EUROWASHER XL - Angelantonisiteadm.angelantoni.it/Media/brc/BRC_0512.pdf · The washing...

Transcript of EUROWASHER XL - Angelantonisiteadm.angelantoni.it/Media/brc/BRC_0512.pdf · The washing...

EURO

WA

SHER

XL

Wa

shin

g-t

he

rmo

dis

infe

cto

r c

ab

inM

ed

ica

l d

evi

ce

EUROPEAN INFECTION CONTROL

2

Ser ies TCS with hor izontal s l id ing doors.

Series TCSD

Series TCSS

Ergonomic loading, h igh product iv i ty .

3

The constant research for greater productivity and effi-ciency distinguishes and accompanies us on a design jour-ney aimed at “Safety”, “Total quality” and “Savings”.

“Saving” is one of the aims that we set ourselves in thedesign phase:

saving in operating consumption,

saving of maintenance with devices, solutions and components of high quality and reliability and long service life.

As medical device, the manufacturing process of the Eu-rowasher XL represents a key factor, because the wash-ing and disinfection of trolleys or containers use to carry sterile surgical instruments covers a critical role, being the first fundamental step to bring down and to stabilise the microbial load, ensuring a repeatable reduction over time.

The washing thermo-disinfectors cabin, dedicated to the washing and disinfection of trolleys, containers, clogs and basins, has been designed to be installed in sterilization or disinfection stations and is addressed to guarantee the correct procedures and paths to reduce contamination risks, increase productivity and make trolleys, con- tainers or clogs perfectly washed and disinfected, with significant SAL.

+50%Service life

Technology

SinergyKnow-how

Ability

Customer support

Exerience

The Eurowasher XL range is a series of new generation washing thermo-disinfectors cabins, result of the most advanced design by Schlumbohm & Angelantoni Life Sci-ence, Leader in the world of Infection Control.

German technology combined with Italian design and cre-ativity, together with the Corporate Know-how matured over decades of activity in the sector, have supported the development of equipment based on the concept of “total quality”, able to meet the requirements of an Elite market requiring total safety assurance, absolute reliability and sterilization processes that can be repeated in time, with-out burdening operators with the risk of assessment.

Total quality to produce medical devices with high con-struction standards, advanced techniques and innovative solutions.

Total quality for an environmentally-friendly project with almost zero impact on the environment by water con-sumption, and extremely low for electricity and heat dis-sipation.

Saving Use

EUROPEAN INFECTION CONTROL

4

Washing and disinfection cycles

-Thermo-chemical washing and disinfection for “T” trolleys at 93°C

- Thermo-chemical washing and disinfection for “C” containers at 93°C

- Thermo-chemical washing and disinfection for “S” clogs at 65°C

- Thermo-chemical washing and disinfection for basins at 93°C

- Thermo-chemical washing and disinfection for surgical instruments at 93°C

- Thermo-chemical washing and disinfection for plastic containers at 65°C

-Thermo-chemical washing and disinfection for “T” trolleys at 93°C - short cycle for 30 minutes

- Equipment washing and self-disinfection

1

2

3

4

5

6

7

8

The Eurowasher XL line is configured with the following cycles:

5

As well as a perfect washing of the instru-ments, it is essential to achieve a sub-stantial reduction of the microbial load at the end of the washing stage.

Furthermore, a constant value should be obtained at the end of the process with a final SAL of 10-2 in order to be able to ensure a SAL of 10-6 after sterilization.

A constant and precise monitoring of the “bioburden” allows the validity of disin-fection, maintaining the performance in time.

The thermo-chemical energy released by the chemical solution diluted in hot wa- ter allows a double action that attack the micro-organisms in order to eliminate their resistance.

In order to validate the process, as well as the final result, cycle after cycle, Eu-rowasher XL range is provided with de-vices and sensors to control and ensure

the correct result, preventing any kind of failure during disinfection stage.

