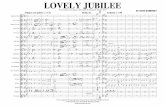

CNT FAte

-

Upload

thanga-pandian -

Category

Documents

-

view

9 -

download

0

description

Transcript of CNT FAte

-

:b,c

ce C

, 560

f T

z C

Neg

; ace 13

Abstract

epoxy thermosets [10,11].

Therefore, it is the purpose of our study to followSWNTs and multi-walled carbon nanotubes (MWNTs)from their production as raw reactor powder agglomerates,via cleaning and subsequent exfoliation steps, towards theirnal position in the nanocomposite. Direct microscopicobservation, especially of the SWNT dispersion during

* Corresponding author. Laboratories of Polymer Technology andMaterials and Interface Chemistry, P.O. Box 513, 5600 MB Eindhoven,The Netherlands. Fax: +31 40 2476999.

E-mail address: [email protected] (J. Loos).

Composites Science and Technolo

COMPOSITESCarbon nanotubes (CNTs) have caused a great deal ofexcitement in the world of materials science since their dis-covery in 1991 by Iijima [1]. Their production, character-isation and application have been topics of muchresearch over the past decade. The unique combinationof properties of CNTs has triggered the current interestin their use as ller material for polymer composites. It isreported that CNT/polymer composites show high strengthand stiness combined with electrical conductivity at rela-tively low concentrations of CNTs [26]. Several CNT/polymer matrix systems have been studied in detail: nano-tube lled thermoplastic polymers such as polystyrene [7],

In a recent study of our research group, we havedescribed a method to prepare single-walled carbon nano-tubes (SWNTs) lled thermoplastic polymer nanocompos-ites based on latex technology [12,13]. We have shown thatalready at low concentrations of about 0.3 wt% SWNT, thecomposites have indeed a conductivity of higher than102 S/cm, which indicates that a conducting network ofSWNTs exists in the polymer matrix. However, knowledgeon the local organisation of this network is very limited,but is imperative for understanding the physical mecha-nisms actually involved for charge transport, especially atsuch low SWNT concentrations.Single-walled and multi-walled carbon nanotubes (SWNTs and MWNTs) were characterised as-produced, after exfoliation and puri-cation, and imbedded in the polymer matrix of nanocomposites by using various microscopic techniques. Transmission electron micros-copy (TEM) shows thickness distribution as well as catalyst presence of as-produced carbon nanotubes (CNTs); scanning electronmicroscopy (SEM) and atomic force microscopy (AFM) are helpful tools to better understand the inuence of post-treatment duringexfoliation and purication, e.g. on the length distribution of CNTs; and nally SEM operated in charge contrast mode oers the poten-tial to monitor the organisation of CNT networks in the polymer matrix of conductive nanocomposites. 2006 Elsevier Ltd. All rights reserved.

Keywords: Carbon nanotubes; Conductive nanocomposites; Transmission electron microscopy (TEM); Scanning electron microscopy (SEM); Atomicforce microscopy (AFM)

1. Introduction poly(vinyl alcohol) [8], and polypropylene [9] as well asOn the fate of carbon nanotubes

Joachim Loos a,c,*, Nadia Grossiorda Laboratories of Polymer Technology and Materials and Interfa

b Laboratory of Polymer Chemistryc Dutch Polymer Institute, Eindhoven University o

d Department of Chemical Engineering and The Ilse Kat

Ben-Gurion University in the

Received 29 October 2005Available onlin0266-3538/$ - see front matter 2006 Elsevier Ltd. All rights reserved.doi:10.1016/j.compscitech.2005.12.029Morphological characterisations

, Cor E. Koning b,c, Oren Regev b,c,d

hemistry, P.O. Box 513, 5600 MB Eindhoven, The Netherlands

0 MB Eindhoven, The Netherlands

echnology, 5600 MB Eindhoven, The Netherlands

enter for Meso and Nanoscale Science and Technology,

ev, 84105 Beer-Sheva, Israel

cepted 14 December 2005October 2006

www.elsevier.com/locate/compscitech

gy 67 (2007) 783788

SCIENCE ANDTECHNOLOGY

-

reectivity. Typical resonance frequencies were 210230 kHz. The AFM was calibrated using a 25 nm heightstandard grating produced by NT-MDT Ltd.

