Digital Transformation to a Connected Mine · Digital Transformation –The Future of Mining...

Transcript of Digital Transformation to a Connected Mine · Digital Transformation –The Future of Mining...

Digital Transformationto a Connected Mine

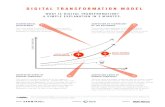

Digital Transformation – The Future of Mining

Visualization & Alerts

Analytics &

Dynamic Scheduling

Digital TwinIntegrated

Automation

Cognitive

Network

In a challenging market, the digital transformation of mining companies has become a business

imperative—leveraging technology to improve processes aligned to value.

“Right information in right time and place, to make better decisions”

Digital Transformation – Visualization & Alerts

Even in the early stages of their digital transformation journey, mining companies can increase

productivity, reduce costs and improve production and safety quickly through

the visualization of data across the entire value chain. By putting the right information in

employees’ hands, they can make better decisions across an integrated production chain.

Acquire Design Plan Drill& Blast

Load& Haul

Stockpile Crush Process Transport Market

Mine MonitorPlatform Big Data Platform

Batch Services

Data Store

Data Integration

Cloud Platform

Security Services

Infrastructure Services

User Interface

Reporting, Analytics & Artificial Intelligence

Dashboards,Reports

Dispatch Historian ERP Mine planning Maintenance

GeospatialVisualization

EnvironmentData

Fleet Management Real-time Systems Energy Management GIS Weather

Connected Work Order Connected C-level Sustainability & ConnectedMine Mobility Plant Dashboard Water Management Rail & Port

Digital Mine Architecture

Analytics Optimization mode

“Unleashing the power of intelligence from data”

Control mineral characteristics through strategies such as drill and blast enhancement and improved

blending to help meet required output.

• Schedule dynamically across whole mine operations based upon predictive alerts.

• Enhance asset health through predictive assets maintenance.

• Improve safety through fatigue monitoring or people and asset tracking.

Digital Transformation – Analytics

Scalable To Your Deployment Needs

“Virtual environments improving real-world decision making”

Digital Transformation – Digital TwinAligning strategic and real-time plans and schedules has long been a challenge for mining companies,

especially when different methodologies for people, processes and technologies are used. The concept

of the Digital Twin offers an immersive virtual environment that merges short-, medium- and long-term

planning horizons to help miners make value-driven decisions across a range of operations—from

boardroom to mine site:

“Virtual handshake improves performance across processes”

Digital Transformation – Integration Automation

The automated mine is just the beginning. Integrating automation across the value chain can

enable mining companies to solve a variety of critical business issues—even faster and more

intelligently.

Process Control

Power Control

Condition Monitoring Safety

Advanced Process Control

Industrial Security

Asset Management

Gap Control

Operator Effectiveness

Information Intelligence

“Embedding autonomous operations into the digital mine”

Digital Transformation – Cognitive Network

Cognitive Network is the next generation of technology being deployed across industries around the

globe. The ability for machines to think and act like humans through the analysis of unstructured data

will drive true transformation across the mining value chain.

The use of artificial intelligence will provide a way for

people to interact with technology and

create an environment that is self-improving,

self-learning, self-healing and self-

controlling.

Smart Manufacturing Leadership Coalition, NNMIs Industrie 4.0

China Manufacturing 2025Industrie du Futur

Manufacturing Innovation 3.0

Produktion 2030

Make in India

Industrial Value Chain Initiative (IVI)

