Corporate (8.5 x 11) - Valves.Comvalvescom.com/pdf/Zero_Leakage_Metal_Seated.pdf · Main Steam Stop...

Transcript of Corporate (8.5 x 11) - Valves.Comvalvescom.com/pdf/Zero_Leakage_Metal_Seated.pdf · Main Steam Stop...

SOLUTIONS1

Valvtechnologies’ mission is to provide zeroleakage isolation valve solutions for severeservice to its customers.

As a global leader in the design and manufacturing of zero leakage

valves. Valvtechnologies has established a worldwide reputation for

superior quality and dependability with customers in every industry.

From standard applications to the most sophisticated,

Valvtechnologies is committed to providing solutions for customers to

manage its process safely and efficiently.

Our approach at Valvtechnologies is based on customer satisfaction,

safety, people, process and performance. By equipping highly trained

people with the latest technology, Valvtechnologies has created an

atmosphere where quality and reliability are built into its prod-

ucts from start to finish. All of Valvtechnologies’ valves are

designed with customers’ requirements in mind and offer proven

reliability, superior engineered performance and unique safety

features. By focusing on these principles, Valvtechnologies has become

an integral part of its customers’ asset management strategy.

Valvtechnologiesfocus is to provide

zero leakageisolation valve

solutions

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

SOLUTIONS

2

With over twenty years of business growth, Valvtechnologies has

maintained a culture for innovation by continuously expanding its

design, production and technology capabilities.

Valvtechnologies’ manufacturing facility features a large production

area that includes a complete machine shop as well as a certified

welding department. These departments along with a large inventory of parts

and stock valves allow Valvtechnologies to have full control of all aspects of

the manufacturing process, even for the most demanding projects.

Valvtechnologies is a committed partner in providing solutions to

manage your process; saving time, money and improving efficiency.

Valvtechnologiesis a committed

partner in providingsolutions to its

customers

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

COMPANY

PEOPLE3

From the shop floor to the purchasingdepartment, employees are committed tocontinually developing innovative design,production and technology capabilities.

At Valvtechnologies, the employees are a valuable asset. The

organization is made up of functional teams that focus on customer

service, safety, product development, quality management, assembly

and testing. With a full staff of professional engineers to a technical

sales team to certified service technicians, we are more than a

manufacturer; we are a partner for providing superior solutions to

your process needs.

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

PEOPLE

PROCESS4

At Valvtechnologies,we relentlesslypursue productand process

improvements

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

RAM® Coating

Complete On-site Machine Shop

At Valvtechnologies, our process andprocedures ensure that our valves

exceed our customers needs.

From raw material through to the finished product, we

are constantly looking for methods to apply innovative

technology to our process. While many valve manufacturers

are focused on cutting corners to save costs, we hold firm to

our core design principals and relentlessly pursue product and

process improvements. Valvtechnologies’ in-house research

and design includes the flow-testing program and the

development of diagnostic tools for measuring energy loss.

We also work directly with customers to develop solutions to

meet unique process requirements and specialty applications.

PROCESS

Flow Loop Testing

Complete On-site Welding Shop

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

PERFORMANCE

PERFORMANCE

Valvtechnologies sets the standard for the nextgeneration of valves

At Valvtechnologies, we are totally committed to quality. We

measure our performance against the standards set out in our

Integrated Quality Program. Our Quality Assurance department

diligently pursues opportunities for improvement and the entire

organization takes ownership of the quality program. In this way, we

can improve our processes while increasing manufacturing efficiency.

Valvtechnologies, Inc. is certified to ISO 9001,and ASME Section 1, API Q1, PED and NB-23.

International quality standards assure conformance to specified

requirements of our total process. These requirements include design,

development, order processing, production, purchasing, quality control,

installation and service. Our plan is based on the requirements of ISO

9001, API Q1, PED and NB-23.

Valvtechnologiesvalves offer

ZERO LEAKAGEperformanceand reduce

maintenance costs

5

SERVICE6

ServiceValvtechnologies is committed to helping our global network of

customers maintain peak valve performance. Valvtechnologies hasmultiple authorized service centers that are available 24 hours a day, 7days a week to assist with valve installation, commissioning,troubleshooting and actuator maintenance on all continents of theworld.