The scanning electron microscope (SEM, XL30 ESEM-FEG, Fei Co.) was equipped with a eld emission electronsource. High vacuum conditions were applied and a sec-ondary electron detector was used for image acquisition.The SEM was operated either in conventional high-voltageor low-voltage mode. No additional sample treatment suchas surface etching or coating with a conductive layer hadbeen applied. Standard acquisition conditions for chargecontrast imaging were as follows: working distance of 10 mm, spot 3, slow scan imaging with approximately2 min/frame.

3. Results and discussion

and Technology 67 (2007) 783788exfoliation and in the nanocomposite, is dicult to applydue to the extreme high aspect ratio of the SWNTs, theextreme dierence in radial (13 nm) and axial dimensions( 1 lm). However, we are aiming at demonstrating thestrength of various microscopic techniques to characteriseCNTs at any stage of the preparation process of CNT/polymer nanocomposites. Special focus is directed on theapplication of scanning electron microscopy operated incharge contrast, recently introduced for imaging the distri-bution of CNTs in the nanocomposite [14].

2. Experimental

Several types of SWNTs have been studied, namely Car-bolex NTs provided by Carbolex Inc. and HiPCO CNTsfrom Carbon Nanotechnology Inc. Carbolex SWNTs areproduced by arc-discharge technology and contain about30 wt% of impurities composed of both carbon impuritiesand nickel and/or yttrium catalyst particles. HiPCOSWNTs have been produced by a modied gas processbased on chemical vapour deposition (CVD), and the batchused contains around 1015 wt% of impurities, composed,according to the manufacturer, of 5 wt% of small iron cat-alyst particles encased in carbon shells and, in some cases,also in the SWNTs themselves. MWNTs were provided byNanocyl S. A., and some MWNTs were self-made in ourlaboratory by a modied CVD process.

The surfactant used for the dispersion of the CNTs inwater is sodium dodecyl sulfate (SDS, 90%) provided bythe Merck Chemical Co. All experiments were carried outwith demineralised water. For exfoliation, all sonicationprocesses have been carried out with a horn sonicatorSonic Vibracell VC750 with a cylindrical tip (10 mm endcap diameter). The frequency is xed at (20 0.2) kHz.

Silicon wafer substrates for scanning electron micros-copy (SEM) and atomic force microscopy (AFM) havebeen treated with 3-aminopropyl triethoxy silane (APTES,provided by Aldrich Chemical Co.) to form a thin mono-layer, wherein the amine groups make the surface attractiveto CNTs [15]. Subsequently, a piece of the wafer wasdipped in the aqueous CNT dispersion, washed with meth-anol and dried with air ow.

Polystyrene was prepared through emulsion polymerisa-tion with SDS as a surfactant and contains 30 wt% solidswith an average latex particle diameter of 75 nm. Solutionsof 1:1 by weight of bare CNTs and SDS in water weremixed with aqueous latex solution. The resulting mixturewas freeze-dried (Christ Alpha 24 operated at 0.25 mbarand 80 C overnight) prior to compression molding at180 C, between poly(ethyleneterephthalate) sheets, usinga Collin 300G hot press.

A transmission electron microscope (TEM, 2000FX,Jeol) was operated in bright-eld mode at 80 kV. Anatomic force microscope (AFM, Smena P47H, NT-MDT)was operated in intermittent contact mode in air using sil-

784 J. Loos et al. / Composites Scienceicon cantilevers with spring constant k = 1115 N/m,which were coated with a gold layer for higher laser beamSeveral studies have demonstrated the power of TEMfor detailed analysis of length and diameter of CNTs, thelatter corresponding to the number of graphitic layers asin case of single-walled, double-walled or multi-walledCNTs, and for characterisation of wrapping and localdefects in the tubes [16]. In our case, the main purpose isto demonstrate that commercial as well as self-made CNTsare not as homogeneous as assumed and show sometimes abroad size and property distribution so that correlation ofproperties of the nal nanocomposite product is verydicult.

First we like to demonstrate that even highly entangledCNTs as-prepared in the reactor can be easily prepared forTEM investigations. Fig. 1 shows a SEM image of uyMWNT material as-prepared by CVD technique. Besidethe MWNTs, bright spots indicate the presence of catalystparticles in the sample. This material can be easily dis-persed by putting a small amount in water and applyinga conventional ultrasonic bath treatment for a few minutes.Of course, the MWNTs still will be highly entangled andlarge akes are visible in the dispersion; however, theseFig. 1. SEM image of as-prepared MWNTs.

