DEVELOPMENT OF RAPD AND SSR MARKER ASOCIATED WITH …€¦ · Web view2- Reducing moisture...

Transcript of DEVELOPMENT OF RAPD AND SSR MARKER ASOCIATED WITH …€¦ · Web view2- Reducing moisture...

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

New Bagasse Based Industries

Mahmoud KH. Soliman

Chairman & Managing Director, Nag Hamady Fiber Board Company Egypt

Introduction:

Recently the economic and environmental conditions are pressing toward the using of agri fibers instead of wood tree in many industries.

On the other hand the fluctuation of sugar global price as well as anticipated competition coming from increasing purchasing price of grain crops should be faced by sugar mills owners by establishing new added value projects that use the industry by-product like molasses and bagasse.

Fortunately, Bagasse thanks to its good properties, it has been used long time ago in many industries like paper pulp, live feed stock and wood based panel industries.

In Egypt Sugar and Integrated Industries Company(SIIC) is the sole company that extract sugar from cane sugar, in addition posses two lines one for particle board other for feed live stock. Also it is the main share holder in two pulp and paper mills as well as one for medium density fiberboard (MDF).

To help investing in using bagasse in new industry this article throw some light on two of untraditional or new industries based on using bagasse as raw material. These industries are natural fiber plastic composites(NFPC) and second generation solid biofuel which give more opportunities for investment.

Key words:

Bagasse-Pith- Wood based panel- Pretreatment-Wood plastic composite (WPC) / natural fiber plastic composite(NFPC)- Pelletizing – sizing- Bio Fuel -Torrefaction.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 1

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

Using Bagasse in industrial scale: There are many industries that can use Bagasse. It can be classified

according to( the age} of the industry into two main sections.

Figure No. 1 Bagasse

Traditional industries new industries

-Wood based panel panels-Pulp and paper natural fiber plastic composite (NFPC) Second generation Biofuel

-Live Feed stock-Compost

Pre procedures of preparing bagasse:There are two main procedures should be adopted before feeding bagasse

to main production line of any industry.First step is mandatory procedures. In general we can mention bagasse

transportation from sugar factory and storing of bagasse.More over these procedures are very crucial as it is costly and can affect

the whole economy of the project.There are many options for each procedure so investor has to study

carefully these stages because the main reason for failure of most projects based on annual agricultural residues refers to wrong decision or bad evaluation of options.

Second step of preparing bagasse differs according to the selected industry and specification of bagasse after storing. This include depething , sizing ,dewatering, drying, and washing procedures.

Guide to new industries(1) - Wood plastic composite (WPC) /Natural fiber plastic composite

(NFPC): The term composite refers to any two or more dissimilar materials which when

combined become stronger than individual material. Bagasse is an example as it is a combination between cellulose fiber and lignin. MDF, ply wood and particle board are the common example of wood composite

10-13 November 2012, Aswan, Egypt M. KH. Soliman 2

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

Wood is combining with polyfins (plastics) to from new composite that has better specification than wood or plastic alone.

The rapid changing of economic and environment conditions putting pressure on the forestry industry in order to replace wood by cellulosic fibers of annual plants.

Economy of this industry lays on using same equipment of ordinary plastic industry like extruder and injection molding .etc but 50% at least of high price plastic is replaced by cheaper wood cellulose..

Recently, in a very advanced step fibers from plant residues replaced wood flour. This fibers work as reinforcement in plastic matrix instead of working as filler in case of wood flour. That means reducing raw material cost and better properties of product.

As we are here dealing with bagasse so we shall use natural fiber plastic composite term instead of wood plastic composite.

RAW MATERIAL USED IN NATURAL FIBER PLASTIC COMPOSITES (NFPCs)1-Bagasse

Flax and hemp are the main fibers used In Europe. Bamboo ,wheat straw and rice husk are used in China and Japan.

Tell now bagasse is not used in industrial scale but not by any means due to its unsuitability. Good results from many experiments for using bagasse were executed all over the world specially in united state and Australia.

We as Nag Hamady Fiber Board company have executed many experiments on Bagasse at many equipment manufacturing companies as well as lab researches centers. Either fresh bagasse or bagasse MDF fibers were sent to Cincinatty Austria, Pallmann and Haller Formhols Germany. Malicron in united states, scion in New Zealand and others . All gave us good results.

