Electric Detonators Used in Wireline Operations

-

Upload

achuthkumar -

Category

Documents

-

view

212 -

download

0

Transcript of Electric Detonators Used in Wireline Operations

-

7/27/2019 Electric Detonators Used in Wireline Operations

1/8

www.titanspecialties.com

August 7, 2007

Electric Detonators Used in Wireline Operations

The information included in this document is intended to inform the users of ElectricDetonators in Wireline Operations of their construction and function. A clear understanding ofthis subject hopefully will help with the determination of the various types of failures that canoccur, how to diagnose and resolve them without catastrophic results.

All illustrations are generic and are not intended to represent or endorse any particularmanufacturer or their product. Some of the details have been obtained from the public domain

and credit for them belongs to the owner/manufacturer.

Titan does not manufacture electric detonators (with the exception of the specialized Ignitersused in Setting Tool operations).

Basic Power Requirements/Specifications:

No Fire: .2 amps (Electric current applied to the device for I minute willnot produce initiation).

Minimum Fire: .5 amps (Electric current applied to the device will result in a

95% probability of initiation).All Fire: .8 amps (Electric current applied to the device will result in a100% probability of initiation).

Static Sensitivity: MIL-STD-322B (Standard used to define the energy expressed inmillijoule or mJ).

Firing current and non-resistorized vs. resistorized detonators:

Devices used in the industry today include those with a nominal circuit resistance of 1, 55, or120 Ohms. Using these values, the specifications listed above are expressed in a usableformat as:

Voltage @ 1 Ohm Voltage @ 55 Ohm Voltage @ 120 Ohm

.2 amp No Fire .2 Volts 11 Volts 24 Volts

.5 amp Minimum Fire .5 Volts 27.5 Volts 60 Volts

.8 amp All Fire .8 Volts 44 Volts 96 Volts

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 1 of 8

-

7/27/2019 Electric Detonators Used in Wireline Operations

2/8

www.titanspecialties.com

As you can see, non-resistorized detonators require a significantly lower voltage to initiate ascompared to resistorized styles. Most manufacturers use No-Fire and All Fire values intheir technical specifications. Graphic illustrations of the internal components and theirarrangement are located in another section of this document.

Although the API RP67 specifically recommends the use of resistorized detonators, the use ofnon-resistorized detonators prevails today.

Static Sensitivity:

It is recognized that the human body can store a significant amount of static energy. Thisstored energy can cause electric detonator initiation if the energy is dissipated from an internalcomponent of the detonator (through the lead wires) through a sensitive explosive componentto the outer shell. An industry method of determining a devices sensitivity is specified in greatdetail in the MIL-STD-322B and the value is expressed in mJ (or millijoules). A laymansdescription of this can be found at the following websitehttp://ourworld.compuserve.com/homepages/G_knott/elect63.htm . For relative comparison, a1 ohm detonator has a value of 78 mJ compared to a 55 ohm version which has a value of 781mJ. The most common way to bleed off the energy is through the use of a conductive rubberplug installed by the manufacturer in the end of the detonator. Bared sections of the leg wirespass through the rubber plug creating a leak path to the outer shell (see illustrations later on in

this document).

Basic Construction:

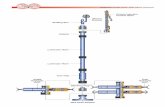

Figure 1, Non-resistorized:

The basic components of a non-resistorizedelectric detonator are illustrated here. This designcontains a bridge wire buried in a sensitive ignition

mix (typically Lead Azide) which is in intimatecontact with a less sensitive secondary explosive(RDX, HMX or HNS). Primarily this design is usedwhere fluid exposure is not anticipated.

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 2 of 8

http://ourworld.compuserve.com/homepages/G_knott/elect63.htmhttp://ourworld.compuserve.com/homepages/G_knott/elect63.htm -

7/27/2019 Electric Detonators Used in Wireline Operations

3/8

www.titanspecialties.com

Figure 2, Resistorized

The addition of two 27 Ohm resistors (one in eachleg wire) for current limitation is the primarydifference between Figure 1 and Figure 2. Tworesistors are used to overcome space constraints.

