality using a Kolmogorov–Smirnov test and results were

confirmed by a Shapiro-Wilk test. To characterise parameters of

interest, the expected value for the mean, minimum value, maxi-

mum value, standard deviation (SD) and relative standard devia-

tion (RSD) were computed. All results graphically presented in this

paper are expressed as the mean of 5 replicates � SD. To compare

the means of two groups, a t-test was applied if the variances of the

two populations were equal. If not, a Cochran–Cox test was

applied. For comparison of the variance between two groups, an

F-test was employed. A P < 0.05 defined statistical significance. All

statistical analyses were conducted in Statistica 10, and graphical

representations were prepared in Microsoft Excel.

ResultsOptimisation of culture medium composition and cultivation

conditions is one of the main methods to enhance the productivi-

ty of a bacterial strain used for biosynthesis of a secondary metab-

olite, such as tacrolimus. Agents, such as precursors or macrolide

structure biosynthesis stimulators, that may significantly increase

productivity need to be identified. For example, propanol and

propionic acid are successfully used in industrial biosynthesis

processes for polyketide antibiotics (e.g., erythromycin).

The effect of three-carbon precursors on biosynthesis oftacrolimus and S. tsukubaensis growthAll tested compounds (propylene glycol, propionic acid and pro-

panol) enhanced strain productivity. Effectiveness and impact on

the mycelial growth differed for compound. The selected cultiva-

tion medium, determined in our previous research to be effective,

provided satisfactory S. tsukubaensis mycelial growth and facilitated

New Biotechnology �Volume 32, Number 1 � January 2015 RESEARCH PAPER

FIGURE 2

The influence of three-carbon chain substrates on mycelial growth andtacrolimus concentration in Streptomyces tsukubaensis cultures. The

relationship between the concentration of medium supplement (propylene

glycol, propionic acid or propanol) and the concentration of tacrolimus (a), S.

tsukubaensis mycelial growth (b) and strain productivity expressed in mg oftacrolimus synthesised by 1 g of mycelial dry mass (c). Data are compared to

the control (100%) and the ratio is expressed as a percentage.ResearchPap

er

good tacrolimus production. Biomass (DCW – dry cell weight)

accumulation for non-enriched medium was approximately 1.2 g

of mycelial dry weight per L of culture medium, while the concen-

tration of FK-506 in culture broth was approximately 4.7 mg/L. The

presented values are the mean of the results of the three series of

control experiments. The absolute values of FK-506 concentration

were 2.4, 5.0 and 6.7 mg/L. For the biomass accumulation they were

0.49, 1.7 and 1.3 g. The concentration of tacrolimus in the culture

broth was determined in each of the cultures grown in enriched

precursors medium. The results were compared with those obtained

from cultures grown in non-enriched medium (control) (Fig. 2).

Propylene glycolThe addition of propylene glycol to culture medium led to

increased biosynthesis of tacrolimus in the studied strain. It

was noted that the higher the concentration of propylene glycol,

the higher the biosynthesis rate of tacrolimus, reaching its

maximum at a concentration of propylene glycol equal to

0.75% (v/v). The concentration of tacrolimus increased from

2.4 mg/L in non-enriched medium to 9 mg/L in medium con-

taining 0.75% propylene glycol. However, when the concentra-

tion of propylene glycol exceeded 0.75%, FK-506 content in the

fermentation broth decreased (Fig. 2a). For strain growth, similar

trends were observed based on concentration of propylene gly-

col, but no growth inhibition was observed at higher concentra-

tions of propylene glycol. Optimal strain growth over 10 days

was observed in cultures containing an initial propylene glycol

concentration of 0.75% (equivalent to 1.04 g/L), which yielded

more than a twofold increase in tacrolimus production (Fig. 2b).

However, strain growth at 0.75% propylene glycol did not sta-

tistically differ from cultures containing 0.25%, 0.5% and 1%

propylene glycol.