2- PLASTICS (POLYOLIFINS) Either In WPCS or NFPC the following normal polymers which are used in

plastic industry are also used:- Polyethylene Polypropylene PVC Fresh as well as recycled polymers can be used but certain grade of melt point

and flexural module are needed for NFPCs.

3- coupling Agents The difference between the surface energy of the natural fibers and the matrix of

the plastic polymer determines the final physical properties of the composite, often requiring the addition of a coupling agent to enable strong interfacial

10-13 November 2012, Aswan, Egypt M. KH. Soliman 3

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

adhesion. Coupling agents encourage dissimilar materials such as plastic and fibers to form an alloy. While plastic is Hydrophobic the fiber is hydrophilic .

Maleated polyproplylene(MaPP) and maleated polyethylene(MaPE} are widely used as coupling agents.

The direct measure of adhesion between bagasse and thermoplastics is bonding strength .Interaction between the anhydride groups of maleated coupling agent and the hydroxyl group of natural fibers can overcome the incompatibility problem as shown in the following figure

4- Other chemicalsSome other chemicals are added as Anti oxidation, Lubricants, Foaming agents, Master coloring batch….etcMost of these chemicals are used in normal plastics industry.

Pretreatment of Bagasse for NFPC1-Depithing

Bagasse as coming from sugar mill contains about 30% parenchyma cell tissue known as pith which should be removed before using bagasse in certain industries like paper and wood base panels .

For NFPC pith represents a decay source in final products . This bad effects may appear when product is subjected to weathering conditions for long time .So depithing is recommended for this industry..

Removing pith from full bagasse is well known procedure, Mechanical pith separating equipment called depithers are commonly used.

Pith could be returned back to sugar factory where it is used as fuel. This needs separate agreement with SIIC or the investor should find another way to use it in other industry.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 4

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

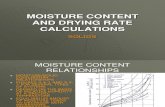

2- Reducing moisture content.(Drying).Drying method depends on moisture content of bagasse after storing.

Accordingly wet bulk storage bagasse with moisture content 80% needs to be dried to 12 % before introducing to mixing equipment.. May combination of both mechanical dewatering and heat dryer systems are needed in this case.

Dry bales storage system needs less drying capacity as normally most of moisture content is naturally removed during storage period.

Over the years many types of dryers using heat as drying element were used such as rotary and flash dryer , On other hand screw presses is an example for mechanical dewatering type.3- Sizing

Bagasse has to be sized into suitable dimensions for feeding and mixing.. 2-3 mm particle size is enough. Normal hammer mill can do this job.

Recently many researches have proved that bagasse fibers (or any other raw material) same as produced in MDF industry using mechanical defibrator give better result due to increasing reinforcement effect of long thin fibers (Aspect ratio)

Sizing procedure could be done before or after drying depending on bagasse moisture content.

4- Pelletizing

Pelletizing is a process in which material is turned into small dry pellets.

Pelleting can be generally defined as an extrusion type thermoplastic molding operation in which the finely reduced particle of the feed ration are formed into a compact and easily handled pellets. It is thermoplastic in nature because the sugar in bagasse and other components become plastic when heated and diluted with moisture The molding portion of the operation occurs when the heated, moistened feed is forced to a die, where it is molded into shape and held together for a short time . It is then exists as an extruded product. Pressure for both molding and extrusion comes from pellet mill rolls which force the feed through the holes inside pelletizer.

Pelletizing is a way to reduce storage and transportation cost . In NFPCs industry it can be used in two stages for two purposes. First feeding bagasse pellets instead of loose form to achieve regular feeding to the mixer to induce good mixing with plastic or as intermediate fiber plastic pellets to be fed either to forming extruder or injection molding.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 5

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

NFPCs Production ProcedureFor simplicity the process for decking product can be summarized as follow1- pretreatment.Bagasse is pretreated as previously described.Recycled plastics needs cleaning ,washing ….etc 2- Up stream

For raw material ( Bagasse ,plastic and additives)

• Weighing

• Gravimetric dosing

• Blending

• Compounding normally in single extruder.

3-Main stream

Used equipments differ according to type of product, so equipment could be either extruders or injection ,pressing mold…etc

In case of decking product twin screw is used

4-Down stream Cooling Sawing "cutting into size" then packing.

