EXECUTION OF CONCRETE STRUCTURES Constructors Obligation ... · EXECUTION OF CONCRETE STRUCTURES...

Transcript of EXECUTION OF CONCRETE STRUCTURES Constructors Obligation ... · EXECUTION OF CONCRETE STRUCTURES...

Spearhead Network for Innovative, Clean and Safe Cement and Concrete Technologies

EXECUTION OF CONCRETE STRUCTURES

Constructors Obligation in QualityControl on Site

SPIN Meeting and Training Workshop in Tanzania,from 30th June to 6th July 2012

Prof. Dubravka Bjegović, Ph.D.C.E.Institut IGH d.d Zagreb and

University of Zagreb, Faculty of Civil Enginering, Department for Materials

Renato Rajzer M.Eng. (Geot .Eng.) Institut IGH d.d. Zagreb

Institute for Materials and Construction

Head of Division for technology and quality of concrete structures

REPUBLIC REPUBLIC REPUBLIC REPUBLIC

OF CROATIAOF CROATIAOF CROATIAOF CROATIA

Parliamentarydemocracy

Independance25.06.1991.

(fromYugoslavia)

Population: 4.480.043

Central Europe

Mediterraneancountry with1246 Islands

Mountains, lakes, national

parks

Capital city - Zagreb800.000 inhabitants

Content

� Introduction� Legislation in EU and Republic of Croatia, Regulations and Standards� Participants in construction process� Bridge Selnica – Bypass Velika Gorica, description of construction site,

application of regulations on site � Quality management and Quality control on site throughout all stages of

drilled concrete piles execution� Main requirements of Technical regulation for concrete structures Annex

“J" and standard HRN EN 13670:2010� HRN EN ISO 9001:2008 Quality management systems� Conclusion

SPIN Meeting and Training Workshop in Tanzania,from 30th June to 6th July 2012

TO BUILD STRUCTURE LIKE THAT YOU NEED:

� People (experts, workers, logistics)� Machines, vehicles, equipment,

materials, products...

But before all that you need� Knowledge, Science� Legislation� Regulations and Standards� Investor, Designers, building permits...

Introduction

Faults and defects that may occureduring all phases of construction

project and especially duringconstruction phase can result with

very large subsequent costs or even complete cancellation of

structure or some part of structure

QUALITY ASSURANCE AND QUALITY CONTROL IN ALL

STAGES OF CONSTRUCTION PROJECT IS VERY IMPORTANT

That is why

CONCEPTUAL DESIGN� Preliminary specifications for

construction and maintenance� Specifications for design

INVESTMENT STUDY� Market Analysis� Economic and financial analysis� Financial structure� Period of investment return

Introduction - The flow of the construction project

DESIGN� Project specification� Specifications for materials,

equipment, parts and assemblies� Essential requirements for building� Load capacity, usability, durability� Building permits

CONSTRUCTION� Execution specification� Supervision� Technical inspection of the

building� Handing over the building

to investor

MAINTENANCE OF BUILDING� Facility management� Monitoring� Construction inspections� Repairs and replacement of worn parts

DEMOLITION ANDRECYCLING

� Concrete� Steel� Bricks and building rubble

QUALITY ASSURANCE AND QUALITY CONTROL IN ALL

STAGES OF CONSTRUCTION PROJECT !!!!!

BID, TENDER� Public open tender� Sending offer� Selection of contractor� Contract for construction

Introduction - The flow of the construction project

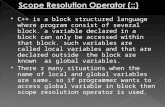

Quality assurance (QA) and Quality control (QC) of concrete on site

Introduction – QA & QC is very important

� Obligation of contractor� Quality plan for the

execution of concretestructures

� Under the supervision- supervisor engineer

� Laboratory on site� Sampling� Curing specimens� Testing, testings result� Records of quality

control procedures� Final report - Proof of

usability of concrete

Test samplesLaboratory forconcrete testing on site

QUALITY CONTROL OF CONCRETE –

IMPLEMENTATION ON CONSTRUCTION

SITE

Legislations in EU and in Croatia

Adaptation and harmonization of legislation with EU legislation is based on the principles:

� New Approach, NA Council Resolution 85/C 136/01 of 7 May 1985 on a new approach to technical harmonization and standards.

