Drawing Document

description

Transcript of Drawing Document

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

Paul Dolan

Athlone IT, Wastewater Treatment Facility

Drawing Schedule

FK LM JC

03/04/2013 N/A13_AD_001

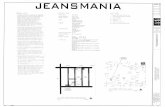

DRAWING SCHEDULE

CLIENT: PAUL DOLAN

PROJECT: ATHLONE IT WASTEWATER TREATMENT FACILITY

DRAWING TITLE DRAWING NO. REVISION NO. DATE

DRAWING SCHEDULE

13_AD_001 03/04/2013

GENERAL NOTES

13_AD_002 03/04/2013

SITE LOCATION MAP

13_AD_003 03/04/2013

WWT FACILITY LAYOUT

13_AD_004 19/04/2013

WWT FACILITY PROCESS DIAGRAM

13_AD_005 03/04/2013

INLET WORKS AND ANCILLARIES

13_AD_006 03/04/2013

PRIMARY SETTLEMENT TANK

13_AD_007 15/04/2013

TREATMENT UNIT

13_AD_008 03/04/2013

SEWER NETWORK

13_AD_009 03/04/2013

SEWER PIPELINE SECTIONS

13_AD_010 12/04/2013

SEWER NETWORK STRUCTURES

13_AD_011 03/04/2013

DRAWING NO. EXPLANATORY NOTES

13_AD_000

YEAR IN WHICH DRAWING WAS FIRST DRAFTED

CORRESPONDS TO THE CONTRACT NUMBER FOR THE GIVEN YEAR

CORRESPONDS TO THE CONTRACT STAGE

D = DESIGN STAGE

T = TENDER STAGE

C = CONSTRUCTION STAGE

A = AS BUILT (CLOSING STAGE)

UNIQUE DRAWING I.D. NUMBER

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

GENERAL NOTES

1 STRUCTURAL DRAWINGS TO BE READ IN CONJUNCTION WITH STRUCTURAL

SPECIFICATIONS, ALL ARCHITECTURAL AND SERVICES DRAWINGS AND

SPECIFICATIONS.

2 THE CONTRACT STRUCTURAL DRAWINGS AND SPECIFICATIONS REPRESENT

THE FINISHED STRUCTURE. THEY DO NOT INDICATE THE METHOD OF

CONSTRUCTION. THE CONTRACTOR SHALL PROVIDE ALL MEASURES NECESSARY

TO PROTECT THE STRUCTURE DURING CONSTRUCTION. SUCH MEASURES SHALL

INCLUDE, BUT NOT BE LIMITED TO BRACING, SHORING OF LOADS DUE TO

CONSTRUCTION EQUIPMENT, ETC. BEFORE RELATED WORK COMMENCES THE

CONTRACTOR SHALL SUBMIT A METHOD STATEMENT AND SEQUENCE OF WORK

TO THE ENGINEER AND ARCHITECT.

3 THE CONTRACTOR SHALL VERIFY ALL DIMENSIONS AND ELEVATIONS WITH

ARCHITECTURAL DRAWINGS PRIOR TO START OF CONSTRUCTION. ALL

DISCREPANCIES TO BE NOTIFIED, IN WRITING TO ENGINEERS AND ARCHITECTS

FOR RESOLUTION.

4 CONSTRUCTION MATERIAL SHALL BE SPREAD OUT IF PLACED ON FRAMED

FLOORS OR ROOF, IN SUCH A MANNER THAT THE STRUCTURE IS NOT

OVERLOADED IN EITHER THE PERMANENT OR TEMPORARY CONDITION WHERE

REFERENCE IS MADE TO VARIOUS TEST STANDARDS FOR MATERIALS, SUCH

STANDARDS SHALL BE THE LATEST EDITION AND/OR ADDENDUM. OTHER

STANDARDS MAY BE CONSIDERED BUT ONLY WITH PRIOR APPROVAL BY THE

ENGINEER.

5 CONTRACTOR TO ESTABLISH AND VERIFY ALL OPENINGS AND INSERTS FOR

ARCHITECTURAL, MECHANICAL, ELECTRICAL AND PLUMBING WITH APPROPRIATE

TRADES, DRAWINGS AND SUBCONTRACTORS PRIOR TO CONSTRUCTION.

