Copy of Chapter 1

Transcript of Copy of Chapter 1

KHALSA INSTITUTE OF MANAGEMENT & TECHNOLOGY FOR WOMEN

LUDHIANA

TABLE OF CONTENTS

Certificate i

Abstract ii

Acknowledgement iii

Abbreviation iv

PART –I

Organizational Profile 1-39

i

ABSTRACT

In an institute, a student learns about theoretical concepts. But in the present day

scenario, environment surrounding the business is complex and dynamic and the

industries are so much diversified and specialized that it requires managers to be

wholesomely nourished with knowledge and skills in their respective fields of

specialization. Exposure is the key in building good future managers.

For this reason, P.T.U., (Jalandhar) designed a scheme under which the

students of M.B.A. have to go for the Summer Training between second and third

semester. During this period, I have written a Report about knowledge and experience. I

have gained knowledge in course of training. This Report has been written in simple

language specifying the Organizational setup and Management Procedures of “Working

Capital Management at Verka Milk Plant” at Verka Plant Distt- Ludhiana. Any omission

or errors are deeply regretted.

ii

ACKNOWLEDGEMENT

This is my first experience in the corporate world and it has been a truly learning

experience for me. The project assigns to me had a great learning potential and

tremendous scope of application. There have been many people who have supported me

throughout the project and I take this opportunity to thank them for their time and effort.

I would like to thank Sh. A. K. Gupta, Accounts Manager, of Verka Milk Plant,

Ludhiana for their willing and constant encouragement in exploration of my present

investigation and preparation of project.

I would fail in my duty if I didn’t acknowledge the blessings of Almighty GOD. I would

also like to thank my respected and loving parents, who kept on motivating me in

completing this Report.

I am extremely thankful for the valuable assistance extended to me by the

respondents of Verka Milk Plant for providing me all the information needed for the

project. I express my heartiest gratitude to them for spending their valuable time. In

the end, I can say only this much that all are not be mentioned but none is forgotten.

Signature of the Student

iii

ABBREVIATIONS

SKM- Pasteurized Skimmed Milk

DTM- Pasteurized Double Toned Milk

SNF- Solid Not Fat

MIS- Management Information System

DHCC- Dairy Helpers Cum Cleaners

OHCC- Office Helpers Cum Cleaners

DY- Deputy

H.A.C.C.P-Hygienic Hazard & Critical Parameters

NDDB- National Dairy Development Board

PDDB- Punjab Dairy Development Board

iv

ORGANIZATIONAL PROFILE

INDUSTRY PROFILE

FOOD INDUSTRY

The food industry is the complex, global collective of diverse businesses that together

supply much of the food energy consumed by the world population. Only subsistence

farmers, those who survive on what they grow, can be considered outside of the scope of

the modern food industry.

The food industry includes:

Regulation: local, regional, national and international rules and regulations for

food production and sale, including food quality and food safety, and industry

lobbying activities.

Education: academic, vocational, consultancy.

Research and Development: food technology.

Financial services: insurance, credit.

Manufacturing: agrichemicals, seed, farm machinery and supplies, agricultural

construction, etc.

Agriculture: raising of crops and livestock, seafood.

Food Processing: preparation of fresh products for market, manufacture of

prepared food products.

Marketing: promotion of generic products (e.g. milk board), new products,

public opinion, through advertising, packaging, public relations, etc.

Wholesale and Distribution: warehousing, transportation, logistics.

1

Retail: supermarket chains and independent food stores, direct-to-consumer,

restaurant, food services.

GLOBAL FOOD INDUSTRY

The global processed food industry is estimated to be valued around EUR 2.5 trillion and

accounts for three-fourth of the global food sales. The global food industry is ever

changing and evolving. However, health, convenience and value continue to be the key

value propositions in this industry.

Despite the large size of the industry, only 6 percent of processed foods are traded across

borders compared to 16 percent of major bulk agricultural commodities. The United

States and European Union together account for over 60 percent of total retail processed

food sales in the world.

Trade liberalization policies through multi-lateral and regional trade agreements have led

to a rapid growth in food processing. In the Asian region, Japan is the largest food

processing market, but India and China are likely to grow at a faster rate in the next

decade. The processed food industry is strong in Japan and South Korea, as they are the

leading meat importing countries in the world and consumption of meat is high in these

countries. The Australian processed food industry is one of the most technically advanced

in the world and it produces products of international standards at comparatively lower

prices for the world market. The U.S. continues to live up to its reputation as the

Europe39%

US21%

Rest of the world9%

Asia Pacific31%

2

“breadbasket to the world”. Countries in the Sub-Sahara African region, Latin America

and parts of Asia continue to be on the lower-end of technology prowess in food items

and are inclined to their staple diets, whereas, those in Europe, North America, and Japan

are on the higher-end of technology, with a sharper shift towards convenience and diet

foods.

Some Features are-

The global food processing industry is dominated by a cluster of highly powerful

multinational corporations.

Some big names are ConAgra, Krafts Foods, Cadbury, General Mills, H.J. Heinz,

Nestlé and Unilever.

The US food industry generated revenue that totaled to $126 billion in 2008.

INDIAN FOOD PROCESSING INDUSTRY

India is one of the largest food producers in the world.

India has diverse agro-climatic conditions and has a large and diverse raw

material base suitable for food processing companies.

Investment requirement of around US$ billion exists in the food processing

sector.

India is looking for investment in infrastructure, packaging and marketing.

India has huge scientific and research talent pool.

A largely untapped domestic market of 1000 million consumers.

300 million upper and middle class consume processed food.

200 million more consumers expected to shift to processed food by 2010.

3

Well developed infrastructure and distribution network.

Rapid urbanization, increased literacy, changing life style, increased number of

women in workforce, rising per capita income- leading to rapid growth and new

opportunities in food and beverages sector.

50 percent of household expenditure by Indians is on food items.

Strategic geographic location ( proximity of India to markets in Europe and Far

East, South East and West Asia)

The industry will generate revenue of around $260 Billion from the current level

of $200 Billion in the next six years (by 2015).

