Evaluation of stress-relief methods on cobalt-chromium ... of stress-relief methods on...

Transcript of Evaluation of stress-relief methods on cobalt-chromium ... of stress-relief methods on...

PEDIATRIC DENTiSTRY/Copyright © 1988 byThe American Academy of Pediatric Dentistry

Volume 10, Number 3

Evaluation of stress-relief methods on cobalt-chromiumorthodontic wiresDavid P. Durr, DMD, MS Rodolfo Vargas, DDSSteven M. Adair, DDS, MS

AbstractStress-relieving heat treatment is reported to accelerate

the elastic memory process in order that the configuration ofcold-worked orthodontic wires becomes more stable. In thisexperiment, 3 methods of stress-relieving O.036-inch cobalt-chromium orthodontic wires used in the fabrication of space-maintaining appliances were evaluated. The results showedthat stress relief in a dental oven, by the electric current of anorthodontic spot welder or by the flame of a dental solderingunit, does appear to accelerate the expression of elastic mem-ory in cold-worked, cobalt-chromium wires. However, afteran initial deformation, the stress-relieved wires tended tostabilize while untreated wires continued to deform. Theexperiment reinforced the need to check stress-relieved wiresand appliances before inserting them into the mouth and toreshape them as required.

When an orthodontic wire is bent, internal stressesare created within that wire. These stresses are createdby irregularities in the atomic lattice structure and maycause the newly shaped wire to deform and seek itsoriginal shape. This progressive change in shape isknown as elastic memory and may result in unwantedtooth movement. At ordinary room (or body) tempera-tures, elastic memory is a gradual process. Stress-reliev-ing heat treatment accelerates the elastic memory proc-ess so that the wire becomes more stable (Thurow 1982;Phillips 1982).

The effects of heat treatment on the physical proper-ties of cobalt-chromium orthodontic wires, such as flex-ural yield strength, modulus of stiffness, fracture resis-tance, hardness, etc. are well documented (Mahler andGoodwin 1967; Martin et al. 1984). However, little re-search has dealt directly with the dimensional stabilityassociated with stress-relieving heat treatment. Durr etal. (1986) showed that 3 common methods of stress-relieving heat treatment using a dental oven, electriccurrent, or a soldering flame, did not reduce the dimen-sional change which occurred in U-shaped 0.036-inch

cobalt-chromium orthodontic wires as compared tononstress-relieved wires. However, almost all of thedimensional change occurring in the experimentalgroups took place during the stress-relief treatmentafter which there were only insignificant changes.Dimensional changes in nonstress-relieved wires con-tinued throughout the 4-week experimental period. Theexperiment demonstrated that the 3 methods of stressrelief accelerated the elastic memory process. However,the U-shaped wires used in the study were not solderedto orthodontic bands, nor were they heat treated onworking casts. Thus, the experiment did not accuratelyrepresent procedures commonly used to fabricate inter-ceptive orthodontic or space-maintaining appliances.The purpose of the present study was to evaluate thesame 3 methods of stress relief on 0.036-inch, cobalt-chromium orthodontic wires under conditions whichmore accurately reflect clinical use.

Materials and MethodsCobalt-chromium 0.036-inch-diameter orthodontic.

wire (Blue Elgiloy ® -- Rocky Mountain Orthodontics;Denver, CO), all from the same batch, was cut into 80pieces, each 10.0 cm in length, using a jig and wirenippers. The wires were bent to a U-shaped form usingfinger pressure and an edgewise arch former (RockyMountain Orthodontics; Denver, CO) and then sol-dered to orthodontic bands which were stabilized onjigs (Fig 1, next page). The outermost width of each shaped wire was measured immediately after solderingwith the wire still on the jig (coded as "baseline" meas-urement). Measurements were made to the nearest 0.1mm using a Boley gauge (Fig 2, next page).

The 80 wires were divided into 4 groups each con-taining 20 wires:

Group A -- Untreated Control Group. These wires wereremoved from the jigs after soldering and initial meas-uring, immediately remeasured with the Boley gauge

Pediatric Dentistry: September, 1988 N Volume 10, Number 3 205

FIG 1. If-shaped 0.036-inch cobalt-chromium orthodonticwire soldered to orthodontic band material on jig.

