diseño para esamblaje

-

Upload

ruben-dario-azael -

Category

Documents

-

view

215 -

download

1

description

Transcript of diseño para esamblaje

-

DESIGN FOR ASSEMBLY

Assembly is an important stage in product development and accounts for one third of the

company labor. Reducing the number of parts and making the assembly easier and faster can

simplify a product. In addition to the cost of assembly operation, designing for assembly has

many other benefits and few are listed below.

When a product is simplified, it becomes easier to assemble in the factory and to

disassemble when maintenance, repair, or disassembly for recycling is required.

Simpler assemblies often can be brought to market sooner because of fewer parts to

design, procure, inspect, and stock with less probability that a delay will occur.

Reducing the number of parts requires fewer engineering and production-control

documents, lower inventory levels, reduced need for inspection and quality-control

documents, fewer setups, less materials handling, and probably, reduced purchasing

workload.

DESIGN CONSIDERATIONS

In order to find various alternatives for smooth assembly operation, a product designer should be

able to visualize how the parts can be put together and what are the difficulties in putting parts

together. The designer is expected to understand the various assembly methods and different

tools, fixtures, and gauges that will be used during assembly. The assembly having the fewest

numbers of parts and the least costly fasteners is considered to be the best one.

Assembly design of each component should be such that a minimum number of manufacturing

and assembly operations are required. The usual procedure is to use the assembly or sub

assembly by putting them to the main assembly with lesser cost than putting complex individual

parts one by one. Most of the design suggestions that follow are applicable to assemblies

fastened by the purely mechanical methods mentioned above as well as to those that are welded,

soldered, brazed, and bonded.

Minimizing the Number of Parts

The basic approach in design for assembly is to reduce the number of parts without disturbing

the functionality of the part.

Some important principles to reduce the number of parts are as follows:

1. Combine parts.

-

This includes integrating the functions of several parts into one part. Integration of several

parts has been demonstrated below through various examples.

a. Incorporate hinges: By incorporating hinges in many plastics parts (if the plastic

material is flexible and the wall section is thin), parts can be integrated together. Many

storage containers are made with integral hinges. Both injection molding and

thermoforming are used in this design approach. A typical example is shown in Figure

M7.2.1.

Figure M7.2.1: Integral living hinge

b. Use of integral springs: Springs can be incorporated in metal and plastic parts and also

in other materials such as fiber. Figure M7.2.2 illustrates the principle.

Figure M7.2.2: Spring function in the lever to eliminate the need for a separate coiled

spring

c. Use of snap fits. Screw-type and other separate fasteners can be replaced with integral

snap-fit elements, tabs, or catches. Such an example is shown in Figure M7.2.3.

-

Figure M7.2.3: Snap-fit principle to attach the cover

d. Use of guides, bearings, covers, etc. In certain manufacturing processes, use of these

elements (guides, bearings, covers, etc.) in the basic parts often reduces the number of

components significantly.

e. Mount electrical and electronic components in one location, and consolidate

components as much as possible.

Additional guidelines for combining specific parts are provided below.

1. Bent tabs or crimped sections are found to be less costly and recommended instead of

using separate fasteners to hold several parts together. (Refer Figure M7.2.4.)

Figure M7.2.4: Bent tabs, rivet-like extensions, and crimped sheet metal members to avoid

separate fasteners

2. It is recommended to use combined fasteners.

-

3. Threaded holes and nuts are to be avoided. Use of self-tapping screws is preferred over

threaded holes as it is more costly to make precision hole with internal screw thread.

Avoid using separate attached label, instead use cast or molded-in identification

4. Some of the fasteners can be replaced by the use of integral locators, hooks, or lips.

(Refer Figure M7.2.5)

Figure M7.2.5: Lips or other hooking elements in the basic parts

5. Threaded or other fasteners can be eliminated by the use of press fits, integral tabs, or

rivets. Press fits with flexible or grooved components are normally less expensive and as

effective as precision-machined parts.

Connection of parts is to be made keeping an eye on the feasibility of connection by raising the

following questions.

1. When the product is being used, does the part move with respect to mating parts?

2. Must adjacent parts be made of different materials?

3. If parts were combined, would assembly of other parts or field service be made more

difficult or unfeasible?