Figure 3, Resistorized

In this example a single resistor (typically 55Ohm) is used instead of the twin resistors andbridge wire.

Figure 4, Resistorized, Fluid Disabled

In this example (G-21 style), a 120 Ohm resistoris in close contact with a sensitive, primary

explosive (Lead Azide). One side of the leadwire is insulated and the other is not. If fluidcomes in contact with the resistor it is cooledand prevented from generating enough heat toinitiate the Lead Azide. The explosive is alsorendered useless if the exposure is of sufficientduration.

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 3 of 8

-

7/27/2019 Electric Detonators Used in Wireline Operations

4/8

www.titanspecialties.com

Figure 5, Resistorized, Fluid Disabled

An alternative to Figure 4 is the BlockDetonator. It uses an Electric Detonator and aSecondary Non-Electric Detonator separated bya Fluid Tunnel. The detonating cord isthreaded through the Block adjacent to the Non-Electric Detonator as shown. Fluid (or debris)present in the Fluid Tunnel will attenuate the

energy from the Electric Detonator, preventinginitiation of the Non-Electric Detonator.

Figure 6, Alternative Design

Referring to the designs illustrated in Figure 1, 2 and 3, an alternativeignition system using a Fusehead (bridge wire coated with apyrotechnic) is commonly used today. In the previous designs, tointroduce fluid disabling of the device, ports are located in the chamber

adjacent to the Bridge Wire. In the Fusehead style, the coated bridgewire is located in a chamber that separates it from the Ignition Mix.Ports located in the chamber area provide a path for fluid to enter intothe assembly. The fluid will prevent to generation of the flame formationat the Fusehead or its projection into the ignition mix located at theother end of the chamber.

Why 55 Ohms?

Many have pondered over the reason behind the use of a 55 Ohm circuit resistance in these

detonators. The original target for the minimum firing current was .25 amps. At that valueand a circuit resistance of 55 Ohms, it required 13.75 volts or more to fire bridge wire electricdetonators with this feature. This voltage level was above the commonly found 12 volt battery(and its charging system) used in and around the wellsite that was recognized as the greatestexposure hazard at the time.

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 4 of 8

-

7/27/2019 Electric Detonators Used in Wireline Operations

5/8

www.titanspecialties.com

Fluid Resistant vs. Pressure Resistant:

Fluid Resistant detonators usually have a low value such as 150 PSI and are used in theprimary side of the Block Detonator. Because there is another mechanism to prevent theinitiation of the rest of the explosive train it is not necessary to utilize a more complex device,thus lowering the cost.

Pressure Resistant detonators are constructed in such a manner to provide for the mechanicalattachment of the detonating cord to the detonator while providing an environmental seal toprevent the intrusion of wellbore fluid into the assembly. Typical pressure resistance valuesare 10,000 22,000 PSI, depending on the detonating cord specifications and time exposureat pressure and temperature.

Fluid Sensitive vs. Fluid Disabled:

These terms are used to describe the relative sensitivity of the detonator when exposed tofluid. Generally speaking, Fluid Sensitive means that the device will be rendered useless aftera period of time. At ambient conditions, the time exposure can be anywhere from a fewseconds to several minutes, depending on the construction of the device. For instance, theexample shown in Figure 6 is designed to not function as soon as fluid enters the chamber

AND wets the Fusehead. Another style of detonator not shown contains a hygroscopic shockdisk that separates two components of the detonator (most commonly the Primary andSecondary Explosive). Fluid must saturate the disc to attenuate the shock wave from one

component to another or wet out the Bridge Wire or Fusehead.

Fluid Disabled is usually associated with the style illustrated in Figure 5 where the presence offluid in the Fluid Tunnel prevents the transfer of the shock wave to the Non-Electric Detonatorand is meant to be instantaneous. Because these terms can be and are usedinterchangeably, the user must review the technical specifications of the device he will beusing and decide which one will best fit the application. For instance, if the application calls forthe use of a single hollow carrier, several styles can be used. If a seal failure is experienced,the detonator should be disabled while running into the wellbore before you attempt to fire thedevice. If you are running a selective fire assembly and fluid enters the next gun after firingthe first gun, the detonator may not have enough fluid time exposure before you attempt to fire

it. The result is a ruptured gun that was partially filled when it was fired.