TVM® providespredictive and preventativemaintenanceprograms.

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

SERVICE

TVM® Total Valve ManagementValvtechnologies encourages end users to apply the principles of

Asset Management to their installed valve population. TheValvtechnologies Total Valve Management (TVM®) program utilizesnext-generation thermal and acoustic monitoring instruments, as wellas a database of performance tables to help customers monitor valveperformance. These tools allow predictive and preventative maintenanceprograms to be fine-tuned for very large or very small valve populations.TVM® can be as simple as a valve survey, or as comprehensive as themanagement of all valve work during your next outage—from erectingscaffolds to repairing, installing, welding and stress relieving.

Washington

Alberta

California

Texas

Trinidad/Tobago

South Africa

Western Australia

Eastern Australia

Venezuela

LouisianaMissouri

North CarolinaWest Virginia

Ohio

Pennsylvania

Italy

United Kingdom

Middle East

MassachusettsNew JerseyUtah

Peru

Chile

Malaysia Singapore

China

Thailand

Russia

Factory Authorized Service Centers

APPLICATIONS7

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

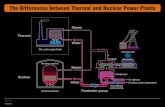

APPLICATIONSFossil FuelBoiler DrainsStartup VentsElectronic ReliefFeedwater IsolationTurbine Bypass SystemsContinuous Boiler BlowdownGauge Glass DrainsAbove & Below Seat DrainsBoiler Feedpump RecirculationAttemporator Spray Control Sight Glass Drains Above & Below Seal Drains Soot Blower Regulators Steam Dump Ash Handling Main Steam StopSeal Steam Regulators Turbine DrainInstrument IsolationFeedwater Heater Drains

NuclearHigh Pressure Oil Safety related Reactor water

cooling system drain and ventsSampling Quench Tank VentsReactor Head VentsRCP System Drains & VentsBoron Water Tank Filling IsolationMain Steam Drains & VentsTurbine Drains & VentsTurbine By-passCCW Seawater Intake Valves & DrainsPressurizer Vents & DrainsWaste Processing Chemical Volume and Control

POWERCoker ApplicationsSwitchingFeed IsolationOverhead Vapor LineCutting Water Isolation

FCCU ApplicationsCatalyst HandlingSlurry Isolation & ControlSteam

CCR ApplicationsLockhopper Feed

H-Oil Upgrading &LC Fining ApplicationsCatalyst Addition & WithdrawalFilter and Pump IsolationOverhead Vapor Isolation

& ControlHigh Delta-P Isolation & Control

Ethylene ApplicationsSteam Decoke IsolationFurnace IsolationSteam VentQuench Oil Isolation & Control

Polyethylene ApplicationsIsolationHigh Cycle (PTO)Reactor Block

HYDROCARBONS

Our design departmentis focused on creating

solutions for yourprocess applications

APPLICATIONS8

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

APPLICATIONSHigh Pressure SlurryTransportation SystemsPump Discharge IsolationPipeline Isolation StationsPipeline Choke StationsRupture Disk IsolationInstrument Isolation

Mineral ConcentratorsThickener Underflow Discharge

IsolationFilter Press Manifold Isolation Slurry Transfer SystemsPRV Isolation

AutoclavesVessel Feed & Discharge Acid InjectionGas InjectionSteam Injection

Waste DisposalPaste Backfill DistributionTailing Distribution

MINING PULP & PAPERBoiler Vent & DrainLiquor Isolation & ControlRapid DrainSteam IsolationSky VentsDryer Pressure ControlDigester Steam ControlLime Mud Isolation & Control

Steam & Water InjectionWellhead Choke IsolationSAGD IsolationCompressor RecyclePig Launcher & ReceiverESDVent to FlareSour Gas Isolation & ControlCryogenicSteam ChokesHIPPS IsolationDouble Block and Bleed

Vacuum Chamber IsolationCombustion Testing Isolation

& ControlCryogenic Fluid Isolation

OIL & GAS

AEROSPACE

V1-19

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

V1-1Forged, High

Pressure ValvesANSI 900 - 4500

1/4 ” - 4” The flagship of the Valvtechnologies’ product

line, the V1-1, is the valve by which all other

metal-seated ball valves are measured. The V1-

1 design includes integral seats, RAM® hard

coatings, blowout proof stem and live-loaded

packing. Primarily used in high-energy applica-

tions in the Power Industry, the V1-1is available in sizes from 1/4" to 4", and ANSI pressure classes

900 to 4500, including interpolated and special ratings. V1-1 valves are manufactured in a variety of

forged materials and end connections to meet our customers’ specifications. Most importantly, every

V1-1valve for Power Industry applications is backed by our four-year ZERO leakage guarantee.