Thus, the results indicate that both tacrolimus biosynthesis and

strain growth can be effectively stimulated by the use of propylene

glycol as a growth promoter. The evidence of strong correlation of

tacrolimus productivity and the strain growth for propylene glycol

is shown in Fig. 3a and is linear. In the following stage of the

studies the correlation of tacrolimus productivity and the strain

growth (productivity per 1 g of DCW) for all three compounds was

examined. The obtained results are presented in a bar graph

(Fig. 2c). There was no evidence that the productivity of 1 g of

S. tsukubaensis is related to the concentration of the supplementa-

tion with propylene glycol. For 0.75% propylene glycol in culture

medium, the observed productivity was 9.65 mg FK-506/g DW and

was significantly higher than in the culture medium containing

0% and 1%. For 0.25% and 0.5% propylene glycol, no statistically

significant difference was observed (P = 0.62 and P = 0.1, respec-

tively). When higher concentrations of propylene glycol were

used, tacrolimus productivity became lower than that of the

control, suggesting that propylene glycol enhances the productiv-

ity of the strain by acting only as a growth promoter. It is highly

probable that S. tsukubaensis uses propylene glycol as an additional

carbon source. Some tacrolimus producing strains of Streptomyces,

including S. tsukubaensis, Streptomyces antimycoticus and Streptomy-

ces hygroscopicus subsp. glebosus, utilise glycerine as a carbon source

[10]. Structural similarity of propylene glycol (1,2-propanediol)

and glycerine (1,2,3-propanetriol) may result in effective utilisa-

tion of propylene glycol by such strains.

Propionic acidThe addition of propionic acid to culture medium also resulted in

higher tacrolimus biosynthesis in S. tsukubaensis. The optimum

concentration of propionic acid was 0.25% (v/v), which led to

more than a 100% increase in tacrolimus concentration compared

to the control. Culture broth contained 12.7 mg/L of tacrolimus,

which was the highest concentration achieved in the entire ex-

periment (P < 0.05, with the exception of 0.75% propionic acid at

P = 0.06). With higher concentrations of propionic acid, FK-506

biosynthesis decreased. However, biosynthesis of tacrolimus in all

www.elsevier.com/locate/nbt 35

RESEARCH PAPER New Biotechnology � Volume 32, Number 1 � January 2015

A

0,4 0,5 0,6 0,7 0,8 0,9 1,0 1,1

Strain Growth [g DW/L]

2

3

4

5

6

7

8

9

10

Bio

synt

hesi

s R

ate

[mg/

L]

B

1,0 1,1 1,2 1,3 1,4 1,5 1,6 1,7 1,8

Strain Growth [g DW/L]

4

5

6

7

8

9

10

11

12

13

Bio

synt

hesi

s R

ate

[mg/

L]

C

0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2

Strain Growth [g DW/L]

6,0

6,5

7,0

7,5

8,0

8,5

9,0

9,5

10,0

10,5

11,0

Bio

synt

hesi

s R

ate

[mg/

L]

FIGURE 3

Correlation between strain growth and tacrolimus productivity. Results are

presented for (a) propylene glycol, (b) propionic acid and (c) propanol.

Research

Pap

er

propionic acid cultures was more effective than non-enriched

medium (Fig. 2a). Moreover, the presence of propionic acid in

the culture media caused a reduction in biomass (Fig. 2). Statistical

analysis showed a significant difference between 0.25% and 0.5%

propionic acid, but not between 0.25% and 0.75% or 1% propionic

36 www.elsevier.com/locate/nbt

acid (P = 0.09 and P = 0.06, respectively). There is no correlation

between the concentration of propionic acid and a decrease of S.

tsukubaensis mycelial growth, indicating that the mechanism of

strain growth inhibition by propionic acid was independent of

dose (Fig. 2b). The relationship between strain growth and FK-506

productivity was determined to be linear as shown in Fig. 3b,

which suggests that enhanced tacrolimus productivity by propio-

nic acid may be the effect of its function as a precursor for

biosynthesis. The amount of FK-506 synthesised by 1 g of myceli-

um was greatest when propionic acid concentration in the medi-

um was 0.25%, just as in the case of FK-506 biosynthesis and it was

15.9 mg FK-506/g DW, which is statistically significantly higher

than in the culture medium 0%, 0.75% and 1%. For 0.5% pro-

pionic acid, the difference was not statistically significant

(P = 0.088; Fig. 2c). Tacrolimus productivity per 1 g of DCW (cal-

culated in mg of tacrolimus per 1 g of DCW) is decreasing with

higher concentrations of propionic acid. This trend is similar to

that observed for tacrolimus biosynthesis (Fig. 2a). The mass of

tacrolimus synthesised by 1 g of mycelium increased 5.5 times

with 0.25% propionic acid, whereas productivity of the strain

(expressed in mg/L) increased by only 2.5 times, proving further

support that propionic acid is active as a precursor of tacrolimus

biosynthesis. The inhibition of the strain growth observed with

higher concentrations of propionic acid may be due to its antibi-

otic properties. Propionic acid is used, among others, in the food

industry as preservative E280 due to its antibacterial and antifun-

gal activity. The concentrations in which it is active have been

reported to range from 0.1 to 1% [31,32].

