EG 445 -Traning report.pdf

-

Upload

nalaka-geekiyanage -

Category

Documents

-

view

151 -

download

1

Transcript of EG 445 -Traning report.pdf

i

REPORT ON

INDUSTRIAL TRAINING

AT

Mike Flora (Pvt) Ltd.

Submitted by

S.N.M. Wickramarathne

06/AG/071

EG - 445

Department of Export Agriculture

(Module Commercial Horticulture)

Faculty of Agricultural Sciences

Sabaragamuwa University of Sri Lanka

Belihuloya

2011

ii

REPORT ON

INDUSTRIAL TRAINING

AT

Mike Flora (Pvt) Ltd.

By

S.N.M. Wickramarathne

06/AG/071

This report is submitted in partial fulfillment of the requirements of the degree of

B.Sc. Agricultural Sciences and Management

Department of Export Agriculture, Module – Commercial Horticulture

Faculty of Agricultural Sciences

Sabaragamuwa University of Sri Lanka

Belihuloya

2011

Approved by

……………………………… …………………………..

Dr. G.D.K. Kumara Mr. Uditha Samarasinghe

(Internal Supervisor) (External Supervisor)

Senior Lecturer, Technical Manager,

Department of Export Agriculture, Mike Flora (Pvt) Ltd.,

Faculty of Agricultural Sciences, Rambukkana.

Sabaragamuwa University of Sri Lanka.

Date: …………………… Date: ……………………

…………………………………

Dr. G.D.K. Kumara

Head/ Department of Export Agriculture,

Faculty of Agricultural Sciences,

Sabaragamuwa University of Sri Lanka.

Date: ………………………………

iii

This Report is

affectionately

dedicated to

my loving parents and

Teachers

iv

ACKNOWLEDGEMENT

First and foremost I am deeply indebted to my internal supervisor Dr. G.D.K.

Kumara, Senior lecturer, Head/ Department of Export Agriculture, Faculty of

Agricultural Sciences, Sabaragamuwa University of Sri Lanka, who directed, assisted,

motivated and encouraged me, all the time in studying and acquiring a better training.

I would like to express my deepest gratitude to my external supervisor Mr. Uditha

Samarasinghe, Technical manager, Mike Flora (Pvt) Ltd., who always helped,

assisted provided necessary information and allowed me to be trained in different

sections of the company to complete this training programme successfully.

I also dedicate my grateful thanks to Mr. Arjuna Balasooriya, General Manager, Mike

Flora (Pvt) Ltd., who gave me the permission to be trained in Mike Flora nursery and

facilitated the requirements during the training period.

I am heartily thankful to Dr. A.D. Ampitiyawatta, Dean, Faculty of Agricultural

Sciences, Sabaragamuwa University of Sri Lanka, for giving this valuable opportunity

of industrial training programme for the fulfillment of my B.Sc Agricultural Sciences

and Management degree programme.

I further thank to Dr. P.K. Dissanayake, Senior Lecturer, the training Coordinator,

Department of Export Agriculture, Faculty of Agricultural Sciences, Sabaragamuwa

University of Sri Lanka, who coordinated me to be trained in a better training center.

I would like to express my gratitude to all the staff members of Mike Flora (Pvt) Ltd.

those who gave me the heartfelt help during my training period to complete the

training ecstatically and successfully.

I want to be thankful to all the other people who helped, encouraged, and motivated

me to success of the training.

v

EXECUTIVE SUMMERY

Recently the floriculture sector is playing an important role in Sri Lankan agriculture

earning considerable foreign exchange and employment opportunities for the country

because the consumption of floricultural products is increasing with the increasing per

capita income in most of countries throughout the world. Sri Lanka is also having

higher potential to gain a greater income by exporting floricultural items. Introduction

of high technology due to globalization and open economy has helped to increase the

production of vast range of floricultural items in quality and quantity wise.

This report provides a broad view of the related theoretical and practical aspects

studied during the industrial training programme undertaken at Mike Flora (Pvt) Ltd.

at Rambukkana which is a leading export oriented foliage nursery in Sri Lanka.

During this training period vast practical knowledge was gained in relation to plant

production activities, research and development activities, administration and some

aspects of marketing.

Mike Flora (Pvt) Ltd. has been recognized as one of the high quality foliage plant

exporter to the international market especially to the Netherlands and to Japan. The

company successfully manages the production flow to achieve the programmed

production. All the activities are properly planned by the company according to the

committed orders. As well as the Strengths, there are several weaknesses in this

company which can be corrected to be more strengthen in the foliage market.

vi

TABLE OF CONTENT

ACKNOWLEDGEMENT ........................................................................................ iv

EXECUTIVE SUMMERY ........................................................................................ v

LIST OF TABLES .................................................................................................... x

LIST FIGURES ........................................................................................................ xi

LIST OF PLATES ................................................................................................... xii

LIST OF ANNEXES .............................................................................................. xiii

