Nanomanufacturing Presentation for UT in Silicon Valley 2013

Composites Breakout Report-Out Workshop on Instrumentation, Metrology, and Standards for...

-

Upload

eleanore-hoover -

Category

Documents

-

view

225 -

download

4

Transcript of Composites Breakout Report-Out Workshop on Instrumentation, Metrology, and Standards for...

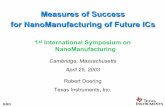

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Scope & Importance/ImpactsScope & Importance/Impacts

Composites and MaterialsComposites and Materials Scope (note that this refers to the areas of discussion – not intended Scope (note that this refers to the areas of discussion – not intended

to be all-inclusive): Instrumentation, Standards and Metrology for to be all-inclusive): Instrumentation, Standards and Metrology for Organic and Inorganic Nanocomposite Organic and Inorganic Nanocomposite Products; as well as Products; as well as associated:associated:

Free Standing Structures (e.g. wings)

Engineered coatings and thin films

Inclusions: Nanoparticles (3D), Nanotubes (2D), Nanoclays (1D) NNI def. of nano

Importance (already here)Importance (already here) Automotive, aerospace, building materials, chemicals,electronics,etc

Impacts – all phases of the Product Design CycleImpacts – all phases of the Product Design Cycle Predictive Product Design

Controllable Processing/Mfg techniques

Supply Chain Consistency

Ultimate Functionality and Product capability/reliability

Product stewardship (EHS for manufacturers and consumers; life-cycle and end-of-life issues, e.g. recycling)

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Current State of the Art: Point Current State of the Art: Point SolutionsSolutions

Application-specificApplication-specific Structural member vs. coating, electrical vs. mechanical etcStructural member vs. coating, electrical vs. mechanical etc

Value Stage DependentValue Stage Dependent Integrators had different needs than raw materials suppliers (e.g. Integrators had different needs than raw materials suppliers (e.g.

Designer might be most concerned with a great new material, while Designer might be most concerned with a great new material, while the producer is more concerned with consistent output on the line)the producer is more concerned with consistent output on the line)

Current SOA is insufficient in its limits of detection to meet the needs Current SOA is insufficient in its limits of detection to meet the needs Modulus to 10 nm Need to understand structure, chemistry, properties on an ever-

decreasing scale (this scale is advancing more quickly than our ability to provide)

Mfg Volume DependentMfg Volume Dependent 300 aircraft wings vs 3M auto bumpers300 aircraft wings vs 3M auto bumpers

Institutional VariabilityInstitutional Variability Not everyone has access to the same “state of the art”Not everyone has access to the same “state of the art”

Current macro metrics must be met/exceeded for new Current macro metrics must be met/exceeded for new material acceptance (old tests)material acceptance (old tests)

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Vision for the FutureVision for the Future Integrated approach to multiscale component / product Integrated approach to multiscale component / product

development and predictive capabilitydevelopment and predictive capability Requires reliability/consistency (consistency can be designed around) (quality)Requires reliability/consistency (consistency can be designed around) (quality) Enable broad applicability of solutionsEnable broad applicability of solutions As you change length/time scales, predictions should still be valid (especially As you change length/time scales, predictions should still be valid (especially

modeling—need sufficient degree of accuracy)modeling—need sufficient degree of accuracy) Transfer from lab/drawing table to realityTransfer from lab/drawing table to reality

Validation/verification of data at all stages (lab through performance)

Design for multi-component systems (interfaces important)Design for multi-component systems (interfaces important)

Seamless communications between computational modeling Seamless communications between computational modeling world and applied R&D worldworld and applied R&D world

Cradle-to-grave representation of performance / predictive Cradle-to-grave representation of performance / predictive capability – how does small sample test result relate to actual capability – how does small sample test result relate to actual performance of product…performance of product…

Toolbox that enables one to create a system that will behave in a Toolbox that enables one to create a system that will behave in a predictable and desired fashion, and then create it in the lab and predictable and desired fashion, and then create it in the lab and as a productas a product

ModelingModeling Raw Materials synthesisRaw Materials synthesis CharacterizationCharacterization ProcessingProcessing

EHS controls/protocols implemented and sustainableEHS controls/protocols implemented and sustainable

EHS

Processing

PropertiesPerformance

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Scientific and Technological Scientific and Technological BarriersBarriers ModelingModeling

Modeling does not yet allow one to predict material properties and product performance based on Modeling does not yet allow one to predict material properties and product performance based on inputs of raw materials, and processing.inputs of raw materials, and processing.