FIG 3. Storage rack for hanging wire during experimentalperiod.

Fi G 2. Outermost width of each U-shaped wire measured withBoley gauge.

FIG 4. Stress-relieving heat treatment using electrodes of anorthodontic spot welder.

(coded as "off-jig" measurement), and then placed on astorage rack (Fig 3).Group B — Oven-Treated Experimental Group. Thesewires were kept on the jigs and placed in a previouslycalibrated dental oven (Ney-Barkmeyer model 260 —J.M. Ney Co; Bloomfield, CT) at 950° F for 8 min as pera method described by the manufacturer of the wire.Group C — Electrode-Treated Experimental Group. Thesewires were stress relieved on the jigs using the elec-trodes of an orthodontic spot welder (Model 660 —Rocky Mountain Orthodontics; Denver, CO), accordingto the directions accompanying the spot welder. Thestandardized method was to stress relieve short seg-ments of wire (Fig 4), each segment being about one-fifth of the total length of the wire, for about 8 sec andthen to proceed on to the next segment. Temper-indicat-ing paste (Rocky Mountain Orthodontics; Denver, CO)

which ignites at 950° F was used to show when thedesired temperature was achieved.Group D — Flame-Treated Experimental Group. Thesewires were stress relieved on the jigs using the flame ofa dental soldering unit (Hydroflame® — Unitek Corp;Monrovia, CA). The temper-indicating paste wasplaced on the wire, and the flame was passed over thewire at a uniform distance of 1.0 cm (Fig 5) until the pasteignited, indicating that the proper temperature of 950° Ffor stress relief had been reached.

Immediately after the stress-relief treatment, wiresin the experimental groups were remeasured on the jigs(coded as "post-tx" measurement), then removed fromthe jigs, measured again (coded as "off-jig" measure-ment), and placed on storage racks.

The wires in all 4 groups were remeasured after: 1,2,3, and 4 hr; 1,2, 3,4, 5, and 6 days; and 1, 2, 3,4, 5, and6 weeks. These time intervals were chosen on the basis

206 STRESS RELIEF OF ORTHODONTIC WIRES: Durretal.

of the results of the earlier ex-periment by Durr et al. (1986).

At the end of the 6-week ob-servation period, the forces gen-erated by the lateral expansionof the U-shaped wires weremeasured using a dial tensiongauge (Model AG30 — JohnChatillon & Sons Inc; New York,NY) to deflect the wires back totheir baseline widths. Then thewires were readjusted to theirbaseline widths. Expansion afterreadjustment was measured at 1-day and 1-week intervals.

Summary statistics were cal-culated for the control and ex-perimental groups at each timeinterval. An analysis of covariance followed by multiplecomparisons testing was used to investigate treatmentdifferences over time. These comparisons were basedon the least square means which differ from raw meansin that they are adjusted for any differences that mayexist among baseline widths of the U-shaped wires(Winer 1971). Statistically significant differences werereported if P values less than 0.05 were found.

ResultsMean widths and standard errors for the 19 measure-

ment intervals of the initial 6-week experimental periodwere calculated, and for simplicity these data werecollapsed into 4 representative epochs: (1) from baselineto off-jig; (2) from of f-jig to day 1; (3) from day 1 to week1; and (4) from week 1 to week 6. Epoch 1 included thestress relieving heat treatment for the experimentalgroups.

Table 1 lists the mean width changes across the 4selected epochs along with the results of analysis ofcovariance and multiple comparisons testing. Duringthe first epoch, wires in the oven-treated (B) groupshowed significantly greater width increases than didwires in the other 3 groups. During the second epoch,

FIG 5. Stress-relieving heat treatment usingflame of dental soldering unit.

the control (A) group hadsignificantly largerchanges than the other 3groups. There were nosignificant differencesamong the groups in thethird epoch, but in thefourth, the control (A) andflame-treated (D) groupsdemonstrated the greatestchange.