CHAPTER ONE ...................................................................................................... 1

1. INTRODUCTION ....................................................................................... 1

1.1 World floriculture industry ...................................................................... 1

1.2 Sri Lankan floriculture industry ............................................................... 3

1.2.1 The world market for Sri Lankan floriculture .................................... 5

1.2.2 Potentials for development of floriculture sector in Sri Lanka ........... 5

1.2.3 Constraints for development of floriculture sector in Sri Lanka ......... 6

CHAPTER TWO..................................................................................................... 7

2. THE COMPANY ......................................................................................... 7

2.1 Background, history and present status of the company............................ 7

2.2 Logo, vision, mission and strategy of the company .................................. 7

2.3 Administrative structure of the company .................................................. 9

2.4 General structure of the company ............................................................10

CHAPTER THREE ...............................................................................................12

3. MAJOR VARIETIES GROWN IN NURSERY ........................................12

3.1 Foliage plant varieties exported and their modes of export ......................12

3.2 Field plant varieties.................................................................................13

3.2.1 Codiaeum variegatum ......................................................................13

3.2.2 Aglaonema spp. ...............................................................................16

3.2.3 Cordyline spp. .................................................................................18

vii

3.2.4 Dracaena spp. .................................................................................20

3.2.5 Miscanthus sinensis .........................................................................22

3.3 Hanging plants ........................................................................................23

3.3.1 Scindapsus spp. ...............................................................................23

CHAPTER FOUR ..................................................................................................25

4. GROWING MEDIA USED IN NURSERY ...............................................25

4.1 Preparation of growing medium for field plants ......................................25

4.2 Preparation of growing medium for propagation .....................................25

4.3 Preparation of growing medium for hanging pots ....................................26

4.3.1 Preparation of Basamid®/ Dazomet treated media ............................26

CHAPTER FIVE ....................................................................................................27

5. ESTABLISHMENT AND MAINTENANCE OF MOTHER PLANT

STOCK ...............................................................................................................27

5.1 Establishment of field plants ...................................................................28

5.1.1 Site selection and bed preparation ....................................................28

5.1.2 Field establishment of plants in beds ................................................29

5.1.3 Field establishment of plants in poly bags ........................................30

5.2 Establishment of mother plants in hanging pots ......................................31

5.3 Establishment of mother plant stock in hydroponics system ....................32

5.4 Maintenance of mother plants .................................................................33

5.4.1 Irrigation .........................................................................................33

5.4.2 Fertilizer application ........................................................................35

5.4.3 Pest and disease management ..........................................................36

5.5 Other maintenance activities ...................................................................39

5.5.1 Pruning ............................................................................................39

5.5.2 Pinching and thumb nailing .............................................................39

5.5.3 Weeding ..........................................................................................40

viii

5.5.4 Replanting or redevelopment ...........................................................40

5.5.5 Outside purchasing of planting materials .........................................40

CHAPTER SIX.......................................................................................................41

6. HARVESTING OF FOLIAGE PLANTS ..................................................41

6.1 Considerations at harvesting ...................................................................41

6.2 Harvesting procedure ..............................................................................42

CHAPTER SEVEN ................................................................................................46

7. PROPAGATION OF FOLIAGE PLANTS ...............................................46

7.1 Sexual propagation .................................................................................46

7.2 Vegetative propagation ...........................................................................47

7.2.1 Sand propagation section .................................................................48

7.2.2 Hydro propagation section ...............................................................50

7.2.3 Canes propagation section ...............................................................51

CHAPTER EIGHT ................................................................................................55

8. POST HARVEST HANDLING AND PACKING OF FOLIAGE PLANTS

55

8.1 Post harvest handling of canes ................................................................55

8.2 Post harvest handling of URC and rooted cuttings ..................................55

8.3 Packing operations ..................................................................................58

8.4 Methods of packaging .............................................................................60

8.5 Packing operations of different plant products ........................................62

8.5.1 Un-rooted cuttings ...........................................................................62

8.5.2 Canes ...............................................................................................62

8.5.3 Cut leaves ........................................................................................63

8.6 Special considerations at packing ............................................................63

8.7 Storage and transportation ......................................................................64

ix

CHAPTER NINE ...................................................................................................65

9. MARKETING AND EXPORT DOCUMENTATION ..............................65

9.1 Marketing procedure at Mike Flora (Pvt) Ltd. .........................................65

9.2 Export documentation .............................................................................65

CHAPTER TEN .....................................................................................................66

10. PLANT QUARANTINE ACTIVITIES .....................................................66

CHAPTER ELEVEN .............................................................................................67

11. DISCUSSION ..............................................................................................67

11.1 Strengths .............................................................................................67

11.2 Weaknesses .........................................................................................68

11.3 Opportunities ......................................................................................68

11.4 Threats ................................................................................................68

12. REFERENCES ...........................................................................................69

x

LIST OF TABLES

Table 1: World top ten importing countries ............................................................... 2

Table 2: World top ten exporting countries ............................................................... 3

Table 3: Sri Lankan Floriculture Exports .................................................................. 4

Table 4: Major plant varieties and their planting space.............................................29

Table 5: Common pests, susceptible plants and control measures performed by the

company ...................................................................................................................37

Table 6: Common diseases, susceptible plants and control measures performed by the

company ...................................................................................................................38

Table 7: Materials for propagator construction and their usage ................................48

Table 8: Plant varieties and required propagation period ..........................................50

Table 9: Propagation period of hydro propagated varieties .......................................51

Table 10: Different types of packing boxes ..............................................................64

xi

LIST FIGURES

Figure 1: Administrative structure of Rambukkana nursery ...................................... 9

Figure 2: General structure and the production flow of the company .......................11

Figure 3: Schematic diagram of coir fiber sterilizing steamer used in Mike Flora

nursery .....................................................................................................................25

Figure 4: Schematic diagram of a constructed bed ...................................................28

Figure 5: Schematic diagram of arrangement of hanging pots ..................................32

Figure 6: Fertilizer cycle for hanging pots ...............................................................36

Figure 7: Major steps in harvesting and potting of cuttings ......................................44

Figure 8: Major steps in harvesting and potting of Miscanthus ................................45

Figure 9: Major steps in harvesting and potting of single nodal cuttings of Scindapsus

spp. ..........................................................................................................................45

Figure 10: Steps of canes propagation .....................................................................53

Figure 11: Postharvest handling of canes .................................................................56

Figure 12: Process of postharvest handling of URCs and rooted cuttings .................57

xii

LIST OF PLATES

Plate 1: Codiaeum variegatum varieties grown in Mike Flora nursery......................15

Plate 2: Aglaonema spp. grown in Mike Flora nursery .............................................17

Plate 3: Cordyline spp. grown in Mike Flora nursery ...............................................19

Plate 4: Dracaena spp. grown in Mike Flora nursery ...............................................21

Plate 5: Miscanthus sinensis grown in Mike Flora nursery .......................................22

Plate 6: Scindapsus spp. grown in Mike Flora nursery .............................................24

Plate 7: Bed preparation and plant establishment .....................................................30

Plate 8: Bed preparation for poly bags .....................................................................31

Plate 9: Arrangement of hanging pots of Scindapsus spp. in Mike Flora nursery ......32

Plate 10: Scindapsus aureus in hydroponic system in Mike Flora nursery ................33

Plate 11: Different irrigation methods practiced in Mike Flora nursery ....................35

Plate 12: Pruning and pinching of foliage plants ......................................................39

Plate 13: Specifications considered at harvesting .....................................................42

Plate 14: Operations of harvesting section ...............................................................43

Plate 15: Queen palm propagation; germinated seeds with pseudo leaves and

transferred plants to plastic pots................................................................................47

Plate 16: Bed preparation in sand propagation section .............................................49

Plate 17: Structure of the propagator house ..............................................................51

Plate 18: Production process of canes section ..........................................................52

Plate 19: Post harvest handling and packaging of foliage plants ...............................59

Plate 20: Other concerns in packaging of foliage plants ...........................................61

Plate 21: Detailed illustration of a packing box ........................................................63

Plate 22: Different types of boxes used for packing of foliage plants in Mike Flora

(Pvt) Ltd. ................................................................................................................. 64

xiii

LIST OF ANNEXES

Annexure 01: Compatibility between pesticides mixed together for application

Annexure 02: Agrochemicals used in Mike Flora nursery

Annexure 03: Quality assurance report (propagators & packing section)

Annexure 04: Variety list with modes and sizes

Annexure 05: Phytosanitary inspection requesting form

Annexure 06: Order form

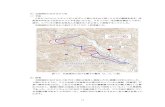

Annexure 07: Site map

Annexure 08: Fungicide cycle

Annexure 09: Miticide cycle

1

CHAPTER ONE

1. INTRODUCTION

1.1 World floriculture industry

The production of flowers and ornamental plants for aesthetic purposes including

indoor gardening is termed as floriculture. Floriculture has been identified as one of

the most profitable agro enterprise. This could generate increased self- employment

from unit land area. The floral industry is one of the major industries in many

developed and developing countries. This industry began in the late 1800s in England.

At the moment the floral industry is a dynamic, global, fast-growing industry, which

has achieved significant growth rates during the past few decades.

Floriculture sector is experiencing rapid changes throughout the world. Consumption

of floricultural products is increasing with the increasing percapita income. The

production of floricultural items has grown quite consistently over the last 20 years.

Floriculture product categories in the world

Foliage plants

o Starting materials

o Semi-finished plants

o Finished plants

Flowering plants

Cut leaves for decorative purposes

Cut flowers

Others

o Bulbs

o Dried flowers and foliage

o Flower seeds

o Tissue cultured plants

o Aquatic plants

o Landscaping plants

2

Foliage market seems to run in the line with the increase in cut flowers sales as a

whole. Consumers buy floricultural items because of traditions, culture and lifestyle.

In the more prosperous countries they use flowers to express themselves in line with

their life style. Furthermore, businesses and organizations also use these products for

decorations to create a certain atmosphere contributing to their image. Buyers require

products with consistent quality, low price, and added value (Anon 01).

During the last century and a half, the foliage plant industry has become truly global.

The current situation can be simplified as four centers of foliage plant origins (Africa,

Asia, Australia, and Central and South America), four regions producing propagules

(Asia, Central and South America, Europe and North America), and three regions of

finished plant production (Asia, Europe, and North America) (Anon 02).