6 OPTIONS ARE FOR CONTRACTORS CONVENIENCE. HE SHALL BE RESPONSIBLE

FOR ALL CHANGES NECESSARY IF HE CHOOSES AN OPTION AND HE SHALL

COORDINATE ALL DETAILS.

7 ALL DIMENSIONS ON DRAWINGS ARE IN MILLIMETERS UNLESS OTHERWISE

NOTED. WRITTEN DIMENSIONS ONLY APPLY. DRAWINGS ARE NOT TO BE SCALED.

8 FOR CLARITY, ALL ROOF AND FLOOR OPENINGS MAY NOT BE SHOWN ON

FRAMING PLANS. FOR EXACT SIZE, NUMBER AND LOCATION FOR OPENING, SEE

ARCHITECTURAL, MECHANICAL, ELECTRICAL AND PLUMBING DRAWINGS. WHERE

OPENINGS ARE INDICATED ON THE STRUCTURAL DRAWINGS, THESE ARE TO BE

CHECKED BY THE CONTRACTOR AGAINST RELEVANT SERVICE ENGINEERS OR

SUBCONTRACTORS DRAWINGS PRIOR TO CONSTRUCTION.

9 ALL LEVELS ARE RELATED TO AN ARBITARY DATUM

10 FOR LOCATION AND DETAILS OF ELECTRICAL EARTHING OF STRUCTURE REFER

TO ELECTRICAL DRAWINGS AND DETAILS.

11 FOR FIRE PROOFING REQUIREMENTS REFER TO RELEVANT ARCHITECTS DRAWINGS

AND RELEVANT FIRE SAFETY CERTIFICATE DRAWINGS.

12 ALL DPMs, DPCs, CAVITY WALL DRAINAGE, INTERNAL DRAINAGE, RADON

PROTECTION BARRIERS AND SUMPS, ETC. TO ARCHITECTS SPECIFICATION &

DETAILS.

MASONRY

1 MASONRY CONSTRUCTION SHALL CONFORM WITH IS325 AND BS 5628.

BLOCKS SHALL BE CONCRETE MASONRY UNITS CONFORMING TO BS

6073. SAND FOR MORTAR SHALL COMPLY WITH BS 1200. CEMENT

SHALL BE ORDINARY PORTLAND CEMENT TO IS1 OR BS12.

2 BLOCKS FOR RISING WALLS SHALL BE SOLID UNITS. BLOCK SIZES

FOR OTHER AREAS SHALL BE AS INDICATED ON DRAWINGS OR

SPECIFICATIONS. JOINT THICKNESS SHALL BE 10mm.

3 THE CHARACTERISTIC COMPRESSIVE STRENGTH OF THE BLOCKS

SHALL BE 5MPA UNLESS NOTED OTHERWISE. BLOCKS SHALL BE

TESTED AT A RATE OF 5 PER 1000 BY AN INDEPENDENT TESTING

AGENCY.

4 MORTAR SHALL COMPLY WITH THE MIX DESIGNATED FOR GRADE (III)

GIVEN IN TABLE 1, IS325, PART 1 UNLESS OTHERWISE STATED ON

DRAWINGS. MORTAR TESTING SHALL BE IN ACCORDANCE WITH BS

5628, APPENDIX A.1.

5 BED JOINT REINFORCEMENT WHERE REQUIRED SHALL BE

"BRICKFORCE REINFORCEMENT" BY BRC BUILDING PRODUCTS OR

SIMILAR APPROVED. BED JOINT REINFORCEMENT SHALL BE PROVIDED

IN ACCORDANCE WITH THE TYPE, SIZE AND SPACING INDICATED ON

THE DRAWINGS. IT SHALL BE IN STAINLESS STEEL GRADE 304,

UNLESS NOTED OTHERWISE ON THE DRAWINGS.

