Enabling on time start up and compliance with low project ... · interven toba tteria tter yon tx...

Transcript of Enabling on time start up and compliance with low project ... · interven toba tteria tter yon tx...

Enabling on time start up and compliance with low project risk and long term asset support

Biomethane to Grid injection solutionsExpertise and support from the global leader in automation

2

Reduce project complexity, ensure safe and consistent production and lower lifecycle costsBiomethane injection into the grid is helping to contribute towards meeting the European Union renewable energy targets and is showing the highest level of growth of any gas market in the world. New biomethane projects need to be brought on stream on time and within budget. Gas must then be produced safely and to the required standard.

Selecting the right automation supplier is critical to the success of a new project. It is important to look for a company that can provide a complete solution that is compliant with current legislation, as well as offering lifecycle support to ensure continued top quartile performance. Installed equipment must support maximum plant availability by helping to avoid any unplanned downtime, thereby generating a greater return on investment.

Single supplier for complete system Proven technology Lifetime asset support

Multiple vendors Complex contracts Service levels lacking

Full time design expertiseDesign according to European standardsDedicated project resources

On time delivery and budget Compliant with regulations and challenging legislation

Established pressure regulation and odorization solutionsLifecycle service

Need to maintain availability Avoid unscheduled downtime Quicker return on investment

Your challenges Our solutions

JULY

ProcessAllarm

3

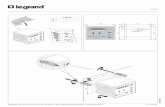

Biomethane skid solutions from a single supplier

Network compliant analyser enclosureFully compliant gas quality measurements

Metrology approved gas chromatograph

Proven sample conditioning system

Control communications enclosureComplete SCADA solution

Flow computer

UPS

Pressure regulation and odorizationPressure regulators

Slam shut valves

Pressure measurement

Odorization system

Flow measurement

Emerson offers a complete portfolio of solutions that address all your biomethane injection skid requirements. Partnering with a single supplier that understands your challenges and provides support at every step helps reduce project complexity, ensure your process complies with safety legislation and European regulations and reduces maintenance in the long term.

Emerson’s technology ensures safe gas production to desired quality standards. This includes gas chromatographs that set the industry standard for accurate online analysis, fiscal metering equipment to measure gas volumes, class-leading pressure control equipment to prevent over-pressurisation and odorization systems to enable safe injection.

Emerson can support you from the concept design phase through the lifetime of your asset.

Schematic example of biomethane injection skid

CUSTOMER AREA

TEL FP FF

eFR

SAFE AREA

PLC

Customer

Limit ofSupply

UPS

TO THE PRODUCTION,COMPRESSION, STORAGE PLANT

DOSAODOR-DPANEL

CONTROL UNITDOSAODOR-D

PRINTER

FEED

ALLARM E / ALARM

4

7

RESET ALLARM IALARM RESET PUSH

LINE A A CAC LINEINTER VEN TO BA TTERIABA TTER Y O N

TX

RXCOM

ALLARME AL TA PORT AT AHIGH FLO W-ALARM

INJEC TO R 1 -ALAR MALLARME INIETT OR E 1

INJEC TO R 2 -ALAR MALLARME INIETT OR E 2

ALLARME SOCCORS O INSERIT OALARM-EMERGENCY SYSTEM ON

ALLARME CALCOL AT OREFLOW COMPUTER-ALARM

PROG OF F

PROG ON

5 6 LOC

0

8

ENT

9

2 3

INIETT ORI / INJECT OR

ESCLUSOEXLUDE D

LAVAGGIOWASHING

MANUAL

SISTEM A / SYSTEM

AUT OMATICOAUT OMATI C

MANUAL E

DOSAODOR-D

INJECTION SYSTEM - DOSAODOR

SISTEM A D I INIEZIONE - DOSAODO R

PROG ON

PROG OFF

1

CLR

PRN

EMERSON

Customer

Limit ofSupply

EMERSON

INIETTORE 2INJECTOR 2

INIETTORE 1INJECTOR 1

INIETTORI 1-2INJECTORS 1-2

TM

XA SERIESGAS CHROMATOGRAPHS

Solving the process industry’s challenges, with predictable success, any time, any place

LinkedIn.com/company/emerson-process-management

Twitter.com/emersonprocess

Facebook.com/EmersonProcessManagement

Emerson Process ManagementRegulator Technologies

AmericasT +1 800 558 5853T +1 972 548 3574

EuropeT +39 051 419 0611

Asia PacificT +65 6770 8337

Middle East / AfricaT +971 4811 8100

EmersonProcess.com

D352466X012 © 2016 Emerson Process Management Regulator Technologies, Inc. All rights reserved. 07/16.The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners.

O.M.T. Officina Meccanica Tartarini S.R.L., Via P. Fabbri 1, I-40013 Castel Maggiore (Bologna), Italy. Tel: +39 051 419 0611R.E.A 184221 BO Cod. Fisc. 00623720372 Part. IVA 00519501209 N° IVA CEE IT 00519501209, Cap. Soc. 1.548 000 Euro i.v. R.I. 00623720372 - M BO 020330

Francel SAS, 3 ave Victor Hugo, CS 80125, Chartres 28008, France. Tel: +33 (0)2 37 33 47 00. SIRET 552 068 637 00057 APE 2651B, N° TVA : FR84552068637, RCS Chartres B 552 068 637, SAS capital 534 400 Euro

Operate & Manage

The systems and tools that provide the decision integrity to run your operation at its full potential.

Measure & Analyse

The broadest range of measurement and analytical technologies for process clarity and insight.

Final Control & Regulate

Highly reliable final control technologies to help your regulate and isolate your process with certainty.

Solve & Support

Expertise and global resources to help you dependably define, execute and support a strategy throughout the lifecycle of your operation.