Table 1: World top ten importing countries

Country Average imports

(million US$)

Percentage share of total

imports (%)

Germany 930.58 21

USA 897.22 20

UK 772.85 17

France 520.85 12

Netherland 508.42 11

Japan 216.57 5

Italy 206.33 5

Switzerland 189.30 4

Austria 76.70 2

Belgium 134.70 3

Total 4452.79 100

Source: Floriculture international 2004

3

Table 2: World top ten exporting countries

Country Export value

(million US$)

Share in world cut flower

market (as %)

The Netherlands 2911.253 64

Colombia 699.457 14

Ecuador 340.810 7

Kenya 231.370 6

Italy 83.624 2

Israel 81.826 2

Spain 76.672 2

Belgium 64.232 1

Thailand 63.611 1

Germany 43.380 1

Source: International Trade Commission UNCTAD Switzerland (2006)

1.2 Sri Lankan floriculture industry

Floriculture is becoming a lucrative industry in Sri Lanka, and today it has become a

profitable industry that provides more benefits than other agricultural crops.

Floriculture has a history of over 2000 years in Sri Lanka. It was only after the British

rule that floriculture really came into practice not as an industry but mainly as a hobby

for pleasure. Later, with many new introductions of tropical and sub-tropical plants

the trend was gradually passed down to other levels of society. Floriculture in Sri

Lanka started as an industry in 1970. It has grown substantially during the last few

years to become one of Sri Lanka's major foreign exchange generating ventures.

Europe is the major market for Sri Lankan floricultural products and accounted for

62% of total floriculture exports in year 2009. The Netherlands is the leading importer

in Europe and continues to be the number one market for Sri Lankan floriculture

products absorbing 36% of total exports in year 2009. Japan, South Korea and the

Middle East are the other major import markets (Anon 04).

Floricultural crop production in Sri Lanka involves 3 main categories.

Large scale - Export oriented cultivators

Middle level - Growers catering to the local market

4

Small-level - Cultivators who sell their products to the two

categories mentioned above.

They play an important role in the Sri Lankan floriculture market for exportation of

products as well as for local consumption. Large scale growers mainly target the

export market.

Western, North Western and Central provinces in Sri Lanka are the major areas where

cut flowers and foliage plants are grown commercially. The total land area under

floriculture is around 500 ha at present and the majority of lands are in the Western

province. There are 10 ha under carnations, 3 ha under roses, 2 ha under gerberas, 10

ha under anthuriums, 3 ha under orchids and 472 ha under foliage plants. These

figures clearly show that the floriculture trends in Sri Lanka have been in favors of

foliage plants.

Sri Lanka is blessed with a wide range of climatic conditions, which facilitates year

around growth of a variety of tropical or temperate floriculture products; hence, it is

good to grow diverse ornamental plants, which could be developed to satisfy the

demands of the industry.

Sri Lankan product assortment consists of the following product lines;

Ornamental foliage plants

Cut decorative leaves

Cut flowers

Aquarium plants

Landscaping plants

Tissue cultured plants

Table 3: Sri Lankan Floriculture Exports

Product

Value of Exports (US$)

2006 2007 2008 2009 2010 Live Plants 4,989,546

4,873,013

6,798,738

5,894,094

5,923,955

Cut Flowers 5,597,486

6,323,128

6,568,802

5,117,526

4,701,978

Fresh Decorative Leaves

661,931

832,232

816,442

435,240

1,116,914

Total 11,248,963 12,028,373 14,183,982 11,446,860 11,742,847 Source: Sri Lanka Customs Statistics (Anon 04)

5

1.2.1 The world market for Sri Lankan floriculture

Total world imports; 2010-US$ billion 17.1

Sri Lankan exports; 2010-US$ million 11.7

Growth in Sri Lankan exports; 2006-2010 - 3%

Sri Lankan share in the world market; 2010- 0.1%

World ranking; 2010-52nd place

(Anon 04)

1.2.2 Potentials for development of floriculture sector in Sri Lanka

Sri Lanka's stable and varied tropical climatic conditions and the geographic

terrains from sea level up to 2200 m of humid mounts have created

magnificent macro and micro environments to house thousands of local as

well as sub-tropical and temperate plants.

Sri Lanka has a favorable location to serve different markets in the world.

Availability of land and the high literacy rate of the average person would be

an added benefit to those who wish to invest in the industry.

In addition, the tax benefits and BOI incentives granted by the government

would help bring in more investors to the country and facilitate further

development of the existing industry.

Furthermore, the new policy framework prepared by the Ministry of

Agriculture and Lands has clearly identified the need to initiate a “Floriculture

Research and Development Programme”. This programme will cover many

areas such as agronomy, pathology, entomology, mutation, breeding, post-

harvest and mass propagation to support the industry.

Institutional support

o Floriculture Produce Exporters Association

o Department of Agriculture

o Department of National Botanical Gardens

o Department of Forest

o Department of Wild Life Conservation

o Department of Commerce

o Sri Lanka Customs, are some supportive institutions for the

development of floriculture sector in Sri Lanka (Anon 04).

6

1.2.3 Constraints for development of floriculture sector in Sri Lanka

Inadequacy and high cost of air cargo

“Sri Lankan Air Lines” the national carrier has always given priority to perishable

cargo. However, the available capacity is not sufficient and the cost of cargo is also

high because the floricultural products are also priced according to weight basis.

Lack of facilities for research and development

So far only the Royal Botanic Gardens, Peradeniya has been involving in providing

assistance all categories of growers, but this is negligible when compared to the ever

increasing demands of the industry.

Lack of trained personnel

The floriculture industry requires trained personnel at each level of production.

Education programmes from schools up to University level and training institutes to

conduct courses on high-tech practical skills in floriculture are essential for the

development of the industry.

Large initial investment on farms

Duty free facilities for import of vital items not produced in Sri Lanka such as shade

nets, UV stabilized polythene, irrigation and fertilizing systems etc. would help to

promote the industry.

Lack of improved systems of marketing

Lack of proper or organized systems for marketing and inadequacy of current

international market information on prices, trends, volumes and data on competitive

countries etc, severely affect the development of the industry.

The uneconomical size of floriculture industry

Difficulty in acquiring suitable land and lack of infrastructure facilities also adversely

affect the industry.

Lack of information on pesticides

Current information on pesticides and their acceptance in various countries is

essential.

Phytosanitary clearance

Phytosanitary inspection just prior to shipment is inconvenient and expensive, besides

leaving no time to rectify any problems (Anon 04).

7

CHAPTER TWO

2. THE COMPANY

2.1 Background, history and present status of the company

Mike Flora group consist of Mike Flora (Pvt) Ltd., Mike Flora International Ltd.,

Mike Biotech Asia (Pvt) Ltd., which have gained much recognition as suppliers of

quality exotic tropical plants to the international market. The head of Mike Flora

group is situated at No 65/11, Swarnadisi place, Koswatte, Nawala, Rajagiriya.

Nurseries are situated at Rambukkana as well as at Nawala.

Rambukkana belongs to the agro ecological region WL 2b with more than 2000 mm

rainfall. Average temperature is about 31.5°С and the average Relative Humidity is

around 85%. The terrain is steeply dissected, rolling and undulating. Red yellow

podzolic soils with strongly mottled sub soil, Reddish brown Latosolic and Low

humic Glay soil types available in this region. All these conditions and moderately

warm climate are ideal for the healthy growth of tropical foliage plants.

Mike Flora (Pvt) Ltd. has been established on 28th of March 1980, funded by its

present Managing Director Mr. Mihindu Keerthirathne who has nurtured over the

years to its present status to make it one leading exporters of foliage plants and flora

to the world. With the time the company has developed year by year with increasing

number of varieties exported and income gained by exportation. Now the land area of

the company extended up to about 68 acres occupied with higher number of plant

varieties.