The Indian food sector possesses strong potential to grow at 30%-40% from the

current rate of 15% in the next 10 years (by 2019). The country is expected to

take its processed foods revenue from Rs 8,200 Billion in 2009-10 to Rs 13,500

Billion by 2014-15.

Under the food industry, Dairy product is very important part of food processing.

Dairy Processing

India ranks first in the world in terms of milk production. Indian production stands at 91

million tones growing at a CAGR of 4 per cent. This is primarily due to the initiatives

taken by the Operation flood programmes in organizing milk producers into cooperatives;

building infrastructure for milk procurement, processing and marketing and providing

financial, technical and management inputs by the Ministry of Agriculture and Ministry

of Food Processing Industries to turn the dairy sector into viable self- sustaining

organized sector. About 35% of milk produced in India is processed. The organized

sector (large scale dairy plants) processes about 13 million tones annually, while the

unorganized sector processes about 22 million tones per annum. In the organized sector,

there are 676 dairy plants in the Cooperative, Private and Government sectors registered

4

with the Government of India and the state Governments.

India has a unique pattern of production, processing and marketing/ consumption of milk,

which is not comparable with any large milk producing country. Approximately 70

million rural households (primarily, small and marginal farmers and landless labourers)

in the country are engaged in milk production. Over 11 million farmer are organized into

about 0.1 million village Dairy Cooperative Societies (DCS) (about 110 farmers per

DCS). The cumulative milk handled by DCS across the country is about 18 million kg of

milk per day. These cooperatives form part of a national milk grid which links the milk

producers through out India with consumers in more than 700 towns and cities bridging

the gaps on account of seasonal and regional variations in the availability of milk.

The Ministry of Food Processing Industries is promoting organized Dairy Processing

sector to accomplish upcoming demands of processed dairy products and helping to

identify various areas of research for future product development and quality

improvement to revamp the Indian dairy export by way of providing financial assistance

to the dairy processing units. 32 Units have been sanctioned financial assistance (Rs. 591

lakhs) under the plan scheme of the Ministry during the year 2006-07.

Major Indian and Overseas Players in the Food industry

ITC Limited

Amul

PepsiCo India Holdings

Nestle

Britannia

MTR foods limited

5

COMPANY DETAILS

MILKFED

The Punjab State Co-operative milk producer’s federation limited popularly known as

MILKFED. Punjab came into existence in 1973. It was backed by twin objective of

providing remunerative milk market to the milk producers of the state on the one hand

and to provide technical inputs to the milk producers for the enhancement of milk

production on the other.

Although the federation was registered much earlier, it took the centre

stage of Punjab dairy scenario in 1983 when all the milk plants of Punjab Dairy

development corporation Ltd were handed over to Co-operative sector and the entire state

was covered under OPERATION FLOOD to give the farmers better value and to

customers the better products. The organizational set up of MILKFED is based on a three

tier system:-

Milk producers Co-operative societies at village level

Milk Co-operative Unions at Districts level.

Co-operative milk marketing federation as an apex body at State level

{MILKFED}.

MILKFED with its network of over 5000 villages milk producers Co-

operative societies and over 3 lakhs milk producers form a strong network providing

assured market to milk producers.

MILKFED and its units have a workforce about 5000 employees and also

provide regular employment to about 600 transporters.

Milk Procurement Network:

Working on “Anand Pattern” the process of organizing societies at village level started in

Punjab as early as 1978. Presently, there is strong Network of about 6432 (as on

6

31.3.2009) Milk Producers Cooperative Societies organized at village level. About 3.65

Lakh milk producer members are attached to these societies. Fresh milk is procured from

the milk producers twice a day through village level societies directly without the

assistance of any middleman.

MILKFED has its milk unions in almost all the districts of Punjab. These district units

are:-

1. Amritsar

2. Bathinda

3. Bassi pathana

4. Chandigarh

5. Faridkot

6. Ferozpur

7. Gurdaspur

8. Horshiarpur

9. Jalandhar

10. Ludhiana

11. Patiala

12. Ropar (Mohali)

13. Sangrur

These plants in all these unions are being run under the brand name

VERKA.

7

Products:

Milkfed has formulated company specifications for its milk & milk products to provide

standard and quality of products to consumers.

Milk

Ghee & Butter

Cheese & Paneer

Drinks

Ice-cream & Sweets

Milk Powder

Fresh Products

Packing

8

Achievements-

On the basis of quality with efficient administration, MILKFED has not only established

new mile stone of providing services to Dairy farmers but scaled new heights in

delighting esteemed customers also. This has resulted into tremendous achievements in

all fields.

TURNOVER:

The annual turnover of Milkfed which was Rs.931 crores in the year 2007-08 has hit the

level of Rs.1150 crores in the year 2008-09.

Turnover (Rs. In Crores)

9

EQUITY PARTICIPATION:

The paid-up equity of Milkfed as on 31.3.2008 was to the tune of Rs.46.86 crores which

comprises of Rs.28.93 crores from the cooperative members and balance Rs.17.93 crores

from State Government.

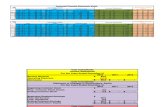

MILKFED GROWTH AT A GLANCE:

PARTICULARS UNIT 04-05 05-06

06-07

07-08 08-09

FUNCTIONAL SOCIETIES

CUMMU.NOS. 6104 61015989

6155 6432

MEMBERSHIPCUMMU.NOS IN LACS

3.56 3.63 3.60

3.62 3.65

AVG. DAILY MILK PROC

LKG SPD 7.81 7.827.78

8.21 9.21

PEAK MILK PROC LKG SPD 11.64 11.3711.54

12.39 14.13

A.I. CLUSTER SOCS.

