Design Project - Electric Furnace for Steel Making

description

Transcript of Design Project - Electric Furnace for Steel Making

DESIGN OF AN ELECTRIC FURNACE FOR MAKING STEEL

BY GROUP 23 : EUGENE TEO GUO SHUN 061933G07

KENVIN TEO SHI YU 061932E07JOELTEE HAN YUN 060420D07FIZH TO CHUN YU 060324H07

MS 3005 DESIGN PROJECTList of Contents

1. INTRODUCTION 2. MOTIVATION 3. SCOPE 4. CURRENT OPERATION OF MAKING STEEL 5. LITERATURE REVIEW 6. WHY STAINLESS STEEL? 7. MATERIALS SELECTION 8. DISCUSSIONS 9. RECOMMENDATIONS 10. REVIEW 11. QUESTIONS AND ANSWERS

MS 3005 DESIGN PROJECTIntroduction

Steel making can be separated into two categories- primary and secondary

Current trend – using of electric arc furnace (EAF) Advantages

400 tons of steel in 60 minutes Mass production= low price Flexible in stopping according to demand

Disadvantages Environmental and efficiency Cost

MS 3005 DESIGN PROJECTMotivation & Scope

The growing Steel processing industry The gist of making stainless steel lies in the decarburization

process. 2 types of decarburization processes

Vacuum oxygen decarburization (VOD) Argon oxygen decarburization (AOD)

hassle of transferring to another ladle focus on improving and redesigning two aspects of the

existing electric arc furnace 1. The process of vacuum decarburization 2. The stirring of the molten steel to obtain a homogenous

melt.

MS 3005 DESIGN PROJECTCurrent Operation of Making Steel

Video

MS 3005 DESIGN PROJECTLiterature Review

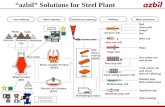

DESIGN OF AN ELECTRIC FURNACE FOR MAKING

STEELOur group is going to focus on

improving the design and manufacturing stainless steel using the Electric Arc Furnace

MS 3005 DESIGN PROJECTLiterature Review

Methods of making steel (Christopher 2007) Hits Focuses on the method of making steel using an electric arc

furnace Manage to come out with an invention make steel at a

reduced cost Generation of source of lime compacted to form a

conglomeration of compacts; charged to the furnace in the shortest period of time to avoid energy loss

Misses Did not explain how different kinds of steel, like stainless

steel, are made directly from the electric arc furnace

MS 3005 DESIGN PROJECTLiterature Review

Making of stainless steel without using electric arc furnace (Clifford 1971)

Hits patented a design which allowed them to produce stainless

steel without the use of an Electric Arc Furnace Misses Uses 2 channel furnaces A channel furnace is employed to mix chromium containing

and chromium-free hot metal, producing a converter feed metal of desired temperature and chemical composition.

MS 3005 DESIGN PROJECTLiterature Review

Making of stainless steel with an electric arc furnace without using secondary processes (Arturo 1991)

Hits identified the problems and enhanced the added oxygen

process to obtain good reducing conditions Installation of devices + lance system to introduce oxygen to

improve efficiency Misses Never looked into reducing the loss of chromium +

homogenization of melt

MS 3005 DESIGN PROJECTLiterature Review

Electromagnetic Stirring Commonly used in continuous casting of metals Prevents the creation of inhomogeneous steel It agitates the molten core Balances the temperature gradient between the outer shell

and inner core of casted metal Feasible in homogenizing the stainless steel melt in the steel

making process

MS 3005 DESIGN PROJECTWhy Stainless Steel?

