COLD TEA CREEK BRIDGE REMEDIATION - etouches · WHAT IS CATHODIC PROTECTION? Traditionally either:...

-

Upload

phungnguyet -

Category

Documents

-

view

213 -

download

0

Transcript of COLD TEA CREEK BRIDGE REMEDIATION - etouches · WHAT IS CATHODIC PROTECTION? Traditionally either:...

INFRACORR COMPANY OVERVIEW

Specialist consultants in the repair and preservation of infrastructure

Infracorr Consulting

Pty Ltd

Investigation and Condition Assessment

Design and Specification of Repair Systems

Durability Design

Construction Quality

Assurance

Commissioning and Ongoing Monitoring

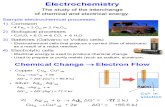

WHAT IS CATHODIC PROTECTION?

Traditionally either:

• Galvanic (voltage source is provided by the anode itself); or

• Impressed Current (DC voltage source)

Galvanic:

• Cannot be adjusted (voltage is set)

• Anode is consumed

• Easy to install & maintain

Impressed Current (ICCP):

• Substantial hardware required (wiring, power source, control system)

• Significant monitoring & maintenance

IMPRESSED CURRENT CATHODIC PROTECTION

Passes a small, permanent current through the concrete to the steel to “stop” corrosion

Cl-

Cl- Cl-Cl-

WHY USE CP ????

• No need to remove chloride contaminated concrete

• Remove & replace loose, delaminated concrete only

• Surface based concrete repair (not behind bars)

• Less disruption & structural impact than full depth concrete repair

• Much cheaper than repeated full depth patch repairs

5

IMPRESSED CURRENT CP

Conventional Impressed Current CP

• Many permanent cables to provide current & monitoring from TR unit

6

WEBB DOCK 4&5 ICCP

• 700m long wharf, 135 # x 15m long beams

• 2000m2 concrete repair

• 30,000+ Discrete Anodes

• 1,100 references

• >500 CP Zones

• $35 m Repair

If conventional ICCP design was adopted, would have required 2500 cables to the TR

7

WEBB DOCK ICCP

• Utilized Distributed TR’s below wharf

• Only one communication cable pair along wharf to Central Control Unit

• Internet based commissioning & monitoring

• Text message alarms

8

COLD TEA CREEK BRIDGE

• Located in the Hunter region of NSW, constructed ~1969

• Three span bridge constructed with 380mm square precast piles, insituheadstocks and precast plank deck beams

• Tidal creek which feeds into Lake Macquarie

Lake MacQuarie

BRIDGE CONDITION

• Cracking and spalling to 10% piles and 5% lower headstocks

• Failed previous patch repairs

10

INVESTIGATION• Half Cell Potential survey

indicated active corrosion to:

• 80% of lower headstocks

• 100% of piles

• Critical chloride levels at the depth of reinforcement

• Corrosion rate of reinforcement measured to be moderate to fast

11

iCorr corrosion rate, no electrical connection required

REPAIR OPTIONS FOR COLD TEA CREEK BRIDGE

• Full Depth Patch Repairs

• Repeated every ~5 years

• ICCP

• Galvanic CP (chloride level too high)

• Hybrid CP

RMS chose Hybrid CP

WHAT IS HYBRID CP?

• Hybrid CP combines both Impressed Current and Galvanic operation.

• Developed approximately 12 years ago in the UK.

• Patented System

• No permanent cabling or power supply.

COLD TEA CREEK BRIDGE

DESIGN – PILES

• Single row of D750 hybrid anodes at 250mm CC spacing

• Anodes installed from mid tide to top of pile

DESIGN – HEADSTOCKS & ABUTMENTS

• Single row of D1000 hybrid anodes at 350mm CC spacing along base of headstocks & abutments

• Anodes designed to protect lower ~300mm headstock

• Silane impregnation to headstocks and deck soffits

HYBRID CP PREPARATION

• Surface based concrete repairs completed

• Anode holes drilled (30mm)

• Negative (rebar) connections completed

• Reference cells installed (monitoring)

16

HYBRID INSTALLATION

• RMS (Hunter Region) work crew completed installation

• Infracorr technical supervision

17

IMPRESSED CURRENT PHASE

• Anodes are installed in 30mm holes in piles and lower headstocks

• Anodes connected to titanium connector wires

• Anode strings connected to positive of portable power supply (or battery)

• 9V DC for ~10 days or minimum charge passed

• Current passed equivalent to 6-12 months ICCP

18

CORROSION RATE

• According to ISO 12696- 2016, a Corrosion Rate of less than 2 mA/m2 indicates that the reinforcement is passive.