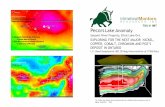

Figure 6 graphicallydemonstrates the dimen-sional changes which oc-curred over time. Most ofthe expansion of the ex-perimental groups (B, C,D) was manifested imme-

diately after the stress-relief procedure at the timethe wires were removed from the jig. After thisinitial expansion, the widths of wires in the oven-treated (B) group stabilized, and those in theelectrode-treated (C) and flame-treated (D)groups increased only slightly. In the control (A)

v>

s15Z

• Control• Oven-treatedA Electrode-treated

Flame-treated

33Base Post 1 day 1 week 6 weeks

FIG 6. Comparison of stress relief methods on cobalt-chro-mium orthodontic wires.

TABLE 1. Width Changes Among Experimental and Control Groups Across Four Selected Time Epochs

Epoch

1. Baseline to off -jig2. Off-jig to day 13. Day 1 to week 14. Week 1 to week 6

Croup AControl

1.04 (0.13)'1

0.38 (0.05)0.08 (0.02)0.09 (0.02)

Croup BOven-Treated

1.49 (0.16)0.01 (0.01)0.00 (0.00)

-0.01 (0.01)

Group CElectrode-Treated

0.98 (0.12)-0.03 (0.05)

0.07 (0.06)0.01 (0.02)

Group DFlame-Treated

1.04(0.12)0.00 (0.02)0.05 (0.02)0.08 (0.01)

p-Valuc fromAnalysis

of Covariance

0.01< 0.0001

0.290.0008

MultipleComparisonsGroupings'"

(C,A,D) (B)(C,D,B) (A)(B,D,C,A)(B,C) (D,A)

a Mean (standard error).b Ordered from least to greatest change; parenthetical groups are significantly different from each other; groups within parentheses are

not significantly different.

Pediatric Dentistry: September, 1988 ~ Volume 10, Number 3 207

group, a substantial amount of expansion was evidentat the time the wires were removed from the jig. Thiswas followed by an increase during day 1 which ex-ceeded that seen in any of the experimental groups to astatistically significant degree. From day I to week 6, thewires in the control group continued to expand, andalthough the expansion over the final 2 epochs wasslight, it was greater than that seen in any other group.

Table 2 shows the lateral forces associated with totalwidth changes of the wires at the end of the 6-weekexperimental period. The mean grams of force andstandard errors are reported along with the results of aPearson product moment analysis which demonstratesignificant positive correlation between the amount offorce generated and the amount of wire expansion.

TABLE 2. Lateral Forces Associated With Total WidthChange of Wires After Six Weeks

Width Change(ram) Force (g)

r9

Group A: control 1.60 (0.15)a 16.58 (1.56)~ .94Group B: oven-treated 1.49 (0.15) 13.91 (1.55) .92Group C: electrode-

treated 1.04 (0.11) 11.18 (1.06) .96Group D: flame-treated 1.16 (0.12) 12.84 (1.00) .96

Mean (standard error).Pearson Product Moment correlation.

Only 10 of the 20 wires in the control (A) group, 6 the oven-treated (B) group, 6 in the electrode-treated (C)group, and 11 in the flame-treated (D) group exhibitedwidth changes I day and I week after readjustment tobaseline measurements. Mean width changes for thegroups were in the 0.05-0.12 mm range. No furtherstatistical analyses were performed on these data be-cause more than half of the wires exhibited no addi-tional dimensional change after readjustment.

DiscussionThe results of this experiment, along with those of a

previous study (Durr et al. 1986), demonstrate thatstress-relieving heat treatment appears to be associatedwith acceleration of the elastic memory process in 10.0-cm long, 0.036-inch diameter cobalt-chromium ortho-dontic wires used in fabrication of interceptive ortho-dontic appliance.

Wires in the experimental groups exhibited almostall of their width change when they were removed fromthe jigs following soldering to the orthodontic bandsand stress relief, but tended toward stabilization withlittle or no dimensional change thereafter. Wires in the

oven-treated group seemed to have the most initialexpansion associated with the stress-relief procedureand the least amount of subsequent expansion.

Wires in the untreated control group also showed asubstantial expansion when they were removed fromthe jig following soldering to the orthodontic bands.Unlike the wires of the experimental groups, these wiresalso exhibited a significant width change during day 1.Subsequent expansion from day I to week 6 was slightbut was greater than that seen in any of the experimentalgroups.

