Concrete Polishing Specialist

description

Transcript of Concrete Polishing Specialist

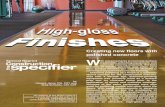

Polishing concrete may be a spirited a part of Flooring business because

the advantages of concrete processed to high gloss area unit wide. The

concrete that has been applied chemically so as to fill pores and is

grounded with progressively finer crushing tools. It’s currently being

accomplished that it’s long run advantages as low value and simple

maintenance. The coloring is applied to boost polished concrete alongside

different such preference as marking, creating radial lines, grids, bands,

borders, and different styles.

The concrete surface is ground down bit by bit by the grinding

grinders that use a mixture of metal bond diamond abrasives and

organic compound bond diamonds that resultantly attain the

required glow and smoothness. Such concrete diamond abrasives

are available completely different grits from a variety of 16 to

3000. The lease varies of grit makes the tool additional hostile

and coarser. If additional shine and gloss are needed than

finishing ought to be with a high variable.

The steps for sprucing concrete area unit as follows;

1 : Analysis of the

condition of the

surface, the hardness

of concrete ought to

be determined.

2 : Existing sealers and coatings ought to

be removed and surface cracks oughtto be

repaired and stuffed.

3 : Sprucing is often started by grinding

with the metal bond diamond abrasives. It

is typically completed in 3 to four steps

relying on the concrete condition.

4 : Application of liquid chemical hardener to supply further protection

from staining and water diffusion.

5 : The last step is to shine out the scratch pattern, by expertise one

involves apprehending once the grit level is switched.

After finishing with the required end of sprucing the

surface ought to be currently protected by applying

commercially used stain guard product, notably if the

surface is to be hospitable the weather to grease, oil

or chemicals. These products resist from stain

absorption and mud and that they area unit applied

by pump sprayer or wax device. For the long lifetime

of the concrete floor, it ought to be hardened. The

properly maintained concrete floor could offer a

hundred years of service as compared to tile that last

10-20 years. Another side is that existing subtracts

area unit utilized in flooring as opposition different

flooring techniques which can peel or fade.

The machine was then fully redesigned to satisfy

the requirement of grind and polish terrazzo and

concrete flooring and additionally to surface

hardwood and tile flooring. The machines area unit

designed for floor flattening, however additionally

wavy and uneven floor. It’s an inventive system

that uses rubber hardness grommets,

categorization, and bumpers. The required

flexibility is often varied by permitting, plant floor

or follow it.

The grinder machine weighs 900 pounds, and it

produces prime quality polished concrete. 2 stage

industrial vacuums area unit put in to stay dirty

for a vacant least. Furthermore, hardener/

densifier is applied when the mentioned method.

This second coat helps in making an especially

dense surface that’s immune to staining and

scratching. Finally, the sealer is applied, and,

therefore, the floor should be bright with a 3000

grit pad that resultantly offers the end a shiny bit,

and additionally secures the surface floor.