Evason Hideaway at Con Dao_STP

Transcript of Evason Hideaway at Con Dao_STP

-

7/31/2019 Evason Hideaway at Con Dao_STP

1/23

-

7/31/2019 Evason Hideaway at Con Dao_STP

2/23

CONTENTSA. DESIGN BASIC ......................................................................................................................................................1

1. W ATER DEMAND .........................................................................................................................1 2. W ASTEWATER FLOWRATE ............................................................................................................1

3. T REATMENT PROCESS ..................................................................................................................1 B. EFFLUENT STANDARD.......................................................................................................................................2

C. OPERATION TIME...............................................................................................................................................2

D. THE PROPOSED SEWAGE TREATMENT PROCESS ...................................................................................3

1. STP P ROCESS .............................................................................................................................3 2. STP D ESCRIPTION ......................................................................................................................4 3. STP SPECIFICATIONS .................................................................................................................7

a. Grease trap .................................................................................................................................................7 b. Septic tank...................................................................................................................................................7 c. Equalization tank .......................................................................................................................................7 d. Anoxic 1 ......................................................................................................................................................8 e. Aeration tank...............................................................................................................................................8

f. Anoxic 2 ......................................................................................................................................................8 g. Aeration tank 2............................................................................................................................................8 h. Clarifier ......................................................................................................................................................9 i. Disinfection tank .........................................................................................................................................9

j. Treated water storage tank .........................................................................................................................9 k. Anaerobic sludge digester...........................................................................................................................9 l. Belt filter press...........................................................................................................................................9

E. ODOR CONTROL SYSTEM ..............................................................................................................................11

F. SOLID WASTE DISPOSAL ................................................................................................................................ 13

G. EQUIPMENT........................................................................................................................................................14

J. OPERATION COST..............................................................................................................................................17 1. S EWAGE TREATMENT PLANT (A).................................................................................................17

a. Electric consumption rate .........................................................................................................................17 b. Chemical consumption rate ...........................................................................................................................18 c. Labor cost .................................................................................................................................................18

2. O DOR CONTROL SYSTEM (B)......................................................................................................18 a. Electric consumption rate...............................................................................................................................18 b. Chemical consumption..............................................................................................................................18

3. S OLID WASTE PROCESSING SYSTEM (C) .....................................................................................19 a. Electric consumption rate .........................................................................................................................19 b. Chemical consumption..............................................................................................................................19 Total operation cost............................................................................................................................................19

-

7/31/2019 Evason Hideaway at Con Dao_STP

3/23

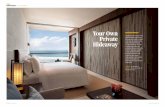

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

A. DESIGN BASIC

1. Water demand

- 24 villas (2 beds/villa) x 1 m3

/villa.day1

= 24 m3

/day- 71 room building x 800l/room.day = 57 m 3 /day- Restaurant 200 guests x 35 l/guest.day 2 = 7 m 3 /day- Other services (spa, gym, shops, etc.) = 10 m 3 /day- Washing = 80 m 3 /day

Maximum water consumption is about 180 m 3 /day.

2. Wastewater flowrate

In general, wastewater flowrate can be assumed as total water demand. Therefore, wastewater

flow for designing the STP is 180 m3

/day.

3. Treatment process

The treatment process includes the following steps:- Pre-treatment by septic tank and equalization tank.- Biological treatment with denitrification process.- Biological and mechanical sludge treatment process.

1 Water demand is 400-600l/bed.day.2 Water demand for restaurant is 35l/guest.day

31-Mar-08 Page |1

-

7/31/2019 Evason Hideaway at Con Dao_STP

4/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

B. EFFLUENT STANDARD

The selection of wastewater treatment processes is based on:

Quality of the influent The Vietnamese Standards of domestic wastewater (TCVN 6772 - 2000, level I)

Table 1. Effluent standards for domestic uses

ValueNo. Parameter UnitLevel

ILevel

IILevel

IIILevel

IVLevel

V1 pH 5 9 5 9 5 9 5 9 5 92 BOD mg/l 30 30 40 50 2003 Suspended solid mg/l 50 50 60 100 1004 Settable solid mg/l 0,5 0,5 0,5 0,5 -5 Total solid mg/l 500 500 500 500 -6 Sulfur (H 2S) mg/l 1.0 1.0 3.0 4.0 -7 Nitrate (NO 3