2.2 Logo, vision, mission and strategy of the company

Logo

8

Vision

Its vision is to be the most preferred horticulture company in Sri Lanka.

Mission

Its mission is to:

o Maintain the best managed nurseries holding the widest in product variety

o Achieve and sustain product quality excellence

o Be the most sought after exporter

And by virtue of that fact to:

o Satisfy their stake holders

o Maintain a competent, pro-active and contended staff

o Be a responsible corporate citizen

Strategy

Mike Flora is an innovative group with the strategy to explore the possibility of

marketing commercially viable new varieties. Cordyline compacta ‘Mike silver’,

Scindapsus “joy” are several products developed by the company and it has obtained

patent rights. While engaging in developing new products, the company has been able

to meet the customer needs, which has given a definite advantage for the company

over its competitors due to the standards maintained by the company. Due to the

standards maintained in the field of exports following achievements and awards has

been awarded (Anon 03).

‘Florissima – 1990

Merit Award – ‘Export Development Council of Ministers – 1990’

Merit Award – ‘Export Development Council of Ministers – 1991’

Award of distinction – ‘Eco Flora – 1997’

Silver Award –‘National chamber of exporters – 2002’

‘Good Growing Practices’ (GGP) – Netherlands

Good Agricultural Practices (GAP) certified

9

2.3 Administrative structure of the company

Mike Flora (Pvt) Ltd. has a well-organized administrative structure for the better

production and exportation of foliage plants for the international market. All staff

members have different kind of responsibilities and specialized in their work with

knowledge and experience. The administrative structure of the Mike Flora (Pvt) Ltd.

is shown in figure 01.

Figure 1: Administrative structure of Rambukkana nursery

Workers

In-charge

Propagator 01 Workers

In-charge

Propagator 02

In-charge

Propagator 03

Workers

Workers

Production

Manager

Technical

Manager

Export

coordinator

Supervisors Clerks Personnel

assistant

Store

keeper

Technical

assistant

Managing Director (MD)

Chief Executive Officer (CEO)

Nursery Manager

Group General Manager (GGM)

10

2.4 General structure of the company

Company has different units or sections and each unit has a responsible leader who

has good experiences on specific operations. There are five major sections in the

nursery. They are;

1. Mother plant stock/ the field

2. Harvesting section

3. Propagators

4. Canes section

5. Packing section

Relationship among above sections is shown in figure 02. Except those major sections

there are other important units which are related to the plant production, exportation

and controlling of general activities of the company such as the office, the laboratory,

stores etc.

11

Mother stock

URCs & cut foliage URCs

Harvesting section

Rooted plants

Treatment application

Potting

Propagation

Administration

Propagation section

Packing section

Selection & grading

Mother plant development

Return for propagation

Good quality plants Poor quality plants

Cleaning & washing

Selection

Grading & cutting

Bundling

Pre cooling

Packing

Weighing

Labeling

Dispose

Composting

Cooling Transportation for export

Figure 2: General structure and the production flow of the company

12

CHAPTER THREE

3. MAJOR VARIETIES GROWN IN NURSERY

Mike Flora grows more than 70 ornamental foliage varieties for exportation. Majority

of those varieties belong to Aglaonema spp., Codiaeum variegatum, Cordyline spp.

Dracaena spp. Miscanthus sinensis, Scindapsus spp.

3.1 Foliage plant varieties exported and their modes of export

Following plant varieties are the major varieties exported by Mike Flora company.

Those varieties are exported in different modes (Annexure - 04). Modes are

represented by different types of plant establishment. That means the same variety is

exported in more than a few export modes. The export mode is determined by the

client or the buyer.

Followings are the major different types of export modes exist in Mike Flora (Pvt)

Ltd.;

URC - Un-rooted Cuttings

Leaf

1ppn - 1 Plant per net pot

2ppn - 2 Plants per net pot

3ppn - 3 Plants per net pot

4ppn - 4 Plants per net pot

5ppn - 5 Plants per net pot

1 ppo - 1 Plants per Oasis

2 ppo - 2 Plants per Oasis

3 ppo - 3 Plants per Oasis

4 ppo - 4 Plants per Oasis

5 ppo - 5 Plants per Oasis

7 ppo - 7 Plants per Oasis

8ppo - 8 Plants per Oasis

1cpn - 1 cane per net pot

13

3.2 Field plant varieties

3.2.1 Codiaeum variegatum

Codiaeum variegatum is a species of plant in the genus Codiaeum, which is a member

of the family Euphorbiaceae. It is native to Southern India, Sri Lanka, Indonesia,

Malaysia, and the Western Pacific ocean islands. It is an evergreen shrub growing to 3

m tall and has large, thick, leathery, shiny evergreen leaves, alternately arranged, 5-30

cm long and 0.5-8 cm broad.

Mother plant stock is maintained under 60% shade in raised beds and in poly bags

using usual growing medium. Mulching is done annually. This species is mainly

exported as un-rooted cuttings. Other than that it is exported in net pots and in oasis

mode too. Fertilizer application is performed according to a programme. All the

sources of macro and micro nutrients are mixed together and field is drenched weekly.

During rainy season Ca(NO3)2; Field grade is applied since the field cannot be

drenched weekly

Big-leaf crotons

Codiaeum variegatum ‘Excellent’

Codiaeum variegatum ‘Petra’

Codiaeum variegatum ‘Wilma’

Mini-leaf crotons

Codiaeum variegatum ‘Gold star’

Codiaeum variegatum ‘Mariana’

Codiaeum variegatum ‘Mini curly’

Codiaeum variegatum ‘Pictum’

Codiaeum variegatum ‘Sunny star’

Codiaeum variegatum ‘Yellow banana’

Codiaeum variegatum ‘Bush and fire’

Codiaeum variegatum ‘Gold sun’

Codiaeum variegatum ‘Mummy’

Codiaeum variegatum ‘Mrs. Iceton’

14

Codiaeum variegatum

‘Excellent’

Codiaeum variegatum

‘Petra’

Codiaeum variegatum

‘Wilma’

Codiaeum variegatum

‘Gold sun’

Codiaeum variegatum

‘Gold star’

Codiaeum variegatum

‘Bush and fire’

Codiaeum variegatum

‘Mini curly’

15

Plate 1: Codiaeum variegatum varieties grown in Mike Flora nursery

Codiaeum variegatum

‘Sunny star’

Codiaeum variegatum

‘Yellow banana’

Codiaeum variegatum

‘Icetone’

Codiaeum variegatum

‘Mummy’

16

3.2.2 Aglaonema spp.

Aglaonema is a genus of about 40 species of foliage plants in the family Araceae,

native to Southeastern Asia. No common name is widely used, though they are

sometimes called "Chinese Evergreens". They are herbaceous perennial plants

ornamentally grown to about 20 cm in height. The leaves are alternate on the stems,

lanceolate to narrowly ovate, about 10-15 cm long and 4-6 cm broad, depending on

the species. In Mike Flora nursery Aglaonema species are grown in raised beds as

well as in grow bags under 60% shade using usual growing medium. Aglaonema

‘Silver Queen’ is the most demanded species out of several Aglaonema species grown

in Mike Flora fields. This variety is exported as un-rooted cuttings as well as oasis

based rooted plants, which are propagated inside the propagator house.

Followings are the major Aglaonema species grown in this nursery.

