EFM audit

-

Upload

wiwis-arie -

Category

Documents

-

view

212 -

download

0

Transcript of EFM audit

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 1/9

Electronic Gas Measurement Audit

Gary P. Menzel & R.Michael SquyresCoastal Flow Measurement, Inc.

P.O. Box 58965Houston, Texas 77258-8965

18th Annual Measurement Short Course

Acadiana Flow Measurement SocietyApril 29-30

Lafayette, LA

As Electronic Gas Meters (EGM) replace the more traditional chart recorders as the method of recordingand calculating custody transfer volumes in the natural gas industry, it becomes more and more importantto be able to audit the volumes produced by these devices.

Our company has been doing some audits on electronic flow meters since 1984 and currently audit over30 different pipelines at EGM custody transfer stations. Over the twelve month period endingDecember1 1992, we found errors on over 3% of all of these stations audited which were resolved by

agreement between the parties involved. The incidence of error on the BOM stations we audit falls in thesame range as that of the chart recorder stations audited.

We have summarized the types of errors we have found in EGM auditing and these results are listed intable one. Where a category is listed as .00%, it is an error which has occurred in the past but that did notoccur in during the twenty four month period included in the table. Where possible, we have kept thesame code numbers as we use to classify errors found in chart auditing, though in fact the location wherenaany of these occur has moved from the office to the field.

Many of these errors were only found because check metering equipment was installed and used toidentify areas where problems existed. Check metering equipment is one of the best tools available toidentify problems in measurement. Many problems can only be identified and corrected where there is a

properly installed check meter. Even a check recorder installed on the same tube is helphil, though it will

not identify problems with the primary device. Where there is a check meter, the auditor has theadvantage of being able to compare two different sources of measurement and can easily find problemsaffecting only one of the meters. If a complete check meter station exists then the auditor should be ableto identify and correct for most errors that occur. If a check meter does not exist, even ifa problem isidentified, there may be no way to determine a more accurate volume than that originally determined. Toreceive an audit adjustrnent, not only must an error exist. but them has to be a method to calculate a

better answer.

In order to properly audit a measurement station, the auditor needs access to all of the measurement

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 2/9

information concerning the station. This includes the measurement and definitions sections of thecontract, test reports and meter tube inspection reports, gas analyses1 check meter records, original andedited (if any) data from the custody transfer station and any other infornnation that is available about themeasurement station. All of the data available to the original party responsible for the measurementshould be made available to the auditor.

For EGM audits, it is better if the original and edited flow records are provided in electronic format tofacilitate review and recalculation. Since most stations will not have problems, computer tools can beused to identify areas where problems may exist If problems exist, the computer can also be used torecalculate the volumes, if this is the method which gives the best answer. Even though changes to flow

parameters and calibration are logged by the meter, it is a good idea to continue to produce meter testreports independent of the meter event logs. This allows comments to be recorded which may providevaluable insight into measurement problems, especially those not associated with the calibration and

programming of the recorder.

Witness testing is also a valuable contributor to the audit program. A properly conducted witness testeliminates some errors before they happen. snce' the witness should catch most mistakes made by themeter tester. Also, it gives the auditor the resource ofhaving theirown meter technician to call upon with

questions about the meter installation and flow conditions. If samples are pulled it can give the auditor acheck on the gas quality.

Even with the best equipment and personnel, problems will still occur. Equipment will fail, or mistakeswill be made. Auditing is generally the last chance to insure the measurement is being done properly. Itshould also be a tool to identify equipment, procedural and operational problems that are adverselyaffecting measurement sothat they can be corrected. The least that can be expected from an audit

program is that it will improve the overall measurement quality at the cash register of the industry. In theworst case, it can result in millions of dollars of recovered revenue.

Audit Errors

The classes of errors found in auditing have been divided into major categories representing the type oferror.

Orifice Plate

These errors occur at the orifice plate. They will always be present when orifice metering is used. These problems occur more often on EGM stations than on chart recorder stations due in part to the difficulty ofreviewing historical data in the field with many EGM models. If no check meter exists or only a checkrecorder, these errors may be difficult to identify or correct.