� Global Approach, GA Council Resolution 90/C 10/01 of 21 December1989 on a global approach to conformity assessment

Croatia will become a member of the EU 01.07.2013, and is adapted all its legislation to that which applies to the EU market

Legislations in EU and in Croatia

�� Construction Product Directive (CPD) 89/106/EECConstruction Product Directive (CPD) 89/106/EEC itit willwill bebe withdrawnwithdrawn 30.06.2013.30.06.2013.

Essential Requirements - There are six essential requirements which need to besatisfied, when relevant, by the product prior to being put on the market

� 1. Mechanical resistance and stability� 2. Safety in case of fire� 3. Hygiene, health and the environment� 4. Safety in use� 5. Protection against noise� 6. Energy economy and heat retention

�� Construction products regulation (CPR) 305/2011Construction products regulation (CPR) 305/2011 01.07.2013. will start to apply01.07.2013. will start to apply

� Novelty - 6 Essential Requirements 7 Basic Requirements (constuction works)- Sustainable use of natural resources Sustainable use of natural resources –– 7. Basic Requirements7. Basic Requirements- Declaration of conformity Declaration of performance- The system of assessment and verification of constancy of performance

System 2 no longer exist- Essential Characteristics (construction products relating to basic requirements

for building)

�� Physical Planning and Building Act Physical Planning and Building Act ((OOG G 76/07,76/07, 38/09, 55/11, 90/11, 50/1238/09, 55/11, 90/11, 50/12))

Construction regulations

Legislations in EU and in Croatia

� Law on Technical Requirements for Productsand Conformity Assessment (OG 20/10)

� Law on the General Safety of Products (OG 30/09)

� Standardization Act (OG 163/03)

� Law on Accreditation (OG 158/03,75/09)

� Law on Metrology (OG 163/03,194/03,111/07)

� Law on Obligatory Relations (OG 35/2005, 63/2008)

Technical Legislation – Horizontal legislations

Legislations in EU and in CroatiaConstruction products

� Act on construction products (OG 86/08)

� Ordinance on technical approval for construction products (OG103/08)

� Ordinance on conformity assessment, documents of conformity and the marking of construction products(OG 103/08, 147/09, 87/10, 129/11)

� Technical regulation on construction products (OG 87/10, 146/10, 81/11, 100/11)

� Technical regulation for concrete structures (OG 139/09, 14/10, 125/10)

� Technical regulation for masonry structures (OG 01/07)

...............and many others

SCHEME EN STANDARDS AS THE BASIS FOR THE DESIGN, EXECUTION AND CHOICE OF MATERIALS FOR CONCRETE WORKS (MAIN MODULES)

+ National annex

HRN 1128:2007+ National annex,

HRN ???

+ Nationally Determined

Parameters, NDPs

+ Nationally Determined

Parameters, NDPs

Legislations in EU and in Croatia

DRAFT OF THE LAW WITH DRAFT OF THE LAW WITH THE FINAL PROPOSALTHE FINAL PROPOSAL

MINISTRYBUILDING ADMINISTRATION

PUBLIC HEARINGSUGGESTIONS, COMMENTS, OPINIONS

TREATMENT OF ALL OPINIONS, TREATMENT OF ALL OPINIONS, COMMENTS AND PROPOSALSCOMMENTS AND PROPOSALS

DRAFT OF THE LAW DRAFT OF THE LAW ––FINAL TEXTFINAL TEXT

CROATIAN GOVERNMENTCROATIAN GOVERNMENT ––ADOPTIONADOPTION OFOF LAWLAW

MINISTRYBUILDING ADMINISTRATION

Technical regulations, regulations,expert opinions and explanations

� Building Regulations is a set of professional rules, laws, ordinances, regulations and other acts regulating and coordinating relations of all participants in construction projects, establishing requirements for construction and procedures

� For the adoption of building regulations in Croatia is responsible the Ministry of Environment, Physical Planning and Construction and Building Administration

� National legal acts are published in "Official Gazette”

Legislations in EU and in Croatia

Participants in construction process

INVESTOR + OTHER PARTICIPANTS IN CONSTRUCTION PROCESS

INDIRECT PARTICIPANTS

� Government bodies� Inspections� Urban planners� Financial organizations� Chambers of commerce� Professional associations� Utility company� Public company

DIRECT PARTICIPANTS

� DESIGNERS� REVISORS� CONSTRUCTORS� SUPERVISOR ENGINEER� Experts and advisers� Companies for exploration work� Faculties and Institutes� Different suppliers (equipment,

machinery, plant and materials)

Participants in construction process

Physical Planning and Building Act(OG 76/07, OG 38/09, OG 55/11, OG 90/11 & 50/12)

In accordance with Article 177.

