Design of the Toggle Jack

Transcript of Design of the Toggle Jack

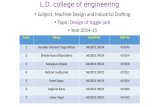

Scissor Jack Design Project

GE 410Fall 2005

Jim Ramirez David Hettinger

Instructor: Hall12/05/2005

ii

ABSTRACT

Scissor jacks are simple mechanisms used to drive large loads short distances. The

power screw design of a common scissor jack reduces the amount of force required by the user

to drive the mechanism. Most scissor jacks are similar in design, consisting of four main

members driven by a power screw. In this report, a unique design of a scissor jack is proposed

which is very easy to manufacture. Each member, including the power screw sleeves, is made of

the common c-shape. This eliminates the need for machined power screw sleeves, which

connect the four members and the power screw together. The manufacturability of the proposed

scissor jack lowers the cost of production.

iii

TABLE OF CONTENTS

Title Page…………………………………………………………………………………... i

Abstract…………………………………………………………………………………….. ii

Table of Contents…………………………………………………………………………... iii

Introduction………………………………………………………………………………… 4

Proposed Design…………………………………………………………………………… 5

Figure 1: Labeled Scissor Jack Design…………………………………………………….. 5

Table 1: Design Criteria……………………………………………………………………. 9

Conclusions and Recommendations……………………………………………………….. 10

Appendix A: Drawings…………………………………………………………………….. 11

Appendix B: Calculations and Assumptions for Components 2, 4, 6, and 8……………… 12

Appendix C: Calculations and Assumptions for Components 3 and 7……………………. 13

Appendix D: Calculations and Assumptions for Components 1 and 5……………………. 14

Appendix E: Calculations and Assumptions for Component 9……………………………. 15

Appendix F: Calculations and Assumptions for All Pins………………………………….. 16

Appendix G: Calculations and Assumptions for Crank Handle…………………………… 17

Appendix H: ANSYS Force Analysis……………………………………………………... 18

iv

Introduction

The most basic scissor jack design is truly engineering at its finest. With the power to

magnify input forces, scissor jacks allow us to raise vast loads using only a fraction of the force

ordinarily needed. Our goal in this project is to design an efficient scissor jack capable of raising

a 2000lb load. As a screw-driven mechanical system, the jack will be manually operated and

have at least 7 inches under load. The design will be transportable and storable, have a

removable crank handle, and operate with a factor of safety of n = 2 using standard mechanical

design methods for all components. The design itself has gone through multiple stages of

development. We have taken several possible failure modes into account and are confident that

our design is efficient and safe.

Proposed Design

Summary

The scissor jack design, shown in Figure 1, consists of four main lifting members, four

connection members, a power screw and a crank. Members 1 through 8 are all primarily c-

shapes with ideal pin connections. Members 1 and 5 both have additional details to account for

the contact surfaces. The power screw is single threaded with a collar at the member 3

connection. All members are 50 ksi strength steel with the exception of the rubber grip on the

crank. The following is a summary of the design features for our proposed scissor jack. Details

of the design specifications and failure criteria can be found in the attached appendices.

Figure 1: Proposed Scissor Jack Design with Labeled Members.

Main Lifting Members:

These members are made from simple c-shapes. The web of the members is cut out near

the pin connections to allow proper serviceability of the scissor jack at its maximum and

minimum heights. Members 4 and 6 have ideal gear connections to balance the load between the

left and right side.

The flanges of the channels are to wrap around the flanges of the sleeve members. The

lifting members are greater in length and are subjected to compression. Lifting member flanges

on the outside of the sleeve flanges is to compensate for slenderness ratio by increasing the

moment of inertia of the lifting members.

Sleeve Members:

The sleeve channels are to open inwards as shown in Figure 2. This is so the flanges are

subjected to tension instead of compression. The bending moment from the power screw creates

tension on the inner edge of the sleeve and compression on the outside edge. Tension along

flanges on the inside prevents the possibility of localized bucking in the flanges from

compressive forces.

Figure 2: Orientation of Sleeve Channels to Prevent Localized Buckling.

Additionally, the threaded sleeve section is to have additional thread surface area, shown

in Figure 3. These additional threads safely transmit the stress from the power screw to the

sleeve. Threading the thickness of the web of the channel would not be sufficient for reasonable

power screw diameters. This addition is only made on the threaded sleeve section and not on the

collared sleeve section. The collar transmits the stress safely to the c-shape.

