Comac: extrusion technology for plastics

-

Upload

pietro-zanotto -

Category

Engineering

-

view

404 -

download

11

description

Transcript of Comac: extrusion technology for plastics

If you see plastic granules, wemay be present.

If you see special plastic granules, our machine is certainly running.

Via per Legnano 57, 20023 - Cerro Maggiore (MI) - ITALY(+39) [email protected]

www.comacplast.com

(t)win screw extruders

Our technological developments are

results of people, investments, passionand continuous research, by offering toour customers what they deserve:quality.

We believe our efforts and flexibility

are the unique answers to a global andmore requiring markets, characterizedby differentiation of products, dailychanges and flexibility of productions.

COMAC: extrusion technology since 1978

We daily develop technology for wide rangeof special compounds in plastic industry.

Our products are fullydeveloped and manifactured in Italy.

sustainability

customers

testing

techncial assistance

lab

masterbatch

adhesive

hot-melt

Wood

plastic

compounds

Bio

plastics

polymer

blends

Nylon Textile

filaments

Long fiber

technology

PETABS

PA

PP

plastic

compounds

LDPEHDPE

we extrude

technological

solutions.

yarn

regeneration

PE

PBT

PU

PC

PSPMMA

EVA

Our products cover different applications:

masterbatchescompoundshot-meltyarn regenerationnylon textile filaments

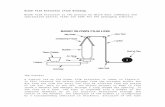

laboratory ExtrudersJolly mixerfilter test

Laboratory lines:

Our extruders can be also integrated into dedicated and special lines

It’s not only matter of design. It’s matter of people.

We work with our partners to create valuable products.

Our design affect the quality. Our technology affects efficiency.

We scrap with your scraps.

COMAC EBC for PET waste reprocessing

• Following this trend, COMAC has developed a special plant with an innovative processing solution by which long glass fibers (roving) are blended in a polymeric matrix producing reinforced anti-crash sheets in a continuous extrusion process.

• This extrusion plant feeds in-line compression moulding machines for making automotive under-body panels (e.g.: inner door panels), covers etc. The process allows production of parts with higher mechanical with respect to standard long glass fiber compression moulding systems.

• The thermoplastic matrix allows an easy end-of-life recycling of the moulded parts and advantages are multiple: highest quality control, reduction of scraps and higher output.

LFT faces a growing demand mostly due to special requirements in the automotive industry.These facts push producers to develop new materials and let us design their needs.

COMAC EBC are applied for direct extrusion of synthetic grassThis special blend of polymers and additives required two things: your knowledge and our technology.

We develop dedicated, sustainable and profitable configurations reducing costs of processing, gaining efficiency an quality.

Our extrusion lines cover multiple applications.We design the mostefficient and profitablelayout, matchingcustomers’ requirmentsand offering the mostadvanced technologicalsolutions.

Training & maintenance

Corotating twin screw

extruders are

sophisticated machines.

We believe in quality to

prevent unexpected and

costly issues, offering

wide range of products,

dedicated technical

assistance and training.

How doesefficiency matter?

2

1

1

3

2

6

1

1

2

8

2

3

3

3

315

3

252

222

12

9

21

1

4 11

22

365

8 2

1010

1

184

2

The future holds opportunities.

«Going small scale to make the big difference»

Thi is the way we support our customers.

This is the way they like.

Via per Legnano 57, 20023 - Cerro Maggiore (MI) - ITALY

(+39) [email protected]

www.comacplast.com

AUSTRIA, CZECH REP, POLANDOTTO KUHNEN WienMr. Stephan Kü[email protected]

BRAZIL, ARGENTINA, PERUiB23 GROUP INDUSTRIAMr. Nicola [email protected]

CHILEOTTO SEIDLITZMr. Alex [email protected]

COLOMBIAFERROMAC LTDAMr. Edgar [email protected]

EGYPTBEHAIRY CO. FOR INTERNATIONAL TRADEMr. Mohammed ElbehairyE-mail: [email protected]

GERMANYKAMBACH Trading + EngineeeringMr. Werner [email protected]

GREECETECHNIMAT – P. VENIZELOS & CO Mr. Periklis Venizelos / Angelos [email protected] / [email protected]

Via per Legnano 57, 20023 - Cerro Maggiore (MI) - IITALY

(+39) [email protected]

www.comacplast.com

Let’s meet:

MACEDONIA, MONTENEGRO, SERBIAEUNETMr. Dejan [email protected]

MEXICOCOMERCIALIZADORA DELVA, S.A. DE C.V.Mr. José Luis & Mr. Gabriel Del [email protected]

ROMANIABIPRAL SRLMr. Angelo [email protected]

RUSSIAGalaxy LTMr. Valentino [email protected]

SPAINMAQUINARIA PARA PLÁSTICOS IMVOLCA, S.L.Mr. Pascal [email protected]

TURKEYNautruelMr. Tamer [email protected]

VIETNAM & SOUTH EAST ASIARegional representativeDr. Ing. Thanh Vu [email protected]

Thank you for your attention!Mr. Pietro Zanotto (Export Dept)

(+39) [email protected]

(+39) [email protected]

www.comacplast.com

Via per Legnano 57, 20023, Cerro Maggiore (MI), ITALY