COOMU.NOS. 341 388433

504 595

FODDER SEED SUPPLIED

M.Ts. 400.30 430.00500.00

572.00 802.00

CATTLE FEED SOLD

M.Ts. 66970 66750 73577

86174 93751

AVG..DAILY CITY SUPPLY

LLPD 5.27 5.675.81

6.16 6.58

SALE OF SFMLAC PKTS/BTLS

35.85 42.4941.92

61.11 56.38

SALE OF LASSI LAC PACKETS 12.20 16.8919.16

29.51 31.97

SALE OF ICE-CREAM

LAC LITRES 10.23 12.1815.61

17.68 16.06

EXPORTS RS.IN LACS 1142.28 713.671140.35

1334.90 1500.00

TURNOVER RS.IN CRORES 653.00 675.00760.00

931.00 1150.00

10

VERKA MILK PLANT

PROFILE

Full Name: The Ludhiana District Cooperative Milk Producers

Union Ltd. Ludhiana

Registered Office: Ferozpur Road, Ldh-141004

Foundation: Hon. S. Prakash Singh Badal in 1970

Capacity: At that time, 1 lakh litre per day. At present 4 lakh litres

per day

Head Office: Punjab State Co-operative Milk Producers Federation

Ltd. S.C.O.153-155, Sec. 34-A, Chd.

Registration Date of Plant: 1974 with Punjab Dairy Development Co-operated

Date of Inauguration: 31st October, 1974

Commencement of Production: Feb, 1979

Quality: Get International Quality Certificate ISO-9002 & IS-

15000 (HACCP)

Products Marketed By: The Punjab State Co-operative Milk Producers

Federation. Ltd. Chd.

Chairman: S. Ajmer Singh Bhagpur

11

No. of Societies: 816

Membership: 78000

Banker: Punjab State Central Co-operative Bank

Brand Name: VERKA

Number of Employees: 494 Permanent 500 Temporary

Chilling Centers: 6

Turnover: 180 crore

Verka milk plant, Ludhiana is known Ludhiana distt. - Co-operative milk produces union.

It is situated on Ferozpur road. It is fully equipped with modern fluid milk plants

facilities.

VMP, Ludhiana is a prestigious milk plant of Punjab State famous all over the country

and abroad for the supply of quality milk products. It has got first position in Northern

Zone. Its functioning stone was laid by S. Prakash Singh Badal, the Chief Minister of the

Punjab on June 22 1970. This plant was inaugurated by our referred Prime Minister Smt.

Indira Gandhi.

Milk plant is a co-operative society and farmers (producers) share all its profit and losses.

Govt does not provide any financial assistance to milk plant Ludhiana. But Govt.

Supervisor and control is there. Law and policy maker is Punjab Govt; here there is no

dishonesty in the milk plant. It is very neat and clean organization. The handling capacity

of the milk plant per day is 4 Lac Litre.

In the year 1983, PDDC merged into milkfed and control of milk plant transferred to

milkfed in year 1983. But the efforts of the Directors and milk producer's control of milk

12

plant transferred to milk union, (union of milk producers).

Milk plant Ludhiana produces variety of milk products like Milk cake, cheese, Butter,

Ghee skimmed milk powder and standardized milk. Milk plant sells better quality of

pasteurized milk to people. Ghee manufactured by this plant is not only sold in country

but also supplied to foreign countries like Nepal, Dubai.

The new achievement of this milk plant is to achieve the International quality certificate

ISO 9002.

Machinery of best technology has been installed in the milk plant. The machinery is

available for the productions of following milk products-

Pasteurized fluid milk

Sterilized flavored milk

Milk-cake

Paneer

Lassi

Ice Cream

Butter

Ghee

Skimmed milk powder

Whole milk powder

Baby food

Infant milk food

13

But according to the demands from the open market the following milk products are

produced:-

Pasteurized/ Sterilized milk

Milk cake

Paneer

Butter

Ghee

Skimmed milk powder

Milk plant Ludhiana is playing a vital role in Socio Economic development of real

merses of Ludhiana Distt. Normally middlemen and traders dominate the market. The

milk plant steadily marched toward fix goal of becoming a strong and viable milk plant

and now is at No. 1 in Northern Zone.

Its entire officers as well as workers are assets to milk plant Ludhiana who are

performing their duties delight and with full zeal and energy. Also the building of milk

plant. Ludhiana is nicely planned and maintained. There is great system of work. We

hope it will maintain its reputation and goodwill.

HISTORY OF VERKA MILK PLANT

Milk Plant, Ludhiana, whose foundation stone was laid by Hon. S. Parkash Singh Ji

Badal in 1970, was commissioned by PDDC in 1974 and was taken over by MILKFED

PUNJAB in 1983 and thereafter by Ludhiana District Cooperative Milk Producers’

Union Limited, Ludhiana in 1988. The capacity of the plant was 1.00 lac litres of milk

per day at the time of commissioning in 1974 and it was increased to 4.00 lac litres per

day in 1992 at the cost of Rs. 18.00 crores. The latest state of art technology in milk

drying is available at this plant. The products manufactured by this Plant, at present are

Ghee, Milk Powder, Butter, Paneer, Liquid Milk and Milk Cake etc. Milk Plant Ludhiana

is the first in Northern India and amongst the first 10 in India in the Cooperative Sector.

14

MILK PLANT’S SALIENT FEATURES

First Milk Plant in India to get ISO-9002 International Quality Certification Mark.

Milk Rate paid to the producers among all the Unions highest in the State.

Milk Procurement highest among all the Unions in the State

Milk Procurement per society/ day highest among all the Unions in the State.

100% Milk producers’ cooperative societies are in profit.

Aggregate profit of the societies in any year is the maximum among all the

Unions in the State. Ever since inception, customer satisfaction and consistency in

quality is the key-thrust area of this organization.

No. of A.I. Cases maximum among all the Unions in the State.

Cattle Feed sold to societies maximum among all the Unions in the State.

No. of Sick animals treated highest among all the Unions in the State.

F.M.D. Vaccination maximum among all the Unions in the State.

Milk transportation cost lowest among all the Unions in the State.

Milk chilling cost lowest among all the Unions in the State.

Average daily city supply maximum among all the Unions in the State.

Embryo Transfer Technology introduced in the field for the first time in Northern

India. No. of Milkotesters (new technology for fat testing at village level)

provided to milk societies is the maximum in the State.

