Failure Prediction Static

-

Upload

baginda-bukhori -

Category

Documents

-

view

230 -

download

0

Transcript of Failure Prediction Static

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 1/16

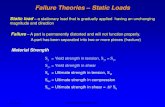

Failure Prediction for Static Loading

Image: The Liberty Bell,a classic case of brittle fracture.

crack

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 2/16

Bow portion of the Titanic.(Painting by Ken Marschall, based on photographs

taken aboard Alvin, Angus, and Argo research vessels. (Courtesey Dr. Robert D.

Ballard, The Discovery of the Titanic.)

FAILURE PREDICTION OF MACHINE COMPONENT BASED ON TYPE OF LOADING :

1. STATIC LOADING

2. CYCLIC LOADING

3. IMPACT LOADING

BASED ON SCOPE OF ITS ANALYSIS :

1. MACROMECHANIC (STRESS, STRAIN, STRAIN RATE, STRESS RATE)

2. MICROMECHANIC (FRACTURE SURFACE ANALYSIS, DISLOCATION,).

3. MESOMECHANICS

4. NANOMECHANICS

BASED ON FAILURE CRITERIA :

1. CONVENTIONAL METHOD (STATIC LOADING)– ( Stress < Strength )

2. FATIGUE FRACTURE CONCEPT(S – N diagram )

3. DAMAGE TOLERANCE APPROACH ( KIC )

( FRACTURE MECHANICS CONCEPT )

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 3/16

DEFINISION OF FAILURE:Failure is a general term for a condition in which a member is

subjected to plastic deformation; in other words, whereirreversible traces are observed in a member.

CLASIFICATION OF FAILURE (BROADLY) :

1. Damage

2. Fracture

3. Break

4. Rupture.

85 – 90 % of failure are generally caused directly by fatigue.

Losses of failure are classified as :1. Direct losses.

2. Indirect losses.

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 4/16

FAILURE AND LOSSES

CLASSIFICATION OF FAILURE ACCORDING TO FAILED

MEMBERS.

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 5/16

CLASSIFICATION OF FAILURES ACCORDING TO CAUSE

CLASSIFICATION OF FAILURES ACCORDING TO FACTOR

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 6/16

COMMONLY OBSERVED

MODES OFMECHANICAL FAILYREIN MACHINECOMPONENT

Axial Load onPlate with Hole

Rectangular plate with hole subjected to axial load. (a) Plate with

cross-sectional plane. (b) Half of plate with stress distribution.

Stress concentration is theregion in which stress raisersare present.

Kc is stress concentration factor

Stress Concentration

Stress Average

Stress Maximum ActualK c

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 7/16

Stress Concentrations for Plate with Hole

Stress concentration factor for rectangular plate with central hole. (a)Axial Load. [Adapted from Collins (1981).]

Stress Concentrations for Plate with Hole (cont.)

Stress concentration factor for rectangular plate with central hole. (b)Bending. [Adapted from Collins (1981).]

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 8/16

Stress Concentrations for Plate with Fillet

Stress concentration factor for rectangular plate with fillet. (a) AxialLoad. [Adapted from Collins (1981).]

Stress concentration factor for rectangular plate with fillet. (b)Bending Load. [Adapted from Collins (1981).]

Stress Concentrations for Plate with Fillet

(cont.)

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 9/16

Stress Concentrations for Plate with Groove

Stress concentration factor for rectangular plate with groove. (a) AxialLoad. [Adapted from Collins (1981).]

Stress Concentrations for Plate with Groove (cont.)

Stress concentration factor for rectangular plate with groove. (b)Bending. [Adapted from Collins (1981).]

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 10/16

Stress Concentrations for Bar with Fillet

Stress concentration factor for round bar with fillet. (a) Axial load. [Adapted from

Collins (1981).]

Stress concentration factor for round bar with fillet. (b) Bending. [Adapted from

Collins (1981).]

Stress Concentrations for Bar with Fillet (cont.)

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 11/16

Stress Concentrations for Bar with Fillet (cont.)

Stress concentration factor for round bar with fillet. (c) Torsion. [Adapted from

Collins (1981).]

Stress Concentrations for Bar with Groove

Stress concentration factor for round bar with groove. (a) Axial load. [Adapted from

Collins (1981).]

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 12/16

Stress Concentrations for Bar with Groove (cont.)

Stress concentration factor for round bar with groove. (b) Bending. [Adapted from

Collins (1981).]

Stress Concentrations for Bar with Groove (cont.)

Stress concentration factor for round bar with groove. (c) Torsion. [Adapted from

Collins (1981).]

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 13/16

FLOW ANALOGY

-To reduce stress concentration as much as possible.-To observe similarity understanding the flowvelocity of fluid in a channel and the stressdistribution of an axially loaded plate.

- The analogy is accurate, since equation of flowpotential in fluid mech. and stress potential in solidmechanics are of the same form.

the volume flow is :

From solid mechanics, the force must be constant atany point :

q

udAq

dAP

Stress Contours in Bar

Bar with fillet axially loaded showing stress contours through a flatplate for (a) square corners, (b) rounded corners (c) small groove, and(d) small holes.

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 14/16

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 15/16

Modes of Crack Displacement

aY K nomci

Three modes of crack displacement. (a) Mode I, opening; (b) mode II,sliding; (c) mode III, tearing.

KcI = stress intensity factor

Critical stress intensity = fracture toughness (fracture resistance)

FRACTURE MECHANICS

Y = dimensionless correction factor that accounts for geometry of partcontaining crack

Nominal stress at fracture, MPaa = Half of crack length, m

nom

7/23/2019 Failure Prediction Static

http://slidepdf.com/reader/full/failure-prediction-static 16/16

FRACTURE MECHANICS

Structural studies that consider crack extension as a function ofapplied load are performed in fracture mechanics.

Fracture failure occur when stress intensity is greater that criticalstress intensity factor, as shown in equation below :

KI ≥ KIC or KII ≥ KIIC or KIII ≥ KIIIC

or combination of each mode.

The broad field of fracture mechanics

Yield Stress and Fracture Toughness Data

Yield stress and fracture toughness data for selected engineeringmaterials at room temperature [From ASM International (1989)].

Material Yield Stress , S y Fracture Toughness , K ciks i Mpa ksi in1/2 Mpa m1/2

MetalsAluminum alloy

2024-T35147 325 33 36

Aluminum alloy7075-T651

73 505 26 29

Alloy steel 4340tempered at 260°C

238 1640 45.8 50.0

Alloy steel 4340tempered at 425°C

206 1420 80.0 87.4

Titanium alloyTi-6Al-4V

130 910 40-60 44-66

CeramicsAluminum oxide 2.7-4.8 3.0-5.3Soda-lime glass 0.64-0.73 0.7-0.8Concrete 0.18-1.27 0.2-1.4

Polymers

Polymethyl methacrylate 0.9 1.0Polystyrene 0.73-1.0 0.8-1.1