101. Orifice Plate Reversed: This condition can sometimes be detected during review, but variable flowrates and other factors may mask this condition. Usually this condition is noted, when found, on themeter test report If no properly recording check meter station exists. This condition can be corrected for

by establishing a ratio of the indicted flow with the plate properly installed to that with the plate in backwards. This ratio may change slightly over the flowing range. If the flow is steady enough, thisestimate can be made from the flows before and after the plate was installed improperly and when the

problem was fixed. Care must be taken to allow for pressure build up, if the flow is shut-in while the p!ate inspection is being made. It may be necessary to conduct tests with the plate installed properly and

backwards to establish this ratio after the fact This problem can easily account for 20% or more of flow.

102. Out of Beta Ratio: The only thing that can be said about this condition is avoid it, or be prepared toget your volumes somewhere else. because answers computed from such sources are generallyunreliable. However, if it is a choice of accepting a plate that is below the minimum recommereded, or of

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 3/9

not properly measuring the flow due to low differential, then the smaller plate is better. Better still wouldbe to change the differential transducer to a lower range. Unless the check meter is a different tube id,here is probably no way to get an adjustment where this problem exists, only fix the problem.

103. Damaged Plate: The plate is nicked, dished, dulled or otherwise damaged. Usually this does not

affect the indicated flow to a noticeable extent This is true beeause the plat6s are replaced when there isonly minor damage and should not be used Man excuse not to replace damaged plates. Occasionally theplate is so damaged that an adjustment is required. This can be made in a similar manner to a backwardsplate. Damaged plates should not be disposed of before it is determined that no adjustment is required. Ifhe plate is severely nicked, then the orientation of the plate should be noted, if possible.

104. Dirty Plate: This is a sneaky problem which can happen so slowly that it will not be detected bymerely observing the recorded flow. Also it cannot be verified that this is the problem unless there is aest repon or other documentation that indicates the plate was found dirty and was cleaned. Even then, it

may not be possible to properly calculate an adjustment without a check meter, since this problem willchange over time as the dirt or other material builds up on the plate and meter tube. A check meter mustbe tested to verify that it does not suffer from the same problem. If this problem is found repeatedly, theubes will probably need to be inspected for build up as well.

105. Plate Too Large: This problem results in the flow, or much of the flow being called zero by themeter due to its low differential cut-off. This is a point, below which the EGM meter will call alldifferential zero so as to not attribute flow to periods of no flow. The meter may have no other data forhese periods of lower flow rate. For this reason check meters are essential 10 distinguish between these

periods and periods of actual no flow. Also the measurement where the meter is recording flow, is notasgood as it would be further up in the meter range. As an EGM device offers additional information andherefore advantages as a check meter to a chart recorder station, so a chart recorder will offer additionalnformation and therefore advantages Macheck meter to an HOM station. One of these advantages is that

a chart recorder will record the differential at zero. Many SCM devices have a low flow alarm wbich canbe set above the low differential cut-off. This alarm can be usedto determine when a plate change isequired; If most of the flow has the low flow alarm condition then the plate is too large and a plate

change may need to be made.

106. Plate Too Small: This problem results in the meter operating above its calibrated range. Theransducer will have a maximum possible differential and will not record above that point. Most EGMs

have a high differential alarm which can give an indication that this problem might be occurring. Somealso have an alarm which tells you when the stop at the top is reached. If these conditions are occurringand no low-flow alarms are occurring then a plate change needs to be made. If both low and high alarmsare occurring then whether a plate change needs to be made or not depend upon the percent of time eachs occurring and where the alarm points are set. In fact the plate may be prpperly sized to measure the

flow as accurately as possible with the existing plate during normal flow conditions. If the meter isoverranged and the check meter does not have a larger plate, then no adjustment may be possible.Sometimes an adjustment can be made by estimating the flow rate at the rate after a plate change wasmade, but only if the meter is still flowing at a similar rate.

107. Plate Missing : Fortunately rare. Either there was no plate installed, or the plate was left in the upperchamber of a "Senior" type fitting during inspection.

Meter Problems

204. Calibration: If the meter is found out of calibration by greater than the contractual amount at theflowing conditions then the volume it calculated needs to be corrected, usually half way back to thepreceding calibration test especially on EGM devices which are usually off on zero. If a check meterexists it maybe possible to more closely determine when the problem occurred. It may also be possible todetermine when the problem occurred by looking at alarm conditions if the problem is severe enough.