Innovate UK

ABII - AssociaçãoBrasileira de Internet Industrial

$

Faster Time to Market

Improved AssetUtilization

Enterprise Risk Management

TH

E C

ON

NE

CT

ED

EN

TE

RP

RIS

E D

EL

IVE

RS

Lower Total Cost of Ownership

INDUSTRY CONSORTIAEnterprise Risk

Management

Value at Stake2017 - 2025$428B-784B

Digital Transformation – Mining & Metals

World Economic Forum 2017 Digital Transformation Initiative: Mining and Metals

most cited benefit Workforce Productivity from Mobile/tablet devices

Simulate Physical Environments

Automation Visualization

BETTER

EQUIPMENT

PERFORMANCE

OPERATIONAL

COSTS

47% 42%IMPROVED

DECISION

MAKING

40%DIGITAL IN MINING: PROGRESS... AND

OPPORTUNITY – Accenture 2017

Mining & Metals Digital Initiatives & Investments

OT/IT Convergence

Integrated Supply & Data Management

Asset Cybersecurity

INTEGRATED ENTERPRISE,

PLATFORM & ECOSYSTEMAUTOMATION, ROBOTICS

& OPERATIONS OPTIMIZATION

NEXT GENERATION

ANALYTICS & SUPPORTDIGITALY ENABLED

WORKFORCE

Autonomous Operations

Smart Sensors & Assets

Connected Worker

Remote Operations Center

Remote Monitoring & Support

Simulation Modeling

Predictive Maintenance

Source: WEF Digital Transformation Initiative Mining and Metals Industry Jan 2017

Copyright © 2016 Rockwell Automation, Inc. All Rights Reserved. 12

EARLY IIoT INVESTMENTS ARE DRIVING RESULTS

46-75%

REDUCTION OF BATCH

RECORD REVIEW

MAN HOURS

MORE THAN

2 MILLIONVARIATIONS IN

PRODUCTION

MANAGED IN

REAL TIME

99%

UPTIMEACHIEVED

AT RETAIL

LNG STATIONS

WITH CLOUD

SOLUTION

20X

INCREASEIN ACCESS TO

PRODUCTION

DATA

ELIMINATED

2,500 HOURSOF MANUAL

COLLECTION

HASSESS &PLAN

SECURE &UPGRADE

DATA &ANALYTICS

OPTIMIZE &COLLABORATE

WE’VE HELPED OTHERS INTEGRATE OPERATIONS

Access to real-time data

minimized line shut downs

6% INCREASE IN

EFFICIENCY

Connectivity to 6 plants provided

real-time equipment status

50% DECREASE IN

INVENTORY

Integrated OT & IT Network infrastructure

connected 21 remote sites

75% DECREASE IN MEAN

TIME TO REPAIR

Where to START

Copyright © 2016 Rockwell Automation, Inc. All Rights Reserved. 14

OT & IT are silo’d

organizations with

different cultures,

objectives and priorities

ORGANIZATIONAL

DISCONNECT

Security breaches can

be a huge contributor to

unscheduled downtime

SECURITY &

DATA PROTECTION

What’s Getting in THE WAY

Tribal knowledge is

getting ready to walk

out the door

NEW WORKFORCE

SKILL GAPS

$4MAVG COST OF

DATA BREACH

Copyright © 2016 Rockwell Automation, Inc. All Rights Reserved. 15

AUTO DISCOVERY ZERO CONFIG DASHBOARDS ORCHESTRATION & WORKFLOW PEOPLE IN THE IIOT

INFORMATION SOLUTIONS CAPABILITIES – Cloud | On-Premise | Edge

SCALABLE EXECUTION SYSTEMS SCALABLE ANALYTICS MOBILITY & COLLABORATION CONNECTED SERVICES

The Connected Enterprise

Customer Outcomes Faster Time

to MarketImproved Asset

Utilization

$Lower Total Cost

of Ownership

Enterprise

Risk Management

ROCKWELL AUTOMATION IIoT INFRASTRUCTURE – Integrated Architecture™

Enabling the Industrial Internet of Things (IIoT)

MOBILE / DISPLAYSCONTROLLERS MACHINES & EQUIPMENT REMOTE ASSETSINTELLIGENT MOTOR CONTROLSENSORS & ACTUATORS

SMART CONNECTED ASSETS – EtherNet/IP Enabled Network