INVESTOR

DESIGNER REVISER CONTRACTORSUPERVISOR

ENGINEER

Participants inconstruction process:

INVESTOR

Participants in construction process

� Legal or natural person in whose name structure is building� Provides with the design, validation and control of projects,

construction and supervision to authorized persons� Obtain all building permits� Investor is required to provide supervision� Investor is required to report beginning or continuation of

construction� Request for obtaining a use permit� Obtain all the documentation for technical inspection of the building� Building owner is responsible for its maintenance so that during it

use to preserve the essential requirements for building� Removal of the building permit, removal, supervision of removal

� Natural person who prepares the building projects� Designer is responsible for project to be made in accordance with

laws and regulations, project must comply with the location permitand must meet essential requirements for structure

� Defines the structure� Defines the use of building� Defines the product� Defines the main requirements for the execution of the building� The main designer is determined by the investor

Participants in construction process

DESIGNER

Participants in construction process

REVISOR

� Natural or legal person authorized for the project control

� Authorized revisor, graduate civil engineer with a minimum of ten years of service

� Revisor is responsible for project or part of project that hecontroled to be made in accordance with laws andregulations, project must comply with the location permit andmust meet essential requirements for structure

� Revisor must be independent

Participants in construction process

CONSTRUCTOR

� Contractor is obligated to build according to approved maindesign and building permit

� Confer performance of construction works and other works topersons who fulfill ordinance requirements for performance ofthese works

� Perform works in order to fulfill essential requirements andother requirements for structure

� Embed construction products and equipment in accordancewith Physical Planning and Building Act

CONSTRUCTOR

Participants in construction process

Provide:� Proof of usability of embedded construction products� Proof of compliance of embedded equipment according to

specific act� Documents of compliance of specific building parts to basic

requirements for structure and from competent authority given proof of quality (testing results, records of conducted control quality procedures etc.)

� Legally dispose construction waste generated during construction on the site

� Draw up a written report of conducted works, and of the maintenance building

Participants in construction process

� In accordance with Physical Planning and Building Act Supervisor Engineer is a natural person who under a special law has the right to use the professional title of a licensed architect or licensed engineer and to conduct technical supervision of construction on behalf of the Investor.

SUPERVISOR ENGINEER

� The supervisor engineer cannot be an employee of aperson who is the contractor on the same building

� Supervise the construction to be in accordance with the main design, building permit, Physical Planning and Building Act and other special regulations

� Determine if a main design in terms of horizontal and vertical dimensions and purpose of the building is made in accordance with the decision on building conditions or location permit

� Determine if construction staking is performed by the person authorized to conduct affairs of state survey and real property under a special law

� Determine whether the contractor meets the requirements for performing construction activities

SUPERVISOR ENGINEER

Participants in construction process

� Determine the implementation of control procedures in respect of compliance assessment, and prove the quality of certain parts of the building by an authorized person

� Immediately inform Investor with all the disadvantages or irregularities perceived during construction, building inspections and other inspections of the measures taken

� Compile a final report on the building construction.

Participants in construction process

SUPERVISOR ENGINEER

Bridge Selnica – Bypass Velika Goricasections of road D-31 with connection to the D-408, PHASE II

BridgeSelnica

Reinforced concrete drilled piles Bridge Selnica

� Application of the regulations through the documentation and records on the construction site and obligations of participants in constructionprocess

� Quality management through all stages of execution of piles� The main requirements of the Technical Regulations for concrete

structures Annex "J" and requirements of the standard HRN EN 13670:2010

Bridge Selnica – Bypass Velika Gorica

BUILDING PARTICIPANTS SHEME

SUPEVISION ENGINEER:Hrvatske ceste d.o.o. Zagreb

INVESTOR:

Hrvatske ceste d.o.o. Zagreb

SUBCONTRACTOR:(AB bušeni piloti)

Crosco d.o.o Zagreb

LABORATORY ON CONSTRUCTION SITE:Viadukt d.d. Zagreb

CONTRACTOR:Viadukt d.d. Zagreb

TECHNICAL SUPERVISION:

INSTITUTE IGH; Department forTechnology and Quality of Concrete

Structures

Bridge Selnica – Bypass Velika Gorica

Bridge Selnica – Bypass Velika Gorica

Reinforced concrete drilled piles Bridge Selnica� Piles - diameter of 120 centimeters (12,4 m3 of concrete for one pile) � 21 piles, heights of 11 meters, under the columns and abutments� Concrete supplier: Concrete plant (ready mix) TBP Pojatno Viadukt JSC.,