-

akes can easily be transferred on a TEM copper grid byshing, and subsequently, after drying, morphology detailsof the MWNTs can be investigated. Details on determina-tion of the MWNT diameter can be found, e.g. in reference[17]. Fig. 2 shows a corresponding TEM image in brighteld contrast of MWNTs. In this case, we have preparedthe MWNTs ourselves, however, the following discussionis also valid for other CNT sources. Looking at theMWNTs it can be seen that dierent MWNTs have dier-ent thickness, which means that the outer diameter variesfrom about 8 nm (the thin MWNT in the middle of theimage) to about 20 nm. Moreover, it seems that the diam-eter of some of the MWNTs varies even at dierent posi-tions within an individual tube. Besides the MWNTs,also some catalyst particles can be identied as dark spotsin the image. In the present case, all the catalyst particlesare embedded in the nanotubes, and somehow the diameterof MWNTs can be related to the size of the catalyst parti-cles. As a rst summary, already simple morphological

exfoliation and purication is the topic of this part ofour study. For this purpose, HIPCO SWNTs were depos-ited on APTES-treated silicon wafers after purication.The initial average length of HIPCO SWNTs is in the orderof 1 lm, and the purication procedure is described else-where [20]. AFM images with size 5 5 lm2 were acquiredand the length distribution of the SWNTs was measured.Fig. 4 shows an AFM amplitude image and the corre-sponding length distribution of the SWNTs. The lengthdistribution is rather broad, and the average SWNT lengthof about 400 nm indicates that tube fracture has occurredduring the exfoliation and the subsequent puricationprocess.

Beside information on length distribution from AFMtopography images, the actual diameter of the SWNTscan be determined. The width of the SWNTs seems to betens of nanometers. However, this is an artifact attributedto the specic curved shape of the AFM tip and the tip-SWNT interaction, and can be corrected by a deconvolu-

J. Loos et al. / Composites Science aninvestigations of as-prepared CNTs may show strikingvariations of CNT properties such as CNT diameter, andthis information helps to understand the performance ofthe nal nanocomposite product better.

However, the simple preparation of CNT samples forTEM investigation does not full the requirement for com-plete exfoliation and stabilisation of SWNTs in water. Forthis purpose, sonication has been carried out with a hornsonicator, and the resulting dispersion is stabilised withSDS. To monitor the exfoliation process we have dippeda silicon wafer treated with APTES in the aqueous CNTdispersion, and subsequently imaged the SWNTs by SEMand AFM. Fig. 3 shows a SEM image of Carbolex SWNTafter exfoliation and deposition. The bright lines representindividual or bundles of a few SWNTs. Because of the spe-cic contrast mechanism involved, the SWNTs appearFig. 2. TEM image of as-prepared MWNTs.thicker than in reality. This issue will be discussed laterin detail. Beside the SWNTs having a broad length distri-bution, also a large amount of catalyst residues can be seenin the image. From other studies [18] we know that exfoli-ation of Carbolex SWNTs requires only low sonicationenergy, which might partly stem from the fact that Carbo-lex SWNTs contain more impurities. Moreover, CarbolexSWNTs are interconnected via catalyst particles, in a spi-der-like structure, as it can be seen in the SEM image.These particles, as well as other carbon impurities are pres-ent between the SWNTs in the bundles, resulting in a smallcontact area and thus fast exfoliation. This behaviour willbe discussed in detail in another study of our group [19].

The large SWNT length distribution as seen in Fig. 3might be an indication for tube breakage during the exfo-liation and purication process. How microscopic tech-niques help us to follow changes of the CNTs during

Fig. 3. SEM image of SWNTs after exfoliation and deposition on anAPTES-treated silicon wafer.

d Technology 67 (2007) 783788 785tion process. Besides deconvolution, the authentic diameterof the SWNTs can be determined by an accurate height

-

anmeasurement of SWNTs located at the surface of the sam-ple. This height proves to be in the order of 2 nm (resultsnot shown here [18]). In conclusion, from microscopy ofnative and post-treated CNTs and the corresponding imageanalysis, we can gain further information on, e.g. tube frac-

Fig. 4. AFM amplitude image and the corresponding length distributionof the SWNTs. Bright spots are catalyst particles and other residues.