Applications and marketing

There are many applications for WPCs &NFPCs. Decking products are the mainly market in USA others like windows , doors frames and interior car components are in Europe.

Residential decking and railings consumed nearly two-thirds of the $1billion (estimated retail) extrude WPC market in the United States in 2005, followed by window and door frames (11%), plus a wide variety of additional applications including but not limited to siding and accessories, fencing, boardwalks, docks, shingles, playground equipment, industrial infrastructure.

In Germany 13% of NFPCs production for interior car components are made from flax as raw material.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 6

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

Figure No( 3) shows the application potential of WFPCS and NFPCs

In Egypt, Decking products start its first steps in market. Interior car component and door, window frames products have better opportunities. Any how investor should consider outside markets as main market specially in the beginning. Also contracting with one or more of Egyptian cars assembling companies in order to manufacture the required component types is very important.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 7

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

10-13 November 2012, Aswan, Egypt M. KH. Soliman 8

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

GUIDE TO NEW INDUSTRIES (2) BAGASSE BIO FUEL INDUSTRY

Any fuel derivate from bio mass is considered bio fuel. Using bagasse as fuel in sugar cane factories returned back to the time of industry itself.

First generation of using bagasse as biofuel passed through three historical stages as follow:-1. Disposal of bagasse regarding its annoying voluminous nature . In that time

low efficiency steam boilers were used just to consume daily produced bagasse in order not leaving any dangerous stock.

2. After fuel crises in the beginning of seventies of last century bagasse was considered as renewable raw material so efficient use of bagasse started by improving juice extraction ,lowering bagasse moisture content and improving boilers design in order to minimize consumption of bagasse to save reasonable quantity mainly for cogeneration purposes.

3. Continuing of oil fuel crises encourage investigations to make bagasse in a suitable form of Bio fuel .Brazil was the pioneer country in this field. Using sugar syrup in ethanol industry was followed by lowering needs of bagasse as fuel in cane sugar factories creating a problem of enormous surplus quantities of bagasse need to be economically used in many industrial and domestic uses.

Recently second generation of using bagasse as biofuel has started.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 9

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

By definition second generation biofuel is a renewable form of fuel that is produced from cellulosic biomass.

Bagasse as solid biofeul could be transformed to any of the three forms, improved solid or liquid or gaseous forms.

For many economic and technical reasons this article is concentrating only on improving solid form of bagasse as biofuel. We think that this is the best procedures of transforming bagasse to economic bio fuel solid form product to be used in many industrial and domestic purposes either as coal & wood replacement or in other grate type boilers.

Also using this product for electricity producing system should be considered specially with the shortage of power supply in Egypt.Pretreatment of bagasse for biofuel

Mandatory and pretreatment steps descried before for NFPCs should also be adopted here. But depithing could be eliminated in this industry so full quantity of bagasse is used.

Torrefaction and pelletizing procedureBagasse as other residues of annual plants has some disadvantages when

used as fuel ,Low calorific value, low bulk density, high moisture content, hygroscopic nature, smoking during combustion, needs appropriate system for boiler feeding…… etc

Drying, baling, pelletizing of bagasse as pretreatment procedures before aim to overcome these disadvantages. But even combination of them all doesn’t eliminate all these disadvantages completely.

Drying leads to improving Bagasse low calorific value but never reach that of charcoal value.

Pelleting aim to densification of bagasse. Reducing moisture content not more than 13% is needed before pelletizing.

For that using combination of torrefaction and pelletizing is a new trend to improve quality of bagasse as second generation solid bio fuel.

Bagasse has not yet been introduced to this industry as biomass raw material. Same time pelletting of bagasse is well known technique long time ago. From other side many experiments has been done on bagasse torrefaction all over the world mostly in Australia through center for tropical crops and bio commodation and in USA as well.Torrefaction

Torrefaction is a thermo-chemical treatment method that is earmarked by an operating temperature ranging from 200°C to 300°C .It is carried out at near

10-13 November 2012, Aswan, Egypt M. KH. Soliman 10

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

atmospheric pressure, and in the absence of oxygen and characterized by low particle heating rates (<50 °C/min).

The process may be called mild pyrolysis. Because pyrolyses is the same procedure but done under higher temperature 400-600°C.

The biomass partly decomposes during the process giving off various types of volatiles.

Biomass consists of three main polymeric structures: cellulose, hemicelluloses and lignin, together these are called lignocelluloses.