WHAT is Stainless Steel? Low carbon steel alloy, 10 wt% of chromium by mass,

chromium oxide layer

Advantages 1. Corrosion resistance 2. Fire & Heat Resistance 3. Hygiene 4. Aesthetic appearance 5. Strength-to-weight advantage 6. Ease of fabrication 7. Impact Resistance 8. Long term value

MS 3005 DESIGN PROJECTMaterials Selection

Stainless Steel chosen for the roof of electric arc furnace typically

Properties considered 1. Melting point - high 2. Fracture Toughness - high 3. Specific Heat Capacity - high 4. Thermal Expansion coefficient - high 5. Thermal Conductivity – high Total number of decisions = N(N-1)/2 = 5(4)/2 = 10 decisions Weighting factors method Gathered data from CES software located at MSE computer lab Scaled data according to criterion Calculate Performance index

MS 3005 DESIGN PROJECTMaterials Selection

Table 1 Application of Digital Logic Method

Property Decision Number

1 2 3 4 5 6 7 8 9 10

Melting Point 1 1 1 1

Fracture Toughness

0 0 1 0

Specific Heat Capacity

1 1 0 0

Thermal Expansion Coefficient

1 0 1 0

Thermal Conductivity

0 1 0 0

MS 3005 DESIGN PROJECTMaterials Selection

Table 2 Weighting Factors

Property Positive Decisions Weighting Factors

Melting Point 4 0.4

Fracture Toughness 1 0.1

Specific Heat Capacity 2 0.2

Thermal Expansion Coefficient 2 0.2

Thermal Conductivity 1 0.1

Total 10 1

MS 3005 DESIGN PROJECTMaterials Selection

Table 3 Property of Candidate Materials for EAF

Material Melting Point

°F

Fracture Toughness ksi.in^1/2

Specific Heat Capacity BTU/lb.F

Thermal Expansion

Coefficient µ strain/°F

Thermal Conductivity

BTU.ft/h.ft^2.F

Wrought 418 Martensite Stainless Steel, tempered at

260degC 2597 24.57 0.1075 5.00E+00 13.29

Wrought 403 Ferritic Stainless Steel, intermediate

temper 2597 47.32 0.1075 5.56E+00 13.29

Wrought 202 Austenitic Stainless Steel, annealed

2552 61.88 0.117 9.17E+00 8.667

Wrought 301 Austenitic Stainless Steel

2552 61.88 0.1149 9.00E+00 9.013

Wrought 301 Precipitation Hardening Stainless Steel

2552 61.88 0.1149 9.00E+00 9.013

Cast Duplex Stainless Steel CD-4CU

2660 46.41 0.1075 5.56E+00 8.667

MS 3005 DESIGN PROJECTMaterials Selection As stainless steels are chosen commonly as roof material for

the typical electric arc furnace, 5 classes of stainless steels are chosen to be analyzed.

Wrought 202 Austenitic Stainless Steel, annealed, should be chosen to be made as the roof of electric arc furnace.

Table 4 Scaled Values of properties and performance index Performance

Scaled (1) Scaled (2) Scaled (3) Scaled (4) Scaled(5)

Wrought 418 Martensite Stainless Steel, tempered at 260degC

39.05 3.97 20 10.91 10 83.93

Wrought 403 Ferritic Stainless Steel, intermediate temper

39.05 7.65 20 12.12 10 88.82

Wrought 202 Austenitic Stainless Steel, annealed

38.38 10 21.77 20 6.52 96.66

Wrought 301 Austenitic Stainless Steel

38.38 10 21.38 19.64 6.78 96.17

Wrought 301 Precipitation Hardening Stainless Steel

38.38 10 21.38 19.64 6.78 96.17

Cast Duplex Stainless Steel CD-4CU

40 7.5 20 12.12 6.52 86.14

MS 3005 DESIGN PROJECTDiscussions - Vacuum Oxygen Decarburization

Concept To produce large steel ingots, rails, ball bearings and other

high quality steels.

MS 3005 DESIGN PROJECTDiscussions - Vacuum Oxygen Decarburization

Concept The oxidation of liquid steel components under the influence

of vacuum would result in the oxygen being used up mainly by the reaction [C] + [O] = {CO}

Use of Ellingham diagram

MS 3005 DESIGN PROJECTDiscussions - Vacuum Oxygen Decarburization

Concept A plot of Gibbs Free Energy ΔG against temperature. The Ellingham diagram shown is for metals which react with

oxygen to form oxides. The position of the line for a given reaction on the Ellingham

diagram shows the stability of the oxide as a function of temperature.

