DENIM BY NATURE - Prismadyeprismadye.com/Files/BROCHURES/Denim_by_nature.pdf · Authentic denim is...

-

Upload

nguyentuyen -

Category

Documents

-

view

217 -

download

4

Transcript of DENIM BY NATURE - Prismadyeprismadye.com/Files/BROCHURES/Denim_by_nature.pdf · Authentic denim is...

ContentS

2

02

03-04

05

06-07

08-09

10

11

12-14

Content Page

Mastering Denim

Conceptualization

Preparation and Pretreatment

Design - Dyeing

Design - Weaving

Shaping

Masterpiece

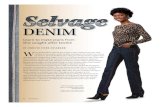

MASTERING DENIM

3

Authentic denim is a specialty and requires years of experience to understand and develop. BASF sees it as an art and a closely guarded secret. The masterpiece is a tone of sophistication, innovation and creativity. We offer our customers superior denim solutions, in terms of performance and quality, trusted by leading denim producers worldwide, so that together, we may explore a better future.

Putting FUTURE into Textiles.We put a better FUTURE in your hands through improved consumer safety, efficient use of resources and reduced carbon emissions. As a reliable partner, FUTURE to us means that we will continue offering solutions for today and tomorrow with the FUTURE already built in. With BASF’s denim range, customers can produce high-quality products efficiently. This contributes to energy savings and ultimately, climate protection.

Conceptualization

5

PretreatmentProcesses: Wetting, Scouring, Mercerizing, Sequestering Here, the yarn is prepared, in order to be ready for taking up dyestuff that includes cleaning, removing dirt and oils – to purify.

Dyeing Processes: Dispersing, Sequestering, Wetting, Anti-foaming, Reducing, Rope opening, Re-beaming There is only a single type of indigo, and the difference between good and bad dyeing is dependant on the auxiliaries.

Garmenting Processes: 3-D effects, Whiskering, Crunching, Different Looks e.g.Vintage, Distressed, Dirty, WetGarmenting provides the final touch on a pair of jeans and converts it into various looks and effects for that exclusive style you desire.

Weaving Processes: Sizes, Sizing Additives Dyed yarns are treated with Size and Sizing additives for weaving.

Finishing/Coating Processes: Flat Finish, Coating, Color Fast Finish, Resin, SoftenerThis is the stage where an authentic/classic denim fabric is transformed into colourful creations by using various types of finishings or coatings, thus offering different styles and provides the wearer with a distinctive character.

preparation and pretreatmentKieralon® Wash MFB

6

Characteristics: • Extraction of water-hardening substances and pectins • Removal of fibre impurities • Prevent precipitation of alkaline earth carbonates and formation of deposits • Low foaming

preparation and pretreatment

7

Characteristics: • Excellent wetting effect in causticizing • Promotes intensive & rapid penetration with caustic soda • Optimum wetting effect in the range of 12-22° Bé caustic soda • Lowers the risk of streakiness on denim especially after garment washing

Kieralon® Mercerizer MC

Design - Dyeing

Dyed at pH 11.5 – dyes are concentrated at the ‘outer ring’ of the yarns which results in darker shades

Dyed with 1.5 g/l(Hydrosulfite E at pH 11.5)

8

Characteristics:

• Re-wetting effect

• Anti-foam in the indigo dyeing process

• Keeps the rollers clean

• Stable even with high salt concentration

• Lowers risk of streaks after stonewash

Primasol® NF

Design - Dyeing

9

Characteristics:

• Facilitate re-vatting in the dye bath • Prevent agglomeration of indigo pigment • Improve the rub fastness of dark denim • Stable against acid, alkali, water hardness and electrolyte

Setamol® WS

Dyed at pH 11.5 – dyes are concentrated at the ‘outer ring’ of the yarns which results in darker shades

Dyed with 1.5 g/l(Hydrosulfite E at pH 11.5)

Design - Weaving

10

Characteristics:

• Very flexible size film

• High weaving efficiency and low rate of yarn breaks

• Improves the desizing properties of natural and modified starch significantly • Less dust in sizing and weaving

• Improves the adhesion of starch to cellulose • When properly used with starch, Size CO maintains an ideal moisture content

Size CO

Dyed at pH 11.5 – dyes are concentrated at the ‘outer ring’ of the yarns which results in darker shades

Dyed with 1.5 g/l(Hydrosulfite E at pH 11.5)

Shaping

11

Shaping is a combination of the Finishing, Coating and Garmenting processes, which gives the final desired form of the denim jeans or garments a unique touch and style.

List of key products for denim with the technical highlights and purposes for different applications during denim manufacturing:

APPLICATION PRODUCT

Pretreatment Kieralon® Wash MFB

Mercerizing Kieralon® Merceriser MC

Dyeing

Primasol® NF

Lufibrol® Chelant TA/TB

Setamol® WS, Setamol® BL

Uniperol® O Micropearl, Albigen® A

Lurotex® A25, Textile Wax W

Sizing Size CO, Size CB

Pigment dyeing and printing Helizarin® Pigments

APPLICATION PRODUCT

Pretreatment Kieralon® Wash MFB

Mercerizing Kieralon® Mercerizer MC

Dyeing

Primasol® NF

Lufibrol® Chelant TA/TB

Setamol® WS, Setamol® BL

Uniperol® O Micropearl, Albigen® A

Lurotex® A25, Textile Wax W

Sizing Size CO, Size CB

Pigment dyeing and printing Helizarin® Pigments** Please see details of our understanding on "APEO-free" at www.basf.com/textile-responsibility

13

APPLICATION PRODUCT

Finishing

Lurotex® Protector RP ECO, Lurotex® Protector RL ECO

Series of Fixapret®, Ekolin®, Condensol®, Perapret®, Siligen®

Fixapret® Resin NF

Perapret® PU New, Perapret® Booster XLR

Coating

Helizarin® Binder TS

Helizarin® Binder TOW

Lurapret® Dispersion D 888

Lurapret® Dispersion DS 335

Lurapret® Dispersion SB 630

Lurapret® Dispersion D 2374

Lurapret® Thickener DTU

APPLICATION PRODUCT

Finishing

Lurotex® Protector RP ECO, Lurotex® Protector RL ECO

Series of Fixapret®, Ekolin®, Condensol®, Perapret®, Siligen®

Fixapret® Resin NF

Perapret® PU New, Perapret® Booster XLR

Coating

Helizarin® Binder TS

Helizarin® Binder TOW

Lurapret® Dispersion D 888

Lurapret® Dispersion DS 335

Lurapret® Dispersion SB 630

Lurapret® Dispersion D 2374

Lurapret® Thickener DTU** Please see details of our understanding on "APEO-free" at www.basf.com/textile-responsibility

14

We look forward to partnering with you to create a better future.

® = Registered trademark of BASF SE in EU and many other countries

Note: The data contained in this publication are based on our current knowledge and experience. In view of the many factors that may affect processing and application

of our product, these data do not relieve processors from carrying out their own investigations and tests; neither do these data imply any guarantee of certain properties,

nor the suitability of the product for a specific purpose. Any descriptions drawings, photographs, data, proportions, weights, etc. given herein may change without prior

information and do not constitute the agreed contractual quality of the product. It is the responsibility of the recipient of our products to ensure that any proprietary rights

and existing laws and legislation are observed. Responsibility for compliance with the requirements of the downstream textile market rests with the textile processor.