6 RISING WALL INTERSECTIONS SHALL BE TIED TOGETHER IN A MASONRY

BOND. OTHER WALLS SHALL BE TIED IN MASONRY BOND AT

CORNERS UNLESS NOTED OTHERWISE ON DRAWINGS. ALL BLOCKWORK

ADJACENT TO CONCRETE WALLS TO BE TIED TO CONCRETE USING

WALL TIES COMPLYING WITH 7. BELOW

7 CAVITY WALL TIES SHALL BE STAINLESS STEEL TYPE 1 TIES IN

ACCORDANCE WITH BS DD140 UNLESS OTHERWISE NOTED ON

DRAWINGS. TIES SHALL BE SPACED IN ACCORDANCE WITH THE

SPECIFICATION AND IS325, PART 1.

8 FOR MASONRY CONSTRUCTION DURING COLD WEATHER REFER TO

THE SPECIFICATIONS AND THE PROVISIONS OF BS 5628.

9 ALL RISING WALLS SHALL BE LAID WITH FULL MORTAR COVERAGE ON

HORIZONTAL AND VERTICAL FACES.

10 THE CONTRACTOR SHALL BE RESPONSIBLE FOR SHORING AND

BRACING OF ALL MASONRY WALLS AS NECESSARY TO ENSURE

STABILITY DURING CONSTRUCTION. SUCH SHORING AND BRACING

SHALL BE MAINTAINED IN POSITION UNTIL THE MASONRY HAS

ATTAINED ITS DESIGN STRENGTH AND THE RESTRAINING

SUPPORT STRUCTURE IS IN PLACE.

11 BACK FILL SHALL NOT BE PLACED AGAINST WALLS WITHIN 10 DAYS

OF COMPLETION OF THE WALL. THE MAXIMUM LEVEL DIFFERENCE

BETWEEN BACK FILL ON EITHER SIDE OF A MASONRY WALL SHALL

BE 225mm. HEAVY EQUIPMENT USED IN BACK FILLING SHALL NOT

OPERATE CLOSER TO THE WALL THEN A DISTANCE EQUAL TO THE

HEIGHT OF THE BACK FILL ABOVE THE FOOTING.

12 REQUIREMENTS FOR REINFORCED MASONRY :

*CONCRETE FOR FILLING CORES OR EMBEDDING

REINFORCING BARS SHALL BE C30/37 XC4 CL-0.4 UNLESS NOTED

OTHERWISE ON DRAWINGS.

*MAXIMUM AGGREGATE SIZE 10mm.

*VERTICAL BAR REINFORCEMENT SHALL BE SECURED IN

POSITION

*CAVITIES CONTAINING REINFORCEMENT SHALL BE COMPLETELY

FILLED WITH CONCRETE AND CLEANED OUT OPENINGS SHALL BE

PROVIDED AT THE BASE OF VERTICAL CORES.

13 FOR LINTEL DETAILS REFER TO PROJECT DETAIL DRAWINGS,

MANUFACTURERS SPECIFICATION AND ORS MASONRY SPECIFICATION.

14 REFER TO ARCHITECTS DRAWING FOR DETAILS OF SETTING OUT TO

MASONRY WALLS.

15 REINFORCED U-BLOCK TO BE PROVIDED AT CILL LEVEL OF ALL

WINDOW OPES.

INSPECTIONS

ENGINEER'S APPROVAL WILL BE REQUIRED BEFORE PROCEEDING

FURTHER AT EACH OF THE FOLLOWING STAGES. IN EACH CASE, THE

CONTRACTOR SHALL PROVIDE A MINIMUM OF 48 HOURS NOTICE TO

THE ENGINEER FOR INSPECTION.

1. WHEN THE SUBGRADE HAS BEEN EXPOSED

2. WHEN THE REINFORCEMENT HAS BEEN FIXED, CHECKED AND IS

READY FOR CONCRETING.

3. BEFORE TAKING REMEDIAL ACTION TO CORRECT IMPERFECTIONS IN

CONCRETE.

4. BEFORE FINISH PAINTING STEEL FRAMEWORKS.

5. BEFORE GROUTING-IN STEEL FRAMEWORKS.

6. BEFORE SHEETING OR BRICKING IN STEEL FRAMEWORKS.

REINFORCED CONCRETE

1 CONCRETE CONSTRUCTION SHALL BE IN ACCORDANCE WITH BS EN 1992.

CEMENT SHALL BE ORDINARY PORTLAND CEMENT COMPLYING WITH IS EN

197 UNLESS OTHERWISE APPROVED. REINFORCEMENT SHALL BE HOT

ROLLED DEFORMED BARS COMPLYING WITH BS 8866. ALL HIGH YIELD

BARS SHALL BE DEFORMED BARS TYPE 2. STEEL FABRIC SHALL

COMPLY WITH BS 4483.