PropanolThe addition of propanol to culture medium did not have as great

an effect as the two previously discussed compounds. A consider-

able increase in FK-506 concentration was observed only for

0.25% propanol, while the tacrolimus concentration in culture

broth was determined to be 10.6 mg/L. With higher propanol

concentrations there was no significant difference compared to

the control (Fig. 2a). A similar trend was observed for biomass

production. Maximum strain growth was observed in cultures

enriched with 0.25% propanol (equal to 1.98 g/L), which was

significantly higher than in other concentrations (P < 0.05). The

addition of higher concentrations of propanol resulted in an

inhibitory effect on biomass production independent of dose

(Fig. 2b). The correlation between strain growth and tacrolimus

production in cultures containing propanol was non-linear

(Fig. 3c), suggesting that the influence of propanol on S. tsuku-

baensis and its production of tacrolimus is complex and requires

further studies. Tacrolimus productivity of 1 g of mycelium

reached its maximum with 1% propanol in culture medium,

yielding 20 mg/g DW. Differences in biomass production com-

pared with the control and other cultures were not statistically

significant (Fig. 2c).

As presented in Fig. 3c, there was no particular correlation

between strain growth and tacrolimus biosynthesis upon addition

of propanol. On the basis of these calculations we hypothesised

that the addition of low concentrations (0.25%) of propanol to the

cultivation medium may act as a growth promoter and with this

mechanism enhance tacrolimus biosynthesis. The linear portion

of the graph in Fig. 3c supports this hypothesis.

New Biotechnology �Volume 32, Number 1 � January 2015 RESEARCH PAPER

0

2

4

6

8

10

12

14

16

18

20

0 50 100 150 200Time [h]

FK-5

06 p

rodu

c�on

[mg/

L]

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

4,0

Biom

ass p

rodu

c�on

[g D

W/L

]

FK-50 6Biomass

0

5

10

15

20

25

30

35

40

0 50 100 150 20 0

FK-5

06 p

rodu

c�on

[mg/

L]

0,0

1,0

2,0

3,0

4,0

5,0

6,0

7,0

8,0

9,0

Time [h]

Biom

ass p

rodu

c�on

[g D

W/L

]

FK-50 6

Biomass

FIGURE 4

The time-course fermentation graphs for cell growth and tacrolimus production in medium containing propylene glycol. The graph illustrates tacrolimus

concentration in the culture broth and biomass accumulation upon addition of (a) 0%, (b) 0.25% propylene glycol.

ResearchPap

er

The effect of propylene glycol on S. tsukubaensis submergedculture: analysis of strain growth and kinetics of tacrolimusbiosynthesisBio-fermenter cultivationPropylene glycol was chosen for use as a precursor in further studies

since it previously demonstrated effective stimulation of tacrolimus

biosynthesis process and the most substantial effect on S. tsuku-

baensis biomass production. The culture medium was enriched with

0.25% (v/v) propylene glycol and compared with the control culti-

vation (Fig. 4a,b). Figure 4 summarises the changes in mycelial

growth and tacrolimus production during the cultivation of S.

tsukubaensis in a 5-L bioreactor. The graphs present a time-course

of tacrolimus concentration in the culture broth and mycelial

biomass. The results indicate that for the culture grown in medium

with 0.25% propylene glycol, the most effective tacrolimus biosyn-

thesis occurred during the logarithmic phase of growth. In the

control culture, the maximum level of FK-506 biosynthesis occurred

during the exponential (logarithmic) phase of growth, approxi-

mately between 10 and 40 hours into the cultivation (Fig. 4a),

whereas this growth phase was extended by an additional 50–

90 hours by supplementation of culture medium with propylene

glycol (Fig. 4b). A significant increase in the concentration of

tacrolimus was observed during the stationary phase of growth

(90–130 hours into the cultivation), indicating that the biosynthesis

process was extended. Tacrolimus concentration increased consid-

erably at the end of the stationary phase and during the lethal phase

of mycelial growth. Cell lysis is probably responsible for the ob-

served decrease in mycelial mass and the increase in tacrolimus

www.elsevier.com/locate/nbt 37

RESEARCH PAPER New Biotechnology � Volume 32, Number 1 � January 2015

Research

Pap

er

concentration in the medium as a result of the cell disintegration

and liberation of intracellularly accumulated FK-506.