Aglaonema circhuwana

Aglaonema ‘Malay beauty’

Aglaonema maranthifolia

Aglaonema ‘Maria’

Aglaonema pseudobracteatum

Aglaonema ‘Silver queen’

17

Plate 2: Aglaonema spp. grown in Mike Flora nursery

Aglaonema ‘Malay beauty’

Aglaonema pseudobacterium

Aglaonema ‘Silver queen’

Aglaonema maranthafolia

Aglaonema ‘Maria’ Aglaonema circhuwana

18

3.2.3 Cordyline spp.

Belongs to family Agavaceae. Cordyline represents about 15 species in tropical, sub

tropical and warm temperate regions, mostly native to New Zealand, Australia,

Malaya, and indigenous to South America. These plants are grown for their handsome

foliage. Mike Flora (Pvt) Ltd. maintains more than 5000 m2 of land area for the

mother plant stock of Cordyline spp. under 60% shade level. This species also

established in raised beds using usual growing medium. Fertilizer application is done

three-week interval. Mulching is done annually with planting medium. While the

Cordyline fruticosa varieties are exported as rooted plants in net pots and in oasis

pieces, the Cordyline terminalis varieties are exported as un-rooted cuttings.

Followings are the major Cordyline varieties grown in this nursery;

Cordyline fruiticosa ‘Purple’ compacta

Cordyline fruiticosa ‘Green’ compacta

Cordyline fruiticosa ‘Red’ compacta

Cordyline fruiticosa ‘Mike silver’ compacta

Cordyline fruiticosa ‘Gold’ compacta

Cordyline terminalis cv. Red edge

Cordyline terminalis cv. White edge

19

Plate 3: Cordyline spp. grown in Mike Flora nursery

Cordyline fruiticosa

‘Purple’ compacta

Cordyline fruiticosa

‘Green’ compacta

Cordyline fruiticosa

‘Red’ compacta

Cordyline fruiticosa

‘Mike silver’ compacta

Cordyline fruiticosa

‘Gold’ compacta

Cordyline terminalis

‘White edge’

20

3.2.4 Dracaena spp.

There are several species of Dracaena cultivated in Mike Flora nursery. Dracaena

sanderiana, Dracaena godseffiana, Dracaena marginata, Dracaena fragrance etc.

Out of that Dracaena sanderiana and Dracaena godseffiana are the major species

grown, as those two varieties are highly demanded over the other species.

Dracaena sanderiana is one of the major plant species grown in Mike Flora nursery.

It is a highly demanded species as un-rooted cuttings (URCs). Other than URCs,

Dracaena sanderiana is exported as rooted plants in net pots and oasis based modes.

This variety is commonly known as “Chinese bamboo” or “Lucky bamboo”. They are

well adapted as house plants and consist with attractive, durable, little rosette and thin

leathery foliage. Dracaena sanderiana is established under 60% shade in raised beds

using usual growing medium. pH of medium is maintained in between 5.5 - 6.0 and it

is adjusted by applying Dolomite. Irrigation is done by means of sprinkler irrigation

and the frequency of irrigation may vary according to the existing weather conditions.

Fertilizer application is done according to a programme [Balanced fertilizer; 21:21:21

and Ca(NO3)2 are applied rotationally]. If any deficiency appears, relevant macro or

micro nutrient is added to recover the problem.

Followings are the four types of Dracaena sanderiana varieties exported from Mike

Flora;

Dracaena sanderiana ‘Gold’

Dracaena sanderiana ‘White’

Dracaena sanderiana ‘Victory’

Dracaena sanderiana cellus

Dracaena godseffiana is a plant species which is having a higher ornamental value as

an indoor plant. This species consist of delicate leaves long elliptic, thicker, and more

spotted with ivory white to yellow color. Establishment and maintenance is same as

the Dracaena sanderiana. Dracaena godseffiana is exported as rooted plants which

are propagated by means of hydro, sand, oasis and coir fiber.

There are two varieties belonging to this species. The leaf color is different in two

varieties.

Dracaena godseffiana ‘Florida beauty’

Dracaena godseffiana ‘Green’

21

Plate 4: Dracaena spp. grown in Mike Flora nursery

Dracaena sanderiana

‘Victory’

Dracaena sanderiana

‘White’

Dracaena sanderiana

cellus

Dracaena godseffiana

‘Florida beauty’

Dracaena sanderiana

‘Gold’

22

3.2.5 Miscanthus sinensis

This belongs to family Liliaceae. The plants consist of an attractive form of leaves:

long-linear, symmetrically arranged, stripped in white or yellow color. Mother plant

stocks of Miscanthus sinensis are maintained under both open field and inside the net

houses. In open field Miscanthus plants are cultivated under natural shade.

Miscanthus species are exported in different modes such as cut foliage, bare roots and

rooted plants in net pots and oasis etc.

Miscanthus sinensis ‘Green’

Miscanthus sinensis ‘White’

Plate 5: Miscanthus sinensis grown in Mike Flora nursery

Miscanthus sinensis ‘White’

23

3.3 Hanging plants

3.3.1 Scindapsus spp.

Scindapsus is the major type of hanging plant or the vine type plant species cultivated

in Mike Flora nursery. Commonly called as ‘pothos vine’ In Mike Flora nursery

several kinds of varieties are grown as mother plants. This species consist of vines

with attractive foliage with different colors mixed with green color. Scindapsus ‘joy’

is the newest variety which has variegated in Mike Flora nursery. These varieties are

grown in hanging pots as well as in beds using Basamid® treated medium. Fertilizer

application for Scindapsus spp. is done according to a programmed cycle (Figure 06).

This species is exported as URCs and rooted plants in net pots and oasis.

Followings are the different Scindapsus species grown in Mike Flora nursery;

Scindapsus aureus

Scindapsus ‘Lime’

Scindapsus ‘Marble queen’

Scindapsus ‘Pictus’

Scindapsus ‘joy’

24

Plate 6: Scindapsus spp. grown in Mike Flora nursery

Scindapsus aureus Scindapsus ‘Lemon lime’

Scindapsus ‘Marble queen’

25

CHAPTER FOUR

4. GROWING MEDIA USED IN NURSERY

Mike Flora (Pvt) Ltd. maintains their own media preparation unit in their own land.

Preparation of sterilized/ fumigated media for hanging pots, palm pots and mixing of

growing media for field plants are done in this section. Different ratios of different

components such as sand, coir dust, compost are formulated according to the

requirement of the crop.

4.1 Preparation of growing medium for field plants

Non fumigated planting medium is used for most field plants. Generally for most field

plants the medium is similar. Medium is consisted with compost, sand and coir dust.

They are mixed together and applied either cow dung, elephant dung or poultry

manure as composting material.

eg; Common growing medium;

coir dust: compost: sand - 2 : 1 : 1

4.2 Preparation of growing medium for propagation

Steamed coir dust is used for the purpose of propagation. A large steamer with the

capacity of approximately 1 m2 volume is used for the purpose of steam sterilization

of coir dust. Steam sterilization is done under 102°С temperature. After a proper

sterilization the coir dust is heaped in clean place on a polythene sheet to prevent

contaminations. Then the heap is covered by polythene sheet until use.

Lid

Coir dust Iron mesh

Water

Fire Figure 3: Schematic diagram of coir fiber sterilizing steamer used in Mike Flora nursery

26

4.3 Preparation of growing medium for hanging pots

Fumigation/ Sterilization of growing medium, which is used for palm pots and

hanging pots is done in the compost preparation unit by using Basamid® granular

(Dazomet)

4.3.1 Preparation of Basamid®/ Dazomet treated media

Basamid® is a micro granular dust which is used as soil fumigant for the control of

soil born diseases, nematodes, soil insects and weeds (seeds, tubers, rhizomes)

containing.

A correct combination of sand, coir dust and compost should be thoroughly mixed at

least 1-2 weeks before the treatment. The medium should be fine and clod free.

During the period of pretreatment the maintenance of sufficient moisture is essential

for the activation of target organism. After leveling the medium, Basamid® is applied

uniformly at a rate of 750 g/m3. Incorporation is done by immediately after

application of Basamid® granules to the media and then water is applied by using

hosepipe. Because the quick transformation of Dazomet in reaction to active fumigant

is also depend on sufficient moisture. Then the Basamid® treated bed is covered with

polythene sheet and sealed for a period of 14 days.