Certificate of factory production control no. 1/05-ZGP-493� The designed concrete C25/30 Dmax 32 S4 XC1 Cl0,10 (R-009)

Composition of concrete for concrete piles C25/30

Cement: Našice cement CEM II/A-M(S-V) 42,5N...............400,00 kgWater: Urban water supply...............................................164,00 lAddition: Glenium Sky Superplastifikator 0,80 %.....................3,20 lAggregate: Radlovac: Crushed aggregate 4-16 mm,

River aggregate 0-4 mm Sava0-4 mm 45%...................................................819,04 kg 4-8 mm 15%...................................................294,65 kg8-16 mm 40%...................................................782,99 kg

w/c.. 0,41 Aggregate total:........................1896,68 kg

TOTAL WEIGHT:............................2463,88 kg

Bridge Selnica – Bypass Velika Gorica

Daily report aboutexecution of drilled

reinforced concrete piles

PILES ARE COLUMNSOF SOLID MATERIALS

WHICH TRANSMIT FORCEOF BUILDINGS INTO THEDEEPER LAYERS OF SOIL

- DEEP FOUNDATIONS

Bridge Selnica – Bypass Velika Gorica

� CONSTRUCTION SITE ORGANIZATION

� CONTRACTING SUPPLIER

� CONTROL PROCEDURES PRIOR TO CONCRETING

� PROJECT DOCUMENTATION

PREPARATORY WORKFOR EXECUTION OF

DRILLED CONCRETE PILES

DRILLING AND COLON INSTALATION

INSTALLATION OF REINFORCEMENT CAGE

� GEOMECHANICAL PROJECT

� GROUND WATER – MEASUREMENT

� TEST DRILLING VERTICALITY

� GEOTECHNICAL PROPERTIES MONITORING

� MEASURING DEPTH AND DIAMETER OF DRILLHOLE

� DURATION OF DRILLING

� STEEL REINFORCEMENT IN ACCORDANCE TO HRN EN

10080 AND TECNICAL REGULATIONS FOR CONCRETE

STRUCTURES ANNEX “B”

� MADE ACCORDING TO PROJECT DOCUMENTATION IN

RAINFORCEMENT FACTORY

� INSTALLED IN DRILLHOLE WITH COLONS

Bridge Selnica – Bypass Velika GoricaQuality management and Quality control on site throughout all stages of performing drilled concrete piles

CONCRETING OF PILES –UNDERWATER CONCRETE

TECHNOLOGY

REMOVING THE UPPER LAYER OF PILE HEAD

INTEGRITY TEST OF PILES

� SPECIFICATION OF CONCRETE-ORDER (HRN EN 206-1)

� TESTING OF FRESH CONCRETE

� CONTROL PROCEDURES DURING CONCRETING HRN EN

13670:2010

� RECORD OF THE CONCRETING

� RECORD ON SAMPLING

� DAILY REPORT – EXECUTIONS OF PILES

� START TIME AND END OF CONCRETING

� ACTUAL AND DESIGNED HIGHTS OF PILES

� REMOVING OF POOR QUALITY CONCRETE FROM THE

UPPER LAYER OF PILES

� CORRECTION, STRAIGHTEN AND CLEANING OF

REINFORCEMENT OF THE PILE HEAD

� EXAMINATION BY AUTHORISED ORGANIZATION

� IDENTIFY POSSIBLE DEFECTS

� DETERMINING THE LENGTH OF PILES (m)

Bridge Selnica – Bypass Velika GoricaQuality management and Quality control on site throughout all stages of performing drilled concrete piles

Bridge Selnica – Bypass Velika Gorica

� Certificate of registration in the register� Consent to carry out construction works and contract association of

contractors under a special law� Act on the appointment of chief site engineer, site engineer, or the

works manager� Act on the appointment of supervisor or main supervisor� Detailed designs with the view of the main designer and certified by

the reviser, Program of quality control and quality assurance� Building permit� Construction site diary, The Site calculations� Supplier Declaration of conformity, certificates of conformity of

products, the certificate of factory production control, technicalinstructions for installation and use of products