Milk products selling at premium rates and ghee exported to Gulf countries and

Philippines & S.M.P. exported to Bangladesh.

Capacity utilization is maximum on yearly basis.

Fuel cost per kg. milk is lowest among all the Unions in the State.

Leading Union to start Cooperative Development Programme to strengthen the

co-operative base at village level and to introduce progeny testing programme for

improvement of animal breed.

Annual turn-over more than Rs. 100.00 crores of rupees, highest among all the

Unions in the State.

15

Embryo Transfer Technology-

Embryo transfer is the technique by which genetic potentials of high pedigree animals are

transferred in the low genetic surrogate mothers to deliver calves of high genetic

potentials. By this technique, we can get large number of calves of high pedigree during

life span of the female animal. The calves born out of this technique will have genetic

makeup of the transferred embryo and not of the mother which gives birth to the calf.

OBJECTIVES

Each organization is formed with some objectives. These aims act as guidelines for

working of concern. Milk Plant was constituted to fulfill following aims:

To procure milk and execute marketing efforts so that milk producers get good

price of their milk.

To uplift social and economic status of milk producers.

To develop dairy as industry allied to agriculture.

To provide better and remunerative prices for milk.

To enhance bargaining power for milk producers.

To provide veterinary aids to animals of milk producers at their doorstep.

To provide better quality cattle feed at reasonable rates.

To educate the milk producers about lowering down the cost of milk without

compromising quality.

To create employment opportunities for rural youth by milk production activities.

To provide awareness among milk producers for socio-economic change through

co-operative set-up.

To provide technical inputs like artificial insemination, to improve the breed of

animals, animals health services, preventive disease treatment and awareness

regarding farm management etc.

To provide ISI marks good quality balanced Cattle feed and fodder seeds to the

farmers.

16

To purchase or assist in purchasing raw material, processing material etc.or to

collaborate with any other Cooperative Institution/NDDB if need arises.

To plan developmental strategies and programme to increase the volume of

procurement and production of the Federation and its members Unions and for its

affective marketing.

To provide financial assistance/credit facilities to member Unions on such rate of

interest fixed by the Managing Director, Milkfed Punjab, from time to time.

MISSION AND VISION

Credibility, integrity and honesty

Commitment to Perfection through Quality and Customer Satisfaction

Straightforward business dealings

Work as a worship

Spirit of Social Service and human respect

QUALITY OF MILK AND MILK PRODUCTS

To improve the quality of raw milk, Clean Milk Production program started in

650 villages and resultantly the quality of products increased.

Under ISO Certification and HACCP (IS 15000) Milk Union started export of

Ghee, SMP to Gulf Countries Philippines, Manila, South Africa, Singapore,

Bangladesh etc. The export is more than 5.5 crore during the last year.

To further improve the quality of Raw Milk, Milk Union started 365 Automatic

Milk collection Stations at village level.

To meet the Challenges of WTO Milk Union started TIFAC program with the

help of Ministry of information.

17

ORGANIZATION STRUCTURE

Organization structure is a systematic combination of people, functions and physical

facilities. It consist a formal structure with defined authority and clear responsibility.

Each and every person is given a job and then authority is assigned to him

for the job, he is made responsible for the job. This organization structure aims at saying,

“EACH ONE FOR A JOB AND JOB FOR EACH ONE”

There is no sole proprietor of this milk plant. It is a co-operative organization i.e. it is run

by many members collectively. These members select their Board of Directors. The

Board consists of 12 Directors. They appoint General Manager and Chairman. Then

there are different departmental heads like Production Manager, Purchase Manager, and

Marketing Manager etc. These heads have deputies for their assistance. Each department

has different employees at departmental level.

The top management of milk plant, Ludhiana is selected through

votings by the members of the milk societies. Now the question arise that how that milk

societies are formed. So, firstly the field staff of milk plant visits various villages for

encouraging people to make co-operative department to procure milk from the villagers.

Minimum 35 members are required for making a society. To become the member of the

society a person has to pay Rs.20 as membership fees and then purchases a share of Rs.2.

18

ORGANIZATION STRUCTURE MILK PLANT LUDHIANA

19

Chairman & BOD

General ManagerManager

ProductionManager

Engineering

Manager Quality Assurance

Manager Procurement

Manager MarketingManager Finance &

Accounting

Manager Administration (Admn.) Manager Purchase

Officers

Head Store Officers Manager MIS

Head Security Officers

Dy.Mgr.Chilling, Processing Dy.Mgr. Ghee Making &

PackingDy. Mgr. Pouch

Filling Dy. Mgr. Milk Powder Plant

Dy. Mgr. Butter Making, Packing

Dy. Mgr. General Dy. Mgr. Instrumental

Dy. Mgr. Chemical

Lab

Dy. Mgr. Bacteriology Lab

Dy. Mgr. Procurement Dy. Mgr. Chilling Centre

Dy. Mgr. Field Officers

Dy. Mgr. Marketing

Dy. Mgr. General Dy. Mgr. Societies

Dy. Mgr. Admn.

St. Assistant Time Keeper

Steno & Clerk

OHCC

Accountants & Cashiers

Accounts Clerks

DHCC

Assistants & Superintend

Assistant MISStore Keepers

Security Inspector

DHCC

BOARD OF DIRECTORS

General Manager Sh. H.S.Grewal

Director S. Manjit Singh

S. Avtar Singh

Smt. Surjit Kaur

S. Jagjit Singh

S. Gurbaksh Singh

S. Ajmer Singh

S. Jaspal Singh

S. Kuldeep Singh

S. Karamjeet Singh

S. Paramjeet Singh

S. Dilsher Singh

S. Raghubir Singh

Joint Registrar (Patiala) Capt T.S. Bedi

Deputy Registrar (Ldh) Sh. Amarjeet Singh

Manager Account Sh. A.K. Gupta

Mgr. Production Sh. G.P. Sharma

Manager Marketing Sh. Parminder Kumar

Dy Mgr Quality Control Sh. B.R. Madaan

Manager Engg. Sh. Raj Kumar

Dy Mgr Purchase S. Amarjeet Singh

H.R. Deptt. S. Amarjeet Singh

20

DEPARTMENTS

MILK PROCUREMENT DEPARTMENT:

HEAD OF THE DEPARTMENT: Dr. Sushil Soni

Milk is collected by milk procurement co-operative societies at the village level and

purchased by milk union which further supplies that milk to Milk Plant after charging

commission from Milk Plant at the rates specified by the Milk Union. The union was

formed with the basic concept of enhancing milk procurement and impairing its quality in

the district so that the producers at the village level gets the remunerative price of its

products at his doorstep and the consumers on the other hand gets the milk of good

quality at reasonable price by eliminating the middleman. Generally milk producers

charge Rs.145 per kg FAT & SNF Rs.106.67 per kg on 8.0%.SNF is 8.80% standard of

one Kg.

This plant was registered in the year 1974 with a primary membership of 45

milk producers’ co-operative societies. At present it has 816 registered co-operative

societies. Procurement Department is headed by the Manager, Milk Procurement, who is

assisted by technical officers and supporting staff in running the activities for attaining

the objectives of the organization. Milk is received at the dairy dock in 40 litres cans

from Milk Co-operative Societies, located near Ludhiana.

OBJECTIVES OF THE UNION-

To ensure better and remunerative fine milk market to the milk producers around

one year for any quantity of surplus milk available at village level.

To provide free veterinary aid to milk producers.

To provide artificial insemination facilities by supplying frozen semen of

improved quality.

To supply balanced cattle feed at nominal rate.

21

To supply certified feeder seeds at subsidized rate.

PROCUREMENT CHANNELS FOR PROCUREMENT OF MILK IN

LUDHIANA

Co-op. Milk Plant Pvt. Sector Milk Plant

Milk Producers Milk Producers

Co-op Societies (at Village Level) Collection Centres

Milk Plant Milk Plant

(Milk transported by the Member producer (Company’s truck lift milk from the

to the Milk Plant) collection centre)

PRODUCTION DEPARTMENT

HEAD OF DEPARTMENT- Mr. G.P. Sharma

Production Department is headed by the Manager, Production and he is assisted by

technical officers, operators and dairymen. Production Department is responsible for –

Proper Milk Reception

Milk Processing

Manufacturing of Milk Products- Powder, Butter, Ghee, Paneer, Milk Cake etc.

Packing of all above mentioned products.

Production is done as per commitment made by marketing department depending on

22

requirement of products. Milk products are manufactured mostly by automatic machines

with best standards of sanitation. Production Manager is responsible for achieving

production target with minimum wastage and maintaining cordial relationship with the

work force. He also guides workers for better performance. Product Planning is managed

by Production Manager & accordingly the workforce produce. Generally product

produced is as such-

Production of Milk as per various Ingredients

Milk

Fluid Milk Surplus FatSurplus

SNF

Packing given Preference Paneer

Lassi Kheer

Milk Cake

White Butter

Table Butter

GheeMilk

Powder

23

NECESSITY FOR PRODUCTION ENHANCEMENT

Milk production in the area increased manifold with the result. Resultantly started

receiving daily 2.50 LPD of milk.

To increase the participation of women 120 exclusively women societies are

organized with 15300 women members. through Punjab Women Dairy Project a

Central Govt. sponsored scheme.

Milk Production in the area increased manifold with the result. Resultantly started

receiving daily 2.50 Lac LPD of Milk and Peak procurement 4.5 Lac LPD.

To cater to the increased demand, necessity of expansion of milk plant arose.

Capacity of Milk Plant enhanced from 1 lac to 4 lac litres with additional powder.

Plant of 30 MTs.

Plant is having latest State of Art Technology with MVR (Mechanical Vapour

Reprocesses) along with a drier with fluidized bed through which agglomerated

Powder is manufactured.

This improved the socio- economic conditions of marginal and poor farmers.

The profitability of the plant and turnover of the plant improved a lot.

No. of societies increased from 94 to 816 and its membership from 5400 to

78000.

All the societies are in net profit and distributing bonus to its members.

QUALITY CONTROL DEPARTMENT

HEAD OF DEPARTMENT Mr. B.R. Madaan

Quality control department is headed by the Manager, Quality Control. He is assisted by

technical staff who conducts all types of tests on raw materials and finished products with

the help of sophisticated equipment.

For maintaining high quality of milk and milk products, there is a quality control

laboratory. The quality control department ensures quality through testing of raw material

received through procurement department and chilling centres as well as of finished

products to make them germ free.

24

The motto of Verka’s quality policy is customer’s satisfaction. So, they commit

themselves to produce and deliver such milk and milk products as meet the customer’s

quality expectation. Milk plant is due to hard work and by following the motto of quality

policy is able to get ISO-9002 and IS-15000 (HACCP) two international quality standard

certificates.

ISO-9002: Milk Plant Ludhiana is India’s first Milk Plant to get this certificate of

International quality standards. It is provided to a concern, which has established

specialization in quality and prices and able to use its full installation production

capacity.

IS-15000(HACCP): Milk Plant Ludhiana has also get this international quality

certificate, which allows it to sell its products at international levels. It actually called

“International Standard-15000 (Hazard Analysis and Critical Control Point).

The staff also keeps a strict watch on cleanliness of equipment and pipelines etc. with a

view to avoid contamination.

MARKETING DEPARTMENT

HEAD OF DEPARTMENT- Mr. Parminder Kumar

Marketing Department is headed by Manager, Marketing, who is further assisted by Sales

Inspector and other supporting staff. Marketing department is responsible for ensuring

maximum possible returns to the organization.

Sub contractors/ agents are appointed by marketing department for supply

of milk and milk products. At present, city supply is done through almost 300 agents;

surrounding areas are also covered through agents. These areas are divided into 40 groups

(routes). Eight milk bars are being maintained by milk plant for customers. These milk

bars are located at Milk Plant Premises, Bus Stand, Clock Tower, Rose Garden, Gorayan,

Neelon, Bija and Mullanpur. The profit margin of these agents is 8-11%.