-) mg/l 30 30 40 50 -8 Oil and grease mg/l 20 20 20 20 1009 Phosphate (PO 4

3-) mg/l 6 6 10 10 -10 Total coliform MPN/100ml 1000 1000 5000 5000 10000

Source: www.nea.gov.vn

C. OPERATION TIMEOperation time:

- 24 hours/day. - 7 days per week.

31-Mar-08 Page |2

-

7/31/2019 Evason Hideaway at Con Dao_STP

5/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

D. THE PROPOSED SEWAGE TREATMENT PROCESS1. STP Process

Figure 1. The proposed STP process

31-Mar-08 Page |3

-

7/31/2019 Evason Hideaway at Con Dao_STP

6/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

2. STP Description

The Sewage Treatment Plant (STP) is proposed to treat wastewater which generates fromfacilities of the resort. Wastewater from villas and hotel building is collected to the STP by the

separate sewer system. Wastewater from restaurant kitchen containing high oil and grease is pre-treated by oil trap before entering the sewer.

In STP, wastewater at first flows to septic tank which includes three chambers: (i) anaerobicchamber, (ii) settling chamber and, (iii) anaerobic filtration chamber.

In septic tank, settleable solids in the incoming wastewater settle and form a sludge layer at thebottom of tank. Greases and other light materials float to the surface where a scum layer isformed as floating materials accumulate. Settled and skimmed wastewater flows from the clearspace between the scum and sludge layer to the downstream treatment facilities. The organicmaterial retained in the bottom of the tank undergoes facultative and anaerobic decomposition

and is converted to more stable compounds and gases such as carbon dioxide (CO 2) methane(CH 4) and hydrogen sulfide (H 2S).

After coming out the septic tank, wastewater flows pass over fine screening bar in order toprotect pumps, valves, pipe lines and other appurtenances from damage or clogging by rags andlarge objects and then wastewater flows to equalization tank.

The equalization tank is used to overcome the operational problems caused by flow ratevariations, to improve the performance of the downstream processes, and to reduce the size andthe cost of downstream facilities. Besides, the equalization tank has the function to reduce anamount of BOD/COD in waste water.

In equalization tank there are two submersible pumps are installed to transfer wastewater to theanoxic and aerobic processes

There are five chambers in anoxic and aerobic processes, the first chamber is anoxic No.1chamber, the second chamber is aeration chamber, the third chamber is anoxic No.2 chamber, thefourth chamber is oxic chamber and finally is the clarifier chamber.

The anoxic and aerobic processes are used to remove BOD and ammonia.

BOD is converted to CO 2 and NH 3 by equation (1).

Organic matter + C 5H7NO 2 + O 2 + nutrients CO 2 + NH 3 + C 5H7NO 2(new cells) +otherproducts (1)

Various forms of nitrogen can deplete dissolved oxygen levels in receiving waters, exhibittoxicity toward aquatic life, affect chlorine disinfection efficiency, present public health hazards,and affect the suitability of waste water reuse. To treat nitrogen in water, nitrification anddenitrification are applied.

31-Mar-08 Page |4

-

7/31/2019 Evason Hideaway at Con Dao_STP

7/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

And, ammonia is oxidized to nitrite (NO 2-N) and nitrite is oxidized to nitrate ((NO 3-N) and thenN2

3223275324 88.1041.198.0021.098.183.1 CO H O H NOO H C HCOO NH ++++++

2223 N O N NO NO NO

The term nitrification is the biological oxidation of ammonium (NH 4+) first to the nitrite (NO 2-)then to the nitrate (NO 3-) form. The conversion of ammonium to nitrite is caused byNitrosomonas bacteria:

2 NH 4+ + 3 O 2 2 NO as Nitrosomon 2- + 4 H + + 2 H 2O

The nitrite in turn are oxidized by the bacteria Nitrobacter according to the following:

2 NO 2-

+ O 2 2 NO r Nitrobacte

3

-

The overall nitrification reaction is as follow:

NH 4+ + 2 O 2 NO Bacteria 3- + 2H + + H 2O

The term denitrification is biological process is used to remove nitrate and nitrite forms of nitrogen in water. The produced nitrate nitrogen in the nitrification process is converted to agaseous form of nitrogen. Pseudomonas, Micrococcus, Achromobacter, and Bacillus are pricipalnitrate reducing bacteria that accomplish denitrification. Using methanol as the carbon source, theenergy reaction is represented as follows:

6 NO 3- + 2 CH 3OH 6 NO 2- + 2 CO 2 + 4 H 2O6 NO 2- + 3 CH 3OH 3 N 2 + 3 CO 2 + 3 H 2O + 6 OH - + 3 O 2 The overall energy reaction:

3 NO 3- + 14 CH 3OH + CO 2 + 3 H + 3 C 5H7O2N + 19 H 2O

In the anoxic tank 1, the denitrification is conducted. As mentioned above, the removal of nitrogen gas can be accomplished biologically under anoxic conditions. The last product of thisprocess is nitrogen gas. This gas is produced as buddle attached with sludge particles and can be

removed by mixing

The wastewater is pumped to the aeration tank 1 for decomposing an amount of BOD in thewaste water under oxic conditions. In this tank, the aerobic bacteria use organic contaminants asinfluent substances to form simpler compounds.

31-Mar-08 Page |5

-

7/31/2019 Evason Hideaway at Con Dao_STP

8/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

For the complete transformation of nitrogen in waste water, the anoxic tank 2 is necessary. Theusing of this tank has two reasons: (i) change ammonia and various organic nitrogen forms intonitrate and, (ii) elimination the residual nitrate to nitrogen gas.

After nitrogen treatment, wastewater is flowed into the other oxic tank for decomposing all

residual BOD.

The biomass informed by activated sludge is separated by clarifier.

The function of the sedimentation tank is to separate the activated-sludge solids from the mixedliquor. The sludge in the inlet wastewater is precipitated to the bottom of the clarifier by gravity.The sludge layer thickens during the operation process of wastewater treatment plant. It iscollected continuously by scraper.The outlet water after separation from sludge flows through effluent trough surround top of fourwalls tank. The effluent trough is designed as V-notch shape to ensure that the outlet water fromclarifier does not contain a large amount of biological sludge.

The disinfection process is used to sterilize water before the utilization.

Disinfection tank is provided by a Sodium Hypochlorite dosing system downstream of theclarifier. A contact tank of 20 minutes minimum retention is provided. This contact tank willachieve a chlorine residual of 1 ml before reuse. This chlorine residuals function is maintainingthe microorganism inactivation activities of sterilizing chemical.

31-Mar-08 Page |6

-

7/31/2019 Evason Hideaway at Con Dao_STP

9/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

3. STP specifications

Design flowrate hmdayh

daymQ / 9

/ 20 / 180 3

3

==

Peak flow: 64 m 3 /h

Capacity: 180 m 3 /day

a. Grease trap

Grease trap is located near the restaurant to remove oil and grease in kitchen wastewater.

Table 2. Specification of Grease trap

No. Parameter Unit Value1 Design flowrate Q m 3 /hour 42 Hydraulic retention time (HRT) Hour 2

Vworking m3 83 VolumeV total m

3 10L x W x H working m 2x 2 x 2.04 DimensionL x W x H total m 2 x 2 x 2.5

5 Material Reinforce concrete

b. Septic tank

Table 3. Specification of Septic tank

No. Parameter Unit Value1 Design flowrate Q m3 /hour 13.52 Hydraulic retention time (HRT) Hour 24

Vworking m3

1793 VolumeV total m

3 204.5L x W x H working m 15 x 4 x 4.04 DimensionL x W x H total m 15 x 4 x 4.5

5 Material Reinforce concrete

c. Equalization tank

Table 4. Specification of Equalization tank

No. Parameter Unit Value1 Design flowrate Q m3 /hour 92 Hydraulic retention time (HRT) Hour 9.5

