Cold rolled low carbon steel strip - Waelzholz€¦ · 02 Cold rolled low carbon steel strip ... In...

Transcript of Cold rolled low carbon steel strip - Waelzholz€¦ · 02 Cold rolled low carbon steel strip ... In...

02 Cold rolled low carbon steel strip

Happy about details – our cold rolled low carbon steel stripJust imagine the following situation: Your colleague sitting at the desk across from you

is on the phone. You have to fetch some important documents, which unfortunately are

kept in the cabinet directly behind him. Isn’t it marvellous that filing cabinet doors can

be opened and hanging file drawers be pulled out and pushed back again almost

without making any noise at all? Your colleague will certainly appreciate it – thanks to

rolling and pull-out cabinet guides made of low carbon steel strip produced by

C.D. Wälzholz. Well, you are bound to be a really nice person, who is always interested

in the well-being of your colleagues. Keep at it! Products made of low carbon steel strip

produced by CDW will work impeccably for many years to come – even after a new

colleague has joined you in the office.

Many products using materials made by CDW cannot be detected at first glance – just

like this rolling and pull-out cabinet guide. But one thing is certain: you will realise our

quality immediately.

On the following pages we will show you what cold rolled low carbon steel strip can do

for you. We will also introduce you to a number of applications using this very special

material.

03Cold rolled low carbon steel strip

Low carbon steel strip produced by C.D. Wälzholz is used in a number of products found

in everyday life – and it certainly does a good job there, for example in the automotive

sector, in the furniture industry and in the construction of electrical cabinets.

Your requests set our benchmarks – application-oriented developmentLow carbon steel strip is extremely versatile. Due to its excellent workability and high

toughness this material allows for the manufacturing of highly accurate precision parts.

Again and again – since CDW’s quality management system guarantees controlled and

reproducible processes and consequently continuous product quality as well.

Low carbon steel strip is used, for example, to produce telescope slides in filing and

storage cabinets. These slides are exposed to loads of more than 100 kg, but they are

nevertheless smooth-running and almost noiseless as well as utterly reliable – and they

will be functioning outstandingly for many years to come.

In the furniture industry this type of steel is used to produce table legs, chair legs and

hinges. You will find it in the shape of charge eliminators in fuse boxes. Low carbon steel

strip also helps to produce the familiar sound of bicycle bells; and transformed into the

sophisticated precision blanked components called gearbox plate it supports countless

gear changes on roads and streets all over the world.

04

Perfect measurements – our standards Low carbon steel strip is characterised by utmost precision during the entire production

process. Therefore we have to try even harder to thoroughly check, measure and weigh

materials as well as co-ordinate procedures. By means of laser measuring and state-of-

the-art electronic control systems we monitor the low carbon steel strip during each

production step ensuring optimal settings for all tolerances. Consequently we are able

to guarantee the most outstanding quality for each individual precision component and

worked part.

Our quality and process management system monitors and controls the entire

production process – pre-roll reduction, heat treatment and then finally skin passing.

This is how we can provide optimal pre-conditions for overall constant properties and

thus for effective subsequent processing.

Thickness 0.08 - 14 mm

Width 7 - 650 mm

Tolerance according to EN 10140 and special agreements

Delivery form pancake coils, oscillated wound coils and fixed lengths

Material according to EN 10139 and special grades

“non-earing” condition on request

Surface condition according to EN 10139, special agreements and surface coated

Cold rolled low carbon steel strip

for further details: www.cdw.de

05

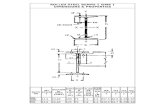

EN 10139 Ladle analysis [% max.] Delivery condition Mechanical properties

Steel type C P S Mn Ti Condition Short symbol Re

[N/mm2]

Rm

[N/mm2]

Elongation r 90

min.

n 90

min.