Staff structure of Marketing Section:

25

PURCHASE DEPARTMENT

HEAD OF DEPARTMENT: Mr. Amarjeet Singh

Purchase Department is headed by purchase officer who is assisted by the supporting

staff in maintaining regular supply of store items. Purchase Department ensures timely

purchase at the lowest cost with the twin objective of ensuring the availability of required

store items and at same time keeping the expenditure as low as possible.

FUNCTIONS OF PURCHASE DEPARTMENT:

To receive purchase requisition from stores.

To buy goods or materials wisely at reasonable prices.

To invite quotation from number suppliers and preparing comparative statement

to choose a right supplier

To record particulars of purchase orders.

To check the supplier’s invoices as regards price, quantity, quality etc.

PURCHASE PROCEDURE FOR PACKING MATERIAL

The following purchase procedure is followed in Verka-

1. Receipt of Purchase Requisition : Purchasing cycle begins with the receipt of the

purchase requisition in the purchasing department. It provides the purchasing

department authorization to initiate action for procuring the required materials,

components and supplies. It contains details as to the materials to be purchased,

quality specifications, quantity and time and place of the delivery.

2. Potential sources of supply : When the purchase requisition is received in the

purchasing department, the purchasing executive looks for the potential sources of

supply. The department maintains the list of approved suppliers for every item

purchased by the company. It is reviewed periodically to add the names of new

suppliers and delete the names of those who have ceased business or whose

suppliers or services have proved to be unsatisfactory.

26

3. Issue of letters inviting quotations : The purchasing department issue letters to

approved suppliers requesting them to send their quotations. If the goods are to be

purchased in bulk than Milkfed send annual tenders. In case the goods are

procured locally on plant level then there is no need of quotations for prices upto

1000 .In case the price is between 1000-5000 then sealed quotations are collected

from market. If the cost is upto 100000 than General Manager has competency. If

the price is more than Rs. 100000 than Board of Directors have competency.

4. Receipt and analysis of quotations : Quotations received from potential

suppliers are opened and analyzed to identify the supplier who offers the lowest

price and most favorable terms and conditions.

5. Selection of Vendor: It is always not necessary to select the vendor who offers

the lowest price and most favorable terms and conditions. The purchasing

executive has to consider various other factors before selecting the vendor. These

factors include reliability of the vendor on the basis of past experience, his

capability and resources to supply the required material and his willingness to

accept the rejected materials without arguments, accommodation relating to

cancellation of orders under conditions beyond control and so forth. The objective

in purchasing is not to reduce the initial cost of materials but the total cost of

purchasing.

6. Purchase Order : Once the purchasing executive has decided on the source of

procuring materials, he issues a purchase order to the vendor. It contains details of

the items to be supplied, quantities, quality, price, time and place of delivery.

7. Follow up and delivery: The purchasers follow up the order to ensure that

deliveries are received according to schedules. The purchase agreements often

contain a penalty clause against late deliveries.

8. Analysis of receiving reports: When materials are received they are inspected by

quality control and verified by the stores department with reference to purchase

order. Shortages and damages if any are reported.

9. Scrutiny and approval of invoices : This is the last step in the purchase

procedure. The invoice received from suppliers is sent to the purchase department

27

for verification with reference to purchase order, inspection report and receiving

department’s reports. If it finds that materials have been received in the ordered

quantity and specified quality, it approves the invoices and forwards them to the

accounting department for payment. In case of shortages, damages or sub-

standard quality, it notifies the vendor immediately and asks him to take remedial

action.

PURCHASE PROCEDURE FOR TOOLS & LUBRICANTS

From companies like IOC (Indian Oil Corporation), HP (Hindustan Petroleum) material

is directly purchased against payment.

28

STORES DEPARTMENT

There are 3 Stores in Verka Milk Plant which are headed by various persons. These

departments store all the essential equipment and material and stationery required in all

departments. It also keeps the records of good purchase and goods in stock as well as

goods used by particular department. All the material purchase for working of milk plant

is firstly handed over to stores department and all that material systematically packed to

be sold is also kept in stores department.

DIFFERENT STORES DEPARTMENT

1. PROCUREMENT STORE

Head of the Department: Mr.Soni

PURCHASE

PACKING MATERIAL

TOOLS & LUBRICANTS

MISC. PURCHASES

USED IN BULK

PROCURED LOCALLY ON PLANT LEVEL

PRODUCTS LIKE FILM, MONO CARTONS, ALUMINUM FOIL

FURNITURE, SPARES,

MECHANICAL PRODUCT ETC.

PRODUCTS LIKE

LUBRICANTS

PRODUCTS LIKE SPARES

Keep Cattle Feed, Mineral Mixture, Seeds etc.

2. MAIN STORE

Head of the Department: Mr. Jagdish Kohli

Spare Parts of Plant & Machinery are kept at Main Store. Every item is stored as per its

code. As per the requisition and then sanction authority passed by General Manager

goods are purchased and then stored in Main Store of Verka Milk Plant. Each item is

assigned a specific code so that items can be easily classified and stored.

3.PRODUCT STORE

Head of the Department: Mr. Baljinder Singh

Goods to be supplied in the market are kept at Product Store. Product Store handles

variety of milk & milk products such as ghee, milk powder etc. Goods are supplied as per

Dealer’s demand.

ENGINEERING DEPARTMENT

HEAD OF DEPARTMENT: Mr. Raj Kumar

Engineering Department is headed by the Manager, Engineering who is assisted by

technical officers expert in one branch of engineering or other. Engineering Department

is divided into various sections viz.

29

Refrigeration

Section

Boiler Section

Mechanical Section

Electrical Section

Manager Engineering is responsible for:

The effective working of all the departments.

Identifying all the machines needing maintenance and preparing

maintenance schedule.

Carrying out the maintenance operation and machine adjustments as per

maintenance schedule.

Monitoring maintenance of machine, including vehicles and calibrating

equipment.