2 ALL CONCRETE SHALL BE IN ACCORDANCE WITH IS EN 206-1.

3 NOMINAL CONCRETE COVER TO REINFORCEMENT SHALL BE AS FOLLOWS

UNLESS OTHERWISE NOTED ON DRAWINGS :

*SURFACE POURED AGAINST EARTH, 75mm

*SURFACE POURED AGAINST FORMWORK 30mm

*BUT IN CONTACT WITH EARTH 50mm

*BEAMS, COLUMN, WALLS 35mm

*SLABS 30mm

4 CONCRETE BLINDING SHALL BE (C12/15) X0. ALL OTHER CONCRETE

SHALL BE C30/37 XC4 CL-0.4

5 FOR CONCRETING IN COLD WEATHER REFER TO THE CONCRETE

SPECIFICATION AND TO THE PROVISIONS OF BS 8110.

6 FOR POSITIONING AND TREATMENT OF CONSTRUCTION JOINTS PROPOSALS

SHALL BE SUBMITTED TO THE ENGINEER FOR REVIEW PRIOR TO

CONSTRUCTION.

7 MOVEMENT JOINT FILLER SHALL BE A COMPRESSIBLE FIBRE BOARD

SUCH AS HYDROCELL XL BY FOSROC INTERNATIONAL OR SIMILAR

APPROVED.

8 MOVEMENT JOINT SEALANT SHALL BE A TWO PART POLYSULPHIDE SEALANT

SUCH AS THIOFLEX 600 BY FOSROC INTERNATIONAL OR AN APPROVED

EQUAL, UNLESS NOTED OTHERWISE.

9 CONCRETE VERTICAL SURFACES ADJOINING MASONRY WALLS SHALL BE

CAST WITH A CONTINUOUS STAINLESS STEEL PROPRIETARY CHANNEL BY

ANCON CCL OR SIMILAR APPROVED.

10 CONCRETE CUBES SHALL BE TAKEN AT A RATE IN ACCORDANCE WITH

THE SPECIFICATION, WITH A MINIMUM OF ONE SET PER DAY PER CLASS

OF CONCRETE. CUBES SHALL BE TESTED AT 7 AND 28 DAYS. ALL THE

RESULTS SHALL BE FORWARDED DIRECTLY TO THE ENGINEER

11 ALL SAMPLING AND TESTING OF CONCRETE TO COMPLY WITH IS EN

12350 AND IS EN 12390.

12 CORE DRILLING OF ANY REINFORCED CONCRETE ELEMENTS OF THE WORK

SHALL NOT BE ALLOWED WITHOUT THE PRIOR WRITTEN APPROVAL OF

THE ENGINEER.

13 150mm KICKERS ARE TO BE UTILISED FOR ALL RISING ELEMENTS.