The addition of propylene glycol to the culture medium accel-

erated strain growth of S. tsukubaensis but also led the culture to

reach its idiophase earlier. Biomass yield was significantly higher

in the culture enriched with propylene glycol compared to the

control. Figure 4a,b illustrates that the addition of propylene

glycol has a specific effect on biomass accumulation where, at

the end of the stationary phase of the strain growth, there is a

significant increase in biomass similar to the end of the logarith-

mic phase. Such observation is probably connected to the uptake

of propylene glycol by S. tsukubaensis cells and a ‘switch’ in carbon

source from maltose to propylene glycol.

The biosynthesis of secondary metabolites (e.g., tacrolimus) in

Streptomyces is dependent on the availability of biosynthetic pre-

cursors which, in addition to co-factors, can be rate-limiting for

secondary metabolism. In a reaction similar to that of fatty acid

condensation, early stages of macrolide biosynthesis require short

chain (2–4 carbon units) compounds for the chain extension reac-

tionofanacylstarterunitbyPKSIenzymes.Assuch,wehypothesised

that exogenous three-carbon chain compounds may enhance tacro-

limus production by acting as a direct precursor. According to

observed results, supplementation of culture medium with each of

the tested as precursors of FK-506 compounds increased the yield of

tacrolimus in the culture broth. All three compounds also had an

effect on strain growth, though the effect was unique for each

compounds. Thus, the mechanism for increased FK-506 biosynthesis

and the mode of action of each of the tested compounds must be

different. Propionic acid and propylene glycol increased the yield of

FK-506. In propylene glycol-enriched cultures, tacrolimus produc-

tivity linearly correlated with strain growth, indicating that propyl-

ene glycol was probably used as an additional carbon source to

promote growth of S. tsukubaensis. Propionic acid effectively stimu-

lated tacrolimus biosynthesis and seemed to be a potent precursor of

the tacrolimus macrolide ring, which is consistent with the mecha-

nism that has been observed in the biosynthesis of other macrolides

[21]. Propionate is directly incorporated as three-carbon units. Pro-

pionyl-CoA (probably as methylmalonyl-CoA) is used together with

acetyl-CoA in the biosynthesis pathway. The influence of propanol

on S. tsukubaensis cultures seemed to be more complex. The enhanc-

ing effect of propanol on FK-506 biosynthesis was the weakest of all

tested media supplements. It is difficult to explain the metabolic

modeofactionatthispoint and moreexperiments arerequired. Also,

the optimal concentration of each media supplement differed. It was

0.75% (v/v) for propylene glycol and propanol, but only 0.25% for

propionic acid to provide a 1.8–5.5-fold increase in tacrolimus

concentration.

In summary, all three-carbon skeleton compounds tested en-

hanced tacrolimus production. Their mechanisms of action

seemed to be unique, with propionic acid acting as a tacrolimus

biosynthesis precursor and propylene glycol specifically promot-

ing mycelial growth of S. tsukubaensis. The obtained results

38 www.elsevier.com/locate/nbt

revealed that for optimisation of tacrolimus biosynthesis the

tested compounds can be used separately. It is highly probable

that because of the different mechanism of action of the tested

compounds they can be mixed and added to the cultivation

medium for potentially even higher productivity of tacrolimus

but this problem will be undertaken in our future studies.

Upon examination of growth kinetics in relation to biosynthesis

of tacrolimus during batch fermentation in bioreactor, the control

culture produced the most tacrolimus during the exponential (log)

phase, whereas biosynthesis was extended into the stationary

phase in cultures supplemented with propylene glycol. Specifical-

ly, the addition of propylene glycol to the culture medium accel-

erated strain growth but also caused that the culture reached its

idiophase earlier. The bioreactor fermentation kinetics indicated

that production of tacrolimus was highest during the logarithmic

phase. Thus, cultivation time of S. tsukubaensis, cultured under the

condition presented in this work, should be no longer than

150 hours since, after this period, FK-506 biosynthesis decreases.

The observed results are promising and indicate that the pro-

posed media supplementation described in this paper and our

previous study [26] may significantly increase tacrolimus biotech-

nological production in submerged cultures of S. tsukubaensis.