There are several positive effects of sealing of Basamid® applied beds. Retention of

active fumigant, retention of moisture in the beds, prevention of over saturation with

water in case of rain fall, solarization effects are some examples. After period of

treatment polythene seal is removed. Then the media should be aerated/ forked to

allow the non-mineralized gasses to disperse. After about 5 days the bed is again

forked. After another five days of 2nd forking, again forking is done. Post treatment

operations are essential to make sure the operation of sterilant/ toxic gasses

completely since the existence could be harmful for the planting materials.

Completely after about 24 days the media is ready for planting. When the Basamid®

granular is in contact with moisture, it releases biologically active gases named

Methylisothiocynate (MITC). Sufficient soil temperature also plays an important role

in the process of fumigation.

Moisture (60%-70%)

Sufficient temperature

MITC (Gass) Dazomet

27

CHAPTER FIVE

5. ESTABLISHMENT AND MAINTENANCE OF MOTHER PLANT STOCK

Total land area under Mike Flora (Pvt) Ltd. is about 68 acres and most of the area has

been used for mother plant stock. Out of total land area around 40 acres is maintained

under net houses. Field has been divided in to different zones as 12 zones of

Rambukkana field and 14 zones of Madawala field. Most of the zones are raised

under artificial shade. Division of land according to the requirements of different

plant varieties, to facilitate easy management of plants, and supply proper infra-

structural facilities for the easiness of their management are several advantages of the

division of land in to different zones. Each zone has given a number for identification.

Number boards have been located in each zone showing the zone number, number of

beds, number of hanging pots in each zone, name of varieties in the zone and total

area under each zone.

Light is one of the most important factors that determine the color and appearance of

foliage plants. Consequently foliage plant varieties require shade management during

their production. Shade is provided in two ways.

Artificial shade

Natural shade

Shade for mother plant stock is mainly supplied artificially through black color shade

nets. 60% shade nets are prominently used. Dracaena sanderina, Dracaena

godseffiana, Cordyline fruiticosa, Codiaeum varieties and Scindapsus spp. etc. are

reared under the 60% shade level. Queen palm requires 80% shade for better

development of leaf color and better appearance of plants. Major advantage of using

artificial shade is the ability to provide even shade level that leads to the production of

quality plants. Dracaena marginata, Chlorophytum, and Miscanthus varieties are

maintained under natural shade using Gliricidia trees. But under natural shade it is

difficult to provide a uniform shade level throughout the time for all plants. Removal

of fallen leaves on beds from shade trees should be frequently done under natural

shade conditions. That counts an extra cost. But establishment cost is low in natural

shade compared to establishment under artificial shade.

28

5.1 Establishment of field plants

5.1.1 Site selection and bed preparation

After a proper planning designing and appropriate land preparation in existing land,

sloping and leveling is done prior to the establishment of mother plant stock. Then the

net house installation is done before bed preparation. All most all beds are constructed

as raised beds. The margins of beds are constructed using bricks and cement or using

roofing tiles (Figure 04, Plate 07). The width of a bed is about 1-1.5 m and the length

is varying according to the land size. The beds are functional at least for 4-5 years.

Drainage is an essentially important factor considered in bed preparation. Proper

drainage is highly considered when preparing beds particularly for croton species and

Aglaonema species which are highly susceptible for root rot diseases. Tile tube is one

of the techniques which put into practice for enhancement of drainage (Figure 04). It

is maintained at the middle of the bed. The width of tile tube is about 20 cm. It just

likes a canal inside the bed which is paved by roofing tiles. Bothe sides of a bed are

sloped towards the tile tube and the slope of the tile tube is directed towards the main

drain, in order to remove excess water from beds to facilitate and ensure proper

drainage. Beds also prepared well sloped towards the main drain. A thin layer of sand

(5-7 cm height) is applied on the bottom of the bed and the growing medium is filled

up to about 20-25 cm height. In addition medium is added time to time as mulch when

the existing medium is reduced.

Figure 4: Schematic diagram of a constructed bed

Bed margins

demarcated by

roofing tiles SLOPE

Tile tube

29

In the re development process the top medium about 20 cm from top of the tile is

removed and well forked the existing soil to improve the soil structure. Then the new

medium is filled loosely to the bed and before planting these beds are drenched with a

recommended fungicide. eg; Captan®

5.1.2 Field establishment of plants in beds

Healthy pest and disease free planting materials are taken for field establishment.

Planting materials are obtained from existing mother plants, non-infected rejects from

harvesting, propagation and packing sections and from outside purchases. The

obtained cuttings are established in prepared beds with an appropriate spacing among

plants. The spacing between plants and between rows is different depending on the

plant variety and size of planting material.

Plant variety Spacing

Big leaf crotons 25×30 cm

Mini leaf crotons 20×25 cm

Cordyline spp. 18×20 cm

Dracaena sanderina 20×25 cm

Dracaena godseffiana 20×20 cm

Aglaonema spp. 25×30 cm

Miscanthus sinensis 30×30 cm

Triangular pattern of planting is used to utilize the space maximally and to avoid

overcrowding of plants.

Table 4: Major plant varieties and their planting space

30

Plate 7: Bed preparation and plant establishment

5.1.3 Field establishment of plants in poly bags

Poly bags are also used for the establishment of mother plants for several varieties

other than raised beds. At the moment, during redevelopment process most of the

croton varieties are established in poly bags. A poly bag is prepared by using black

polythene. Bags are prepared in to two different sizes for croton varieties and for

Aglaonema varieties. The croton bag is 17 cm in height and 8 cm in width and the

Aglaonema bag is 15 cm in height and 4 cm in width. Poly bags are filled with

medium and arranged in the bed in to triangular pattern for maximum space

utilization and to provide proper spacing for plant growth. The plants are established

in prepared bags and then the bags are kept on the beds. Beds are prepared as same

way to field plant establishment bed preparation procedure mentioned in above

chapter. But the medium is not applied on the bed. Instead of that sand is filled up to

1/3 of bed and then some tile pieces are spreaded on the surface. After that the bags

with plants are kept on the bed in triangular manner.

Advantages of poly bags

Low requirement of medium compared to beds

Maximum space utilization

Ease of handling for maintenance practices

Bed preparation for field plant

establishment

Establishment of plants in beds

(Dracaena sanderiana)

31

Facilitate better monitoring of pest and disease problems; because plants are

established in individual poly bags. Thus monitoring is easier compared to

beds.

Lessen the favorable conditions for disease spreading etc.

5.2 Establishment of mother plants in hanging pots

The company efficiently utilizes the land by using hanging pots. Most of areas under

shade nets are occupied with hanging pots. Each bed consist a row/ two rows of

hanging pots occupied with following varieties

Scindapsus spp.

Philodendron spp.

Hoya spp.

Clay pots (21 cm diameter and 9 cm depth) are used as hanging pots. When old pots

are used in redevelopment processes they are treated with Formaldehyde for about 4

hours. As the medium for hanging pots, always use Basamid® treated medium. Shoot

tips, non-infected rejects from harvesting and propagation sections are used as

planting materials. Planting materials are dipped in a Carbofuran® solution before

planting in pots to kill nematodes, scales and mealy bugs. About six to seven cuttings

are planted per one pot and water is applied. Pots are hanged inside the net houses

provided with 60% shade.