14 REINFORCEMENT BAR NOTATION:

DIRECTION OF SPAN OF

200 DEEP FLOOR SLAB

GENERAL NOTATION

200 PC

H/CORE

RISING CONCRETE OUTLINES

HIDDEN CONCRETE OUTLINES

VOID IN CONCRETE

1

556

DETAILED SECTION 1-1 SHOWN

ON DRAWING 061_127-556

STRUCTURAL STEEL BEAM ON PLAN

DIRECTION OF SPAN OF FLOOR DECK

RISING BLOCKWORK

T2 - BOTTOM LAYER OF TOP REINFORCEMENT

T1 - TOP LAYER OF TOP REINFORCEMENT

B - BOTTOM

B1 - BOTTOM LAYER OF BOTTOM REINFORCEMENT

B2 - TOP LAYER OF BOTTOM REINFORCEMENT

T - TOP BARS

EF - EACH FACE

N1 - OUTER LAYER OF NEAR FACE

N2 - INNER LAYER OF NEAR FACE

F1 - OUTER LAYER OF FAR FACE

F2 - INNER LAYER OF FAR FACE

ABR - ALTERNATE BARS REVERSED

SFL - STRUCTURAL FLOOR LEVEL

TOC - TOP LEVEL OF STRUCTURAL CONCRETE

FFL - FINISHED FLOOR LEVEL

T.O.S - TOP OF STEEL

RC - REINFORCED CONCRETE

PC - PRE-CAST

BM. - BEAM/S

COL - COLUMN/S

CONC. - CONCRETE

C - CENTRE LINE

B - EXTENT OF EXISTING STRUCTURE

- APPROXIMATELY EQUAL TO

UNO - UNLESS NOTED OTHERWISE

FOUNDATIONS

1 FOR LEVELS TO TOP OF ALL FOUNDATIONS REFER TO

FOUNDATION LAYOUT DRAWING & SECTIONS THEREOF. THE

EXCAVATION SHOULD BE TAKEN TO THE STIFF BROWN

GRAVELLY CLAY, WHICH HAS AN ALLOWABLE BEARING

CAPACITY OF 200 Kn/m2.

THIS LAYER IS APPROXIMATELY 2.5-3.5 METRES BELOW

EXISTING GROUND LEVEL. THIS IS REQUIRED UNDER ALL PADS

AND STRIPS AND BACKFILLED WITH LEAN MIX CONCRETE.

2 CONCRETE BLINDING SHALL BE PROVIDED UNDER ALL

FOUNDATIONS TO A MINIMUM THICKNESS OF 75mm. EXCAVATED

SURFACES SHALL BE FREE OF LOOSE MATERIAL, DRY AND

BLINDED AS SOON AS POSSIBLE AFTER INSPECTION OF

BEARING SURFACES BY THE ENGINEER.

3 FOUNDATIONS TO BE CENTERED UNDER WALLS UNLESS NOTED

OTHERWISE ON THE DRAWINGS.

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

I:\cover pic.jpg

G1 Schemedesign Consulting EngineersLtd.