Figure 3: Addition to C-Shape to Provide Adequate Threaded Area.

Contact Members:

The members that make contact with ground and the service load are members 1 and 5

respectively. Member 1 has additional flanges to provide a stable base for the mechanism while

servicing the load. Member 5 has an attached plate atop to provide sufficient contact area. Most

scissor jacks have ridges which lower the area of contact. This causes stress concentrations

which can damage the underside of a car.

The Power Screw:

The Power Screw is single threaded with a collar on the side in contact with Member 3.

The collar is assumed to be frictionless and the power screw has been designed to be self-

locking. The primary raising method is through the power screw’s hook coupling which is

common to most scissor jacks. Incorporated into our proposed design is an option for a

secondary raising method. The collar on the power screw doubles as a bolt with a hexagonal

head. In a situation where the main hook coupling becomes inoperable, a standard socket

wrench can be used on the hexagonal nut to raise the mechanism.

Design Criteria

The design checks used in the design of the scissor jack are summarized in Table 1. The

criteria are organized by failure mode with the applicable members identified.

Table 1: Design Checks for Different Failure Modes of Members.Failure Mode

Member(s) Criteria Check Comments

Torsion 9

Buckling 2,3,4,6,7,8 Long Columns (C=1)

Buckling 2,3,4,6,7,8 Intermediate

Length Columns (C=1)

Yielding in C and T

2,3,4,6,7,8 Distortion Energy Theory

Self-Locking

9

Bearing All PinsNominal

is the

projected area.Check both and

Shear All PinsNominal

Nominal includes threads in shear

plane area

Conclusion and Recommendations

Our proposed design is similar to common scissor designs in some aspects, but also

advantageous in others. Similar to others, our proposed design can safely raise a load of 2000

lbs to the required heights with relative ease on the user. Unique to our design, however, is the

manufacturability of our design, which is much simpler. Since only c-shapes are utilized, bulk

material can be more efficiently purchased and used. Also, less machining is required since

there are no complex sleeves for the power screw. Only simple attachments which can be

welded on are proposed. Therefore, when compared to similar scissor jack designs that perform

equally as well, our proposed design is recommended for its manufacturability and lower cost.

Appendix A: Drawings

Note: All Drawings are in Inches

Appendix B: Members 2, 4, 6, 8

Buckling Criteria (Long Columns):

Buckling Criteria (Intermediate Length Columns):

Yielding Using Distortion Energy Theory:

*See “Appendix B Support” for supporting calculations (not computer-generated)

**See ANSYS printouts in Appendix H: All force analysis support can be found there.

Appendix C: Members 3 and 7

Yielding Using Distortion Energy Theory:

This calculation simplifies the cross-section of member 7. The

addition of material inside the C-section (left) is added support for the power screw. It allows for increased shear strength. As a result, this calculation is conservative.

Combined Bending and Axial Compression:

for Member 7 (see Drawings section)

For this particular section, we understand that combined bending and axial compression leads to

eccentric loading that in turn magnifies the bending moment. However, given the small member

size it is highly unlikely that the member would bend significantly enough to consider a change.

Therefore, we just assume neglect the eccentric loading for our purposes.

*See “Appendix C Support” for supporting calculations (not computer-generated)

Appendix D: Members 1 and 5

Yielding Using Distortion Energy Theory:

Note: The members are too short to consider buckling as a mode of failure.

Appendix E: Member 9

Yielding Using Distortion Energy Theory:

Combined Tension and Torsion

Assume a frictionless collar.

Self-Locking:

Assume coefficient of friction =0.15, =0.62in and =0.11in. (Referenced Table 8-3 Shigley)

Bearing Stresses on the Collar: where

Appendix F: All Pins

Bearing Stresses: where

Note: We use two times the projected area because there are actually two identical projected areas through which the pin passes.

Shear Stresses: where

Note: We use two times the cross-sectional area because there are actually two shear planes through which the pin passes.

We can assume that these hold true for all pins. The maximum axial force is 3.162 kips, so all of our designs assume a worst-case scenario.

Appendix G: Crank Handle

Check of Raising Torque Requirement:

Assume a human force of 50 lbs is applied to the crank handle.

Appendix H: ANSYS Force Analysis

Note: Power Screw is composed of members 9 and 10 in ANSYS report