Actuator Mounting Pad

Gland

Live-Loaded Gland Springs

Gland Packing

Hard FacedOne-Piece Blow-Out Proof Stem

High Load Belleville Spring

High Load Belleville Spring

Upstream Seat Guide

Hardcoated Ball

Body Seal

Hardcoated Integral Seat

V1-2 10

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

V1-2 Low Pressure, Flanged ValvesANSI 150 - 6001/2 ” - 36”

The V1-2 valve applies our core design con-

cepts to industrial processes where lower pressure

classes are more common. This valve is designed for

critical isolation applications in Hydrocarbon

Refining and Processing, Mining, Oil & Gas

Production, Pulp & Paper and other industries. The V1-2 is available in pressure classes

150 to 600, sizes 1/2" to 36", and in virtually any cast or forged material. The valve can

be custom designed to include special end connections, purge ports, cavity fillers, cryogenic

stem extensions, fugitive emission bonnets, abrasion resistant linings and many other

process-specific options. Furthermore, the standard V1-2 design is fire safe to the API

607 Rev. 4 fire test standard.

Actuator Mounting Pad

Gland

Live-Loaded Gland Springs

Gland Packing

Hard FacedOne-Piece Blow-Out Proof Stem

Upstream Seat Guide

High Load Belleville Spring

High Load Belleville Spring

Upstream Seat Guide

Hardcoated Ball

Hardcoated Integral Seat

11

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

PRODUCTS

V1-4 High Pressure Large Bore Valves

ANSI 900 - 45004” - 36”

The V1-4 category extends our core design concepts to largerdiameter and higher pressure applications. This valve is designed forcritical isolation applications in the Power Industry, HydrocarbonRefining and Processing, Mining, Oil and Gas Production and otherindustries. The V1-4 is available in ANSI pressure classes 900 to 4500, insizes 4” to 36” and in virtually any material with pressure containing partsmade from forgings. Standard end connections are butt weld and flanged orvalves can be custom designed to include special end connections; as well as purgeports, cavity fillers, fugitive emission bonnets, abrasion resistant linings and many other process-specific options.

V1-3Investment Cast ValveANSI 150 - 6001/2 ” - 2”

The V1-3 is an investment cast valve that incorporates the Valvtechnologies coredesign into a smaller package. Primarily used in low-pressure drain applications,the V1-3 is available in ANSI pressure class 150 to 600, in sizes 1/2" to 2” and inboth full and reduced-port configurations. End connections are typically butt weldor socket weld, or can be adapted to our customers’ specifications. As with all ofthe Valvtechnologies product line, the V1-3 features RAM® hardcoatings, ablow-out proof stem, live-loaded packing and absolute zero leakage.

12

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

ERV Electronic Relief ValvesANSI 150 - 4500

The Valvtechnologies Electronic Relief Valve (ERV) is the answer to the need for azero-leakage, pilot-operated relief valve. The ERV package combines Valvtechnologies’zero-leakage isolation valve with electronic controls to monitor and regulate systempressure. Whether in a capacity-relieving function requiring the ASME V-stamp, orsimply in an overpressure protection application, the Valvtechnologies ERV providesreliable protection for standard safety valves in many industries. Repairs to ASMEV-stamped product are certified through the I.A.W., NB-23 and the “VR” stamp willbe applied. Valvtechnologies can also provide an integral isolation valve,eliminating the need for costly field welding.

PRODUCTS

PSGV Parallel Slide Gate ValvesANSI 900 - 45006” - 36”

The Valvtechnologies’ Parallel Slide Gate Valve (PSGV) addresses the need for true in-linevalve repairability in large diameter, high-energy piping systems. Specifically designed for

steam and feedwater applications, the PSGV provides bi-directional zero-leakage usingthe RAM™ coating systems. It is available in sizes 6” to 36", pressure classes ANSI 900to 4500, and can be manufactured in any material. When used in Power Industry

applications, the PSGV carries the Valvtechnologies four-year ZERO leakage guarantee .