In torrefaction when bagasse is heated, drying takes place first. Further heating removes new amount of water from chemical reaction through thermo-condensation process which occurs at temperature over 160°C, formation of carbon dioxide gas begins. At temperatures between 180°C and 270°C an exothermical reaction takes place and degradation of hemicellulose goes on. Biomass begins to be brown and gives off moisture, carbon dioxide and large amount of acetic acid with some phenol are produced. These compounds have low energy value. So biofuel retains most of energy potential, it loses its hygroscopic properties and becomes more friable than original form. About 280°C the reaction is entirely exothermic and gas production is increased, carbon monoxide and hydrocarbon are developed. Phenols, crosol and other heavier products are formed.Figure No 4 material balance of torrefaction.

Next figures No 5&6 show lay out of torrefaction continuous procedure as invented by the French company Thermya , the product under trade name

TORSPYDFigure 5

10-13 November 2012, Aswan, Egypt M. KH. Soliman 11

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

Figure 6

10-13 November 2012, Aswan, Egypt M. KH. Soliman 12

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

PELLETIZING AFTER TORREFACTIONPelletizing of bagasse is well known operation Brazil is the pioneer

country in that field. Converting sugar syrup to ethanol instead of sugar production creates excess of bagasse due to reduction of heat needs. As has been mentioned before palletizing reduces transportation cost of biofuel, makes feeding to boiler more regular and to some extent keeps specification of biomass unchanging.

Also torrefaction could be done alone but combination with pelletizing gives better quality .For that we think that this new trend is preferable as suitable markets could be more available.

The following figure (7) illustrates this meaning as described in TOP process of Netherland.

Figure No 8

10-13 November 2012, Aswan, Egypt M. KH. Soliman 13

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

Added value of torrefied biomass pelletsTorrefied and densified biomass has several advantages in different markets,

which makes it a competitive option compared to conventional biomass pellets:1.Higher energy density2.More homogeneous composition3.Hydrophobic behavior

Bagasse pellets has hydrophobic properties, and when combined with torrefaction make hulk storage in open air feasible,

4. Elimination of biological activityAll biological activity is eliminated consequently reducing the risk of fire

hazard and biological decomposition.5.Improved grindability

Torrefaction of bagasse leads to improved grindability of biomass. This leads to more efficient co-firing in existing coal fired power stations .

Capacity of project:Selection of project capacity depends on many factors like available quantity

of bagasse and volume of marketing of each product …etc.

We can divide the selected capacity into two categories:Small capacities that need maximum 50000 T/Y of bagasse .This capacity is

suitable for live feed stock, compost ,(NFPC) and Biofuel industries.This quantity of bagasse could be procured from Abu Korkas sugar factory

and from the supposed daily saved quantity of bagasse from other factories except Edfu, ,Kous and Deahna.

Big capacity like pulp and paper ,wood based panels and biofuel industries can take full produced quantity of bagasse either from Nag Hamady or Kom ombo sugar factories.

It is obvious that second generation bagasse biofuel industry has the advantage of being either small project in case of exporting product to cold countries for housing uses or big in case of industrial uses specially for power generation.

References

1- Wood plastic composites based on MDF fiber reinforcement Jermy warnes, forest research, New Zealand,3rd wood fiber polymer composites international symposium 2007.

2- The pelleting process, Riehard H.Leaver, Andritz sprout publication3- WPC from bagasse, Palimann Germany publication.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 14

GL3.1/

International Conference on: “New Role for the World Sugar Economy in a Changed Political and

Economic Environment ”

4- Development of new generation coupling agents for WPC Equistar company publication.

5- Maleatcd coupling agents for NFPCs, T.J.Keneer6- Use of natural fibers in composites in the German automotive industry.

Production 1996-2003, Mieheal Karus and others, Nova institute-Germany

7. Torrefaction of gricultural and forest residues, D.Tito & others, conference publication 2004 .Cuba

8- Combined torrcfaclion & pe11etization, The top process P,CA. ECN biomass Com, Netherland.

9- Pretreatment for energy use of rice straw, foday Robert, African journal of agricultural research, December 2009.

10- Thermya French Company, publication.11- Co firing of biomass with coal, A.Maciejewska & others. DG JRC,Institute

for energy,2006.

10-13 November 2012, Aswan, Egypt M. KH. Soliman 15