Vworking m3 85.43 Volume

V total m3 96L x W x H working m 6.2 x 3.8 x 4.04 DimensionL x W x H total m 6.2 x 3.8 x 4.5

5 Material Reinforce concrete

31-Mar-08 Page |7

-

7/31/2019 Evason Hideaway at Con Dao_STP

10/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

d. Anoxic 1

Table 5. Specification of Anoxic 1

No. Parameter Unit Value1 Design flowrate Q m3 /hour 92 Hydraulic retention time (HRT) Hour 2.33

Vworking m3 213 Volume

V total m3 24

L x W x H working m 3.8 x 1.7 x 4.04 DimensionL x W x H total m 3.8 x 1.7 x 4.5

5 Material Reinforce concrete

e. Aeration tank

Table 6. Specification of Aeration Tank 1

No. Parameter Unit Value

1 Design flowrate Q

m3

/hour 52 Hydraulic retention time (HRT) Hour 6.22

Vworking m3 563 Volume

V total m3 63

L x W x H working M 4.2 x 3.8 x 4.04 DimensionL x W x H total M 4.2 x 3.8 x 4.5

5 Material Reinforce concrete

f. Anoxic 2

Table 7. Specification of Anoxic 2

No. Parameter Unit Value1 Design flowrate Q m3 /hour 92 Hydraulic retention time (HRT) Hour 2.33

Vworking m3 213 Volume

V total m3 24

L x W x H working M 3.8 x 1.7 x 4.04 DimensionL x W x H total M 3.8 x 1.7 x 4.5

5 Material Reinforce concrete

g. Aeration tank 2

Table 8. Specification of Aeration tank 2

No. Parameter Unit Value1 Design flowrate Q m3 /hour 9

2 Hydraulic retention time (HRT) Hour 3.11Vworking m

3 283 VolumeV total m

3 31.5L x W x H working m 3.8 x 2.3 x 4.04 DimensionL x W x H total m 3.8 x 2.3 x 4.5

5 Material Reinforce concrete

31-Mar-08 Page |8

-

7/31/2019 Evason Hideaway at Con Dao_STP

11/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

h. Clarifier

Table 9. Specification of Clarifier

No. Parameter Unit Value1 Design flowrate Q m3 /hour 182 Hydraulic retention time (HRT) Hour 2.64

Vworking m3 543 VolumeV total m

3 48L x W x H working m 3.8 x 3.8 x 44 DimensionL x W x H total m 3.8 x 3.8 x 4.5

5 Material Reinforce concrete

i. Disinfection tank

Table 10. Specification of Disinfection tank

No. Parameter Unit Value1 Design flowrate Q m3 /hour 92 Hydraulic retention time (HRT) Hour 1.77

Vworking m3

163 Volume V total m3 20

L x W x H working m 4.2 x 2.4 x 2.04 DimensionL x W x H total m 4.2 x 2.4 x 2.5

5 Material Reinforce concrete

j. Treated water storage tank

Table 11. Specification of Treated water storage tank

No. Parameter Unit Value1 Design flowrate Q m3 /hour 92 Hydraulic retention time (HRT) Hour 6

Vworking m3 543 Volume

V total m3 48L x W x H working m 7.9 x 2.4 x 4.04 DimensionL x W x H total m 7.9 x 2.4 x 4.5

5 Material Reinforce concrete

k. Anaerobic sludge digester

Table 12. Specification of Anaerobic sludge digester

No. Parameter Unit Value1 Design flowrate Q m3 /hour 12 Hydraulic retention time (HRT) day 6.25

Vworking m3 1503 Volume

V total m3

167L x W x H working m 8.1 x 5.5 x 4.54 DimensionL x W x H total m 8.1 x 5.5 x 5.0

5 Material Reinforce concrete

l. Belt filter press- Belt Filter press:

o Capacity: 1m 3 /h

31-Mar-08 Page |9

-

7/31/2019 Evason Hideaway at Con Dao_STP

12/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

o Manufacture: Shun-Huei, Taiwan,

Accessories: electric control panel, handrail, washing pump, compressor, recycle system,polymer solution tank, mixer, electric wire

31-Mar-08 Page |10

-

7/31/2019 Evason Hideaway at Con Dao_STP

13/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

E. ODOR CONTROL SYSTEM

All tanks have internal vent holes through the tank walls above water level and are vented into

the same line to allow the excess air in the STP to absorber to remove odor before discharged.

