Dayton Business Jounal 4.28.11

-

Upload

definity-partners -

Category

Documents

-

view

149 -

download

0

Transcript of Dayton Business Jounal 4.28.11

APRIL 29, 2011 dayton.bizjournals.com

PDI increases local manufacturingSpringboro firm posts

20% revenue boost BY JOE COGLIANO

DBJ STAFF REPORTER

JOE COGLIANO DBJ

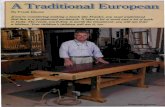

Smart Changes: Lou Vilardo, president of Springboro-based PDI Communication

System stands in front of the company’s movable televisions, which are used in

health care facilities. Vilardo reconfigured his facility last year to bring more manu-

facturing under his roof.

BY JOE COGLIANODBJ STAFF REPORTER

About a year ago, Lou Vilardo faced a dilemma.

The president of PDI Communication Systems Inc. wanted to bring more man-ufacturing work under the roof of the company’s 70,000-square-foot plant in Springboro, but had run out of space.

PDI makes personal televisions, support arm assemblies and mounts for health care facilities — such as hospitals, dialysis and oncology care facilities and nursing homes — and Vilardo pictured a better bottom line by scaling back on the production it outsourced.

His first thought was to build an addition or lease other buildings around town, but Vilardo’s advisory board suggested he go in another direction: launch a new efficiency, or lean, campaign.

This would involve reconfiguring the production floor and training all levels of management to work smarter.

“You probably have the space within your four walls, you just don’t know it,” the board told Vilardo, an auto industry veteran who joined the company in the late 1990s and became sole owner in 2007.

Vilardo took the advice and went on a mission to tear apart and rebuild the way PDI operates.

Since completing the project last fall, he said about half of PDI’s revenue now comes from products manufactured in Springboro, compared with 20 percent just a few years ago. The company’s bottom line also improved by more than 10 percent.

In terms of revenue, the company posted a 20 percent increase last year, compared to 2009, and Vilardo expects the company to match revenue this year.

At the same time, PDI saved money since an addition project could have run nearly $1 million while the lean campaign cost about $300,000, including everything from consulting fees to new concrete floors to support equipment that had to be moved.

“So we can do the assembly work here and compete fairly well with China or Korea,” Vilardo said. “We’re a manufacturer,

we make stuff, we don’t want to be a ware-house distributor.”

A different approach

PDI had gone through lean initiatives in the past, but those were relatively small projects and the outcomes never really took hold.

So, Vilardo hired Mason-based Definity Partners last spring to put PDI under a microscope and develop an initiative that would be sustainable.

Definity Partners is a business improve-ment firm.

For starters, Definity helped PDI revamp

PDI increases local manufacturing

See PDI page 9

JOE COGLIANO DBJ

Smart Changes: Lou Vilardo, president of Springboro-based PDI Communication System stands in front of the company’s movable televi-sions, which are used in health care facilities. Vilardo reconfigured his facility last year to bring more manufacturing under his roof.

Springboro firm posts 20% revenue boost

STRATEGIES8 DAYTON BUSINESS JOURNAL bizjournals.com/dayton APRIL 29, 2011

For years, we believed that if customers received bad service, they would pass the word along to 20 or so people. Conversely, if they were on the receiving end of great service, they might tell a few folks, but not in numbers anywhere near the

bad-news story.Enter the Internet. Bad

reports can span the globe instantly. Good reports can too, but they are not shared as frequently. One company that learned

this lesson the hard way is United Airlines. In March 2008, Dave Carroll and his band, Sons of Maxwell, were flying on United Airlines from Halifax to Omaha with a stopover in Chicago. At that first stop, a woman seated near the band looked out the window and exclaimed, “They’re throwing guitars out there!”

Band members witnessed their expen-sive instruments being handled roughly. Carroll’s guitar alone was a $3,500 Taylor model. Concerned, he approached the flight attendant and was sent to another

agent outside the plane. But that per-son claimed to have no authority and walked away. A third employee at the gate dismissed his complaint, explaining “that’s why we make you sign the waiver.” Problem: Carroll and the band members had neither been offered nor signed such a waiver.

When he finally got to check out his guitar in Omaha, he discovered the base of the guitar had been smashed. Even a $1,200 repair didn’t restore it to its original condition.

And Carroll’s experience with United as he sought restitution is a horror story that spanned nine months of phone calls, emails, faxes, buck-passing and a final “Sorry, but we’re not paying.”

Most of us would have given up at that point, but then most of us aren’t as cre-ative as Dave Carroll. He turned it into a career opportunity.