Documentation on construction site

Bridge Selnica – Bypass Velika Gorica

� Specifications of materials and construction products � Record of the geodesic construction staking� Quality plan for execution of concrete structures� Laws, regulations, technical regulations and standards� Study on site organization with the work protection and safety and

fire protection� Records of the control activities carried out on site� Evidence about the quality of the built-in concrete (reports of

examinations conducted on the site)� Proof of usability of concrete structure according to Technical

regulations for concrete structures annex “J.2.4”� Other documents, licenses and permits for which the

special regulations stipulates that the contractor afterbeginning construction of the building must have on-site

Documentation on construction site

Quality management systems of participantsin construction process

� VIADUKT JSC HRN EN ISO 9001:2009HRN EN ISO/IEC 17025:2007HRN EN ISO 14001:2009

� CROSCO Ltd HRN EN ISO 9001:2009 OHSAS 18001:2007HRN EN ISO 14001:2009

� INSTITUTE IGH JSCHRN EN ISO 9001:2009 - Quality management systemsOHSAS 18001:2007 - Occupational Safety and HealthHRN EN ISO 14001:2009 - Environmental Management SystemHRN EN ISO/IEC 17025:2007 - General requirements for thecompetence of testing and calibration laboratories

Quality management and Quality control on site

Quality management and Quality control on site

MAIN DESIGNPROGRAM OF QUALITY CONTROL

AND QUALITY ASSURANCE

QUALITY PLAN QUALITY PLAN FOR FOR

EXECUTION OF EXECUTION OF

CONCRETE CONCRETE

STRUCTURESSTRUCTURESHRN EN ISO 9001 HRN EN ISO 9001

CONCRETING PLANAND QUALITY CONTROL

OF CONCRETE

Specification of concreteDelivery, receipt and construction site transport of concreteWorks during concretingConcreting and compactionCare and protectionWorks after concretingSpecial technology ofexecutionChecking the conformity of concrete propertiesControl of execution

ORGANIZATIONAL ORGANIZATIONAL

PROCEDURESPROCEDURES

OPERATIONAL OPERATIONAL PROCEDURESPROCEDURES

RECORDS, INFORMATION, STANDARDSRECORDS, INFORMATION, STANDARDS, ,

LAWS,TECHNICAL LITERATURE, GRAPHS,LAWS,TECHNICAL LITERATURE, GRAPHS,

SCHEME, DRAWINGS, TABLESSCHEME, DRAWINGS, TABLES

Quality Plan includes:� Information about the structure, organization of the

construction site and contractor� Description of the construction site management and quality

during execution, responsible personnel� List of selected suppliers of construction products in

accordance to project requirements

QUALITY PLAN QUALITY PLAN FOR EXECUTION OF FOR EXECUTION OF CONCRETE STRUCTURESCONCRETE STRUCTURES� It is made by the contractor before starting work in accordance with main

design, and in accordance with applicable regulations� It must be approved by supervising engineer

� Concrete specifications, quantities and selectedtypes of concrete

� Delivery, downloading and site transport of freshconcrete

� Sequence, breaks and endings of concreting� Installation, compaction and surface treatment of

concrete� Care and protection of concrete� Sampling plan and testing of concrete on siteQUALITY PLANQUALITY PLAN

Quality management and Quality control on site

QUALITY PLAN FOR THE EXECUTION OF CONCRETE STRUCTURES

Quality management and Quality control on site Contractor records and documentation

Regulates the management and execution ofconcrete works and ensuring quality control

during the execution of concrete works

Contain the required quality level of performance and implementation of quality

control and testing during construction works

INCLUDES: - responsible persons, materials, construction products, equipment, technology, suppliers, scaffolding, reinforcement, casting,

precast elements, geometric tolerance, supervisior and repair,

CONCRETE CASTING RECORDS

Quality management and Quality control on site Contractor records and documentation

Concrete casting records includes:

� Control before concreting

� Fresh concrete testings and control

before casting

� Casting and compacting of concrete

� Control after casting

� Control of precast concrete elements

� Record for each concreting

� Signatures of persons responsible

� Archiving of records

RECORD OF TAKING SAMPLES

Quality management and Quality control on site Contractor records and documentation

Record of taking samples includes:

� Generala data of construction site

� Data about concrete

� List of necessary hard concrete testings

� Data about taking samples – signatures,

dates

UNIFORMITY OF COMPRESSIVE STRENGTH TEST RESULTS

Quality management and Quality control on site Contractor records and documentation