Paul Dolan

Athlone IT Wastewater Treatment Facility

GENERAL NOTES

LM FK

03/04/2013 N/A13_AD_002

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

Paul Dolan

Athlone IT Wastewater Treatment Facility

Site Location Map

FK LM JC

03/04/2013 1:125013_AD_003

PR

OD

UC

ED

B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

Skip

Screenings

Feed Reactor

Discharge Reactor

Primary Settlement Tank

Cover Level 98.0m

Invert Level 95.5m

Influent Collection MH 122

Invert level 99.070m

Inlet Works

Pipe Invert Level 97.94m

Effluent Discharge MH 111

Invert level 97.162m

Buffer Tank

Cover Level 98.0m

Invert Level 95.5m

Municipal Discharge MH 131

Invert level 96.528m

Back Drop MH 112

Invert level 94.484m

Pumping Station

Invert level 89.415m

Invert level 92.869m

Invert level 96.520m

Treatment unit - Pumped Flow Bio-film Reactor

Cover Level 98.0m

Invert Level 96.0m

Direction of Flow

Hydraulic Flow

Pumped Flow

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

Paul Dolan

Athlone IT Wastewater Treatment Facility

WWT Facility Process Diagram

FK JC LM

03/04/2013 N/A13_AD_005 0000

Athlone IT Wasrewater Treatment Facility - Process Diagram

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

Flow

Overflow pipe

Overflow channel

Flow

Flow

Overflow pipe

Flow

Screenings

Skip

Screenings

Augar housing

Ground Level

Inlet Works

Pipe Invert Level 97.94m

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

Paul Dolan

Athlone IT Wastewater Treatment Facility

Inlet Works and Ancillaries

FK LM JC

03/04/2013 1:2013_AD_006 0000

Treatment Unit Elevational Section

Treatment Unit Elevation

Treatment Unit Elevation

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

FO

RM

N

O F

RM

-0

10

RE

VIS

IO

N 1

RE

VIS

IO

N D

AT

E 0

5/1

2/1

1

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

PAUL DOLAN

AIT WASTEWATER TREATMENT FACILITYPROCESS STAGE

PRIMARY SETTLING TANKSTEEL REINFORCEMENT DETAILS

LM JC

15/04/201313_AD_007

DRAFT G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

Primary Settlement Tank

Buffer Tank

Feed Reactor

Discharge Reactor

Discharge

Manhole

Inlet Pipe

Dry Well Mounted Pump to take effluent

from Discharge Reactor to Feed Reactor

or Discharge Manhole

Dry Well Mounted Pump to take

effluent from Feed Reactor to

Discharge Reactor

Dry Well Mounted Pump to take effluent

from the Buffer Tank to the Feed Reactor

Dry Well Mounted Pump to take Sludge

from the Reactor Tanks to the Screening

Manhole

Note: Primary settlement and buffer tank

details can be seen in drawing

13_AD_007

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

Paul Dolan

Athlone IT Wastewater Treatment Facility

Treatment Unit - Pumped Flow Bio-film Reactor

JC LM FK

03/04/2013 1:4013_AD_008 0000

PFBR Treatment Unit

Treatment Unit Elevation

Treatment Unit Plan

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

99.549

99.669

99.819

99.911

99.809

99.706

99.570

99.483

99.396

99.142

98.698

98.086

97.574

97.268

99.367

99.327

98.665

98.036

98.780

98.870

98.619

98.097

97.298

97.154

97.275

97.526

97.775

98.486

99.377

95.616

95.711

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

CL

100.070

99.857

99.862

101.537100.544

101.312

101.405

100.443

100.565

101.309

101.876

101.777

101.360

100.653

100.475

101.453

101.687

102.172

101.188

100.850

100.477

100.300

99.851

99.648

99.921

99.865

100.207

99.717

99.268

99.902

100.326

98.872

99.205

99.685

100.272

101.527

102.095

102.012

100.487

100.067

99.488

99.181

99.409

99.727

98.530

98.711

98.002

97.780

97.455

100.367

100.078

99.999

100.375

99.965

100.378

100.033

100.361

99.963

100.381

100.067

100.350

99.936

99.860

99.835

99.793

99.71099.623

100.111

99.986

99.918

99.656

99.429

99.363

99.164

98.609

98.026

97.463

97.337

97.101

97.255

97.362

97.750

98.200

99.179

99.391

99.548

99.571

100.212

99.205

99.405

99.467

99.610

99.827

99.934

99.527

99.385

99.267

99.130

98.717

98.110

97.420

96.978

96.943

97.317

97.732

98.224

98.664

96.346

96.263

95.886

95.927

96.130

96.323

96.321

96.190

95.967

95.670

95.400

95.549

95.789

95.658

95.526

95.650

95.751

95.728

95.545

95.537

95.509

95.751

95.672

95.585

95.532

95.480

95.484

95.452

95.474

95.479

95.640

95.682

95.610

95.550

95.416

95.362

95.525

95.536

95.831

95.930

95.996

96.183

96.513

96.805

96.926

96.925

96.843

96.703

96.699

96.678

96.556

96.271

96.033

95.742

95.719

95.725

96.708

96.652

96.616

96.907

97.216

97.485

97.713

97.860

97.517

97.527

97.217

96.835

96.560

96.558

96.672

0

0

5

0

1

0

0

1

5

0

2

0

0

2

5

0

3

0

0

3

5

0

4

0

0

4

5

0

4

5

3

MH122

MH123

MH124

MH112

P

ip

e

1

0

31

5

0

m

m

P

V

C

P

ip

eL

1

7

.9

3

0

Pip

e1

04

15

0 m

m P

VC

P

ip

e

L 6

0.6

82

Pipe105

150 m

m

P

VC

P

ipe

L 49.791

P

i

p

e

9

5

1

5

0

m

m

P

V

C

P

i

p

e

L

5

2

.