The management system constantly monitors those cycle parameters that can affect the final result and/or make the performance lower over time, such as:

detergent and disinfectant dosing

PH control at discharge

water temperature

contact time of water (at temperature) with the surface of the instruments (A0)

chemical residue after rinsing

Eurowasher XL range has been tested in compliance with all the reference stand-ards to ensure an high quality of the dis-infection process.

Automatic washing

Disinfection

The automatic washing reduces contamination risks, accelerates the washing time, de-creases costs and allows that the washing cycle can be validated.

In order to ensure that the process maintain the same performance in time, Eurowasher XL range is provided with devices and sensors to control and ensure the correct result, preventing any kind of failure during washing stage.

The management system constantly monitors those cycle parameters that can affect the final result and/or make the performance lower over time, such as:

water pressure water temperature water jet moving speed water jet mechanical action chemical product added

Eurowasher XL range has been tested in compliance with all the reference standards to ensure an high quality of the washing process.

EUROPEAN INFECTION CONTROL

6

Productivity

Ergonomic loading

Thanks to the large sizing of the washing chamber and the quick cycle, the Eurowasher XL range allows high hourly productivity.

The extreme care for every single system, component and device intervening in the washing and disinfection cycle and affecting the performance, makes each stage quicker and reduced in time, with a final increase in productivity.

In particular, the reduced amount of water per phase, the design of the chamber that allows to take quickly the water back to the pump, the water preheating, the quick water loading, the high performance re-circulation pump, the quick water discharge system and the turbulent drying through the impeller blades of the trolley and the diffusers in the lower part of the chamber, opposite to the suction.

Eurowasher XL range can be easily installed with the bottom of the chamber at floor level .

This operation ensures a full ergonomic loading, being the internal loading level at the same level of the external floor. The loading of “C” containers and “S” clogs is safer, reducing the risk of incidents for operators.

Both for the “T” transportation trolley and the universal trolley for “C” container and “S” clogs, the fact that the cham-ber bottom is seamless at the same level of the floor, makes loading easier and eliminates strain and risks for operators.

Washing-disinfection chamber is designed to allow the circulation pump to works properly with a lower consumption of water. This allows you to have a savings of water, for each type of connection, of 60%.

The Eurowasher XL line has been developed by applying environmentally friendly design with the aim of preserving the environment in which we live; adopting innovative technical solutions and high quality components, in order to significantly reduce consumption and, therefore, reduce pollution throughout the entire life cycle.

Building on the idea of producing sustainable consumption equipment, reducing environmental impact, significant and measurable objectives have been reached that enhance the Eurowasher XL line in view of the performances it reaches.

Highlighted aspects are:

● water consumption

● energy consumption

● recycling

Environmental impact

100%Recyclable

-40%Energy consumption

-60%Water consumption

7

Validation is one of the most important operations as it allows verifying, after installation, whether design conditions are respected. In particular, for the load object of the validation, we can verify that temperature, doses of chemical so-lutions and time fall within the correct parameters to ensure the effectiveness of the washing and disinfection process in compliance with the reference standard UNI EN ISO 15883-1.

Validation

The position of the components, main units and operational phases to facilitate pre-assemblies and general assem-blies, are analysed since the design phase, to significantly reduce times and costs in a serial production. The reduction of phases and the repetition of assembly operations, together with the optimisation of the semi-finished products, support the industrialisation of the production process and constant preservation of high quality standards of the finished product.

Industrialisation

Directives, Certificates, Qualityand Construction StandardsThe Eurowasher XL line equipment is CE marked with the identification number issued by the Notified Body accord-ing to European Directive 93/42/EEC and 2007/47/EEC as a Medical Device and with European Directive 2009/125/EEC (eco-design).

They also comply with European Directives: 2006/95/EEC for Low Voltage, 2004/108/EEC for Electromagnetic com-patibility and 2006/42/EEC for Machinery.

