Endcap assembly update C Buttar UK-SCT-MB RAL 2 nd Sept 04.

-

Upload

jesse-fitzpatrick -

Category

Documents

-

view

218 -

download

0

Transcript of Endcap assembly update C Buttar UK-SCT-MB RAL 2 nd Sept 04.

Endcap assembly update

C Buttar

UK-SCT-MB RAL 2nd Sept 04

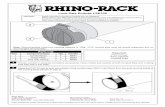

Nikhef disk cylinder assembly tooling

TPPCs 4x32ch PCBs

Thermal plug

accesswindows

Cooling pipes

LMT trays

Service Handling

Disk insertion tooling

Diskcylinder tooling

• Shielding foil added to cylinder• Thermal feedthrough prepared• Cylinder and stub wings

assembled onto tooling• 4 disk alignment tools being

made by Manchester delivered to Liverpool

• Disk grabber-design by Nikhef-manufactured by Sheffield/Lancaster; tested with a diskCCDs and lighting now added and tested

• Disk fixations from Nikhef and Liverpool-delivered

• alignmenttarget holders designed (Nikhef) and manufactured (Lancaster)z-alignment tool needs to be finished

Still to do…..

•Qualify disk-grabber and disk alignment

•How to mount and de-mount the central beam

•concept ready, need to test

Cylindertooling

• Pre-aligment of rear stub wing mounting point• Rear stub wing mounted onto frame• Cylinder placed over beam and left on table with

foam supports• Cylinder bolted to rear stub-wing• front wing offered up using sling for support and

mounted• Disk placed on disk grabber and cylinder aligned• Disk moved through cylinder• Very useful exercise! - lots of details to be

sorted/have been sorted

Diskcylinder insertion

• Capture and align a disk•need to consider disk masses

Service status• LMTs

Testing of UK tapes at GlasgowPreparation of LMTs before assembly into traysJT

• TIsWill be tested as part of LMT-TI harness at GlasgowFirst 100 delivered, full order soon

• ‘String test’ LV/HVtest cableTPPCTILMTPPF0wiggly tapehybrid/module at Liverpool

• FibresLancaster has volunteered to take on reception testingFibres for disk testing (D1+D2) at Liverpool, D9 at the end of Aug (?)

• Cooling pipesNow too late to assemble cooling on cylinder at Liverpool, now retro-fitted at CERN ?Assume no cooling pipes initially and connect direct to disk as for disk testing, then connect at STFT if pipes are delivered

TPPC string test (J.Voosebeld+P.Dervan)

String testTest cable TPPCTILMT

harnessPPF0wiggly tape hybrid

direct to hybrid String test

TPP-CString-test on single channel test board complete TPP-C ordered, string test on 32 channel pre

prod board (1ch only) completetry and do 2ch test ? (need additional LMT)

Service handling•Thermal plug ordered and being manufactured in Sheffield (caravans!)

•PPF1 trays for LMTs in production

•PPF1 tray holdersorder placed last week-being modified

•temporary PPF1 for fibresLancaster have volunteered to make this, awaiting design from NikhefAt Liverpool we need to ensure we can connect in the coldroom

Cooling-replicate disk testing system and connect direct to the disk-or similarre-evaluate when cooling pipes/connects start to be available

Test cable installation • Test Cables for endcap testing installation started—Ray Thompson, Andy Elvin, Richard French

• Basic mapping ready

Thermal plug

Status, going forward

• Assembly tooling is ~ready needs to be tested– cylinder mounted and disk moved through on the

beam– Still to do:

• test run of disk alignment, capture and removaldone but need disk masses

• Z-alignment tool• Removal and insertion of the beam• interface to disk holder• floor, bracing and wheels, move in and out of cold room• scaffolding for working on the cylinder

Status, going forward

• Service handling is progressing– thermal plug being assembled– LMT trays and tray holders in production– Still to do:

• DCS to be investigated• Fibre holder design to be finalised• Cooling, connect direct to disks at Liverpool, otherwise interfaces

must be defined now to allow disk insertion+testing to go forward assume HEX that we connect to disks/pipes at STFT so no longer need cooling pipes in service handling-how to make connections in the cold room-design manifold? replicate disk test system and connect to disks

– Need services (LMTs+Fibres) to start developing methods for putting services on

• what tooling is required• how to make test-fibre connections !

Status, going forward

• Developing tests for diskcylinder assembly– test cooling on disk with services

– during assembly to check connectionseg LMTs, check thermistors on modules

• Similar tests to those made on populated disks

DAQ/DCS•PSU system

2 Artysyn power packs / shelves received & installed.Original batch of LV/HV cards installed.Dummy load fabricated to allow testing of each channel. Testing of ~ 6 channels completed.

•Readout and display disk thermal sensors

•DAQ2 Rev E RODs installed.5 hybrids & 1 module mounted on disk 9 in cold room for multi-module readout tests (NB. Convective cooling to ~ 0C room only).

Cooling plant

• Cooling Plant– Manifold re-located to cold room, re-

connected & tested with 3kW load OK.– Interlock using DCS from cooling pipes being

developed