Results from the current study can be widely applied to the

biosynthesis process of tacrolimus and may help to optimise the

biotechnological production process. Searching for biosynthesis

precursors as well as optimisation of the biosynthesis process is

important research that, when taken together with research on

regulation of FK-506 biosynthesis by molecular mechanisms, may

contribute to the development of an improved and efficient

industrial fermentation process.

ConclusionsThe addition of 3C precursors, such as propylene glycol, propanol

and propionic acid, to culture medium induces tacrolimus bio-

synthesis in S. tsukubaensis and exerts a specific effect on mycelial

growth of the strain. The proposed precursors of the FK-506

biosynthesis pathway and the compositions of culture medium

may hold promise for use in hyper-production of FK-506 on a large

bioreactor scale. Propanol, propylene glycol and propionic acid

increased the production of tacrolimus by S. tsukubaensis by 1.8–

5.5-fold. The activity of tested compounds, defined as the influ-

ence of the tested medium supplement on S. tsukubaensis produc-

tivity of FK-506 per 1 g of DCW, decreased in the following order:

propionic acid > propylene glycol > propanol. The current study

also demonstrated that the biosynthesis-stimulating mechanism

of 3C agents was not related to stimulation of strain growth,

proving that 3C agents specifically enhance tacrolimus biosynthe-

sis in S. tsukubaensis submerged cultures. Despite structural simi-

larities, the mechanisms of action of the tested compounds are

diverse. Application of findings may lead to improvement of

tacrolimus yield in industrial fermentation processes and reduce

the cost of this clinically important immunosuppressive agent.

References

[1] Goto T, Kino T, Hatanaka H, Nishiyama M, Okuhara M, Kohsaka M, et al.Discovery of FK-506, a novel immunosuppressant isolated from Streptomycestsukubaensis. Transpl Proceed 1987;5(Suppl. 6):4–8.

[2] Tanaka H, Kuroda A, Marusawa H, Hashimoto M, Hatanaka H, Kino T, et al.Physicochemical properties of FK-506, a novel immunosuppressant isolatedfrom Streptomyces tsukubaensis. Transpl Proceed 1987;5(Suppl. 6):11–6.

New Biotechnology �Volume 32, Number 1 � January 2015 RESEARCH PAPER

ResearchPap

er

[3] Spencer CM, Goa KL, Gillis JC. Tacrolimus: an update of its pharmacology andclinical efficacy in the management of organ transplantation. Drugs 1977;54(6):925–75.

[4] Morris R. Modes of action of FK506, cyclosporine A and rapamycin. TransplProceed 1994;26:3272–5.

[5] Mann J. Natural products as immunosuppressive agents. Nat Prod Rep 2001;18:417–43.

[6] Ruzicka T, Assmann T, Homey B. Tacrolimus: the drug for the turn of themillennium? Arch Dermatol 1999;135:574–80.

[7] Graziani EI. Recent advances in the chemistry, biosynthesis and pharmacologyof rapamycin analogs. Nat Prod Rep 2009;26:602–9.

[8] Allison AC. Immunosuppressive drugs: the first 50 years and a glance forward.Immunopharmacology 2000;47:63–83.

[9] Bieber T. Topical tacrolimus (FK-506): a new milestone in management of atopicdermatitis. J Allergy Clin Immunol 1998;102:555–7.

[10] Okuhara M, Tanaka H, Goto T, Kino T, Hatanaka H. Tricyclo compounds, aprocess for their production and a pharmaceutical composition containing thesame. US patent 4,894,366; 1990.

[11] Singh BP, Behera BK. Regulation of tacrolimus production by altering primarysource of carbons and amino acids. Lett Appl Microbiol 2009;49:254–9.

[12] Vaid S. A novel fermentation fed batch process for producing the immunosup-pressant Tacrolimus (FK-506), using the mutant microorganism Streptomyces sp.Utilizing vegetative oil as sole source of carbon in production medium. USPatent 27/0142424 A1; 2006.

[13] Kim HS, Park YI. Isolation and identification of a novel microorganism produc-ing the immunosuppressant tacrolimus. J Biosci Bioeng 2008;105:418–21.

[14] Martinez-Castro M, Salehi-Najafabadi Z, Romero F, Perez-Sanchiz R, Fernandez-Chimeno RI, Martin JF, et al. Taxonomy and chemically semi-defined media forthe analysis of the tacrolimus producer Streptomyces tsukubaensis. Appl MicrobiolBiotechnol 2013;97:2139–53.