HV

A80 A50 Lo = 5.65 So

DC 01 0.12 0.045 0.045 0.60 annealed A 270 - 390 28 30 32 max. 105

slightly skin-passed LC max. 280 270 - 410 28 30 32 max. 115

cold worked C290 200 - 380 290 - 430 18 20 24 95 - 125

C340 min. 250 340 - 490 105 - 155

C390 min. 310 390 - 540 117 - 172

C440 min. 360 440 - 590 135 - 185

C490 min. 420 490 - 640 155 - 200

C590 min. 520 590 - 740 185 - 225

C690 min. 630 min. 690 min. 215

DC 03 0.10 0.035 0.035 0.45 annealed A 270 - 370 34 36 37 max. 100

slightly skin-passed LC max. 240 270 - 370 34 36 37 1.3 max. 110

cold worked C290 210 - 355 290 - 390 22 24 26 95 - 117

C340 min. 240 340 - 440 105 - 130

C390 min. 330 390 - 490 117 - 155

C440 min. 380 440 - 540 135 - 172

C490 min. 440 490 - 590 155 - 185

C590 min. 540 min. 590 min. 185

DC 04 0.08 0.030 0.030 0.40 annealed A 270 - 350 38 40 40 max. 95

slightly skin-passed LC max. 210 270 - 350 38 40 40 1.6 0.180 max. 105

cold worked C290 220 - 325 290 - 390 24 26 28 95 - 117

C340 min. 240 340 - 440 105 - 130

C390 min. 350 390 - 490 117 - 155

C440 min. 400 440 - 540 135 - 172

C490 min. 460 490 - 590 155 - 185

C590 min. 560 590 - 690 185 - 215

DC 05 0.06 0.025 0.025 0.35 slightly skin-passed LC max. 180 270 - 330 40 42 42 1.9 0.200 max. 100

DC 06 0.02 0.020 0.020 0.25 0.30 slightly skin-passed LC max. 180 270 - 350 38 40 40 1.8 0.220

Cold rolled low carbon steel strip

for further details: www.cdw.de

Achieving perfection through precisionLow carbon steel strip produced by C.D. Wälzholz

is the result of long experience combined with

state-of-the-art computer technology – perfecting

our process technology and optimising quality

assurance.

Low carbon steel strip is always the first choice

when it comes to precision parts and worked

steel components. This material meets even the

highest requirements as to working and forming

properties. It is also extremely tough and can be

exposed to high loads. In order to achieve these

properties our steel strip is produced in a highly

sophisticated process. CDW has 4-stand tandem

rolling mills, where strip thicknesses are recorded

by means of non-contact x-ray and isotope

measuring devices whilst strip length and speed

data is collected by means of laser beams.

Consequently even the slightest deviation can be

corrected immediately and the appropriate

adjustments are made at once. Subsequently the

steel is annealed in HICON batch-type annealing

furnaces conjointly developed by Ebner, the

manufacturer, and CDW. With these special batch

furnaces, which play a crucial role within the

coordinated heat treatment processes of cold rolled

low carbon steel strip, spheroidise annealing with

temperatures of up to 850 °C is possible.

Furthermore, CDW has several continuous

annealing lines extending the heat treatment

range to 1,050 °C.

06 Cold rolled low carbon steel strip

In this way properties like e. g. flatness are realised,

and application-oriented adjustments to produce

isotropic grades, for example, are thus made

possible.

CDW also specialises in low carbon steel strip

surface treatment. With the so-called “single sided

plates” surfaces are created independently, i. e. the

different surface roughness and thus the different

adhesive properties of the sides are flexibly aligned

with envisaged applications. The combination of

smooth and rough surfaces will therefore ensure

a perfect match between material properties and

end product requirements.

Subsequent processes, after the actual production

of low carbon steel strip at CDW, may include

separation processes like die cutting or fine

blanking as well as various working and forming

procedures: by means of deep drawing, stretch-

forming, bending and stamping, precision parts

and worked steel components of above-average

dimension accuracy can now be manufactured.

For us at C.D. Wälzholz precision is more than just

a word – it is our philosophy and it enables you to

achieve perfection!

07

Nominal thickness

[mm]

Thickness tolerances for nominal widths [mm]

< 125 125 < 6001)

> A B C A B C

- 0.10 ± 0.008 ± 0.006 ± 0.004 ± 0.010 ± 0.008 ± 0.005

0.10 0.15 ± 0.010 ± 0.008 ± 0.005 ± 0.015 ± 0.012 ± 0.010

0.15 0.25 ± 0.015 ± 0.012 ± 0.008 ± 0.020 ± 0.015 ± 0.010

0.25 0.40 ± 0.020 ± 0.015 ± 0.010 ± 0.025 ± 0.020 ± 0.012

0.40 0.60 ± 0.025 ± 0.020 ± 0.012 ± 0.030 ± 0.025 ± 0.015

0.60 1.00 ± 0.030 ± 0.025 ± 0.015 ± 0.035 ± 0.030 ± 0.020

1.00 1.50 ± 0.035 ± 0.030 ± 0.020 ± 0.040 ± 0.035 ± 0.025

1.50 2.50 ± 0.045 ± 0.035 ± 0.025 ± 0.050 ± 0.040 ± 0.030

2.50 4.00 ± 0.050 ± 0.040 ± 0.030 ± 0.060 ± 0.050 ± 0.035

4.00 6.00 ± 0.060 ± 0.050 ± 0.035 ± 0.070 ± 0.055 ± 0.040

6.00 8.00 ± 0.075 ± 0.060 ± 0.040 ± 0.085 ± 0.065 ± 0.045

8.00 10.00 ± 0.090 ± 0.070 ± 0.045 ± 0.100 ± 0.075 ± 0.050

CDW thickness ranges exceeding EN 10140; nominal widths on request

> A B C

10.0 12.0 ± 0.110 ± 0.090 ± 0.055

12.0 14.0 ± 0.120 ± 0.100 ± 0.060

A = Normal tolerance B = Fine tolerance C = Precision tolerance 1) Nominal width possible for low carbon steel strip up to 650 mm.