“At that moment it occurred to me that I had been fighting a losing battle …”

Customer service in Internet Age takes new wave of concern

See MACKAY page 9

HARVEY MACKAY: SWIMMING WITH THE SHARKS

Contact: Lou Vilardo, presidentAddress: 40 Greenwood Lane, Springboro 45066Phone: (800) 628-9870Web: pdiarm.comBusiness: Personal television and related arm assem-blies for health care facilities

PDI COMMUNICATION SYSTEMS

About a year ago, Lou Vilardo faced a dilemma.

The president of PDI Commu-nication Systems Inc. wanted to bring more manufacturing work under the roof of the company’s 70,000-square-foot plant in Spring-boro, but had run out of space.

PDI makes personal televisions, support arm assemblies and mounts for health care facilities — such as hospitals, dialysis and oncology care facilities and nursing homes — and Vilardo pictured a better bottom line by scaling back on the production it outsourced.

His first thought was to build an addition or lease other buildings around town, but Vilardo’s advisory board suggested he go in another direction: launch a new efficiency, or lean, campaign.

This would involve reconfiguring the production floor and training all levels of management to work smarter.

“You probably have the space within your four walls, you just don’t know it,” the board told Vilardo, an auto industry veteran who joined the company in the late 1990s and became sole owner in 2007.

Vilardo took the advice and

went on a mission to tear apart and rebuild the way PDI operates.

Since completing the project last fall, he said about half of PDI’s revenue now comes from products manufactured in Springboro, com-pared with 20 percent just a few years ago. The company’s bottom line also improved by more than 10 percent.

In terms of revenue, the company posted a 20 percent increase last

year, compared to 2009, and Vilardo expects the company to match rev-enue this year.

At the same time, PDI saved mon-ey since an addition project could

Reprinted for web use with permission from Dayton Business Journal. ©2011, all rights reserved. Reprinted exclusively by Scoop ReprintSource 1-800-767-3263.

have run nearly $1 million while the lean campaign cost about $300,000, including everything from consult-ing fees to new concrete floors to support equipment that had to be moved.

“So we can do the assembly work here and compete fairly well with China or Korea,” Vilardo said. “We’re a manufacturer, we make stuff, we don’t want to be a ware-house distributor.”

A different approach

PDI had gone through lean ini-tiatives in the past, but those were relatively small projects and the outcomes never really took hold.

So, Vilardo hired Mason-based Definity Partners last spring to put PDI under a microscope and devel-op an initiative that would be sus-tainable.

Definity Partners is a business improvement firm.

For starters, Definity helped PDI revamp work areas and production lines, boosting efficiency while opening up 5,000 square feet for much-needed storage space and 2,500 square feet for new products lines.

Then, it went about changing the way PDI employees think about their jobs.

Vilardo said his people worked hard, but admits PDI wasn’t very efficient before the project. The

company — with 95 employees plus as many as 20 temps working at any time — had higher-level manag-ers who were micromanaging the operation and floor supervisors who spent too much of their time work-ing on the assembly line.

To fix the issue, several top man-agers at PDI were schooled in how to train middle man-agers on being more effective supervi-sors. This produced a ripple effect that cut the need for top managers to micromanage and floor supervi-sors to perform the work of their operators.

PDI also launched a daily huddle, 10- to 15-minute morning meetings, where individual departments could gather to discuss everything from what went well — and what didn’t go well — the previous day, plus worker ideas.

Since completing the initiative, Vilardo said PDI is producing 50 percent more televisions with the same number of workers.

“We’ve always had great people, we just needed to do some things differently,” Vilardo said. “Any time you give people the freedom to think about what they’re doing and improve their work environment, that’s a good thing.”

Jay Kuhn, president of Defin-

ity, said it is common for manufac-turing companies to start on lean initiatives that don’t take hold because they only focus on one part of the equation — processes.

“They never really work on chang-ing people’s mindset,” Kuhn said. “That’s really what prevents your false starts is really changing the attitude of the people.”

PDI’s roots trace back to a con-tract machine shop called Precision Industries. In late 1980s, Preci-sion Industries started making arm mounts for a client and migrated into putting modified consumer-brand televisions on the end of the arms. Over time, PDI morphed into the main business and began pro-ducing its own televisions as well as bigger sets beyond the arm-mounted models.

The company sells its product to health care facilities through dis-tributors.

Precision Industries still exists, but much of its work is done for PDI.

PDI’s future looks bright. Vilar-do looks to add more produc-tion in Springboro, such as a new arm-mounted TV with computing options and two private label prod-ucts, which could spur the need for another six employees.

As a result, he may soon be facing the need for more space.

“At least for now, I know we’re getting the most out of what we have,” Vilardo said.

PDI: Company may add additional lines for production at its Springboro facility

Jay Kuhn