The lateral forces generated by the expansion of thewires ranged from 1.0 to 32.8 g with the greatest forcesbeing associated with those wires exhibiting the great-est amount of expansion. These forces are clearly withinthe range capable of causing undesirable lateral move-ment of abutment teeth (Weinstein 1967).

Readjustment of the wires to their baseline measure-ments showed that a majority of the wires, even those inthe control group, remained stable at the readjusteddimension for I week. Those wires that did re-expanddid so to a much lesser extent than that seen after theinitial bending. Much of the re-expansion occurredduring the first day following readjustment. An obser-vation made during this part of the study was that thosewires which were overcompressed and then expandedslightly to meet baseline measurements seemed to ex-hibit the least subsequent change.

The fact that wires in the control group remainedstable after being readjusted suggests further study. Itmay be possible that untreated appliances can be over-compressed immediately after fabrication and removalfrom the working cast, expanded to meet baselinemeasurements, and then remain stable. If feasible,stress-relieving heat treatment may not be necessary,although heat treatment to alter other physical proper-ties, such as hardness, still may be desirable.

It must be noted that the results of this experimentare specific for appliances fabricated from 0.036-inchdiameter cobalt-chromium orthodontic wires approxi-mating 10.0 cm in length. Wires of other diameters,configurations, and/or lengths may react differently tostress-relieving heat treatment procedures.

SummaryThe procedures used in this experiment parallel

those used in the fabrication of a fixed space-maintain-ing appliance using cobalt-chromium orthodontic wire.The results show that the immediate deformation ofsuch appliances related to stress-relieving heat treat-ment may approach that encountered by untreatedwires over time. After the initial deformation, the heat-treated wires tend to stabilize and untreated wirescontinue to expand. The forces generated by such defor-

208 STRESS RELIEF OF ORTHODONTIC WIRES: Durr et al.

mation may be sufficient to cause unwanted movementof abutment teeth. Thus, the experiment reinforces theneed to check stress-relieved orthodontic wires andappliances before inserting them into the mouth and toreshape them as required. Very little dimensionalchange appears to be associated with the readjustedwires.

The authors acknowledge the assistance of Mark Espeland, PhD,Bowman-Gray School of Medicine, Wake Forest University, Win-ston-Salem, North Carolina, and Howard Proskin, PhD, EastmanDental Center, Rochester, New York, for their assistance in thestatistical analysis.

Dr. Durr is assistant chairman and Dr. Adair is chairman, pediatricdentistry, Eastman Dental Center, Rochester, New York; at the timeof the study Dr. Vargas was a postdoctoral student at Eastman andcurrently is in the private practice of pediatric dentistry in Guate-mala, Guatemala, Central America. Reprint requests should be sentto: Dr. David P. Durr, Dept. of Pediatric Dentistry, Eastman DentalCenter, 625 Elmwood Ave., Rochester, NY 14620.

Durr DP, Vargas R, Ward K: Evaluation of stress-relief methods ofcobalt-chromium orthodontic wires. J Dent Res 65 (abstr):228,1986.

Mahler DB, Goodwin L: An evaluation of small diameter orthodonticwires. Angle Orthod 37:13-17, 1967.

Martin RL, Sarkar NK, Schwaninger B: Effect of heat treatment onvarious properties of Blue Elgiloy. J Clin Orthod 18:432-35,1984.

Phillips RW: Skinner’s Science of Dental Materials. Philadelphia; WBSaunders Co, 1982 p 609.

Thurow RC: Edgewise Orthodontics. St Louis; CV Mosby Co, 1982 p50.

Weinstein S: Minimal forces in tooth movement. Am J Orthod 53:881-903, 1967.

Winer BJ: Statistical Principles in Experimental Design, 2nd ed. NewYork; McGraw-Hill Co, 1971 pp 752-812.

MOVING ?Please let us know if you are mov-ing -- report your addresschange promptly so you won’tmiss a single issue of PediatricDentistry. Please include an oldmailing label and fill in your new

Name Phone

Address

address on this form or on a sepa-rate sheet of paper. City State/Province Zip Code

Mail to: American Academy of Pediatric Dentistry, 211 East Chicago Avenue N Suite 1036, Chicago, IL 60611.

Pediatric Dentistry: September, 1988 - Volume 10, Number 3 209