The odor control system consists of three parts: (1) deodorization column, (2) exhaust fan and,(3) chemical mixing tank. The chemical mixing tank contains NaOCl 10% solution for absorptionprocess. The exhaust fan collects contaminated air from tanks and houses of the STP into theabsorber. The air from these tanks has many components with various ratios, such as: CH 4, H 2S,CO 2, H 2O Polluted air stream enters the absorber from the bottom and passes upward througha wetted plastic packed bed. This packed bed in the odor control system has two functions: (i)lengthening the contact time between polluted air and deodorized solution, thus, thedeodorization efficiency will be higher and, (ii) widespread distribution the solution from the topof the absorber. To treat foul gases in the inlet air stream, NaOCl is used as deodorized chemical.

The liquid - NaOCl 10% solution enters the top of the column and is uniformly distributed overthe column packing through spray nozzles.

Figure 2. Odor control system

Sodium hypochloride is a pale greenish liquid also known as soda bleach or liquid bleach. As apowerful oxidative qualities and slight alkalinity, NaOCl is used to mitigate odor problems inwastewater collection and treatment facilities. NaOCl oxidizes pollutants in the air inlet streamto simpler compounds that have less uncomfortable smell. For example, with hydrogen sulfide(H2S) gas - one of the most common causes of foul odor in wastewater, NaOCl oxidizes it intothe last form sulfate ion H 2SO 4 as the following reaction:

31-Mar-08 Page |11

-

7/31/2019 Evason Hideaway at Con Dao_STP

14/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

H2S + 4 NaOCl 4 NaCl + H 2SO 4

In this deodorization system, the NaOCl concentration is 10%. NaOCl is contained in chemicaltank for stabilization concentration. When the odor treatment system works, NaOCl solution is

pumped into the absorber and distributed by sprayers from top as droplets. After contacting andreacting with contaminated gases in the inlet air, the solution is collected at the bottom of theabsorber. Then, it is circulated into the chemical tank for the next treatment circle.

The outlet gas after treatment that is odorless goes to the atmosphere from the top of the absorber.

31-Mar-08 Page |12

-

7/31/2019 Evason Hideaway at Con Dao_STP

15/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

F. SOLID WASTE DISPOSAL

The solid waste in Con Dao Resort should be separated into two main types (a) biodegradable

waste including wasted food, vegetables, sludge from the STP and garden waste (b) non-biodegradable wastes such as plastics, paper, plastic bottles and cans.

Due to the fact that Con Dao has no sanitary landfill, all the solid waste must be reasonablytreated on-site. Biodegradable and non-biodegradable waste shall be handled in two differentways.

The biodegradable waste will be degraded in a anaerobic digester and the compost will be used asfertilizer for garden in the resort or selling to local farmers.

The non-biodegradable waste will be separated into the following types: papers, plastic bags,

plastic bottles, glasses and metal cans. Packaging machine will be used for compaction eachwaste.

The compacted waste packages will be stored in the ware house and transported to the recyclingfacilities in the inland or Con Dao Island.

The solid waste generation rate is about 1 kg/guest.day (chosen of generation rate based on Table13)Thus, the maximum solid waste quantity is about:(24 villas+ 71 hotel rooms) x 2 guest/unit x 1 kg/guest.day = 190 kg/day.

Assume solid waste contains 50% biodegradable waste. Therefore, the quantity of waste to bedigested is approximately 100 kg/day.

Sludge from the CSTP is around 180 kg/day.

Total solid waste is 280 kg/day.