General Sensitivity of All Styles (containing Primary and Secondary Explosives):

If electrical energy is applied to the detonator in excess of the No-Fire level, it will fire. If it isexposed to heat beyond its maximum time/temperature rating or shock or impact energy,spontaneous detonation can occur. What you may not know are these facts:

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 5 of 8

-

7/27/2019 Electric Detonators Used in Wireline Operations

6/8

www.titanspecialties.com

Pulling on the lead wires (accidentally or intentionally) can create more than enough

energy to cause the ignition mix to react as if the heat was created by the Bridge Wire.

If you are not careful of where you place the crimping tool, you could be over the top of

the Lead Azide component of the detonator when you crimp the detonating cord inplace. This is the MOST SENSITIVE component of any detonator assembly.

Detonators that have been exposed to elevated wellbore temperatures should never be

reused. Explosives become highly energetic (and sensitive to shock) at elevatedtemperatures and some of them remain that way for an extended period of time afterthey have been returned to ambient conditions. This can become a serious safety

consideration when one or all of the conditions in first two paragraphs are encountered. Block style detonators (Figure 5) contain an electric detonator that has a low pressure

rating (generally 150 PSI or less). Fluid or gas pressure can enter into the assemblyand remain there until it slowly bleeds off or is caused to be released rapidly. The rapidrelease can be triggered by applying excessive force on the lead wires or by jarringforce during the removal of the detonator from the perforating gun assembly. If thepressure is being held back by the sealing plug, it can be dislodged from the outer shell,dragging the bridge wire through the ignition mix. Several instances have beendocumented over the years where this has been found to be the cause of several non-fatal surface detonations.

The cause of fluid pressure entry into the detonator is easily understood. Gas pressure

entry is a bit more complicated, especially when there is none present in the wellenvironment. Gas pressure can be generated by the explosive components beingexposed to elevated temperature for a period of time in excess of their prudent timerating. This can be a result of choosing the wrong explosive for the job or pushing itsoperating limits. Another common source is a fluid leak into the gun. Long selective firegun assemblies utilizing dart isolation between guns are more prone to this hazard.The dart requires a significant amount of energy (usually generated by the detonation ofthe shaped charges) to drive it into a seat, effectively sealing the spent gun from thenext one up in the toolstring. Because, in multiple guns, the darts are not on seat untilthe gun below is fired, the annulus of the assembly from bottom to top is open. Fluidentry will compress the air column until it is equal to the wellbore pressure or it may be

slow enough that the gun will be extracted before it can equalize to the wellbore. Ineither case, all of the components above the static fluid level in the assembly will beexposed to this compressed air column, which in turn charge the detonator with airpressure. As stated earlier, a sudden release of this stored energy can cause thesealing plug to dislodge, dragging the bridge wire through the ignition mix, causingdetonation.

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 6 of 8

-

7/27/2019 Electric Detonators Used in Wireline Operations

7/8

www.titanspecialties.com

Why a Carbon Resistor?

Earlier designs incorporating a resistor(s) in conjunction with or replacing a bridge wire utilizedcarbon composition resistors. As you may know, when these devices are exposed to highcurrent loads, they generate a lot of heat and when they fail, flames and smoke are the endresult. In electronic components, this can also lead to collateral damage to other veryexpensive components. This is one of the primary reasons that the electronics industryswitched to wire wound resistors (and for precise resistance values). Today, carbon resistorsare commonly available in the film type. Instead of a cylinder of carbon with lead wiresburied in each end, there is a shell of carbon surrounding an inert core attached to lead wiresto provide the same resistance value as its predecessor. In comparison, a carbon film resistor

is much less expensive than the cylinder style (supply and demand). Wire wound resistorscannot be reliably used for the initiation mechanism in electric detonators and the carbon filmis the most cost effective and reliable.

Carbon Resistor/Bridge Wire vs. Carbon Resistor?