EVALUATION OF TEST RESULTS IN ACCORDANCE WITH ANNEX “B” OF

STANDARD HRN EN 206-1:2006

≥ fck

- 4≥ fck

+25-6

≥ fck

- 4≥ fck

+12-4

≥ fck

- 4Not Usable1

Each individual result

(fci

)(N/mm2)

The mean value of "n" results

(fcm

)(N/mm2)

Criteria 2Criteria 1The number "n" test

results of compressive

strength of definedquantity ofconcrete

Technical regulations for concrete structures Annex “J”

� Concreting

o Concreting in accordance with HRN EN 13670:2010 o Testing of fresh concrete, samplingo 1 sample on 100 m3 of concrete o Minimum 1 sample /dayo Record of taking sampleso Evaluation of test results HRN EN 206-1 annex B

� Installation of reinforcement� Installation of precast concrete elements� Usability of concrete structures� Subsequent proving the technical

properties of concrete� Maintenance of concrete structures

HRN EN 13670:2010

� Terms and definitions� Execution management� Falsework and formwork� Reinforcement� Prestressing� Concreting� Execution with precast

concrete elements� Geometrical tolerances� Annex A-H

Quality management and Quality control on siteMain requirements in quality control of concrete on site

Concrete plant Pojatno -capacity 160m3/hour

Quality management and Quality control on siteOrdering of concrete, Specification of concrete

The user must provide the following information, in accordancewith HRN EN 206-1, to producer when ordering concrete

� Specification of concrete� Date, time, delivery dynamics and method of payment� Mode of transportation to the site� Intended method of concreting� Other requirements essential for the transport and delivery

Specification for designed concrete:

o Requirement to meet standard HRN EN 206-1o Compressive strength class, eg. C25/30o Exposure classes depending on the work

environment according to HRN 1128:2007o Maximum chloride content, eg. Cl 0,10o Maximum nom. upper size of the aggregate, Dmax 32o Class of consistency, eg, S4

C25/30 Dmax 32 S4 XC1 Cl0,10

Quality management and Quality control on siteProduction of concrete

Procedure for conformity certification of concrete

Continued validity orwithrwal of the Certificate

of FPC

Continuous inspection and assessment offactory produstion control, rendom sampletestings

Certificate of factoryproduction control

Initial factory inspection and initial inspection offactory produstion control

AUTHORISED PERSON

Initial type testing

Testing of samples according to the plan andconformity control

Declaration ofconformity

(after reciving a certificateof FPC)

Factory production control

PRODUCER

DocumentActivity

CONCRETE - conformity assessment system 2 +(modified requirement for national testing in compression on a random sample of the authorized person)

Quality management and Quality control on siteTransport of fresh concrete - documentation

DECLARATION OF CONFORMITY

Document issued by the producerafter reciving a Certificate of FPC

In accordance to Act on construction products (OG 86/08) Declaration ofconformity must follow each product

which is delivered

Producer should send a declaration of conformity to the Ministry within maximum

10 days from the date of issue

Quality management and Quality control on siteTransport of fresh concrete - documentation

TECHNICAL INSTRUCTIONS

Document issued by the producer

In accordance to Act on construction products (OG 86/08) Declaration ofconformity must follow each product

which is deliveredIt contains:

� Identification of products and producer� Product description and ingredients� Range of applications� Casting and care of fresh concrete� Technical information of the concrete� Limit application of the product� Conformity Assessment� Protection and Safety at Work

Quality management and Quality control on siteTransport of fresh concrete - documentation

CONCRETE DELIVERY NOTE

Document issued by the producer

It goes with every shipment

It must contain information in accordanceto standard HRN EN 206-1, 7.3:

� Name of the concrete plant� Serial number of concrete delivery note� Date and time of shipping� Number and vehicle registration� Name of customer� Name and location of construction site� Quantity of concrete� Mark of conformity� Time – arrival of concrete on site, start

of shipping and end of shipping� Specification of concrete

Quality management and Quality control on siteSubmission of concrete on site

Minimum requirements for quality control of concrete on construction site – in accordance with Technical regulation for concrete structures

(OG 139/09, 14/10, 125/10)

Fresh concrete testings

Control of concrete delivery note

Activity Frequency

Every shipment

Consistency of fresh concrete – visualcontrol

Every shipment

Measuring the consistency of concreteaccording to HRN EN 12350-2

� During making control samplesfor compressive strength

� At any reasonable doubt

Quality management and Quality control on siteSubmission of concrete on site

Fresh concrete testings

Activity Frequency

Air content in accordance to HRN EN 12350-7

Temperature of fresh concrete andtemperature of air

At the start of concreting in thewinter and summer conditions(+ 5°C – 30 5°C )