Metrology to support such modeling often does not existMetrology to support such modeling often does not exist Does not yet provide smooth continuum in scale. Does not yet provide smooth continuum in scale. Not sensitive to end need (performance) in complex systemsNot sensitive to end need (performance) in complex systems We often do not know what it is we need to modelWe often do not know what it is we need to model Interdependency issuesInterdependency issues

MetrologyMetrology Needs are approaching and going beyond the theoretical limits of current techniques; we lack Needs are approaching and going beyond the theoretical limits of current techniques; we lack

basic understanding of nanocharcterization. New tools are needed (ex: nanotomography)basic understanding of nanocharcterization. New tools are needed (ex: nanotomography) Our ability to make fundamental measurements (force, length, voltage, etc.) outstrips our ability to Our ability to make fundamental measurements (force, length, voltage, etc.) outstrips our ability to

usefully interpret the data through analytic and computational models.usefully interpret the data through analytic and computational models. Unmet need for characterization of interfacial properties (particle-particle, particle-matrix, particle-Unmet need for characterization of interfacial properties (particle-particle, particle-matrix, particle-

coating, film-substrate, etc.)coating, film-substrate, etc.) Needle-in-a-haystack problem / multiscale problem; How do you measure nanoparticles in a Needle-in-a-haystack problem / multiscale problem; How do you measure nanoparticles in a

room? A defect in a nanotube?room? A defect in a nanotube? Metrology needed to enable the needs of product manufacturing (cheap, fast, easy, operator Metrology needed to enable the needs of product manufacturing (cheap, fast, easy, operator

independent)independent) Insufficient interoperability and standardizationInsufficient interoperability and standardization Interdependency issuesInterdependency issues

Limited Access to existing State of the art, especially for small businessesLimited Access to existing State of the art, especially for small businesses Insufficiently educated workforceInsufficiently educated workforce EHS is empirical and therefore lags discoveryEHS is empirical and therefore lags discovery

Toxicity, exposure routes, Toxicity, exposure routes, Effectiveness of PPE and engineering controls all experimentally determinedEffectiveness of PPE and engineering controls all experimentally determined

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Future R&D DirectionsFuture R&D Directions

PredictionPrediction Computational Multiscale modelingComputational Multiscale modeling

Reactivity, reaction pathways, real systemsReactivity, reaction pathways, real systems

Transfer function between lab and operating environmentTransfer function between lab and operating environment

ProcessingProcessing Scale up, Scale up, Scale upScale up, Scale up, Scale up

Need realistic sample volumes for macroscale testing as well as Need realistic sample volumes for macroscale testing as well as statistically valid nanoscale samplingstatistically valid nanoscale sampling

PropertiesProperties Interface CharacterizationInterface Characterization

NanotomographyNanotomography

Particle agglomeration, particle surface chemistryParticle agglomeration, particle surface chemistry

Particle Mechanical BehaviorParticle Mechanical Behavior

EHSEHS

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Infrastructure needsInfrastructure needs

Infrastructure for integration of experimental results and Infrastructure for integration of experimental results and modelingmodeling

Toolbox of available models, materials, and processing methods in open Toolbox of available models, materials, and processing methods in open domain that can be combined to give desired properties and domain that can be combined to give desired properties and perfomance. perfomance.

Information management (including but not limited to data).Information management (including but not limited to data). Technology for integrating parts of the toolbox (Integration technology).Technology for integrating parts of the toolbox (Integration technology). Tools must cross time and length scalesTools must cross time and length scales

MetrologyMetrology Standard reference materials and methodsStandard reference materials and methods Ability to measure multiple properties simultaneously (magnetic, Ability to measure multiple properties simultaneously (magnetic,

mechanical, electrical, optical, etc.) at the nanoscale in particular mechanical, electrical, optical, etc.) at the nanoscale in particular interfaces.interfaces.

More inter-agency (industry, gov’t, academia) and even More inter-agency (industry, gov’t, academia) and even international cooperation to solve pre-competitive issues international cooperation to solve pre-competitive issues (like Sematech). No single company can address these (like Sematech). No single company can address these problems in a competitive way.problems in a competitive way.

Education at all levels (should be a major consideration for Education at all levels (should be a major consideration for any interagency cooperative effort.)any interagency cooperative effort.)

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Implementation Strategies: Implementation Strategies: FederalFederal

Be a unifying forceBe a unifying force Provide stewardshipProvide stewardship Provide rules of engagementProvide rules of engagement Create MOU, define IP, etcCreate MOU, define IP, etc Foster collaborationFoster collaboration Define roadmap that is sensitive to industrial needs and Define roadmap that is sensitive to industrial needs and

bring appropriate parties to the table.bring appropriate parties to the table. Define limits of pre-competitive stateDefine limits of pre-competitive state Foster (and enforce?) EHSFoster (and enforce?) EHS Foster standardizationFoster standardization

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Implementation Strategies: Int’l Implementation Strategies: Int’l communitycommunity

U.S. needs to coordinate with EU (which U.S. needs to coordinate with EU (which has nanotech roadmaps), Asia (CNTs), has nanotech roadmaps), Asia (CNTs), China, JapanChina, Japan

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Implementation Strategies: Implementation Strategies: AcademiaAcademia

Education Education

Provide cross-disciplinary capabilitiesProvide cross-disciplinary capabilities

Pursue high risk, limited reward, projects. Pursue high risk, limited reward, projects. Once others articulate truly difficult, longer Once others articulate truly difficult, longer term problems, work on these.term problems, work on these.