13

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

TBS Turbine Bypass System

The Valvtechnologies Turbine By-Pass System (TBS) is designed for the new generation ofcombined-cycle power plants. It combines the Xactrol® control valve design with a state-of-the-art de-superheating control system. The system allows the plant operator to keep the gasturbine and the HRSG on line in the event of a steam turbine trip. The TBSalso facilitates fast CT and HRSG start-upsin peaking power plants, and allows theseplants to operate at turndown conditionsfar below the levels that can beachieved with standard governor systems.

PRODUCTSXACTROL® Severe Service Control Valves

ANSI 150 - 45001/2 ” - 36”

The Xactrol® product group unites Valvtechnologies’ zero-leakagetechnology with special designs that allow rotary modulating control. FromMark I design that features a characterized upstream seat, to the Mark III’sprecision engineered stacked disks, the Xactrol® allows the customer tocombine precise flow control with tight shutoff. The Xactrol® is typically used

in applications where minimum flow and relatively high differential pressuresare required. It is available in sizes from 1/2" to 36" and in pressure classes ANSI150 to 4500.

14

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

NEXTECH-2 ™ High Pressure TrunnionAPI 5000, 10000, 15000

2” - 12”ANSI 900 - 4500

2” - 36”

The Valvtechnologies high-pressure, trunnion Nextech-2 features atwo-seat design that allows for a double block and bleed, bi-directional

shut-off. The optional top entry design for inline repair-ability andsolids proofing allows the valve to work successfully in severe

applications such as in high sulphur water and solids Available in sizes ANSI2” – 36”, API 2” – 12”, the Nextech-2 can be used in a variety of industriesincluding Oil & Gas, Hydrocarbon Processing and Power.

NEXTECH-1 ™ Low Pressure TrunnionANSI 300 – 900

2” - 12”

The Valvtechnologies low pressure, trunnion-style, metal-seated ball valves incorporates manyof the features of the traditional integral seat design into a lower-torque, bi-directional valve.The Nextech-1 features a readily adjustable stem sealing design with a four-stud,live-loaded, industrial-grade packing gland assembly and offers diamond mate-lappedTungsten or Chromium Carbide RAM® coating on sealing surfaces. The split-body designallows for safety and ease of maintenance and the Grafoil®/Inconel seals and packing allowfor high temperature operation. The Nextech-1 is available in sizes 2” – 12” and in avariety of end connections to meet customer’s specifications.

PRODUCTS

15

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

PRODUCTSSteam Choke Valves

ANSI 150 –1500 Temperatures up to 800° F

The Valvtechnologies steam choke is designed for the harsh conditions associated with

steam injection. The rugged, maintenance-free steam choke features a self-adjusting,

double live-loaded design. Various orifice shapes, sizes and configurations are available for

a wide range of production rates and control requirements. The steam choke can easily be

retrofitted with new discs if well conditions or production rates change over time. Available

in a variety of end connections including: socket weld, butt weld, raised face flange and hub

end connections. As with other Valvtechnologies specialty products, the steam chokes offer

a four year ZERO emissions guarantee*.

CCryogenic ValvesANSI 150 – 4500

The Valvtechnologies cryogenic metal seated ball valve offers repeatable

zero-leakage during cryogenic testing and is tested to API 607 Rev. 4 AND BS 6364 standards.

All of Valvtechnologies’ valves for cryogenic service undergo exhaustive process simulation testing

in a proprietary vaccum test chamber as well as the more common immersion testing tanks. The

vacuum chamber allows accurate process Available in a variety of materials that are suitable for

extremely low temperature environments, the cryogenic valve

* Guarantee valid only if the Valvtechnologies, Inc. installation and operations procedures are followed.

16

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

3-Way ValvesANSI 150 – 4500Temperatures up to 1400° F

Valvtechnologies metal seated 3-way valves are designed for designed for the

most severe most severe applications where solids, high temperature and

high velocity are combined with the need for reliable tight shutoff.