8

7

8

P

ip

e

9

6

1

5

0

m

m

P

V

C

P

ip

e

L

5

0

.4

9

7

MH113

98.200

98.400

98.50098.100

MH131

MH129

MH114

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

PAUL DOLAN

AIT WASTEWATER TREATMENT FACILITY

SEWER NETWORKPLAN LAYOUT

LM FK

03/04/2013 SEE DRAWING13_AD_009

DRAFT

ENGINEERING BUILDING

INDOOR

SPORTS ARENA

PUMPING STATION

TOWN SEWER

COLLECTION

POINT

DISCHARGE

MH

INLET WORKS

SETTLING TANK

PFBR UNIT

Meters

0

25

50

G1 SCHEME DESIGN

CONSULTING ENGINEERS LTD

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

MH

PUMPING STATION

CONTINUED

Level

0UTLET - LONGSECTIONSCALE: H 1:500,V 1:500. DATUM: 90.000

90

91

92

93

94

95

96

97

98

99

100

Existing Levels

Chainage

96.178

95.865

95.651

95.518

95.619

95.716

95.672

95.670

95.543

95.526

95.445

95.411

95.423

95.461

95.512

95.611

95.768

95.865

96.030

96.293

96.647

96.735

96.698

96.671

96.619

96.580

00.000

10.000

20.000

30.000

40.000

50.000

60.000

70.000

80.000

90.000

100.000

110.000

120.000

130.000

140.000

150.000

160.000

170.000

180.000

190.000

200.000

210.000

220.000

230.000

240.000

250.000

260.000

270.000

280.000

290.000

300.000

310.000

320.000

330.000

340.000

MH111

MH112

MH113MH114

MH115

Pipe95

Pipe96

Pipe97

Pipe98

Pipe99

Pipe108

MH131

1.310 VM 1200mm DIA CONC

COVER LEVEL = 97.838

SUMP LEVEL = 96.528

100mm Reinforced Concrete INV IN LEVEL = 96.53

Level

90

91

92

93

94

95

96

97

98

99

100

96.671

96.619

96.580

96.580

96.584

96.716

96.830

96.939

97.054

97.175

97.287

97.398

97.529

97.684

97.694

320.000

330.000

340.000

350.000

360.000

370.000

380.000

390.000

400.000

410.000

420.000

430.000

440.000

450.000

452.620

Pipe109

MH122

Level

Level

FLOW PIPE - LONGSECTIONSCALE: H 1:500,V 1:500. DATUM: 95.000

95

96

97

98

99

100

101

102

103

104

105

95

96

97

98

99

100

101

102

103

104

105

Chainage

Existing Levels

00.000

10.000

20.000

30.000

40.000

50.000

60.000

70.000

80.000

90.000

100.000

110.000

120.000

130.000

135.068

100.375

100.297

100.260

100.242

100.213

100.222

100.247

100.211

99.886

99.574

MH123

MH124

Pipe104

Pipe105

Pipe103

PFBR

UNIT

CONTINUED0UTLET - LONGSECTIONSCALE: H 1:500,V 1:500. DATUM: 90.000

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

PAUL DOLAN

AIT WASTEWATER TREATMENT FACILITY

SEWER PIPELINE LONGITUDINAL SECTIONS

LM FK

12/04/2013 SEE DRAWING13_AD_010

DRAFTG1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

PFBR UNIT SEE DRAWING No.

13_AD_008 FOR DETAILS

SEE DRAWING No. 13_AD_011

FOR DETAILS

EXISTING GROUND SURFACE

INLET WORKS

SEE DRAWING No.

13_AD_006 FOR DETAILS

EXISTING GROUND SURFACE

EXISTING GROUND SURFACE

ENGINEERING BUILDING

OUTLET POINT

NOTES:

FOR PIPE DETAILS AND

DESIGN INFORMATION

SEE DESIGN DOCUMENT NAME

'PUMPING STATION AND

SEWER DESIGN'

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PR

OD

UC

ED

B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCT

PR

OD

UC

ED

B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

100mm Outlet Pipe

MH

Grunfos Submersible Pump

Precast Concrete Pump Station

Pump Start Level

Min Water Level

Pump Control Notes:

The pump station shall be supplied with a pump control

panel which shall provide local pump control and shall

interface with the Remote Telemetry Unit (RTU) being

supplied by the Instrumentation and Control System

Integrator.In normal operation level in the wet well shall be

detected by a level sensing device supplied by the

Instrumentation and Control System Integrator.

Interior components:

1.Stainless steel hardware including, but not limited to,

the

following:

a) Lifting chains

b) Anchor bolts

c) Bolts and nuts

d) Guide rails

e) Rail guides

f) Cable holder

g) Discharge piping.