Construction is done in compliance with the European Standards of reference UNI EN ISO 15883-1-2:2009 (wash-ing and disinfection) and those related to it. UNI EN ISO 17665-1 (development, validation and routine testing), CEI EN ISO 61010-1 (electrical safety), CEI EN ISO 61010-1-040 (electrical safety), CEI EN ISO 61010-2-041 (electrical safety) CEI EN ISO 60204-1 (electrical equipment), UNI CEI EN ISO 17050-1:2005 (conformity assessment), UNI EN ISO 14971-1:2000 (risk analysis), EN IEC 62304:2006 (software validation) and EN IEC 62366:2008 (human-machine inter-face).All of that within a UNI EN ISO 9001 Quality System (quality certification) and UNI EN ISO 13485 (medical qual-ity certification).

EUROPEAN INFECTION CONTROL

8

For the “T” trolley treatment cycle, a device was designed consisting of a set of mani-folds placed vertically on the two sides of the washing chamber with automatic recip-rocating motion, on which are installed a set of nozzles fed by a high flow rate pump in order to fully cover the washing and disinfection area.

For the “C” container treatment cycle, a universal trolley with levels that allows 20 containers to be loaded simultaneously from a sterilization unit including lids fastened onto specific kits. The trolley is provided, for each level, with rotating arms with spray-ing nozzles fed by a high flow rate pump in order to fully cover the washing and disin-fection area.

For the “S” clogs treatment cycle, a universal trolley with levels that allows 120 clogs to be loaded simultaneously onto specific kits. The trolley is provided, for each level, with rotating arms with spraying nozzles fed by a high flow rate pump in order to fully cover the washing and disinfection area.

For the basins treatment cycle, a universal trolley with levels that allows to load si-multaneously a combinations of different sizes and models of basins. The trolley is provided, for each level, with rotating arms with spraying nozzles fed by a high flow rate pump in order to fully cover the washing and disinfection area.

For the trays treatment cycle, a universal trolley with levels that allows 20 trays (1 DIN) to be loaded simultaneously without the need for specific kits. The trolley for each level is provided with rotating arms with spraying nozzles fed by a high flow rate pump in order to fully cover the washing and disinfection area.

For the plastic container treatment cycle, a universal trolley with levels that allows the load of a combinations of different sizes and models of plastic containers. The trolley, for each level, is provided with rotating arms with spraying nozzles fed by a high flow rate pump in order to fully cover the washing and disinfection area.

The equipment in the Eurowasher XL range is fitted with specific, suitably designed devices in order to optimise wash-ing and disinfection phases depending on applications, thus the connected device must be selected depending on the material to be handled:

Technical solutions for the various applications

9

BiosealThe modern concept of a sterilization unit calls for equipment, flows, paths, procedures, checks and traceability that must be implemented in order to consider instruments’ “re-process-ing” safe. Specifically, the separation of clean and dirty environments is thus essential to reduce contamination risks. Hence the need to create a barrier inside the instrument wash and disinfect appliance, between clean and dirty, that pre-vents contact between the areas.The Eurowasher XL line is produced in order to fully meet this need through complete separation of the equipment on the sterile side - the so-called “Bioseal”, which is aligned and sealed with the wall.

Range of EUROWASHER XL productsSeries Model Capacity

(lt)Trolleyscapacity

Chamber dimensions (WxHxD mm)

Overall dimensions (WxHxD mm)

TCSS MD.WSD.TCSS.2550.1/2HSD.E/S/ES 2550 1 850X2000X1500 2300x2600x1700

TCSD MD.WSD.TCSD.5100.1/2HSD.E/S/ES 5100 2 850X2000X3000 2300x2600x3200

Definition of the model code:

● Eurowasher: Containers, trolleys ,clogs, basins and trays washing and disinfecting appliance