Provide knowledge of R&D “pod”Provide knowledge of R&D “pod”

Make suggestions to close gaps.Make suggestions to close gaps.

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Implementation Strategies: Implementation Strategies: IndustryIndustry

Participate/commit to developing roadmapParticipate/commit to developing roadmap

Obtain commitment at no cost to gov’tObtain commitment at no cost to gov’t

Provide research requests and figures of Provide research requests and figures of meritmerit

Identify and articulate key specific end Identify and articulate key specific end states (desires and goals). (Players at states (desires and goals). (Players at different parts of value chain have different different parts of value chain have different end states.)end states.)

Negotiate pre-competitive line (MOU)Negotiate pre-competitive line (MOU)

Bring product to marketplaceBring product to marketplace

Participate in standardization effortsParticipate in standardization efforts

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

MiscellaneousMiscellaneous

Small business: SBIR/STTR/corporate Small business: SBIR/STTR/corporate funding to handle work that is not funding to handle work that is not glamorous but very important (ex: glamorous but very important (ex: systematically characterizing dispersion as systematically characterizing dispersion as a function of processing for a specific a function of processing for a specific material system.)material system.)

Consortia and trade organizations: Consortia and trade organizations: Work on pre-competitive issuesWork on pre-competitive issues

Focus standardization efforts with the appropriate Focus standardization efforts with the appropriate organizations (ASTM, ISO, IEEE)organizations (ASTM, ISO, IEEE)

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Cross-cutting issuesCross-cutting issues

EducationEducation

Foster EHS Foster EHS

Information managementInformation management

Integration of modeling, materials, Integration of modeling, materials, processing, properties, and performance. processing, properties, and performance. Further, all of these must be supported by Further, all of these must be supported by metrology.metrology.

Cradle to grave of products; sustainability Cradle to grave of products; sustainability (Ex: Does burning for disposal cause (Ex: Does burning for disposal cause problems? First-responder issues?)problems? First-responder issues?)

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Implementation Strategies: Implementation Strategies: Roadmap?Roadmap?

Discovery R&D Production Market Disposal

Industry-specific goals

Gov’t lead Industry lead

Common goals

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Summary/Conclusions/PrioritiesSummary/Conclusions/Priorities

Integration of modeling, materials, processing, Integration of modeling, materials, processing, properties, and performance.properties, and performance.

Cross-cutting issues: EHS, metrology, education, Cross-cutting issues: EHS, metrology, education, information management.information management.

Need to develop a roadmap for nano Need to develop a roadmap for nano materials/composites with broad-based support.materials/composites with broad-based support.

Roles:Roles: Industry needs to identify targets, metrics, and challenges; Industry needs to identify targets, metrics, and challenges;

government partners to facilitate, support, and inspire,government partners to facilitate, support, and inspire,

Academia educates and pursues fundamental research Academia educates and pursues fundamental research

Industry-gov’t-academia consortia collectively Industry-gov’t-academia consortia collectively bound pre-competitive steps on the roadmap.bound pre-competitive steps on the roadmap.

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Issue: Don’t understand physical mechanisms

• Model NanoConsitituent interaction in complex resin system

• Tailor material system per requirements

Issue: Can’t control material properties

• Dispersion/model interactions

• Validate modeling predictions

• Optimize system per requirements

Issue: No standards for materials

• Establish acceptance criteria for material constituents and system

Consistently produce material that meets targeted engineering requirements

CoNECT Combines Three Needs Into One Solution

Validated path for others to follow that unlocks the knowledge gate of nano

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Objective:

Predict material properties

Deliverables:

Parametric model that allows for quick variable evaluations

Technical Approach:

Investigate nanotube interactions in a complex resin system by manipulating bond strength, volume percentage, etc.

Investigate dispersion effects on material system

Objective:

Repeatably produce engineered material

Deliverables:

Quality-controlled manufacturing process for material system

Technical Approach:

Interactively work with modeling team on manufacturing challenges

Use a building-block approach to manufacturing the modeled mechanisms to achieve targeted material properties

Objective:

Measurement criteria to evaluate manufacturing processes (constituents, modifications) to ensure reproducibility

Deliverables: Standards, Specifications, Acceptance Test

Technical Approach:

Interactively work with modeling and material teams to identify critical mechanisms and processes that require quality criteria

Set allowables

Overview of Three Studies

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Participants/ContributorsParticipants/Contributors

TextText

Composites Breakout Report-OutWorkshop on Instrumentation, Metrology, and Standards for Nanomanufacturing, 10/17-19/06

Sidebars for Sidebars for Report/AssignmentsReport/Assignments

TextText