Prepared beds for poly bags Triangular way of placing bags on prepared beds

Plate 8: Bed preparation for poly bags

32

5.3 Establishment of mother plant stock in hydroponics system

Other than above three ways (filed, poly bags and hanging pots) there is a mother

plant stock of Scindapsus spp. maintained in a hydroponic system. Hydroponic

system has established by using P.V.C. pipes. Two rows of hydroponic pipe lines are

established in two sides of a one bed in several zones. Albert solution is used as the

growing medium. Solution is provided to the tubes time to time. pH and EC

(Electrical Conductivity) are maintained as 5.1 and 1.4, respectively.

Figure 5: Schematic diagram of arrangement of hanging pots

Plate 9: Arrangement of hanging pots of Scindapsus spp. in Mike Flora nursery

33

5.4 Maintenance of mother plants

In order to obtain an enough quantity of produce with enhanced ornamental quality to

full fill the market demand and also for the re development of mother plant stock,

continuous monitoring and maintenance of existing mother plants is essential.

Because, for exportation requires pest and disease free products in large quantities.

Consequently for healthy and lush growth of mother plants company performs various

maintenance practices.

5.4.1 Irrigation

Water is a vital for plant survival. Therefore company strictly considers supplying

required amount of water in appropriate time periods. Irrigation is done by using well

water. Several wells are established to supply water to the nursery. Water is pumped

to the main tank with the capacity of 40,000 l through a sump. Then water is

distributed among zones by several electric motors.

Three types of irrigation methods are mainly used by the company. They are,

Manual watering

Sprinkler irrigation

Drip irrigation

Manual watering/ hose irrigation

Manual watering with a hose is the easiest irrigation system to set up and use.

However, hand watering is a labor intensive method.

Plate 10: Scindapsus aureus in hydroponic system in Mike Flora nursery

34

Sprinkler irrigation

It is possible to irrigate both normal lands and unleveled lands by sprinkler irrigation.

Sprinkler system can water a large area at once and need to e carefully placed and

checked after for plugging of sprinkler heads. The distance between two sprinklers

determines overlapping wetting area. Discharge rate vary and that determines the time

duration of sprinkler operation to supply water requirement for total area. Daily

irrigation is done during dry period and irrigation duration is determined according to

the water requirement and weather condition.

Drip Irrigation

Drip irrigation is done in a limited area of the nursery, for hanging pots.

Manual watering by baskets Manual watering by hose

Sprinkler irrigation to mother

plants

A sprinkler in the field of

Mike Flora nursery

35

Plate 11: Different irrigation methods practiced in Mike Flora nursery

5.4.2 Fertilizer application

Reductions of nutrients occur in commercial cultivation due to continuous growing

and harvesting and leaching out of nutrients by rainfall and irrigation. Therefore,

continuous supply of macro and micro nutrients is essential for proper growth of

plants and for a quality harvest. There are fertilizer packages for all varieties including

different ratios of macro and micro nutrients according to the requirements of

different plant varieties.

Macro and micro nutrients are supplied in liquid basis for Codiaeum varieties as twice

per week. Micro and macro nutrients are applied using an injector pump. Calcium

nitrate is dissolved in a concentrated solution while all other fertilizers are dissolved

in a separate concentrated solution. Solutions are mixed and pumped by the injector

pump and applied to plants using a rubber hose with a shower. Granular fertilizers are

applied during rainy season.

For Dracaena sanderiana Ca(NO3)2 soluble grade and 21:21:21 (N:P:K) fertilizers

are applied rotationally. For Dracaena godseffiana varieties the croton fertilizer

mixture is applied in same manner. For Cordyline spp. liquid fertilizers are not

applied. But for all above three species (Dracaena sanderiana, Dracaena godseffiana,

Cordyline spp.) and Aglaonema spp. granular fertilizers also applied in 3-week

interval.

Drip irrigation to mother plants

A dripper in a hanging pot of

Scindapsus ‘Marble queen’

36

For hanging pots there is a pre-determined fertilizer application cycle as shown in

Figure 06. Nutrients are more generally applied in available forms within a pH range

of 5.5 - 6.2. Therefore, soil pH is frequently checked by the laboratory. pH level is

adjusted using lime and Dolomite accordingly. pH value of fertilizer solutions should

be within the range of 5.5 - 6.2 while EC of the solution should be maintained less

than 2.

5.4.3 Pest and disease management

Pests and disease management is a very important practice for a commercial nursery

as they are rare crops in large scale especially for export market. Company pays

higher attention on the availability of pest and disease incidences throughout the

whole mother plant stock and also in propagators. Frequent monitoring is done by the

laboratory staff and control measures are taken accordingly. Common pests, their host

plants and particular control measures which are generally practiced by the company

are indicated in Table 05 and Annexure 02 and the most common diseases, their host

plants and control measures are indicated in Table 06 and Annexure 02.

Mites, scale insects, mealy bugs, caterpillars, nematodes, snails and slugs like pests

and several bacterial and fungal diseases are commonly found in this nursery.

Plant starter N: P: K 10:52:10

Ca(NO3)2

S/G

Polyfeed Green

N: P: K

21:21:21

Nitro Plus

N: P: K

30:10:10

Figure 6: Fertilizer cycle for hanging pots

37

Pests Common host plants Control measures

Mites

Two spotted spider mite

Red spider mite Cyclone mite

Codiaeum spp.

Cordyline spp.

Scindapsus spp.

Introduce non-infected plants to the mother plant stock.

Adequate irrigation Frequent checking their

availability and removal of infected plant

Facilitate proper field sanitation Removal of weeds from

surrounding area Application of chemicals using a

power sprayers on underside of leaves

Scales

Aglaonema spp.

Scindapsus spp.

Dracaena sanderiana

Introduction non-infected planting materials for the mother stock

Removal of plants and plants with high infestation

Mealy bugs

Codiaeum spp.

Scindapsus spp.

Introduce non- infected plants in to mother stock

Removal of plants and plant parts with high infestation.

Nematodes

Cordiaeum spp.

Scindapsus spp.

Aglaonema spp.

Dipping of planting materials in a corbofuran® solution prior to planting

Use of Basamid® treated medium for hanging pots

Introducing of nematodes free planting materials in to the mother stock

Incorporation of nematicides to the infected areas (eg; Carbofuran®)

Caterpillars

Leaf eating caterpillars Leaf rolling caterpillars

Cordiaeum spp.

Scindapsus spp.

Frequently checking of plants and removal and destruction of plants and plant parts with higher infection.

Application of recommended insecticides

Slugs and Snails All varieties Collection and removal Maintain field hygiene

Table 5: Common pests, susceptible plants and control measures performed by the company

38

Disease Common host plants Control measures

Pythium infection Cordiaeum spp. Removal of infected plants with

their intact medium

Rhizoctonia leaf

spots

Cordiaeum spp. Removal of infected plants

Fusarium infection Cordiaeum spp.

Dracaena sanderiana

Maintain field sanitation

Application of recommended

fungicides

Scab disease Scindapsus spp. Removal of infected plant parts

Application of recommended

fungicides

Leaf spots Cordyline spp. Removal of infected plants and plant

parts

Dipping of planting materials in

fungicides prior to propagation

Erwinia stem rot &

Erwinia leaf spot

Aglaonema spp. Introduction of non infected

planting materials to the mother

plant stock

Maintain field hygiene

Avoid excess irrigation

Maintain appropriate plant density

Table 6: Common diseases, susceptible plants and control measures performed by the company

39

5.5 Other maintenance activities

Regular maintenance of mother plant stock is needed to have higher productivity

throughout their life time. Pruning, pinching or thumb nailing, Weeding and

replanting are several maintenance practices that are occupied by the company.

5.5.1 Pruning

Pruning is done to get good quality and large number of sprouts, to control the height

of plants in to a harvestable level, to improve the appearance of plants, to remove pest

and disease infected plant parts and to avoid their spread, to facilitate chemical

application, etc. Over matured branches, diseases branches and dead branches are

normally removed in pruning.