Cold rolled low carbon steel strip

Patented innovationsC.D. Wälzholz is well known for its consequent

application-oriented approach. One example for

this philosophy is our production of material for

flux cored welding wire for off-shore technology.

In this area of low carbon steel strip production

we have managed to optimise chemical ingredients

in order to avoid spraying during welding work.

Our low carbon steel strip has to undergo exacting

tests like e. g. the notch impact test. Therefore we

are able to guarantee the necessary ductility of

the cored wire even at low temperatures.

But that is not everything. In order to be able to

meet even the most demanding requirements

CDW has developed LIN rolling, a patented

procedure for surface treatment. LIN denotes

“liquid nitrogen” and refers to the liquid nitrogen,

which replaces common coolants like oil or

emulsions during the rolling process.

Thanks to this process innovation our strip steel

for flux cored welding wire is characterised by

particularly even surfaces and a complete absence

of oil. For the user this means no more smoke

emissions and the highest possible safety level.

08 Cold rolled low carbon steel strip

09

Economic miracle – our oscillated wound coilsApart from developing high-quality materials one of our main objectives has always been

process optimisation. Together with our customers we constantly aim at making

production processes more efficient. One good example for co-operation and continuous

enhancement is the development of our strictly application-oriented oscillated wound coils.

For the production of our cold rolled low carbon steel strip coils we have managed to

increase the length of the individual steel strips from 1,000 to 30,000 metres. Moreover,

steel strips can be joined by means of modern welding technology. A further advantage

is our computer-controlled oscillating winding procedure. Thanks to our state-of-the-art

technology our customers have crucial advantages since operating times are up to

30 times longer now, and you all know what that means: labour-intensive set-up times

and unprofitable shutdown times are minimised.

Here they are again in short form – the advantages of our oscillated wound high carbon steel strip coils:» Strip widths of up to 70 mm

» Strip length/operating times 30 times longer

» Individual coil widths of 250 mm - 550 mm

» Jumbo coils with a weight of up to 3,500 kg

Cold rolled low carbon steel strip

10

For us at C.D. Wälzholz it is important that our

cold rolled low carbon steel strip reaches your

company in perfect condition. Therefore we aim

for the highest quality and exacting standards not

only in regards to production and material, but

also with respect to packaging. Our modern

automatic packaging equipment can guarantee

smooth logistics between production line and

shipping department and will ensure that the low

carbon steel strip will reach its destination in

perfect condition.

We have developed suitable and appropriate

packaging for different means of transportation

and for national or international destinations.

Have a nice journey!Take our heavy-duty overseas packaging, for

example, which will have to withstand the strains

of long and rough transportation across the ocean.

Protection of all our products is extremely

important to us, but we will never use more

packaging material than absolutely necessary.

After all, this is for the benefit of the environment

and of our customers.

Due to our long international experience we have

continuously improved our coil packaging: apart

from optimal protection and clear marking we will

always make sure that distinct traceability is

guaranteed.

Cold rolled low carbon steel strip

11

C.D. Wälzholz – at home everywhere in the worldSteel is an extremely versatile material. The C.D. Wälzholz Group of Companies is just

as versatile itself. As a progressive German cold rolling mill with a long tradition,

C.D. Wälzholz today has subsidiaries and agencies all over the world. Therefore we are

in a position to offer our international customers cold rolled low carbon steel strip in

virtually any type and grade required – everywhere in the world.

Satisfied customers, highest quality as well as a responsible handling of the environment

are our goal. Always.

Cold rolled low carbon steel strip

Cold rolled high carbon steel strip

Hardened and tempered steel strip

Electrical steel strip

Cold rolled low carbon steel strip

Bonderized steel strip

Narrow steel strip

Profiles

C.D. Wälzholz KGFeldmühlenstr. 55 58093 HagenGermany

Phone: +49 (0) 23 31- 9 64 - 0Fax: +49 (0) 23 31- 9 64 - 21 00Internet: www.cdw.deE-mail: [email protected]

Locations: Hagen, Hohenlimburg, Plettenberg, Oberkochen, Iserlohn/Germany Götzis/Austria . Thiers/France São Paulo/Brazil . Cleveland, Ohio/USA . Taicang/China

Rem

ind

Adve

rtis

ing

10/1

3