Exhaust Brake

-

Upload

mohamed-ibrahim -

Category

Documents

-

view

100 -

download

1

Transcript of Exhaust Brake

JACOBS EXHAUST BRAKE®

Increased Vehicle Control Reduces slowing time and distance on fl at

land and enables faster downhill control speed, offering driver comfort and peace of mind.

Reduced Downtime and Maintenance Cost: Helps service brakes last three

or more times longer.

Reliable Exclusive design eliminates contamination

and carbon build-up in the housing and keeps the butterfl y plate opening and closing freely.

Durable High-silicon molybdenum casting and butterfl y offer better

heat resistance and durability. Chrome plated butterfl y axles reduces friction and prevents sticking.

Effi cient Aerodynamic design of the housing and butterfl y plate allows

a smooth exhaust gas fl ow to maintain fuel economy.

No Maintenance Design No need for lubrication or adjustments.

Versions In-line and turbo-mount designs available as well as multiple mounting

orientations. Lightweight unit puts less stress on the turbocharger.

Warranty 5 years or 150,000 miles, whichever comes fi rst, on brake assembly and

1 year unlimited mileage warranty on Jacobs attaching components.

Jake Brake Heritage With 3 million brake kits sold, the trucking industry has come to embrace the

Jake Brake brand, with 1.8 trillion miles of proven road experience and high customer satisfaction.

Rigorous Testing Jacobs conducts comprehensive endurance, dyno-performance and salt spray

testing to ensure the quality, effectiveness and longevity of your exhaust brake.

FOR THE ROAD AHEADE NG INE E R E D

Ferrellgas runs 191 T300 Kenworth’s

powered by the CAT C7 engine

equipped with the Jacobs Exhaust

Brake. After seeing our brake life

increase 50% from 40,000 miles to

60,000 miles we have made this a

standard feature on our truck spec.

Our Drivers also appreciate the added

braking control and reliability the

exhaust brake has added.

Jim Hottel, Fleet Maintenance Manager, Ferrelgas

Introducing the latest Exhaust Brake designed for Caterpillar Medium Duty Engines- C7 and C9

Kenworth’s T300 Straight TruckC7 engine application only

Technical Specifications for C7 & C9

JACOBS EXHAUST BRAKE C7, C9

Jacobs Vehicle Systems, Inc

22 East Dudley Town Road Bloomfi eld, CT USA 06002 www.jacobsvehiclesystems.comP/N 25636 Rev. C 2/05

FOR THE ROAD AHEADE NG INE E R E D

1000 1200 1400 1600 1800 2000 2100 2200 2400 2500RPM

28 42 59 79 103 131 147 164 195 210HP

Retarding Power

“A” Measurement 9.09 in. 231 mm

“B” Measurement 3.62 in. 92 mm

“C” Measurement 10.91 in. 277 mm

Weight 13.6 lbs. 6.17 Kg.

Exhaust Pipe Size 4 in. 101.6 mm

Air Supply Pressure 75-145 psi 5.2-10 BAR

Air Cylinder Thread 1/4-18 NPT

2800

Ret

ard

ing

Po

wer

(H

P)

140010

50

90

130

170

210

250

1575 1750 1925 2100 2275 2450 2625

C9 Exhaust Brake Performance

RPM

140010

50

90

130

170

210

250

1575 1750 1925 2100 2275 2450 2625 2800

C7 Exhaust Brake Performance

RPM

Ret

ard

ing

Po

wer

(H

P)

1400 1600 1800 2000 2200 2400 2600 2800RPM

40 54 74 91 114 136 160 188HP

Retarding Power

C9 Exhaust Brake PerformanceC7 Exhaust Brake Performance

P E R F O R M A N C E

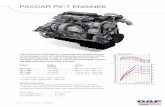

HIGH SILICON HIGH SILICON

MOLYBDENUM MOLYBDENUM

CASTING AND CASTING AND

COMPONENTSCOMPONENTS

TURBO OR IN-

LINE MOUNTING

OPTION

FULLY SEALED

AIR CYLINDERAIR CYLINDER

CHROME PLATED CHROME PLATED

BUTTERFLY AXLESBUTTERFLY AXLES

“A” Measurement 9.09 in. 231 mm

“B” Measurement 3.25 in. 82.5 mm

“C” Measurement 10.75 in. 273 mm

Weight 12.2 lbs. 5.5 Kg.

Exhaust Pipe Size 4 in. 101.6 mm

Air Supply Pressure 75-145 psi 5.2-10 BAR

Air Cylinder Thread 1/4-18 NPT

A

B

C

C9*

C7*

JACOBS EXHAUST BRAKE®

AERODYNAMIC

DESIGN

NO PRODUCT NO PRODUCT

MAINTENANCEMAINTENANCE

Also available for Models 3116, 3126, 3126B and 3126E* Please visit www.jacobsvehiclesystems.com for application information