5.5.2 Pinching and thumb nailing

Pinching is a kind of pruning method that is practiced to remove apical dominance

and to enhance branching. Removal of apical bud is done by pinching. When

establishing mother plants of Cordiaeum spp. pinching is done in their young stage to

enhance branching.

Plate 12: Pruning and pinching of foliage plants

Pinching of codiaeum sp.

A well pruned cultivation of

codiaeum sp.

40

5.5.3 Weeding

Weeds are destructive due to several reasons. They are competing with plants for

nutrients, water, light and space. They also harbor insects, mites, nematodes plant

pathogens, etc. Other than that, there is a possibility to contaminate harvested plant

parts with weed seeds and create problems in exportation. Therefore it is necessary to

control weeds in commercial cultivation. Company takes high attention to control

weeds in the mother plant stock. Weed control in beds and in hanging pots is done

manually while it is done using weedicides (eg; Gramoxone®) in pathways and among

beds. Generally manual weeding is done monthly. Available mosses on paths are

removed by scraping.

5.5.4 Replanting or redevelopment

Land is one of the limiting factors that determine the extent of mother plant

cultivation. Therefore, it is important to maintain the mother plant stock in their

maximum productivity level. Mother plant stock should be re-established after

economical life span as their further maintenance is not economically beneficial.

Economic life spans of some varieties are given bellow.

Dracaena godseffiana 7-8 years

Dracaena sanderiana 5-6 years

Cordiaeum variegatum 4-5 years

Cordyline compacta 4-5 years

5.5.5 Outside purchasing of planting materials

Major portion of planting materials are obtained from their own mother plant stock.

Small portion of planting material requirement for the field and major portion of the

requirement of canes are supplied by the outside suppliers to the company. Canes of

Polyscias spp., Codiaeum spp., Cordyline ‘purple’ compacta, Dracaena sanderiana,

are several major types of planting materials purchased from the outside suppliers.

Suppliers are paid according to the length of canes.

41

CHAPTER SIX

6. HARVESTING OF FOLIAGE PLANTS

Harvesting of foliage plants is very important practice of foliage plant production.

This activity decides the quality of the export material too. Thus this process should

be well organized and well programmed.

Generally the harvesting is done for main two purposes.

Export as un-rooted cuttings (URC).

For propagation

The cuttings which are exported as URCs are harvested by packing section while the

cuttings which are exported as rooted plants are harvested by harvesting section.

6.1 Considerations at harvesting

As harvesting is a major activity of the foliage plant production many factors are

considered to keep the quality of the harvested plants.

Time of harvesting

Generally most varieties are harvested in the morning. The planting materials which

are harvested for propagation are sent to the propagators before 9.00 am. The planting

materials which are exported as URCs and cut foliages are harvested in early morning

of shipment date.

Maturity of the plant parts

The shoots with acceptable maturity are harvested. If not during propagation plants

show defects in rooting and the URCs are rejected during packaging process.

Quality of the branches

The erect shoots without bends and mal forms of any place are harvested as

URC and also for propagation.

The leaves should consist with required color by the client.

Free from pest and diseases.

The abnormal branches such as crinkled and twisted are not harvested.

Harvesting is done according to the given specifications (Height, number of

leaves per plant or cutting etc. should be matched with given specifications by

the client).

42

Method of harvesting

Method of harvesting is also an important factor which is affecting on the quality of

the harvest. Sharp secateurs are used for harvesting in order to avoid the mechanical

damages on cutting surface. The height of certain cuttings is measured by using a

scaled gauge from the leaf tip avoiding two top most leaves.

Harvesting is done as 2-3 leaves are remained for the mother shoot of the plant to

obtain food for re-growth of plant. The harvested cuttings are collected to the plastic

crates and transported to the harvesting section or to the packing section by trolleys or

two-wheel tractor as soon as possible.

6.2 Harvesting procedure

Harvesting section comprises of separate building for potting and store. Man power

consists of one supervisor and female workers. Harvesting of plants, selecting and

grading, cleaning, dipping or washing, sizing and potting are the duties of workers

while order management, dividing of task among workers, target analysis are some

duties of supervisor. Harvesting is done according to a programme. Harvesting

schedule is supplied weekly to the supervisor and the supervisor’s responsibility is to

plan the harvesting and potting of required plants on time according to the schedule.

Harvestable amount of a variety is determined according to the committed order and

its reject percentage. Workers are supplied targets for all duties of the harvesting

section and all workers are specified to maintain their targets. Targets are varying

according to the variety harvested and their mode of propagation.

Plate 13: Specifications considered at harvesting

43

Harvesting is mainly done from mother plant stocks in the company using a scaled

stick and secateurs. Secateurs must have sharp cutting surfaces to have a sharp cut

surface. Quality cuttings are harvested for propagation and mother plants should be

well grown and free from pests and disease. Harvested cuttings are then collected in

to cleaned plastic crates. Exposure of harvested cuttings to sunlight should be avoided

to avoid excessive evaporation. Crates with harvested materials are transported to

harvesting section as soon as possible. Transportation is facilitated by the cool truck

or the two wheel tractor.

Selection of harvested Scindapsus

‘Lemon lime’ shoots

Insertion of shoot tips of selected

Scindapsus sp. in to oasis pieces

A prepared Scindapsus sp. shoot for

propagation

Plastic crates used for collection of

harvested cuttings

Plate 14: Operations of harvesting section

44

gs

Harvesting

Transportaton

Selecting & Grading

Washing

Sizing

Application of rooting hormones

Potting

Figure 7: Major steps in harvesting and potting of cuttings

45

s

Figure 9: Major steps in harvesting and potting of single nodal cuttings of

Scindapsus spp.

Harvesting of vines

Cutting in to sections

Selecting & grading

insertion in to oasis or potting in net pots

Uprooting of plants

Transpotation

Slecting and cleaning

Cutting of excessive roots

Washing

Sizing

Application of rooting hormones

Potting

Figure 8: Major steps in harvesting and potting of Miscanthus

46

CHAPTER SEVEN

7. PROPAGATION OF FOLIAGE PLANTS

Majority of foliage plants is multiplied by asexual methods while few are multiplied

by sexual methods. In this nursery, palm species are exclusively propagated by seeds.

Plants are propagated for establishment of mother plants and exportation of rooted

plants.

7.1 Sexual propagation

Plants raised from seeds are usually healthy and have a long life; however they take

rather long life to attain a good size for display. This method offers an opportunity to

produce new hybrids.

In Mike Flora nursery Livistona rotundifolia, Veitchia merrillii, etc. like palm

varieties are propagated by seeds. Seeds are sown immediately after the collection as

they trend to loss the viability. The seeds should be collected when fully ripe and

stored, until next planting time, in sealed containers, preferably in desiccators, at low

temperature.

The seeds are bought from outside suppliers. The quality of seeds is highly considered

in order to obtain near 100% germination. Then the ripened seeds are placed in a

plastic barrel and water is added to softener the outer cover of the fruit, which act as

an inhibitor for the germination. The seeds are established inside the propagator and

the propagator is sealed with black color polythene. Because of optimum temperature

and humidity inside the sealed propagator seeds are get germinated. When the plants

grow about up to 10 cm in those are potted in 8 cm diameter plastic cups and when

the character leaves are appeared, transferred to the 10 cm cups and allowed to grow.

47

7.2 Vegetative propagation

Vegetative propagation enables to reproduce plants identical to the parent plant within

a shorter time period. The vegetative propagation is done in order to propagate the

cuttings as planting materials, export as young plants, production of canes for export

etc. In here the plant propagation is done mainly for two purposes.

Establish as mother plants

Export as rooted semi-finished plants