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 4/9

Calibration is usually the only tolerance addressed in the measurement contract. This contractualolerance which is usually two percent, should be lowered for EGM devices since they are supposed to

have much better tolerances for calibration. For BOM stations this error includes the error in zero whichs listed as a separate error for chart recorders. . On some of the meters when the meter shuts itself down

due to low power in order to preserve the data it has already taken, it will lose calibration. If it is brought

back on and not recalibrated, its calibration may be wildly off until it is recalibrated.

207. Meter Out of Service: The meter manifold valves were left closed, the equalization valve was leftopen, or the meter tube was left totally or partially bypassed. This problem is normally only identifiablewith a proper check meter, & if it is noted on a field test. If no check meter exists, the volume needs to beestimated from periods where the meter was in service. Well meters may be used, even if not up tocustody transfer standards, to identify flow rate changes and down time.

208. Overranging: Of course, for the period when the overranging occurs, the plate is too small, buterrors are placed in this category only when the plate is correctly sized and the overranging is forelatively short periods, usually occurring after periods of down time, or as the result of brief and

unpredictable surges. Corrections can be made for this condition only where another source ofmeasurement exists which is not overranging. If the problem recurs, operational changes may need to bemade.

Data Entry Errors

This category of errors includes incorrect data, entered either into the EGM device itself by fieldpersonnel with failure to correct for it in the office or entry of incorect data in the office resulting inerroneous corrections. This problem is usually a maner of not entering the correct data rather thanentering incorrect data.

403. Wrong Plate Size: Usually a plate change was skipped or incorrectly entered. Seldom is it a casehat the wrong plate size was entered. The data can usually be racalculated using the proper plate size.

405. Wrong Specific Gravity: This is usually a failure to use the most current specific gravity. It may alsobe the failure to correct in the office for an estimated specific gravity used in the field. This problem isespecially likely when a new meter is placed in service since it may be some time before a routinesample is taken.

408. Reported Wrong Volume: This represents the cases where the volume was not supposed to havebeen changed, but somewhere in transferring it from the EGM to the final gas accounting statementsomething was changed. This can occur due to a bug in the software or hardware. It may also he due to aprocedural error on the part of any of the people translerring the data.

EGM Errors

This class of errors are those unique to the EGM devices. Though similar errors may occur on chartecorders, the correspondence is not exact. These are listed out of order in the text to preserve continuity

with the errors found for chart recorders.

601. Bad Transducer: These errors nesult when the transducer fails either partially or completely. orwhere it exhibits excessive calibration drift If no check meter exists then estimates may have to be madeusing flow from before and after the problem occurred. The transducer should he replaced if this has notalraady been done.

602. Calibration Zero is off, Leak During Test: This represents a leak in the test equipment or manifoldesulting in a high or low zero on the meter being used to set its zero point at working pressure. A similar

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 5/9

problem can occur if the taps an left open to the flow line while the pressure is being tested if pulsationexists due to gage line error. In this latter case, it may further exaggerate the measurement errors due tohe presence of pulsation.

603. Calculation Methodology: This represents errors from recalculating the volume on separate

computers, usually related to not carrying enough precision in the transferred data or from not calculatingor recalculating using the proper factors.

604. Missing Data: Either data was not collected before it vanished from the field device or it was lost inransmission to the office or once it reached the office. No estimate was made for the missing data inhese cases. Care must be taken in designing a downstream processing system so that missing data isdentified and cannot be mistaken for no flow records. Thene should be some backup method fordentifying and collecting missing data before it disappears from the meter.

605. Data Deleted: A decision was made that the data presented by the meter was false flow and this datawas deleted. Unless precise production records are kept or check meters are available, it rnay bempossible to prove that this data represents valid flow.

606. Set Up Factors Incorrect: The original programming of the EGM was incorrect when it was placedn service or these factors were changed incorrectly at some point after the meter was installed. Thiisncludes setting it up as an incorrect transducer range or tube I. D. or incorrectly specifying included or

excluded factors.