• The Concrete Society Technical Report #60 (Electrochemical Tests for Reinforcement Corrosion) states:

i. Less than 2 mA/m2 – steel is passive

i. 2 to 5 mA/m2 represents a low corrosion risk (Cracking 15 years+)

ii. 5 to 10 mA/m2 a moderate corrosion risk (Cracking 5 – 15 years)

iii. Greater than 10 mA/m2 a high corrosion risk (Cracking <5 years)

• A corrosion rate of 2 mA/m2 is approximately equivalent to a section loss of 2 mm in 1000 years

GALVANIC PHASE

• After ~10 days impressed current, power supply and cables are removed

• Anode, negative and reference cables terminated at local junction box (JB)

• Anode cables are connected to negative (reinforcement) to continue galvanic CP current (1-2 mA/m2)

• Commissioning & Monitoring completed from JB

• Remote monitoring is available if required

20

COMMISSIONING

• Commissioning was completed on the 17th and 18th

of July

• Galvanic Current, Reference potentials, Instant-Off, 24 hour Depolarization

• Corrosion Rate (Using the Butler-Volmer Equation)

• System Life Calculation (Anode exhaustion)

COMMISSIONING – PIER C

Current Density (Corr. Rate) - PIER C

Panel/Zone C1 C1 C2 C2 C2

Reference ID R1 R2 R3 R4 R5

Reference Location Headstock Pile Headstock Headstock Pile

Natural (Base) Potential (mV) -80 -164 -70 -82 -263

Instant Off Potential (mV) Recorded 17th July 2017, 12:10pm

-154 -293 -103 -131 -311

Depolarization Potential (mV) - Recorded 18th July 2017, 12:05pm (24hrs)**

-76 -216 -53 -68 -266

Depolarization [∆V] (mV) 78 77 50 63 45

Galvanic Current (mA) 11.67 11.67 13.42 13.42 13.42

Steel (reinforcement) Area (m2) 12.46 12.46 12.46 12.46 12.46

Corrosion Rate [icorr] (mA/m2) 0.221 0.226 0.484 0.353 0.553

MONITORING

• Recommended at 12 to 24 month intervals

• Take galvanic current and depolarization results from JB’s

• Calculate Corrosion Rate (<2mA/m2)

• System can be re-energized with battery should it be required

23

COLD TEA CREEK BRIDGE

SUMMARY OF WORKS

• Concrete repairs were completed between February to April 2017

• The installation of anodes was completed in April

• The impressed current period was in June

• Commissioning was completed in July

• The system is operating as designed

• Life of corrosion protection 30 years +

• Cost of Repair approximately $150K

BELONGIL BRIDGEBYRON SHIRE COUNCIL

• Concrete repair & Hybrid to piles above mid tide

• Silane to headstocks and deck soffit 4/1

2/2

01

7

25

BMA HAY POINT BERTH 2

• 3 No. inverted Table caissons (4 legs each)

• 12 No. caisson columns 12x12m

• 9 cells per column x15m high

• Hybrid & water ICCP

• $35m (2015-2018)

26

HYBRID OR ICCP ?

ICCP is the Ultimate Corrosion Control

• Full control over current level

• Control System & Cabling

• Acid attack can be an issue (poor design)

• Requires regular monitoring & maintenance

Hybrid provides an alternative option

• Cannot vary the current, must get design right

• Ideal for remote sites without power

• Small scale projects are economical

• Significantly less monitoring and maintenance

• Cheaper to install

27

Infracorr wish to acknowledge & thank

• RMS Bridge Division

• RMS Hunter Region

• RMS Hunter Region Work Crew

…….for their assistance with the successful completion of this project.

28