During making control samples for compressive strength (only for for aerated concrete)

Sampling according to HRN EN 12350-1Making and curing specimens for testing

hardened concrete according to HRN EN 12390-2

According to Quality plan forexecution of concrete structures –Sampling plan

Quality management and Quality control on siteFresh concrete testings

Measuring the consistency of concreteaccording to HRN EN 12350-2

Air content in accordance to HRN EN 12350-7

Temperature of fresh concrete andtemperature of air

Sampling according to HRN EN 12350-1 Making and curing specimens for testing hardened concrete

according to HRN EN 12390-2

Curing ofspecimens

on site

Constructionsite

laboratory

Quality management and Quality control on siteFresh concrete testings

Uniformity of compressive strength test results

Activity Frequency

� Minimum 1 sample/day� 1 sample on 100 m3 of

concrete � Minimum 1 sample for

constructive elements� Record of taking samples� Evaluation of test results

HRN EN 206-1 annex B

Quality management and Quality control on siteHardened concrete testings

Minimum requirements for quality control of concrete on construction site – in accordance withTechnical regulation for concrete structures (OG 139/09, 14/10, 125/10)

Making and curing specimens for testing hardened concrete according to HRN

EN 12390-2 and testing accordingHRN EN 12390-3

Durability testing, water resistance, resistance concrete to frost, frost and

salt, wear resistance...Sampling plan, project requirements

Quality management and Quality control on siteHardened concrete testings

Compressive strenght of test specimensaccording to HRN EN 12390-3

Depth of penetration of water under pressureaccording to HRN EN 12390-8:2009

Freeze-thaw resistance - Scaling according to HRN CEN/TS 12390-9:2006

Testing the freeze-thaw resistance of concrete –

Internal structural damage HRN CEN/TR 15177:2006

ISO 6784:1982Concrete - Determination of static modulus of elasticity

in compression

Quality management and Quality control on siteUsability of concrete structures

In proof of usability should consider:� Construction site diary records of properties and other information

on construction products built into the structure

� The results of all control procedures prior to installation

construction products in concrete construction

� Approvals (test results, records of the procedures, etc.) provided by

the contractor during the construction of concrete structures

� The test results of load test of concrete structure

� Conditions construction and other circumstances in accordance

with construction diary and other documentation which may affect

the properties of concrete

Quality management and Quality control on siteSubsequent proving the technical properties of concrete

For concrete structure, which is not provided project determined properties orcan not be determined due to lack of documentation it is necessary to

subsequently prove the quality of concrete by a series of standards HRN EN 12504 and standard Assessment of in-situ compressive strength in structures

and precast concrete components HRN EN 13791:2007

Usually it is a combination of destructive and non-destructive testing methods

HRN EN 12504-2:Testing concrete instructures-Part 2 Non-destructive testing-

Determination ofrebound

HRN EN 12504-3:Testing concrete in

structures-Part 3 Determination

of pulling force

Drilling of cylinders fordestructive concrete

testings

HRN EN 1542: 2001Products and SystemsProtection and Repairconcrete structures -

Measuring the strength ofAdhesion pull-off

HRN EN ISO 9001:2008 Quality management systems

Today's business conditions, competition, large EU market dictate greaterrequirements than the legal minimum so it is very important for construction

companies:

� to establish, document and implement Quality Management System (QMS)

� it is recommended that contractors introduce a quality management system

according to the requirements of HRN EN ISO 9001:2008, ensuring a process

approach and continuous measurable improvement in quality

� QMS is not legally required but the investors are increasingly requiring

in a tender

All this indicated earlier in this paper represents:

Minimum requirements for quality control of concrete on constructionsite – in accordance with Technical regulation for concrete structures

(OG 139/09, 14/10, 125/10)

The main factors of quality management

� Inspection, verification� Quality control (QC)� Quality assurance (QA)� Total Quality Management (TQM)

Quality is the ability to feature products, systems or processes to meet customer requirements and other interested parties.

Few definitions:

Quality is customer satisfaction.

The quality is the compliance with the requirements.