607. Bad Board: The electronics in the meter failed and no corrections wern made. This problem may bendistinguishable from missing data.

608. Dead Battery: The battery ran out of charge and the meter shut itself down for low power. Noestimate was made for the time during which the meter was not recording. Upon restatting the meter, itshould be recalibrated as some meters lose their calibrating during a low power time-out

609. Not Resetting Volume After Plate Change: When a plate change is made, care must be taken that

he meter begins calculating wing the new plate size immediately after the meter is put back in service.Otherwise the meter may calculate for the remainder of the hour, using the new differential but the oldplate size.

610. Zero Cut-Off Set Incorectly: If the zero cut-off point is set too high it will call all or part of the flow,no-flow. We believe that the tern cut-off should be set only to account for transducer drift, if that, andhat other problems which cause a false differential during no flow should be corrected by zeroing them

out in the office. Because most BUMS make no record of the differential during periods below the lowzero cut-off, data is lost by setting it higher than absolutely nccessary

611. Meter Zeroed During Test: During most tests the EGM should be locked in to its prior readingbefore the manifold valves are equalized to test the meter. If the flow must be shut in during a portion ofhe test- the meter should be locked in at zero only for that time.

Miscellaneous

501. Meter Freeze: A very common problem. Though most frequent in winter, it can occur any time thephysical conditions for hydrate formation are present. These conditions may be a temperatures up toabout seventy degrees. and may occur regardless of flowing temperature, since the meter manifold andeads have no flow through them. The error may be the result of incorrect estimates for the affected

periods. or ofsimply failing to attribute any volume for those periods. However it is also likely that thecondition was not recognized and no correction to the original erroneous volume was made when this

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 6/9

condition occurs on an BUM station. Without knowledge of the flowing conditions andlor a check meter.t may be impossible to determine that this condition even exists. A check meter is likely to freeze during

similar time periods. but ifit is recording different from the sales meter, it indicates that a problem exists.

502. Leaks: The leak could be at the seal ring or meter or somewhere in the upstream section of the

custody transfer equipment. Depending upon the site of the leak. it can remain undetected for longperiods. unless them is another sounce of measurement for comparison.

503. Fluids: The meter should not have its low zero cut-off raised to account for fluids since this willhave the effect of calling any low flow rate zero and it prevents themeter from recording the flow -metersduring these times. Instead, any false flow created by liquids should be eliminated in the office. Also, ifpossible, the conditions causing liquids to become trapped in the manifold or tubing should be rectifiedn the field. This category represents cases in which false flow due to fluid was not zeroed out and also

cases where real flow was erroneously attributed as false flow due to fluids.

505. Incorrect Estimate: These are erroneous estimates. Sometimes these were the best estimates possiblewith the in-formation available to the original party and sometimes false assumptions were used to makehese estimates. This category shows that at least this data was reviewed and some effort was made to

correct a problem. There is an all to common tendency to sul:oose that if the BUM indicates a volume, itdoes not need to be reviewed for measurement errors.

These then are some of the areas in which to look for errors in BUM auditing. The data presented forEGM audit must enable the auditor to find these errors and make a reasonable estimate for their effect Todo this, original, unedited values recorded by the SCM device should be presented in a format that willenable the auditor to review the data and make recalculations on a computer the same as the originalparty responsible for measurement In addition the anditor should have copies oftest reports onhemeterandtheatiditingparty should witness these tests. This isa must, since now not just recording of

mw data, but all of the factors involved in measurement are done in the field. The witness should alsocollect enough data from the field unit to venfy that any changes made to the data downstaeam areogged as being changed. The auditor should also ohtain any check meter records which pertain to the

station or even line balance information ifthat is all that is available. The auditor should receive a copy ofhe final gas accounting statement showing the custody transfer volumes. Finally, if any changes were

made between the EGM data and the final statement then the auditor should receive a description of thechanges made and the reasons for those changes.

There will always be errors, both simple mistakes and errors of judgment in any measurement. At firstook you would expect to see many fewer errors using BUM since many areas of human judgment have

been eliminated. However, this has not been our experience. The incidence of error found on SCM auditshas been about the same as that found in conventional chart audits. Some of this can be attributed to theearning curve involved with using this new, more sophisticated equipment. Some, unfortunately, can be

attributed to the tendency of people to think that if a computer says its right then it is and does not needo be reviewed. Computers malfunction the same as other equipment and the answer a working computer

gives is only as good as its programming and data.