Thus Engineering Department ensures proper implementation of lubrication and

maintenance schedules of all machines and transport vehicles owned by milk plant and

the milk union. The department makes all out efforts to keep the no. of breakdowns and

production downtime as low as possible.

PERSONNEL AND ADMINISTRATION DEPARTMENT

HEAD OF DEPARTMENT: Mr. Amarjeet Singh

This department is headed by Manager who is assisted by supporting staff to carry out

functions of this department. This department ensures compliance labour laws,

maintenance of proper records and completion of administrative formalities for timely

payment of dues to the employees. This department is also responsible for maintaining

cordial relationship between workers and management. The staff of this section looks

after the process of disciplinary cases.

Objectives:

To establish fair and equitable remuneration.

To ensure timely payment to employees.

To attract competent personnel.

30

To improve union management relations.

To improve public image of the company.

To ensure proper compliance of labour laws.

ACCOUNTS DEPARTMENT

HEAD OF DEPARTMENT: Mr. Ashok Gupta

The accounts department is headed by the Accounts Manager, who is assisted by Deputy

Manager, accountants and other supporting staff. This department records all transactions

in proper books to provide necessary information to the authorities whenever required.

Various Auditors are deputed to check the daily transactions. Workouts profit and loss

account on the monthly basis. This department is responsible to ensure timely payment to

all the employees and parties dealing with milk plant.

Functions of This Department:

The functions that are performed by accounting department are:-

To prepare monthly profit and loss.

To keep up-to-date accounts.

To take out the monthly trial balance.

To prepare daily cash flow.

To make computer punching of vouchers regularly.

To prepare the financial follow up report and send it to concerned bank.

To ensure proper execution of legal notices and its follow up.

To prepare the business plans and compare it with accruals.

MANAGEMENT INFORMATION SYSTEM

HEAD OF DEPARTMENT Mr. Mukesh Sharma

Up to date information regarding various activities of Milk Plant and Dairy industry are

being kept by MIS Department of the milk plant. M.I.S. is the system wherein

31

information about the activities of plant is supplied to management and decision. Here

data are collected from different related department which can be useful to the

management for decision making.

The following aspects are maintained and supplied to the management as and when

required:-

Progress report of dairy plant (monthly/yearly)

Progress report of input activities (monthly/ yearly)

Progress report of procurement activities (monthly/yearly)

Report on activities of chilling centers (monthly)

Report on unit costing (monthly)

Report on product wise costing (monthly)

Stock statement (monthly)

Sale and return (monthly)

Transportation cost of milk collected ( route wise)

Section wise salary report (monthly)

Running hours of machine (monthly)

Financial Position (Yearly)

Dairy co-operative societies progress (monthly)

SECURITY DEPARTMENT

HEAD OF DEPARTMENT Mr. Prem Chand Bhumla

Security Department is managed by one Senior Security Employee who is assisted by a

team of well trained personnel. This department is for safety and security of all the assets

of milk plant. This department keeps proper watch on men, money and materials entering

in and going out of the plant so that no vehicles or material leave the factory without

authorization. This department ensures cleanliness in the plant premises by making best

32

possible use of available man power. This department is responsible for any

pilferage/theft of material from the premises of the unit.

COMPLIANT REDRESSEL COMMITTEE

If we overlooked the grievances, how can we accept the good words about the image.”

Verka milk plant formed a committee to handling the complaint. The committee consists

of managers of different departments like production manager, quality control manager

etc. Any complaint for example, less weight, timely delivery reach at plant on telephone

as well as .written complaint and is attended by member of committee to satisfy the

valuable customers so that they maintain to belief in verka milk plant

HORTICULTURE DEPARTMENT

HEAD OF DEPARTMENT: Mr. Prem Chand Bhumla

In order to ensure the proper landscaping at the plant its milk centers, milk bars and

others premises horticulture has been established.

CANTEEN

INCHARGE: Mr.Ganga Datt

Run on no profit no loss basis.

PRESENT STATUS/ACHIEVEMENTS OF THE PLANT

1. No. of societies increased from 94 to 816 and its membership from 5400 to

78000.

2. Milk Procurement has increased from 10200 LPD to 2, 50,000 LPD.

3. Products being manufactured by Ludhiana Plant are sold at premium rates

through out of the country and in the International Market.

4. City supply has increase from 66000 LPD to 1, 60,000 LPD.

5. Turnover the plant touched to 180 crores Profit of the union has increased

manifold.

6. Capacity utilization of the plant is more than 80%.

33

SWOT ANALYSIS

The SWOT analyses is a systematic identification of internal strength and weaknesses of

the business and environment opportunities and threats being faced by that business and

provide information that is helpful, in matching the firm’s resources and capabilities to

the competitive environment in which it operates. It is necessary for the organization to

analyze its weakness that can be removed by undertaking the project and what

opportunities can be exploited and strengths can be strengthen more. As such, it is

instrumental in strategy formulation and selection. It is dynamic and useful framework

for choosing a staretgy.The following diagram shows how a SWOT analysis fits into an

environmental scan.

SWOT Analysis Framework

Environmental Scan

34

STRENGTH:

Internal Environment

External Environment

Internal Environment

External Environment

Strength Weakness Opportunity Threats

Emotional attachment of people to Verka as they consider it as brand of Punjab.

Such a status is not enjoyed by any of the other brands in the market.

Verka offers complete range of milk as well as milk product which is presently

not offered by any of the other brands for city market.

Extensive network of DCS at the procurement side and wide network of

distributors and milk parlors in the city.

High quality products at an affordable rate to its customers.

Reputation of being a cooperative organization which provides fair value to

demand as well as supply side.

Verka is a local player and thus has the ability to make acceptable margins to

retailers and wholesalers, with lower overheads.

Work culture among officials and employees is very good. Plant is identically

located where all basis requirements are fulfilled.

Milk Plant is having institutional support from NDDB, PDDB. Its women

societies are sponsored by the central government.

WEAKNESSES

The plant is having very limited human resources and most of its departments are

falling short of work force putting extra burden on present workforce.