● Medical Device - “MD”: Hospital Application

● Termochemical - “WSD”: Washing and Disinfection Medium

● “T”: Loading capacity 1 or 2 trolleys (T1 or T2) “C”: Loading capacity 1 or 2 trolleys with 20 containers of 1 US each “S”: Loading capacity 1 or 2 trolleys with 120 clogs each (S1 or S2) Trays: Loading capacity 1 or 2 trolleys with 20 DIN trays each Basins: Loading capacity 1 or 2 trolleys with combinations of different sizes of basins

● Volume liters - “from2550 to 5100 lt”: Chamber capacity in litres

● Execution - “1 o 2”: Numbers of doors

● Door movement - “HSD”: Automatic horizontal sliding door

● Heating: E: Water electrical heating S: Water heating by direct steam from external source ES: Water heating by heat exchanger working through external steam

Example model MD.WSD.TCSD.5100.2HSD.EMedical DeviceTermochemical5100 Lt.2 Automatic horizontal sliding doorsElectrical internal steam generator

EUROPEAN INFECTION CONTROL

10

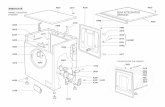

AISI 304 stainless steel frame, front and side panels.AISI 316L, 2 mm thickness washing chamber.Chamber bottom with central drain and filtration.Door/s in double high resistance thermal glass with argon/krypton gas inside.Door sealing by dynamic «air chamber» gasket.Horizontal door sliding device.Stainless steel AISI 304 containment tank for cold water.Stainless steel AISI 304 pre-heating tank for treated water.Stainless steel AISI 304 recovery tank for rinsing water.Drying unit provided with bacteriological filter, turbo fan and steam exchanger heating system.Rotating washing arms for the Universal Trolley.Manifolds with vertical nozzles and top/bottom rotating washing arms for the chamber.Chamber perfectly drainable and cleanable.Automatic ramp connecting to the floor.High delivery performance single (TCSS) or double (TCSD) pump.Air recirculation bypass. (optional)Loading height floor level or free standing.Integrated light for chamber.Pre-heating energy recovery system for drying air.Chemicals dispensers (three) with flow meter. (the 4th chemicals dispenser is optional)Water flow meter device. (optional)Drain pump. (optional)Drain water PH control device.Rotation of washing arms control device. (optional)AISI 304 stainless steel Idraulic pipeline.Automatic cart type recognition.Central chemical dispenser connection.Traceability system connection.Inclined chamber with pre-filtering and filtering system.Chamber water heat-exchanger.Automatic pneumatic system for chamber base movement.Automatic pneumatic system for vertical sprayers movement.Chamber hot air inlet valve.Stainless steel water recirculation filter with triclamp connection (self cleaning).Stainless steel steam condenser.Bio-seal shield: separation between dirty side and clean side. (optional)Double data detection systems Siemens Simatic ET200S integrated safety, programmable controller.Touch screen Siemens TP900 Comfort, 9 inches, full color and high resolution. Second touch screen on unloading side. (optional)Total integrated electrical board with IP protection and telescopic arm.Built-in alphanumerical printer.Remote connection-ready. (optional)USB connection for data back-up.Modular Universal Trolley.Automatic connection (water and hot air) among the equipment and the Universal Trolley.Rack for washing disinfection of medical shoes. (12 pair of shoes each rack).Rack for washing disinfection of packing and transportation containers (2 containers , dimensions 300x300x600 mm, each rack).Rack for washing disinfection of bowls (combination of differents dimensions).

Main construction features1.2.3.4.5.6.7.8.9.

10.11.12.13.14.15.16.17.18.19.20.21.22.23.24.25.26.27.28.29.30.31.32.33.34.35.36.37.38.39.40.41.42.43.44.45.46.47.48.

20

39 42

16

21

22

2436

11

The Universal Trolley has been designed to allow the washing and disinfection of surgical instruments, containers (packing or trasportation), medical shoes, basins or plastic containers.

The surgical instruments can be placed on trays directly on the shelves.

Container, medical shoes and basins require specific racks.