Standard materials include A-105, 316SS, and 304SS, but others are

available on request. Available configurations for the 3-Way Valve are “Y”

Pattern and 90 degree and end connections are offered in flanged, hub,

and butt-weld.

DB-2 Double Ball ValvesANSI 150 – 4500

Temperatures up to 1600° F

The Valvtechnologies DB-2 Double Ball Valves answers the demanding needs

for industrial applications where zero leakage isolation is required in

bi-directional or double-block-and-bleed valves. This valve is particularly

useful when solids and high temperatures are present and can also be used in

cases where space is limited, two sealing units are required and one actuation

device is preferred. The bi-directional version has the added advantage of back

pressure protection and even in very high pressure applications, this design prevents the the sealing

surfaces from separating. The seats are cleaned with every valve cycle and solids cannot interfere with

the seal. Standard materials include A-105, 316SS, 347SS and F-11, but other metals are available on

request. All DB-2 valves are tested and warranted to be bubble-tight under field

conditions for all fluids and gases including Hydrogen.

PRODUCTS

17

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

PRODUCTS

HPAL – Acid Injection Isolation ValvesANSI 150 –900

1/2 ” - 4” The Valvtechnologies Acid Injection Isolation Valve is a unique productcreated and designed for the isolation and emergency shutdown of HPALautoclave acid injection systems. This valve uses ceramic seats/coatingsand exotic metals to provide plant security in the harshest of process conditions.

High Pressure Slurry Check ValvesANSI 600 –15004“- 24”

The Valvtechnologies Slurry Check Valve is an upgrade of a product that has beenused successfully in service for more than 30 years. In response to a need from ourclients, Valvtechnologies has re-engineered and improved the design of this productto be in-line with our own technology for coatings and manufacturing

improvements. The combination of the Valvtechnologies Abrasotech™ slurry ball valveand our check valve provides long and uninterrupted service for pumping installations.

ABRASOTECH™ Slurry ValvesANSI 150 – 25001/2 ” – 36”

The Valvtechnologies ABRASOTECH™ valve is the combination of more than 15 years ofexperience in providing reliable valves for the transportation of slurries in pipelines. Withan installed base of over 3,000 slurry service valves throughout the world,Valvtechnologies is the leader in this application. The ABRASOTECH™ valve is offered incarbon stainless steel and in both cast and forged configurations. The valves internals canbe protected against erosion and corrosion with the use of RAM coatings as well asmetallic or urethane liner.

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

Valvtechnologies’ mission is to provide severeservice isolation valve solutions to its customers.

Z E R O L E A K A G E I S O L A T I O N V A L V E S O L U T I O N S

CORPORATE OFFICE & MANUFACTURING PLANT

Valvtechnologies, Inc. 5904 Bingle Road

Houston, Texas 77092 U.S.A.Telephone: (713) 860-0400Facsimile: (713) 860-0499

E-mail: [email protected]: www.valv.com

Represented by:

CALIFORNIAValvtechnologies, Inc.

2815 Mitchell Drive, Suite 108,Walnut Creek, California 94598

Telephone: (925) 943-1898Facsimile: (925) 889-2089Email: [email protected]

EUROPE Valvtechnologies, Inc.

Pennine House, Concorde WayPreston Farm, Industrial Estate

Stockton on Tees, TS18 3TlL, U.K.Telephone: 44 (0) 1642 356733Facsimile: 44 (0) 1642 882233

Email: [email protected]

FRANCE Valvtechnologies, Inc.164 rue Jeanne d’Arc75013, Paris, France

Telephone: (33) (0) 616110471Facsimile: (33) (0) 153013826Email: [email protected]

ASIA Valvtechnologies, Inc.

Hong Kong New World Tower 47/FRoom 32, 33, 300 Huaihai Zhong Road

Shanghai, 200021, PRCTelephone: 86 21 5116 2859Facsimile: 86 21 5 116 2907

Email: [email protected]

SOUTH AMERICAValvtechnologies, Inc.

Av. B S/N Urbanizacion Ex Fundo OquendoCallao, Lima, Peru

Telephone: (51-1) 613-6050Facsimile: (51-1) 613-6060Email: [email protected]