It is probably not feasible to combine the parts if the outcomes of these questions are yes.

Otherwise the part is a good candidate to be combined with others. A simple example has been

demonstrated in Figure M7.2.1 on this line. Further, Figure M7.2.6 explains the large number of

functions that have been consolidated into a few parts in a common everyday product (finger nail

clipper).

Feasible Better

-

Figure M7.2.6: Finger nail clipper

2. Make an outright reduction in the number of parts

The fasteners can be reduced by using smaller number of heavier fasteners.

3. Make a major or full-product redesign

When the assembly is redesigned, it is sometimes possible to achieve the function

supplied by a separate component by another method. One example would be the

replacement of a flanged and bolted pipe system with a threaded pipe system.

4. Use a different technology

Often with drastic change in design, it is possible to achieve the same function by some

other methods. For example, when a mechanical device is replaced by an electronic

micro circuit.

OTHER MAJOR GUIDELINES FOR ASSEMBLY IMPROVEMENT

General Recommendations

1. Use standard fasteners and other parts. It is recommended to use few sizes and styles to

reduce the total number. Minimizing the varieties is also important. The subassembly

which is usable in several products is to be standardized.

2. If the subassembly process is different from the final assembly process then it is

recommended to use subassemblies; particularly modular subassemblies. Modular

assembly provides quality and reliability advantages together with serviceability

advantage.

3. It is recommended to avoid too many sub-assemblies. This will add to the overhead in the

form of additional floor space, inventory and manufacturing specifications and also

increase the manufacturing throughput time.

4. Parts need to be designed such that they cant be inserted incorrectly.

-

5. It is recommended to avoid the use of flexible parts, if possible, because positioning and

handling the part to a proper location consumes more time. Further, such parts are also

susceptible to tangling.

6. Open-end slots are preferable to holes or closed slots if the design permits and the part

can be contained. This would permit shafts or other mating parts to be assembled from

the top (or side) instead of endways.

7. Use layered top-down assembly. Design the part in such a way that parts can be added

from the top, not from side or bottom. If top down assembly is not possible design the

part in such a way that it can be assembled in a single step translation.

8. If the space is limited for doing the assembly operation avoid adding simultaneous

addition of several parts to the main assembly.

9. Design parts to be self-aligning. (See Figure M7.2.7)

Figure M7.2.7: Self-aligning features in the right side

10. Eliminate adjustments as much as possible.

11. Recommended to use chamfered shape openings of holes and slots whenever possible to

help with the insertion of mating parts. Taper is put on the parts that are to be inserted to

the other part. (Refer Figure M7.2.8)

Figure M7.2.8: Funnel-shaped openings and tapered ends to facilitate insertion of parts

-

12. If the assembly quantities are large, it is recommended to use fasteners that fed

themselves to hoppers, strips or other automatic feeding methods.

13. Parts need to be designed so that they can be handled easily. This may involve adding

grasping element or projection to the part.

14. Slots or oversized hole are recommended on one of the parts for taking care of

misalignment when mating parts have through holes.

15. Situations in which one has to manually hold the part till all other parts are assembled are

to be avoided. This creates quality problem as well as additional assembly time and cost.

16. Loosest fit possible between mating parts is recommended to use, unless it will affect the

product function.

17. Internal mechanisms are to be kept accessible.

18. Threaded fasteners are to be avoided as these take more time for assembly. Assembly

time can be reduced by the use of push-on fasteners instead of threaded fasteners, if snap

fits are not feasible. (Refer Figure M7.2.9)

Figure M7.2.9: Push-on fasteners to speed assembly operation

19. It is recommended to design small parts so that they can be inserted in as many ways as

possible, from both ends.(Refer Figure M7.2.10)

20. Recommended to use plastic molding or zinc die casting to hold metal parts together.

(Refer Figure M7.2.11)

-

Figure M7.2.10: Design of small parts for inserting many possible ways

Figure M7.2.11: zinc die casting to hold metal parts

21. If possible, right and left-hand parts and subassemblies should be made identical, thereby

avoiding the need for extra part designs with separate inventories, etc. (Refer Figure

M7.2.12)

Figure M7.2.12: Combine right and left hand features

-

22. The use of components that can tangle when in a mass prior to assembly is to be avoided.

For example, hook like projections should be avoided, surfaces should be smooth, and

holes and slots should be avoided. (Refer Figure M7.2.13)

Figure M7.2.13: Design of parts to avoid entangle

23. It is recommended from a manufacturing cost standpoint to use fewer large fasteners

instead of a larger number of small fasteners.