The trolley is made up of 5 double meshed levels with respective double washing rotating arms.

Automatic connection to the water and recirculation system.

The MD.WSD.TCSS model can process one Universal Trolley at time

The MD.WSD.TCSD model can process two Universal Trolleys at time.

Universal trolley set up for medical shoes washing.

Up to 60 pairs

Shoe rack

Universal trolley set up for containers washing.

Up to 20 1STU

Universal trolley set up forplastic containers washing.

Up to 20

Container Rack Plastic container Rack

The device automatically brings the trolley from loading area into the washing chamber. The device can be placed on both loading and unloading sides of the machine.

The lift brings the trolley from the ground level to the loading height. This system is designed for a device placed with chamber height not at the floor level.The lift can be placed on both loading and unloading sides of the machine.

The lift brings the trolley from the ground level to the loading height, then the trolley is automati-cally placed inside the washing chamber by the charging device. This system is designed for a de-vice with chamber height not at the floor level. The lift can be placed on both loading and unload-ing sides of the machine.

Universal trolley set up for medical basins washing.

Combinations of different sizes

Basins Rack

Universal Trolley configuration

Accessories for loading/unloading

ALS is one of the worldwide leading manufacturers of biomedical refrigeration, non contamination and sterilization equipment constantly committed to innovation and to environmental or biological safety.

Research centres, hospitals, universities, chemical and pharmaceutical companies are ALS Customers: our company can satisfy any requirement of scientific refrigeration, infection Control (autoclaves) and microbiological safety through a wide range of standard and special products.

In this field we can offer now a complete range of equipment and services to meet the needs of sterilization (CSSD), disinfection stations (CSDD) and special applications BSL3 laboratories - BSL4 and treating infected wastes (Biohazard).

ALS can be an ideal partner in Science and Technology due to a wide range of products and to the market presence in more than 50 Countries with local Agents and Distributors.

ALS invests more than 5% of its turnover in research and development involving a multidisciplinary team of scientists that support clients with cutting-edge, standard and customized solutions in terms of quality, reliability and innovation.

ALS is a subholding of Angelantoni Industrie Group established in 1932, worldwide known for innova-tion, R&D and high tech (19 active patents) such as climatic chambers and space simulators (Ange-lantoni Test Technologies), spattering machines for thin film technology (Kenosistec), solar receiver tubes for concentrated solar power plants ( Archimede Solar Energy) refrigeration turbo devices for energy saving (Turboalgor) in addition to ALS advanced and patented products such as Hemosafe, Smartfreezers and Waster.

Angelantoni Life Science

Copyright © Life Science 2016 Angelantoni s.r.l./Rev. 13/2016-illustrations, descriptions and technical data may change without notice.

Our skills and basic services for total customer satisfaction:

● Training, either at our premises a the customer’s premises

● Testing and quality control

● Process Validations (IQ-OQ-PQ)

● Design for Central of sterilization (CSSD) and central of disinfection (CSDD).

● Management of traceability and remote control of the equipment

● Certificate tools SIT Calibration

● Service contracts “full risk”

● Extended warranties

● Research and development

● Production and Assembly

● Installation and commissioning

● Preventive maintenance

● Market analysis and advice

● Special applications

ALS HeadquarterAngelantoni Life Science srl

Loc. Cimacolle 464,06056 Massa Martana (PG) - Italy

T. +39 075 89551 - F. +39 075 [email protected] - www.angelantoni.it

ALS Milan BranchAngelantoni Life Science srl

viale Monza, 291 - 20126 Milano (MI)T. (+39) 02.939701.1 - F. (+39) 02.93970123

[email protected] - www.angelantoni.it

ALS products are distributed in North-Central Europe bySchlumbohm

Medizin-Labor-Technologie GmbH Grenzkehre 1

21079 Hamburg - GermanyT. +49 40 769 150 0 - F. +49 40 769 150 26

[email protected] www.schlumbohm-medizintechnik.de