786 J. Loos et al. / Composites Scienceture caused by the treatment applied.Until now, we have shown the importance of morpho-

logical characterisation for the determination of homoge-neity of as-produced CNTs and for monitoring severalsubsequent preparation steps, such as exfoliation and puri-cation. For the nal application of CNTs in nanocompos-ites, however, knowledge on CNT dispersion andorganisation in the polymer matrix is most important tounderstand the properties and performance of the nano-composites. In this respect, especially imaging of SWNTswith their small diameter in the order of 12 nm is chal-lenging. Studies on the organisation of SWNTs were per-formed by TEM imaging of cross-sectional cut samples.Within the polymer matrix, it is very dicult to visualiseSWNTs because of the lack of contrast. Only occasionally,and mainly close to holes in the samples, we were able toimage SWNTs covered with or sticking out of the polymermatrix (Fig. 5). The TEM, image conrms that the diame-ter of the exfoliated SWNTs used in our study is in theorder of 2 nm (Fig. 5, dark central line represents aSWNT). Unfortunately, based on the results obtained byTEM it is dicult to draw conclusions about the homoge-neity of the SWNT distribution in the polymer matrix, and even more important for the present study on the globalorganisation of the conductive SWNT network.

To gain more information on the organisation of CNTsin a polymer matrix, we have applied a microscopic tech-nique recently described in the literature, which is basedon charge contrast imaging using a SEM [14]. Fig. 6 showsthe charge contrast images of two samples, which were pre-pared in dierent manners. Besides a more or less darkbackground, bright lines are visible, which representSWNTs distributed in the polymer matrix. The dierencebetween the two samples is that, in the rst case, after exfo-liation the SWNTs were just melt-mixed with the polymer,which results in agglomeration and heterogeneous distribu-tion of the SWNTs in the matrix (Fig. 6a). For the secondcase, the nanocomposite was prepared according to theabovementioned route using latex technology, whichresults in a homogeneous distribution of the SWNTs in

Fig. 5. TEM image of SWNT sticking out of and coated with the polymermatrix.

d Technology 67 (2007) 783788the polymer matrix (Fig. 6b).In such charge contrast SEM images, for an acceleration

voltage of 20 kV the penetration depth of the primary elec-trons is in the order of 2 lm for a carbon sample [21]. Thisactual penetration depth of primary electrons in a samplecan be calculated by using either the KanayaOkayamarange calculations or Monte Carlo simulation routines.The KanayaOkayama range is given by

RKO 2:76 1011AE1:670 =Z0:889 d cm; 1where E0 is the incident electron energy in keV, A is theaverage atomic weight in g, d is the density of the materialin g/cm3, and Z is the atomic number of the target [22].Therefore, using charge contrast imaging at high accelera-tion voltage, we are able to gain representative informationon the three-dimensional organisation of a conductive sin-gle-walled or multi-walled carbon nanotube network in apolymer matrix. The SEM charge contrast images repre-sent a two-dimensional visualisation of these three-dimen-sional SWNT network structures in the polymer matrix.The brightness variations visible in the SEM charge con-trast images can be related to the position of the SWNTsin the sample: high brightness means a position of the

-

d (b) homogeneously distributed SWNTs in a polymer matrix.

e anSWNTs at or near to the surface, whereas SWNTs locateddeep in the nanocomposite appear darker. However, alsoother explanations for the brightness variations of theSWNTs might be possible. For example, it cannot be ex-cluded that parts of the SWNT network are disconnectedfrom the major part of the network (disconnected fromground, lower brightness), but the presence of a mixtureof conductive (high brightness) and semi-conductive (lowbrightness) nanotubes [23] is a possibility as well. A studywith the aim of understanding the origin of the charge con-trast in more detail is currently in progress.

Depending on the type and properties of CNT and thedegree of their dispersion in the polymer matrix, percola-tion threshold for the formation of conductive CNT net-works can be found far below 1 wt% even for highly

Fig. 6. SEM charge contrast images of (a) agglomerated an

J. Loos et al. / Composites Sciencviscous polymer matrixes [1214]. In contrast to sampleshaving a CNT concentration above the percolation thresh-old for the formation of a conductive network, sampleswith CNT concentrations below the percolation thresholdshow strong charging at high acceleration voltages. Thisprevents imaging of details of the CNT organization inthe polymer matrix: only overall charging of the sampleis observed.