Table 13 Municipal solid water generation in Viet Nam, 2003

Generation rate(kg/person.day)

% organic

Urban areas 0.7 55Ho Chi Minh city 1.3Ha Noi 1.0Da Nang 0.9Rural areas 0.3 60-55

Source: Urban data by consulting data group survey 2004.Rural data calculated using studies by NEA(2000) and Agriculture University No.1(2003)

31-Mar-08 Page |13

-

7/31/2019 Evason Hideaway at Con Dao_STP

16/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

31-Mar-08 Page |14

The treatment of solid waste is given in Figure 2.

Biodegradablewaste Anaerobic

DigesterShredding

Sludgepump

Belt Filterpress

Reuse foragriculture

Slurry tank Storage andtransfer to

Figure 3. Schematic diagram of solid waste management system

Non-biodegradablewaste

Ware housePackaging Recyclingfacilities

-

7/31/2019 Evason Hideaway at Con Dao_STP

17/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

G. EQUIPMENT

No. Description Location Tag number Brand Specification

SEWAGE TREATMENT PLANT

1 Macerator TK-101A M-101 2 Submersible sludge pumps TK-101A/B P-101A/B Tsurumi Japan 0.75 KW, 3-ph.380V/50Hz

3 Submersible pump TK-102 P-102A/B Tsurumi Japan 1.5 kW, 3-ph.380V/m3/h, H = 8m

4 Submersible mixer TK-102 SM-102 Tsurumi Japan 0.4 kW, 2.8m 3/m

5 Drive and mixer TK-201 M-201 A/B Sumitomo-japan0.75 kW, 380V/3phTorque: 98.5 Nm, ORPM. Mixer and sh

6 Air blowers TK-202 BL-202A/B Anlet Japan 5.1 kW, Model: BE50kPa, ANLET Roo

7 Return flow pump TK-202 P-202A/B Ebara Italy 0.75kW ,Q = 5 m

8 Drive and mixer TK-203 M-203 A/B Sumitomo-japan0.75 kW, 380V/3phTorque: 98.5 Nm, ORPM. Mixer and sh

9 Gear motor of sludge scraper TK-205 M-205 Sumitomo-japan 0.039 rpm, 0.2 kW

10 Sludge scraper TK-205 SCP-205 Vietnam SUS 304

11 Return sludge pump TK-205 P-205A/B Ebara Italy 1.1kW, Q = 8 m 3

12 Chlorine dosing pump TK-301 DP-301A/B Blue White-USA 0.15kW, Q= 0-> 50l/h, H =1

13 Chemical mixer: drive and mixer TK-301 M-301 Sumitomo-japan0.75 kW, 380V/3phTorque: 98.5 Nm, ORPM

14 Chlorine tank TK-301 T-301 Vietnam PE, V=200 L 15 Treated water pump TK-302 P-302A/B

16 Submersible mixer TK-401 SM-401A/B Tsurumi Japan 0.4 kW, 2.8m 3/m

17 Air Diaphragm Pump TK-401 SDP-401A/B Sandpiper - USA

31-Mar-08

-

7/31/2019 Evason Hideaway at Con Dao_STP

18/23

18 Fiter belt press TK-401 SP-401 Shun Huei0.4kW, 380V/3phacapacity: 30-80kg-width: 800mm

19 Air compressor TK-401 CR-401 Puma - Taiwan 5.25kW, 8kg/cm2, 75l/ph, 1

20 Polymer dosing pump TK-401 DP-401A/B Blue White-USA 0.15kW, Q= 0-> 50l/h, H =1

21 Air Diaphragm Pump TK-401 SDP-401A/B Sandpiper - USA =34mm

22 Polymer tank TK-401 T-401 Vietnam PE, V=200 L

ODOR CONTROL SYSTEM

23 Deordorization column DC-500 DC-500 Vietnam 2.5, H=4m, SS 3

24 Air Diaphragm Pumps DC-500 CDP-500A/B Sandpiper - USA

25 NaOCl tank DC-500 CT-500 Vietnam PE, V=1000 L

26 Fan for Deodorization column DC-500 FAN-500 Vietnam 5.25kW

27 Pick up hoods FP-401 Vietnam SUS 304

SOLID WASTE PROCESSING28 Sludge pump TK-600 SP-600A/B Ebara Italy 1.1kW, Q = 8 m3/h, H = 10