Another reason for error which is common to all measurement departments is a lack of time to fully

esearch a problem. The auditor will allways have the advantage of being able to spend more time on aproblem to find the right answer and will usually have access to more information. These reasons, plussimple human error, insure that regardless of the technology, there will always be a need to audit.

The following is a partial outline of a typical EGM audit

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 7/9

1. Verify Station Set-Up Information

1. Station name

2. Station number

3. Meertype

4. How is information provided5. Contract terms

1. Pressure and BTU base

2. Calibration Tolerance

3. Test Frequency

4. Contract day and hour

5. Calculation methodology

2. Verify receipt of data

1. Hourly History

2. Events

3. Alarms

4. Current characteristics

5. Analysis data

6. Final GM Volume Statement

7. Reconciliation report

8. Field test report(s)

9. Any other data for station

3. Check meter information

4. Verify that data meets contract terms

1. Base conditions

2. Contract day and hour

3. Test frequency

4. Calculation methodology

5. Test Report data1. Previous test report

2. Current test report

3. Following test report

4. Any calibration adjustments required

5. Were they applied correctly?

6. Is the test frequency per contract

6. Analyze data

1. Previous analysis

2. Current analysis

3. Was it applied properly?

4. Was it a bad sample?

7. Characteristics

1. Verify current characteristics

2. Back calculate each characteristic

3. Check back calculated characteristics versus test reports and last months characteristics

4. Calculate coefficients for each characteristic and verify flow rates calculated

8. Alarm

1. Review alarm settings

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 8/9

2. Review alarm histories

9. Review flow data

1. Freeze

2. Liquids

3. Other

4. Is low flow cutoff set properly

5. Is plate sized properly

6. Cornpare to check meter

10. Document findings

Coastal Flow Measurement, Inc.

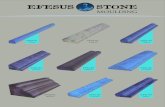

TABLE 1Classification of Measurement Errors for EGM Stations

Code Orifice Plate Percent

101 Orifice Plate Reversed .00

102 Out of Beta Ratio .00

103 Damaged Plate 1.40

104 Dirty Plate .00

105 Plate Too Large 8.39

106 Plate Too Small 3.50

107 Plate Missing .00

Subtotal 13.29

Orifice Meter

204 Calibration 11.89

207 Meter Out of Service 2.80

208 Overranging 6.99

Subtotal 23.68

Data Entry Errors

403 Wrong Plate Sir .70

405 Wrong Specific Gravity 18.18

408 Reported Wrong Volume 4.19

Subtotal 23.07

EGM Errors

601 Bad Transducer .70

602 Calibration Zero Off - Leak During Test .00

603 Calculation Methodology 6.99

604 Missing Data 3.50

605 Data Deleted 4.19

Electronic Gas Measurement Audit - ... P

p://www.afms.org/scourse/97sc2.htm 08/03/2010 7:09:0

8/22/2019 EFM audit

http://slidepdf.com/reader/full/efm-audit 9/9

[ Electronic Flow Measurement ] [ Gas Measurement ] [ LiquidMeasurement ] [ Regulatory Issues ]

[ Sampling / Chromatography ] [ Web Sites ] [ Miscellaneous ] [ NewsArchives ]

[ News ] [ History ] [ Contact ] [ Library ][ Forum ] [ Search ] [ Sponsor ]

1999,98 Net-Step Media, LLC. All rights reserved.Web Design by Net-Step Media, LLC.

E-mail us your thoughts or suggestions.

606 Set Up Factors Incorrect 2.10

607 Bad Board 2.10

608 Dead Battery .00

609 Not Resetting Volume After Plate Change .00

610 Zero Cut-Off Set lncorrectly .00611 Meter Zeroed During Test .00

Subtotal 19.58

Miscellaneous

501 Meter Freeze 4.20

502 Leaks .00

503 Fluids 15.38

505 Incorrect Estimate 2.80

Subtotal 22.38

Total 100.00

Electronic Gas Measurement Audit - ... P