[15] Mo SJ, Nan Y-H, Park W-J, Yoo YJ, Yoon YJ. Enhanced FK506 production inStreptomyces clavuligerus CKD1119 by engineering the supply of methylmalonyl-CoA precursor. J Ind Microbiol Biotechnol 2009;36:1473–82.

[16] Huang D, Xia M, Li S, Wen J, Jia X. Enhancement of FK-506 production byengineering secondary pathways of Streptomyces tsukubaensis and exogenousfeeding strategies. J Ind Microbiol Biotechnol 2013;40(9):1023–37.

[17] Motamedi H, Shafiee A. The biosynthetic gene cluster for the macrolactone ringof the immunosuppressant FK506. Eur J Biochem 1998;256:528–34.

[18] Motamedi H, Cai S-J, Shafiee A, Elliston KO. Structural organization of amultifunctional polyketide synthase involved in the biosynthesis of the macro-lide immunosuppressant FK506. Eur J Biochem 1997;244:74–80.

[19] Goranovic D, Kosec G, Mrak P, Fujs S, Horvat J, Kuscer E, et al. Origin of the allylgroup on FK56 biosynthesis. J Biol Chem 2010;285:14292–300.

[20] Papagianni M. Recent advances in engineering the central carbon metabolism ofindustrially important bacteria. Microb Cell Fact 2012;11:50.

[21] Martin JF, Liras P. Rapid incorporation of precursors into candicin by restingcells of Streptomyces griseus. J Antibiot 1976;29:1306–9.

[22] Donadio S, Staver MJ, McAlpine JB, Swanson SJ, Katz L. Modular organizationof the genes required for complex polyketide biosynthesis. Science 1991;252:675–9.

[23] Aparicio JF, Mendes MV, Anton N, Recio E, Martin JF. Polyene macrolideantibiotic biosynthesis. Curr Med Chem 2004;11:1643–56.

[24] Mo SJ, Kim DH, Lee JH, Park JW, Basnet DB, Ban YH, et al. Biosynthesis of theAllylmalonyl-CoA Extender Unit for the FK506 Polyketide Synthase (PKS)proceeds through a dedicated pks and facilitates the mutasynthesis of novelanalogs. J Am Chem Soc 2011;133:976–85.

[25] Recio E, Aparicio JF, Rumbero A, Martin JF. Glycerol, ethylene glycol andpropanediol elicit pimaricin biosynthesis in the PI-factor-defective strain Strep-tomyces natalensis npi287 and increase polyene production in several wild-typeactinomycetes. Microbiology 2006;152:3147–56.

[26] Turło J, Gajzlerska W, Klimaszewska M, Krol M, Dawidowski M, Gutkowska B.Enhancement of tacrolimus productivity in Streptomyces tsukubaensis by theuse of novel precursors for biosynthesis. Enzyme Microb Technol 2012;51:388–95.

[27] Turło J, Gutkowska B, Gajzlerska W. Submarged cultivation of Streptomycestsukubaensis in media composed of waste products of ford industry. Acta PolPharm 2006;62:463–5.

[28] Kino T, Hatanaka H, Hashimoto M, Nishiyama M, Goto T, Okuhara M, et al. FK-506, a novel immunosuppressant isolated from a Streptomyces. I. Fermentation,isolation, and physico-chemical and biological characteristics. J Antibiot1987;9:1249–55.

[29] Akashi T, Nefuji T, Yoshida M, Hosoda J. Quantitative determination of tauto-meric FK-506 by reverse-phase liquid chromatography. J Pharm Biomed Anal1996;14:339–46.

[30] Nishikawa T, Hasumi H, Suzuki S, Kubo H, Ohtani H. Kinetic analysis ofmolecular interconversion of immunosuppressant FK506 by high-performanceliquid chromatography. Pharm Res 1993;10(12):1785–9.

[31] Seventeenth Report of the Joint FAO/WHO Expert Committee on Food Addi-tives, Wld Hlth Org Techn Rep Ser 1974; 539; FAO Nutrition Meetings ReportSeries, 1974; 53.

[32] Lind H, Jonsson H, Schnurer J. Antifungal effect of dairy propionibacteria-contribution of organic acids. Int J Food Microbiol 2005;98(2):157–65.

www.elsevier.com/locate/nbt 39