24. Subassemblies of loosely held and flexible parts that can be damaged or entangled in

handling are to be avoided if possible. Under unavoidable situation, fixtures should be

provided to facilitate assembly and holding boards used to facilitate handling.

25. Snap rings are considered to be an inexpensive way to fasten parts; particularly when

freedom of movement is desired, as in the case of rotating shafts. A separate retaining

ring is often more economical than the use of a headed pin because considerable

machining can be eliminated. (Refer Figure M7.2.14)

Figure M7.2.14: Snap ring to act as holder

Rivets

Rivets are used to provide strength and performance to a joint. The design rules that need to be

referred for the economical use of rivets are listed below.

1. Sufficient space around the rivet location is to be provided for the movement of standard

rivet gun location and prevent the marring of the work piece as shown in Figure M7.2.15.

-

Figure M7.2.15: Provide sufficient room for rivet-clinching tools

2. Eyelets and tubular rivets are recommended whenever they provide sufficient holding

power for the application. Tubular and semi-tubular rivets and eyelets require much

lower clinching forces and can be hopper-fed, inserted, and set automatically on

inexpensive equipment. (Refer Figure M7.2.16)

Figure M7.2.16: Tubular and semi tubular rivets and Bifurcated are preferred

3. When two work pieces are to be joined, the hole diameter must be correct. The

recommended diametric clearance is 5 to 7 percent. If the rivet hole is too large then the

rivet will buckle during clinching, which will create a loose and weak joint.

4. If one side of the assembly is not accessible blind rivets are to be used. But blind rivets

are more expensive than the conventional rivet.

5. In case of riveting thick materials, buckling of rivets can be avoided by counter boring

the rivet holes. (Refer Figure M7.2.17.) Counter bores are to be made wide enough to

permit access of the riveting tool.

Figure M7.2.17: Use wide counter bores for riveting thick components to avoid buckling

the rivets

-

6. A minimum and maximum edge distance has to be maintained from the edges of the parts

being joined. Holes should be between 1.5 to 8 stock thicknesses from the edge. This

provides good support for the riveting tool and ensures that the edges are held together.

(Refer Figure M7.2.18.)

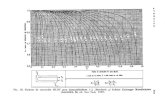

Figure M7.2.18: Recommended rivet-to-edge dimensions

7. Rivets of proper length are to be used to avoid incorrect clinching. (See Figure M7.2.19)

The recommended rule-of-thumb for clinching allowances C is as follows: solid rivets,

200 percent of shank diameter; semi-tubular rivets, 50 to 70 percent of shank diameter;

and full tubular or bifurcated rivets, and 100 percent of shank diameter.

Figure M7.2.19: Proper rivet length is important

8. While joining pieces of different thickness, it is preferable to upset the rivet against the

thicker, stronger material. (See Figure M7.2.20)

Figure M7.2.20: Upset rivets against the thicker, stronger material

-

9. In case of joining soft or fragile materials with rivets, it is desirable to use metal washers

to distribute the force of upsetting and prevent damage to the weak part. (Refer Figure

M7.2.21)

Figure M7.2.21: Metal washers distribute the force of upsetting

10. When joining a weaker material (such as leather, plastic, or wood) to a stronger material

(such as sheet steel or aluminum) with a blind rivet, it is best to use a large head that

bears against the weaker material and to clinch against the stronger material.

11. Adequate tool clearance is to be provided in case of blind rivets for the clinching tool on

the side from which the rivet is placed. If the space is limited, it is advisable to rivet from

the other side.

12. Blind rivets, though they do not have the strong axial forces of conventional rivets, still

should not be set against insufficiently supported surfaces. (Refer Figure M7.2.22)

Figure M7.2.22: Use of blind rivet

13. It is sometimes feasible to have rivet-type fastening by incorporating integral lugs on one of

the assembled parts. This eliminates the need for rivets as separate parts. (Refer Figure

M7.2.4).