Datasheet SimSci FCC-FluidCatalyticCrackerReactorModel 12-11

description

Transcript of Datasheet SimSci FCC-FluidCatalyticCrackerReactorModel 12-11

Software Datasheet

Summary

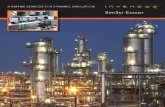

SimSci-Esscor’s fluid

catalytic cracker (FCC)

Reactor Model provides

you with a key component

of the refinery, FCC

units, within the ROMeo

Refinery Modeling

software so that the

refinery can be simulated,

monitored and optimized.

Tested and proven on

industrial units, the model

gives the flexibility of

tuning parameters online,

providing an accurate

representation of your

FCC reactor.

Business Value

• Helpunderstandingthe

process and complex

interaction between

riser/reactor and

regenerator

• Debottleneckingand

process improvement

study

• MonitorFCCprocess,

track pressure and

heat balances and

catalyst activity for peak

performance

• Maximizeprofitby

optimizing the FCC unit

continously

RIGOROUS FCC MODELING SimSci-Esscor’s™ Fluid Catalytic Cracker (FCC) Reactor Model is one of the reactor models for Refinery Modeling in SimSci-Esscor’s industry-leading ROMeo® Online Performance Suite. The FCC Reactor Model can be used to model industrial FCC reactors of different designs.

FEATURESThe FCC model offers the following key features:

•ConfigurableinterfaceaccommodatesdifferentFCCdesigns• Inputsincludefeedcharacteristics,dimensionsofthereactorandoperating

condition• Rigorousheatbalancearoundreactorandregenerator•CatalystinformationcanbeuseddirectlyviaE-CATdata• PredictsProductcompositionandpropertiessuchasoctane,cetanenumbersand

sulfur distribution and many others• Predictconversionandtemperatureprofilesintheriser•Containsdetailedkineticsub-modelsforriser,reactorandregenerator,anda

pressure balance model for accurate catalyst circulation modeling• YieldsandPropertiestunablewhilethemodelisonlinetomaintainmodelaccuracy

with changing feeds and operating conditions

Fluid Catalytic CrackerReactor Model

Invensys,theInvensyslogo,ArchestrA,Avantis,Eurotherm,Foxboro,IMServ,InFusion,SimSci-Esscor,Skelta,Triconex,andWonderwarearetrademarksofInvensysplc,itssubsidiariesoraffiliates.Allotherbrandsandproductnamesmaybethetrademarksorservicemarksoftheirrepresentativeowners.

©2011InvensysSystems,Inc.Allrightsreserved.Nopartofthematerialprotectedbythiscopyrightmaybereproducedorutilizedinanyformorbyanymeans,electronicormechanical,includingphotocopying,recording,broadcasting,orbyanyinformationstorageandretrievalsystem,withoutpermissioninwritingfromInvensysSystems,Inc.

Invensys Operations Management • 5601 Granite Parkway III, #1000, Plano, TX 75024 • Tel: (469) 365-6400 • Fax: (469) 365-6401 • iom.invensys.com

APPLICATIONS•Refinery-widemodelingandoptimizationforunderstandingtheinteractionbetweentheFCCandupstream/downstreamunits

•Operatorandengineerfamiliarizationforbetterunderstandingoftheprocess•PlanningmodelupdatesbasedoncurrentFCCunitcharacteristicsandoperatingconditions•OnlineorOfflineFCCperformancemonitoringandoptimization•Offlineengineering&processimprovementstudieswithofflineSIM4ME®PortalExcel®interface

ROMeo REFINERY MODELINGROMeoRefineryisauniquesolutionthatenablesscalablerefinery-widemodeling&optimization.Whiletraditionalmodelingsolutionscanonlysimulateindividualprocessunitsorprovidepointsolutionstosolveaspecificproblem,theROMeoOnlinePerformanceSuiteprovidesascalableplatformthatenablescompaniestooptimizerefinery-wideperformanceaswelloptimizeotheraspectsofrefineryprofitabilitysuchasUtilitiesandinstrument/equipmenthealthmonitoring.Additionalbenefitsarederivedfromleveragingthedata-generatedrigorousmodelstoenhancedplanningandschedulingdecisions,leadingtoincreasedrefinerymargins.

Rev.12/11PNSE-0158

![ST INDEX FUTURES SIMSCI SIMSCI FUTURES/media/MAS_Newsletter/SIFC24062013... · By SIOW LI SEN [SINGAPORE] Banks here handled deals worth over twobillion yuan (S$411mil-lion) yesterday](https://static.fdocuments.in/doc/165x107/5ad8468e7f8b9a32618d4fc6/st-index-futures-simsci-simsci-mediamasnewslettersifc24062013by-siow-li-sen.jpg)