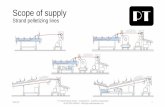

Euroblast Scope of Supply

Click here to load reader

-

Upload

umair-awan -

Category

Documents

-

view

220 -

download

0

description

Transcript of Euroblast Scope of Supply

-

SCOPE OF SUPPLY OF THE EUROBLAST PROGRAMME Sandblast Equipment Portable or stationary pressure and suction type sandblast machines ranging from 30 liters to 300 liters in single or double chamber models. Suitable for all type of abrasive Range includes Machine spares parts that are interchangeable with most

brand Blast Machines in the market Special abrasive grit valves for Garnet and Steel grit abrasives. Bulk Blast Sandblast Units-Stationary or Mobile Capacity 6-40 tons, 4 6 Nozzles. Remote control systems for Sandblast Machines Fully pneumatic and electro-pneumatic (12 /24 V) remote control valve Deadman handles for fully pneumatic and electro-pneumatic remote

control systems. Remote control hose and fittings. Operator Safety Equipment Blast helmets with inner visor, large viewing area, easily changeable

outer lenses, air pressure control, cape and belt. Blast suits leather, cotton or leather/cotton Air Filters for helmet air Temperature control systems to cool or heat the air Gloves Pressure regulators Inner and outer lens and caps for all major brands of sandblast helmets Sandblast lights

-

Sandblast Nozzles Liners of Tungsten Carbide, Silicon Carbide, Silicon-Nitride, Born-Carbide

or Born-Alloy. Jackets of Aluminium, rubber or polyurethane 1 or 1 inlet sizes Long, medium or short venturi length Length 50mm thread, fine thread or stick-up type Angle nozzles with 1,2 or 3 outlets Hypodermic needle gauges for control of the right blasting pressure Sandblast Hoses, Couplings and Nozzle Holders All most commonly used sizes of extremely durable sandblast hose Couplings of Aluminium, cast-iron, brass or nylon Nozzle holders of Aluminium or light weight nylon with fine or large

thread Threaded couplings for machine connection Air Hose All commonly used sizes and qualities ranging from to 4 ID Specialized Product Wet blast injector system The clean blast system to eliminate dust

during blasting. Abrasive Vacuum systems. Internal Pipe Blasting Equipment for manual and automatic Internal Pipe Coating Equipment for manual and automatic Abrasive Conveyors Suction Guns Vacuum blast equipment Blast Cabinets Portable blowers for job-site ventilation and dust extraction Extractor fans Moisture separators and after-coolers Blast lights for internal tank operation High pressure water jetting machines with pressure up to 40,000 PSI

-

Tank Coating Equipment DEHUMIDIFIER from 5000 to 20000 CMPH capacity to control humidity

to obtain optimum result during blasting and painting designed for the Middle East climate condition.

Vacuum Recovery Equipment to recover spend abrasives from tank internal designed to meet the various conditions of horizontal and vertical heights vis--vis suction capacity.

DUST COLLECTION SYSTEMS to recover dust from tank internal with varying capacity from 5000 to 20000 CMBH.

Blast Room and Paint Booth Supply erection and commissioning of Blast Room and Paint Booth

depending on customer use and request. Automatic Wheel Blast Machine Supply erection and commissioning of Tailor made automatic wheel

blast machines for the following a) Pipes and profiles Steel Plates b) Steel Plates c) LPG cylinders d) Any components of mass production ULTRABLAST A combination of slurry blast with UHP Boost for high productivity and low abrasive consumption. HP & UHP Tailored supply of electrical or diesel driven systems. Systems also available in Zone 1 & 2 rating. These systems range from 100 bar up to 3,500 bar with flow rates between 5 lpm to 1,668 lpm. Typical accessories accompanying these systems are: Jetting Guns (electronically or mechanically controlled Rotating nozzles (rotated by air, hydraulics or by HP / UHP water)

-

Self propelled vacuum blast units Abrasive water jet cutting (cold cutting) nozzles Oil & Gas field Equipments Weelhead control units (DHSV/MV/WV/BOP/ESD Hydraulic test units Gas test units Chemical injection units High pressure valves, fittings & tubings according to NACE Chart Recorders PC Data Acquisition System Automated Hose Test Units with integrated Test Compartments Pressure Gauges Pressure Transmitters Spindle & Hand pumps Rupture Discs High Pressure Filters Quick connectors Bending, Coning and Threading Tools Custom made high pressure systems

GRACO PAINT SPRAY EQUIPMENT & ACCESSORIES

Airless Paint spray system Air Assisted Airless Paint spray outfit Electrostatic paint spray Equipment Two Component Application Equipment Conventional Paint spray Equipment High Volume Low Pressure Paint spray Equipment

PLURAL COMPONENT SPRAY SYSTEMS AND FAST SETTING EQUIPMENT

Plural Component heated or non-heated spray systems with Original GRACO equipment for metering, mixing, pumping, spraying and dispensing fluid material. We design and build this equipment to the work site, material viscosity, degree of mixing required and the portability required.

-

Xtreme Mix 1:1 up to 10:1 variable ratio Hydracat Tailor made to suit paint specification Reactor 1:1 ratio for Polyurea / Foam / Polyurethane application Accessories Airless spray guns Airless pole guns Gun accessories such as tip guards, inlet filters, swivels, adapters, and

gun extensions. Reversible tip holders, adjustable paint spray tips, ball tips, cylinder tips High pressure paint hose, bulk or assembled Low and medium pressure hose for air and fluid service Swivel adapters Hose fittings Nipples and adapters Hex reducing nipples Gauges and air control components Ball valves Paint mixers, hand or air operated

TESTING EQUIPMENT

Elcometer range Testing Equipment for blasted and painted surfaces.

BLAST CLEANING ABRASIVES Coal Slag Aluminum Silicate Copper Slag Iron Silicate Garnet Abrasives Aluminum Oxide Glass Beads Plastics Abrasives Steel Shot & Steel Grit

![Scope and influence of procurement and supply [L4M1]€¦ · CIPS Level 4 – Diploma in Procurement and Supply Scope and influence of procurement and supply [L4M1] Sample Answer](https://static.fdocuments.in/doc/165x107/60350a3f569c2110ad685372/scope-and-influence-of-procurement-and-supply-l4m1-cips-level-4-a-diploma-in.jpg)