HRN EN ISO 9001:2008 Quality management systems

HRN EN ISO 9001:2008 Quality management systemsThe basic principle of quality management in execution is a process approachProcess approach is a strategy of management

Quality Management System is a network of processes

The process consists of: people, work, activities, tasks,records, documents, forms, resources, policies,regulations, reports, materials, supplies, equipment

The application of any standards is voluntary.

The decision on the application of certain standards each participant accepts “game rules" about the consistent application of that standard

Standards are mandatory, if the laws and regulations refer to them

HRN EN ISO 9001:2008 Quality management systems

The benefit of implementing a quality management system:

� Improving the quality of services� Increase employee motivation� Successful teamwork (which contributes to the compactness and

unity of the department)� Continuous training of staff (which affects the steadily increasing expertise)� Improving co-operation with clients� Continuous improvement of the quality system� Better position to market and greater resistance to the instability of the

market� A better quality of execution, greater durability of the building, better

visual impression and surface quality� Material saving� Better safety, less injuries at work

HRN EN ISO 9001:2008 QMS

HRN EN ISO 9001:2008 QMSImplementation on construction site

In order to successfully manage the quality management process for concretestructure execution except compliance with all legal requirements it is

necessary to implement the following:

� Very thoroughly study all the execution documentation and resolve all doubtsbefore starting work with other participants in construction

� Establish a system of quality control and quality assurance of reinforcedconcrete structures execution, to determine the responsible person, duties andresponsibilities

� All activities within the process clearly define and document� Define a way to manage changes during the execution and responsible person� Appoint the internal control of execution� Plan and provide training for all participants whose work affects the quality� Define a procedure for resolving non-compliance performance� Prepare a Quality plan for execution of concrete structures which is aligned with

the main project, define personnel in quality control and quality assurance� Obtain an independent assessment of the management process for execution

of concrete structures in order to create trust between contractor andcontracting authority

Conclusion

� Process of adaptation building regulations to EU regulations (Laws,technicalregulations ,Decrees, Regulations, Standards) in Croatia is almost finished

� Now we need follow and implement regulations� We need to adapt to new regulations

Construction Product Directive (CPD) 89/106/EEC it will be withdrawn 30.06.2013.Construction products regulation 305/2011 01.07.2013. will start to apply

Act on construction products (OG 86/08) - Amendment of law 2013?National Annex of standard HRN EN 13670:2010 Execution ofconcrete structures – still in progress

� The obligation of all participants it to meet the requirements of current building regulations

� Biggest croatian companies has introduced quality management system but most of croatian companies did not or it is poorly implemented

� Currently in Croatia are about 2500 certified companies according to HRN EN ISO 9001:2008 (all companies, not just construction companies)

� It takes several years to implement a quality management system and it must be decision of management

Literature

� Construction site documentation – Bridge Selnica� Execution documentation – Bridge Selnica� Radić, Bleiziffer, Žderić, Šavor, Tkalčić: Concrete structures in Croatia from 2002 to 2006 – Croatian

National Report, The Second fib Congress Naples, Italy 5-8 June 2006� Jure Radić, Concrete structures – Manual; University Zagreb, Andris 2006� Jure Radić, Concrete structures - part 4 – Execution; University Zagreb, Andris 2006� Physical Planning and Building Act (OG 76/07, 38/09, 55/11, 90/11, 50/12)� Law on Technical Requirements for Products and Conformity Assessment (OG 20/10) � Law on the General Safety of Products (OG 30/09)� Standardization Act (OG 163/03)� Law on Accreditation (OG 158/03,75/09) � Law on Metrology (OG 163/03,194/03,111/07)� Law on obligatory relations (OG 35/2005, 63/2008)� Act on construction products (OG 86/08) � Ordinance on technical approval for construction products (OG103/08)� Ordinance on conformity assessment, documents of conformity and the marking

of construction products (OG 103/08, 147/09, 87/10, 129/11)� Technical regulation on construction products (OG 87/10, 146/10, 81/11, 100/11)� Technical regulation for concrete structures (OG 139/09, 14/10, 125/10)� Technical regulation for masonry structures (OG 01/07)� Internet documentation� Personal photo archive� IGH photo archive

Contact: Renato Rajzer, M.Eng. (Geot.Eng.)

INSTITUTE IGH d.d. Zagreb Janka Rakuše 1Institute for materials and structures

Division Manager – Division for Technology and Quality of Concrete Structures

tel. 01/6125-115 faks. 01/6125-100 mob. 098/9844018

E-mail: [email protected] Web: www.igh.hr

THANK YOU FOR YOUR

KIND ATTENTION