Cross Brush Cleaners - STARTSEITE | SCHLEIFSTEIN ... · Cross Brush Cleaners If dry is enough …...

-

Upload

nguyenlien -

Category

Documents

-

view

218 -

download

3

Transcript of Cross Brush Cleaners - STARTSEITE | SCHLEIFSTEIN ... · Cross Brush Cleaners If dry is enough …...

Cross Brush Cleaners

If dry is enough …

As alternative to the washing machines (wet-washing procedure) our newly devel-oped dry-cleaning machine is especially destined for the use in press shops.

The cross brush cleaner is used where blanks and coils with light to medium surface dirt must be cleaned prior to the forming process or further processing. The dry-cleaning process has been well-tried also for car outer panels. Moreover, for cer-tain applications no washers can be used.

The costs for investment and operation for a cross brush cleaner are lower com-pared to a washing machine.

The SCHLEIFSTEIN-cross brush cleaner, as expected from us, is a solid design for permanent operation in press shops. It is known for its compact and maintenance-friendly design as well as for a high de-gree of automation. The cleaning function is continuously controlled and adjusted by means of special sensors and actors.

And if your process requires any oiling after cleaning, we then supply our cross brush cleaner in combination with our leading spray lubrication technology out of one hand …

RZ_Querbuerstmaschine_2010_engl_V1.indd 1 12.10.12 16:35

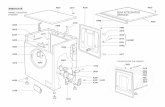

Technical DataCross Brush Cleaner

blank thickness standard: 0.5 – 3.0 mm, or as requiredblank width crosswise to passing direction standard width: 500 – 5000 mm in grids of 100 mm, or as required blank length in passing direction min. 200 mmblank shape/type rectangular and formed blanks, also with cutouts, double and multiple blanks next to each other, welded blanks

blank material steel, non-galvanized and galvanized, aluminium, other nonferrous metals

passing speed max. 180 m/min drives blank conveyor frequency-controlleddrives linear brushes frequency-controlled

type linear brushes heavy-duty flat belts; garnishing: polyamide; Ø 0.2 mm; h=20 mm duplex brushes 2 x 40 mm above/below each

design standard: stationary optional: manual or traversible by motor

control Siemens S7 alternatively: Allen-Bradley ControlLogix Beckhoff Twincat

visualisation standard: Siemens WIN CC Flexible alternatively: Allen-Bradley FactoryTalk

Design of the machine:

•solidsteelconstructionsuitablefortheuseinpressshops•completehousingaroundthemachine,analogousmovementofthemachinecoverings•maintenance-friendlydesign:highstrokesofthebrushandconveyoraggregates•veryshortbrushreplacingtimes;highlifetimeofbrushes•frequency-controlledbrushingspeed•automaticbrushwearsensor•automaticandexactbrushadjustmenttotheblankthickness•functioncontrolofthebrushes•brushcollisionprotectionvialightbarriersensororcrashlever,quick-strokefunction•brushcleaningbyrotationstripperswithintegratedairnozzles•suckingoffthedirtbyheavy-dutysuctionventilatorswithdirt-controlledfilterunit•oilsumpswithfillinglevelcontrol•solidandefficientblankconveyorsystem,frequency-controlled:noslippingorlateraloffset•upperconveyortablespneumaticallyliftable•flexibleinterfacestosuperiorcontrols

The SCHLEIFSTEIN- cross brush cleaner isperfect for the combination with a subsequent SCHLEIFSTEIN-spray lubrica-tion system. By using a SCHLEIFSTEIN-Brusher/Oiler-combinationyousignificantlyimprovethe availability of your machines and the quality of the subsequent processes.

Schleifstein Maschinentechnik GmbHSiegstrasse 92 | 57076 Siegen | Germanyphone +49 (0)2 71-77 51-0 | telefax +49 (0)2 71-77 51-150e-mail: [email protected] | www.schleifstein.de

smt | conveying | cleaning | oiling | all out of one hand

RZ_Querbuerstmaschine_2010_engl_V1.indd 2 12.10.12 16:35