MS 3005 DESIGN PROJECTDiscussions - Vacuum Oxygen Decarburization

MS 3005 DESIGN PROJECTDiscussions - Vacuum Oxygen Decarburization

Concept Carbon unusually useful as a reducing agent. Ellingham Diagram This process helps to decarburize the steel with minimum

chromium losses. Complete deoxidizers then desulfurizing slag Problem?

MS 3005 DESIGN PROJECT Discussions - Vacuum Oxygen Decarburization

Design of the Furnace in incorporating an extensible roof with vacuum

Combine step of Vacuum Oxygen Decarburization

MS 3005 DESIGN PROJECT Discussions - Vacuum Oxygen Decarburization

Design of the Furnace in incorporating an extensible roof with vacuum

2 roofs which are interchangeable Simultaneous addition of oxygen Use of Vacuum Eliminates the need for another furnace

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Importance of Stirring the Molten Melt Homogenizing of molten melt Improving heat and mass transfer rates Reduce processing times Metallurgical restrictions

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Current Practice: Gas Stirring Use of Inert gases 2 commonly used methods: gas valve semi permeable refractory material

Safety Height

Vacuum Pump OutletLadle Lid

Molten Steel

Porous Plug or valve for gas injection

Gas Injection System

Refractory Material and Ladle Wall

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Disadvantages of Gas Stirring Additional processing step

Cost Inability to cut off gas flow Violent turbulence

Dangerous ejection of the melt

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Proposed solution: Electromagnetic stirring Applied in continuous casting processes Non-invasive Adjustable stirring strength Simplifies furnace process Variable stirring pattern

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Electromagnetic stirring: Working principle

Three Phase Power Supply

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Electromagnetic stirring: 2 proposed solutions Installation of stirrers at top of furnace

Installation of stirrers at side of furnace

Proposed solution 1: Installation of Inductor at top of furnace

Bottom Ring

Molten Melt

Refractory Material and Ladle Wall

Furnace Lid

X

X

MS 3005 DESIGN PROJECTDiscussions - Electromagnetic Stirring

Energizing (toroid)

coils

Top Ring

Top View of Furnace Lid

MS 3005 DESIGN PROJECT Discussions - Electromagnetic Stirring

Proposed solution 1: Installation of stirrers at top of furnace

Electromagnetic transducer

Predicted Flow lines

MS 3005 DESIGN PROJECT Discussions - Electromagnetic Stirring

Proposed solution 1: Installation of stirrers at top of furnace

Verdict: Unsuitable Inefficient Stirring pattern generated Inadequate Stirring strength

Stirring strength will have to rely on a single electrode Distance of electrode to melt

Solution: Installation of stirrers at side of furnace

MS 3005 DESIGN PROJECT Discussions - Electromagnetic Stirring

Proposed solution 2: Installation of stirrers at side of furnace

Electromagnetic transducers

Slag

Molten Metal

F

H

ν

Electromagnetic transducers

MS 3005 DESIGN PROJECT Discussions - Electromagnetic Stirring

Proposed solution 2: Installation of stirrers at side of furnace

Final Solution Installation of transducer at side of furnace

Summary Placement and number of magnetic stirrers Ability to control flow strength Predetermined stirring patterns for optimum performance Workable idea

MS 3005 DESIGN PROJECTRecommendations

Installation of Heat Exchanger system

Improvements in Refractory Material

Refractory Cooling System

MS 3005 DESIGN PROJECTReview

Summary of the current electric furnace operation present Literature review Why stainless steel is chosen Materials selection of the roof for the EAF (group design) Ellingham diagram and Vacuum Oxidation Decarburization Design of the Furnace in incorporating an extensible roof with

vacuum Design of the Furnace by implementing and installing

magnetic stirrers – side of furnace versus top of furnace Recommendations for future work

Last but not least . . .

MS 3005 DESIGN PROJECTQuestions & Answers

“Now… who ever said that steel making was a process that is hard to understand...”

“perhaps if your presenter was that informative, more students will be interested to venture into the steelmaking industry!”

Thank you. . . Questions and Answers