4. Conclusions

We have demonstrated that the application of micro-scopic techniques is very useful to control the status ofCNTs at any time during the preparation process ofCNT/polymer nanocomposites, and moreover, to gaininsights on parameters important for better understandingthe performance of the nal nanocomposite material basedon CNTs. We could show that CNT akes prepared bysimple sonication in water in an ultrasonic bath are satisfy-ing for CNT thickness measurements and provide someinformation on the catalytic growing process involved.SEM and AFM investigation of CNTs deposited on siliconwafers treated with APTES allow, e.g. to relate the degreeof exfoliation and the CNT length distribution to the pro-cedures applied. We could show that applying more robustprocedures results in CNT fracture. Based on this informa-tion the exfoliation and purication process can be opti-mised. Finally, we have shown that conventionalscanning electron microscopy, operated in the charge con-trast imaging mode, is able to visualize the overall organi-sation of conductive SWNT networks at high resolution.

Acknowledgements

The authors are thankful to the Dutch Polymer Institute(DPI) for the nancial support of DPI project # 416.Moreover, we thank Ton Peijs and Lan Lu for providingd Technology 67 (2007) 783788 787the sample described in Fig. 6a, and Stijn Brand for somehelp with the AFM investigation.

References

[1] Iijima S. Nature 1991;354:56.[2] Rouse JH, Lillehei PT. Nano Lett 2003;3:59.[3] Jin Z, Pramoda KP, Xu G, Goh SH. Chem Phys Lett 2001;337:43.[4] Qian D, Dickey EC, Andrews R, Rantell T. Appl Phys Lett

2000;76:2868.[5] Schadler LS, Giannaris SC, Ajayan PM. Appl Phys Lett

1998;73:3842.[6] Biercuk MJ, Llaguno MC, Radosavljevic M, Hyun JK, Johnson AT,

Fischer JE. Appl Phys Lett 2002;80:2767.[7] Dufresne A, Paillet M, Putaux JL, Canet R, Carmona F, Delhaes P. J

Mater Sci 2002;37:3915.[8] Shaer MSP, Windle AH. Adv Mater 1999;11:937.[9] Valentini L, Biagotti J, Kenny JM, Santucci S. J Appl Polym Sci

2003;87:708.[10] Gong XG, Liu J, Baskaran S, Voise RD, Young JS. Chem Mater

2000;12:1049.[11] Sandler J, Shaer MSP, Prasse T, Bauhofer W, Schulte K, Windle

AH. Polymer 1999;40:5967.[12] Regev O, El Kati PNB, Loos J, Koning CE. Adv Mat 2004;16:248.[13] Grossiord N, Loos J, Koning CE. J Mat Chem 2005;15:2349.

-

[14] Loos J, Alexeev A, Grossiord N, Koning CE, Regev O. Ultrami-croscopy 2005;104:160.

[15] Liu J, Casavant MJ, Cox M, Walters DA, Boul P, Lu W, et al. ChemPhys Lett 1999;303:125.

[16] Cowley JM. Ad Me Semicond Clusters 1998;4:67.[17] Thostenson ET, Chou T-W. J Phys D Appl Phys 2003;36:573.[18] Grossiord N, Regev O, Loos J, Meuldijk J, Koning CE. Anal Chem

2005;77:5135.

[19] Grossiord N, Loos J, Meuldijk J, Regev O, Miltner HE, Van Mele B,et al., Compo Sci Technol, submitted for publication.

[20] Zhou W, Ooi YH, Russo R, Papanek P, Luzzi DE, Fischer JE, et al.Chem Phys Lett 2001;350:6.

[21] Seah MP, Dench WA. Surf Interface Anal 1979;1:2.[22] Kanaya K, Ohayama S. J Phys 1972;D5:43.[23] Ouyang M, Huang J-L, Cheung CL, Lieber CM. Science

2001;292:702.

788 J. Loos et al. / Composites Science and Technology 67 (2007) 783788

On the fate of carbon nanotubes: Morphological characterisationsIntroductionExperimentalResults and discussionConclusionsAcknowledgementsReferences