Political and government interference in the day to day operations which results in

less flexibility towards changing external environment and less flexible policies

for deciding procurement as well as packed milk prices.

The brands of milk are giving tough competition, as it does not advertise its

products completely.

Although management is devoted to its work but they are traditionally educated

so they learn by experience.

Verka is not able to communicate its quality assurance aspects to its customers

and thus they are having wrong notions about verka milk in their mind.

35

Visibility of advertisement for verka products is very poor.

OPPORTUNITIES:

Skimmed milk powder (SMP) is cheaply available to milk plant as it is prepared

in house when procurement is more than demand. This allows milk plant to give

competitive prices for procuring milk and attract more and more dairy farmers.

Although Verka is having a broad range of products but still there are certain

niche products which verka do not manufacture until now. Verka should make

efforts in developing such products like skimmed milk in tetra packs.

Milk Plant is already exporting ghee to gulf countries. It has received export

orders for skimmed milk powder, ghee & raseela. Thus, it is expected that by

more exports, it will earn more precious exchange for country.

National Dairy Development Board is also helping milk union to increase milk

procurement.

Health consciousness among people is increasing day by day and thus there is

huge market for pro-biotic milk and milk products.

THREATS:

Big multinational companies (MNC) like reliance are foraying into milk business.

There is a possibility of this trend being followed by other MNCs and thus

creating tough competition for Verka

In the absence of strict quality parameters for private dairies, the entry barrier for

them is very low.

Each and every person related is afraid of news of milk products exports by other

countries; Denmark & Netherlands which are two main producers of milk. These

companies are able to sell milk at lower rate.

The cost for the raw material is continuously rising and this might cause waning

interest of people from dairy farming.

Many imitation brands -Verva, Volka etc. are in markets which are a major threat.

36

COMPETITOR ANALYSIS

Milk is a commodity which is consumed in almost all the households daily in one

form or another. Thus there is a huge demand for it through out the year and thus it offers

good business opportunity. New player emerges into the market at tremendous speed

with new and improved products. As a result, the information age has also increased the

need for businesses to be thoroughly familiar with their competitors.

In order to compete effectively, organization needs to know the following things:

Who are competitors?

What are competitors’ strengths and weaknesses?

What are competitors planning to do next?

What are competitors’ spending trends?

COMPETITORS:

Competitors can be classified into two categories:

Competitors offering similar products

Competitors offering substitutes for the products supplied by organization

There are a number of players that are presently supplying liquid milk to the market.

Verka enjoys a healthy share of more than 75 percent of the total packed milk market.

But the real competition is not from the organized sector but from the unorganized sector.

There is still a large population which consumes milk supplied by private small dairies

and milkmen. People find dairy farming more profitable than agriculture. The milk

supplied by such milkman is often adulterated with water. Sometimes traces of urea,

pesticides and flour are also detected. In spite of all this, many milk consumers have this

notion in their mind that milk from milkman is more fresh and better than packed milk.

This may be attributed to the traditional buying pattern of consumers in country. As milk

from various sources is not differentiable thus prices for milk plays an important role in

consumer’s decision making process. Packaged full cream milk is present at Rs.27 per

liter while loose milk sold by private vendors ranges from Rs.18 toRs.25 per litre. Apart

from that people also find buying milk from private

37

milkman an easier option as almost all of them deliver milk at customer’s door steps. In

today’s fast lifestyle where almost every adult in family is working, home delivery

becomes very important. Consumer’s have an option of buying as much quantity as they

want while in case of packaged milk minimum packing is 500gms. There are many

people who prefer cow’s milk and such demand can only be catered by vendors selling

loose milk as no packed milk brand is selling cow’s milk. Due to these factors

unorganized sector is giving stiff competition to organized sector selling packed milk.

When we talk about competition within packed milk companies, verka almost rule the

city’s market. Whenever people think about packed milk, verka is the first thing that

comes to their mind. This may be attributed to strong distribution network of verka milk

as well as ubiquitous presence of verka booths in city which no other brand is presently

having. Verka is one brand which caters to all their need for milk as well as milk

products. The only brand that comes closest to Verka is ‘Vita’, which is also owned by

cooperative organizations of Haryana state. Now we will have a short discussion on all

the brands that are presently available.

38

Serial no. Name of Milk Brand Market Share (percentage)

1 Verka 75.48

2 Milk Time 5.28

3 Dairy pure (Reliance) 0.76

4 Dairy home 0.89

5 Vita 11.43

6 Aditya 1.18

7 Super 1.36

8 Uttam Milk 0.30

9 Virat 0.73

10 Royal 0.58

Vita: Vita’s packing is very much similar to verka’s packing and customer is often

not able to differentiate between the two at first glance. It is only after careful

observation that one is able to distinguish one brand from another. Vita offers better

margin to distributors and thus is more preferred by them while customers’ choice is

otherwise.

Dairy Pure (Reliance): Reliance group is as such not involved into processing and

packing of milk but it is just marketing the milk under its own brand name. It is a

new entrant into the market and response for its milk is not so favorable among

consumers. It has to cover a lot of ground in case it wants to improve upon its market

share. The only advantage that reliance is having is its availability in ‘Reliance Fresh’

stores. These stores have opened in many sectors in Ludhiana but still their number is

much lesser than the number of verka booths presently operating in city. The strength

of Verka can be gauged from the fact that even reliance store are selling verka milk

along with their own brand.

Amul and Nestle: Both these brands are operating into the niche segment and just

providing homogenized double toned milk in tetra packs. This milk can be store for

nearly 120 days. Younger generation who are health conscious and do not want to

take trouble of buying milk daily are the main consumers of such kind of milk.

Presently Verka is not offering this variant to general public and just supplying it to

Indian Army. It should consider marketing of this variant as market for it is

increasing with time.

Milk-time, Dairy Fresh, Uttam etc: All these brands are also available in the market

but their sales are negligible when we compare it with that of verka milk. The only

advantage that these brands are offering is better margin to distributors and retailers.