29 Grinder TK-600 G-600 Vietnam Motor 2.25 kW

30 Mixer TK-600 M-600 Sumitomo-japan0.75 kW, 380V/3phTorque: 98.5 Nm, ORPM. Mixer and sh

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

31-Mar-08

-

7/31/2019 Evason Hideaway at Con Dao_STP

19/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

31-Mar-08 Page |15

I. CONSTRUCTION WORKS

No. Item Quantity Specifications Dimension Volume,(V tl) m3

1 Grease trap 1 - HRT: 2h- Material: reinforced concrete

- L x W x H tl=2mx2mx2.5m

10

2 Septic tank 1 - HRT: 24h- Material: reinforced concrete

- L x W x H tl =15mx4mx4.0m

246

3 Equalization tank 1 - Hydraulic retention time (HRT):9.5 h.- Material: reinforced concrete

- L x W x H tl =6.2mx3.8mx4.5m

106

4 Anoxic 1,2 2 - HRT: 2.33h- Material: reinforced concrete

- L x W x H tl =3.8mx1.7mx4.5m

29

5 Aeration tank 1 1 - HRT: 6.22 hours.- Material: reinforced concrete

- L x W x H tl =4.2mx3.8mx4.5m

72

6 Aeration tank 2 1 - HRT: 3.11 hours- Material: reinforced concrete

- L x W x H tl =3.8mx2.3mx4.5m

31.5

7 Clarifier 1 - HRT: 2.64 hours- Overflow rate: 17 m 3 /m 2.h.- Material: reinforced concrete

- L x W x H tl =3.8mx3.8mx4.5m

65

8 Disinfection tank 1 - HRT: 1.77 hours- Material: reinforced concrete

- L x W x H tl =4.2mx2.4mx2.5m

25.2

9 Treated wastewaterstorage tank

1 - HRT: 6 hours- Material: reinforced concrete

- L x W x H tl =7.9mx2.4mx4.5m

86

10 Anaerobic sludgedigester

1 - HRT: 1days- Material: reinforced concrete

- L x W x H tl =8.1mx5.5x5.1m

227

11 Control house 1 - Material: reinforced concreteAnd bricks

- L x W x H tl =6.5m*5.5m*3.4m

-

7/31/2019 Evason Hideaway at Con Dao_STP

20/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

J. OPERATION COST1. Sewage treatment plant (A)

a. Electric consumption rate

No. Equipment Code Manufacturer Specification QuantityMotor

capacity (kW)

SEWAGE TREATMENT PLANT

1 Submersible sludgepumps P-100A/B Tsurumi Japan0.75 KW, 3-ph.380V/50Hz 2 0.75

2 Submersible pump P-102A/B Tsurumi Japan1.5 kW, 3-ph.380V/50Hz( run in shifts), Q = 10m3/h, H = 8m

1 1.5

3 Submersible mixer SM-102 Tsurumi Japan 0.4 kW, 2.8m3/min 2 0.45 24

4 Drive and mixer M-201A/B Sumitomo-japan

0.75 kW,380V/3phase/50Hz ,Output Torque: 98.5 Nm,Output Speed: 58 RPM

1 0.75

5 Air blowers BL-202A/B Anlet Japan5.1 kW, Model: BE80E,4.04m3/min, 50kPa,

ANLET Roots type2 5.1

6 Return flow pump P-202A/B Ebara Italy 0.75kW , ( run in shifts),Q = 5 m3/h, H = 8m 2 0.75

7 Drive and mixer M-203 A/B Sumitomo-japan

0.75 kW,380V/3phase/50Hz ,Output Torque: 98.5 Nm,Output Speed: 58 RPM.Mixer and shaft: SUS304