2. Level control is to be provided by ultrasonic level

controller or submersible transducer.

3. Provide high water and low water alarm activated by

ultrasonic or submersible level control system and

backup float switches.

4. Locate level switch where flow from the inlet pipe will

not interfere with the float.

5. Provide a hanger for the float switch cable and

power cables.

6. Line wetwells, walls, and bottom surface of the top

cover with a high density polyethylene (HDPE)

concrete protective liner (CPL) or Raven epoxy coating.

7. Provision should be made for ventilation of the

wetwell.

7mm Chip for

Bedding & Cover

Green Field Section

In the Road In Road margin

but < 1m from Road

150mm Topsoil

Selected material

Wearing Course

Pipe of specified size

7mm Chip for

Bedding & Cover

80mm stone

well compacted

Pipe of specified size

80mm stone

well compacted

Pipe of specified size

7mm Chip for

Bedding & Cover

150mm Topsoil

TYPICAL MANHOLE DETAIL

SCALE 1:20

1220x685mm MULTIPLE

DUCTILE IRON COVER

BEDDED ON MORTAR

MORTAR HAUNCHING TO MH

COVER AND FRAME

COVER SLAB BEDDED ON PC

CHAMBER SECTION WITH

MORTAR, PROPRIETARY

BITUMEN OR RESIN MASTIC

SEALANT

CONCRETE SURROUND

150mm ST4

HIGH STRENGTH CONCRETE TOPPING TO BE

BROUGHT UPTO A DENSE SMOOTH FACE

NEATLY SHAPED AND FINISHED TO ALL

BRANCH CONNECTIONS (MINIMUM

THICKNESS 20mm)

ST4 CONCRETE BASE

CLASS B ENGINEERING BRICKS

CONCRETE BLOCKS OR PRECAST

CONCRETE COVER FRAME

SEATING RINGS. MIN 2 BRICKS,

MAX 4 BRICKS

1200x675mm OPENING IN COVER

SLAB

LIFTING EYES IN CONCRETE

RINGS TO BE POINTED

BENCHING SLOPE TO BE 1 IN 10

TO 1 IN 30

BOTTOM PRECAST CONCRETE

RING TO BE BUILT INTO BASE

CONCRETE MIN 75mm

DISTANCE BETWEEN TOP OF PIPE

AND UNDERSIDE OF PC CHAMBER

TO BE 50mm

225mm TO BARREL OF PIPE

TYPICAL BACKDROP DETAIL

SCALE 1:20

ST4 CONCRETE SURROUND TO BACKDROP

TO BE CAST INTEGRAL WITH MH

SURROUND

SHORT RADIUS 90 DEGREE BEND

CONSTRUCTION JOINT

PIPE SET VERTICALLY

CARE TO BE TAKEN TO MAINTAIN

FLEXIBILITY OF JOINTS

STANDARD TUMBLING BAY JUNCTION

INVERT OF RODDING EYE TO BE NOT

GREATER THAN 1.5m ABOVE TOP OF

BENCHING

PRECAST CONCRETE MANHOLE SECTION

A1

CLIENT:

PROJECT:

TITLE:

DRAWN: CHECKED: APPROVED:

DATE: SCALE:

DRAWING NO: REV:

REV NO: DATE: REVISION NOTE: CKD BY:DWN BY:

50mm100

5

15

403020

ON ORIGINAL

25

SITE LOCATION

©

Datum: Malin HeadGrid System: ITM

G1 SchemeDesign Consulting Engineers Ltd.

Expertise, Technology, Results

Paul Dolan

Athlone IT, Wastewater Treatment Facility

Sewer Network Structures

FK JC LM

03 / 04 / 2013 See Drawing13_AD_011 0000

DISCHARGE PUMPING STATION

SCALE - 1:50

Sewer Network Plan

SCALE - 1:1250

DISCHARGE PUMPING STATION

TYPICAL SEWER BEDDING DETAILS

SCALE - 1:20

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT

PRODUCED BY AN AUTODESK EDUCATIONAL PRODUCTP

RO

DU

CE

D B

Y A

N A

UT

OD

ES

K E

DU

CA

TIO

NA

L P

RO

DU

CT