In earlier illustrations, it was shown that there are basically two styles of detonators that utilizea resistor(s). One where the resistor(s) is used with a bridge wire as a current limiting device(Figure 2) and the other where it is used by itself(Figure 3 and 4) to generate heat whenexposed to firing voltage. The bridge wire style simply generates heat to effect initiation. Onthe other hand, the carbon style is quite a unique animal. One of two (or a combination of

events) will occur with the application of power. In one case, the resistor overheats andionizes, creating a white hot ember. In another, the overload causes the resistor to fragmentsending hard plastic fragments into the explosive. Remember that explosives can and willreact to heat and/or impact energy. The key to proper initiation is to apply power at an even,steady rate for predictable results. Many resistor/detonator failures can be attributed to thepower being applied too quickly whereby the resistor fragments suddenly with little heatgenerated. The most common and successful firing method is to apply voltage starting at zeroand increasing it to a maximum level over a period of 3 - 4 seconds. This is an easy taskassigned to a computer and is commonly used in PC based logging systems. Pre-setting thefiring voltage with a rheostat and dumping the power on the line with the firing switches willresult in a high number of miss-fires. Bridge wire type detonators can be fired using this

technique but the operator doesnt always know what is inside of the device. ALL detonatorscan be fired using the roll up technique. This is a matter of best practices, in my opinion.

One peculiar anomaly can be observed when firing a carbon resistor type detonator. Theoperator will notice the current and voltage meters on the firing panel respond to the powerbeing applied as the rheostat is being rolled up. As the resistor heats up and just before thedetonator fires, the current will drop off slightly. Once that event is observed, the operatorusually rolls the rheostat up to full power momentarily before returning it to zero.

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 7 of 8

-

7/27/2019 Electric Detonators Used in Wireline Operations

8/8

www.titanspecialties.com

Safe Detonators

High Energy Style detonators are newer class of devices intended to enhance the safety ofoperations using ballistic devices, primarily in unknown RF frequency and strengthenvironments. The one thing that all of these devices have in common is that they contain nosensitive, primary explosives such as Lead Azide. These devices are usually referred to as(and a brief description of their attributes):

EBW or Exploding Bridge Wire The traditional Bridge wire is replaced with a robust

material bridging two internal contacts. A firing cartridge stores energy (voltage appliedfrom the firing panel) until it reaches a pre-determined level and is discharged acrossthe bridge wire. The energy is dissipated in a manner that causes the wire to explode

thus transferring the energy to the secondary explosive with enough energy to initiate it. EFI or Exploding Foil Initiator Very similar to the EBW except that a foil disk is

propelled into a target of secondary explosive with sufficient energy to initiate it. Alsoreferred to as a Slapper Device.

SCB or Semi Conductor Bridge Similar to EBW whereby a large energy source is

dumped across an electronic device causing it to catastrophically fail and the resultingenergy is directed into the secondary explosive. This is the device that deploys theairbag in your vehicle.

All of these devices require the application of voltage stored in a discharge device until thevoltage level reaches level (some up to 1,200 volts) that will cause the violent destruction of

some component to release the energy into the explosive. They all have their drawbacks.Firing leads must be kept short, they will not tolerate any insulator leakage between thestorage/discharge unit and the detonator or arcing will occur.

Some devices require a non-standard AC frequency (600 Hz) or can also be integrated with adigital signature code to effect firing.

Google (on the Internet) semiconductor bridge, exploding foil initiator, Rig EnvironmentDetonator and PX-1 fireset for additional information. Also search all of the knownmanufacturers websites for proprietary Safe initiation systems, panels anddetonators. There is a lot of interesting data out there.

I hope this information proves to be useful and stimulates the curiosity to learn more.

In the past 30 years I have investigated many accidents, injuries and deaths associated withsurface detonations. The vast majority have been due to the accidental application of firingpower from the surface by a human. Even the safestsystem is susceptible to this event. Wemust continue to train and raise the awareness of all individuals associated with operationsinvolving explosives to be diligent regarding their responsibilities to themselves and others.

11785 Hwy 152 P.O. Box 2316 Pampa, Texas 79066 Tel 806.665.3781 Sales 800.692.4486 Fax 806.665.8882

Page 8 of 8