2 0.75

8 Gear motor of sludge scraper M-205 Sumitomo-japan 0.039 rpm, 0.2 kW 1 0.2 24

9 Return sludge pump P-205A/B Ebara Italy 1.1kW, ( run in shifts), Q= 8 m3/h, H = 10m 2 1.1

10 ChlorineDosingpumpDP-301A/B Blue White-USA

0.15kW, ( run in shifts),Q= 0-> 50l/h, H =35m 2 0.15

11 Chemical mixer:drive and mixer M-301 Sumitomo-japan0.75 kW,380V/3phase/50Hz ,Output Torque: 98.5 Nm,

1 0.75

31-Mar-08 Page |17

-

7/31/2019 Evason Hideaway at Con Dao_STP

21/23

Output Speed: 58 RPM

12 Treated water pump P-302A/B 1.1 kW, ( run in shifts), Q= 8m3/h, H = 20m 2 1.1

13 Submersible mixer SM-

401A/BTsurumi Japan 0.4 kW, 2.8m3/min 1 0.4 8

14 Polymer dosingpumpDP-401A/B Blue White-USA

0.15kW, ( run in shifts),Q= 0-> 50l/h, H =35m 2 0.15

15 Fiter press SP-401 Shun Huei

0.4kW,380V/3phase/50Hz,Disposal capacity: 30-80kg-D.S/hr, Fiter clothwidth: 800mm

1 0.4

16 Air compressor CR-401 Puma - Taiwan 5.25kW, 8kg/cm2, 75l/ph,160l 1 5.25

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

Page |18 31-Mar-08

-

7/31/2019 Evason Hideaway at Con Dao_STP

22/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

Assuming electric tariff: 1,000 VND/kWh225,80 kWh/day x 1,000 VND/kWh = 225,800 VND

b. Chemical consumption rate

N0 Chemical Consumption Unit price Total1 Chlorine 1,2 kg 30,000/kg 36,0002 Polymer 500 gram 70,000/kg 35,000

Total 71,000

c. Labor cost

Salary: 50,000 VND/worker.day x 2 workers = 100,000 VND/day

Total cost (Total A): 225,800 + 71,000 + 100,000 = 396,800 VND/dayOperation cost for 1 m 3 treated wastewater: 396,800/180 = 2,200 VND /m 3

2. Odor control system (B)

a. Electric consumption rate

No. Equipment Code Manufacturer Specification Quantity

Motorcapacity

(kW)

Operationtime

(hr/day)

Powerconsumption

(kWh/day)

1 Fan for Deodorizationcolumn

FAN-500 Vietnam 5.25kW 1 5.25 8 42

2 Air DiaphragmPumps

CDP-500A/B

Sandpiper -USA

Total 42

b. Chemical consumption

N0 Chemical Consumption Unit price Total

1 NaOCl 3 kg 15,000/kg 45,000Total 45,000

Total cost (Total B): 42,000 + 45,000 = 87,000 VND/day

31-Mar-08 Page |18

-

7/31/2019 Evason Hideaway at Con Dao_STP

23/23

EVASON HIDEAWAY AT CON DAO Sewage Treatment Plant: General Description

3. Solid waste processing system (C)

a. Electric consumption rate

No. Equipment Code Manufacturer Specification Quantity

Motorcapacity

(kW)

Operationtime

(hr/day)

Powerconsumption

(kWh/day)

1 SludgepumpSP-600A/B Ebara Italy

1.1kW, ( runin shifts), Q =8 m3/h, H =10m

1 1.1 4 4.4

2 Mixer M-600 Sumitomo- japan0.75kW,58RPM 1 0.75 4 3

3 Grinder G-600 Vietnam Motor 2.25kW 1 2.2 4 8.8

Total 16.2

Assuming electric tariff is: 1,000 VND/ kWh27 kW.h/day x 1000 VND/kWh =27,000 VND

Total cost ( Total C): 27,000 VND/day

b. Chemical consumptionN0 Chemical Consumption Unit price Total1 C-polymer 1 kg 30,000/kg 30,000

Total 30,000

Total C = 27,000 + 30,000 = 57,000 VND

Total operation cost

= Total A + Total B + Total C= 225,800 VND/day + 87,000 VND/day + 57,000 VND/day = 369,800 VND/day