Ch3 Contact Stiffness

Transcript of Ch3 Contact Stiffness

Ad

van

ced

Con

tact

Training Manual

3. Contact Stiffness

00136130 May 2000

3-2

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

A. Basic Concepts

Review:

• Recall that all ANSYS contact elements use a penalty stiffness (contact stiffness) to help enforce compatibility at the contact interface.

• Some finite amount of penetration, , is required mathematically to maintain equilibrium.

• However, physical contacting bodies do not interpenetrate ( = 0).

The contact spring will deflect an amount , such that equilibrium is satisfied:

F = k where k is the contact stiffness.

F

00136130 May 2000

3-3

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Basic Concepts

• As an analyst, you face a dilemma:

– Minimum penetration gives best accuracy.

• Therefore, the contact stiffness should be very great.

– However, too stiff a value causes convergence difficulties.

• The model can oscillate, with contacting surfaces bouncing off of each other.

Iteration n Iteration n+1

F

F

FcontactF

Iteration n+2

00136130 May 2000

3-4

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Basic Concepts

• The contact stiffness is the most important parameter affecting both accuracy and convergence behavior.

• You must carefully determine an appropriate value for contact stiffness.

– Balance the convergence efficiency against the required level of accuracy.

– The “best” value is problem dependent, and must often be determined by trial-and-error.

• Estimate a trial value to use, then examine the convergence behavior and accuracy.

00136130 May 2000

3-5

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

B. Determining a value

• Frequently, you can estimate a good value for the contact stiffness as a function of the relative stiffness of the areas in contact.

• The stiffness of a bulky solid will generally be greater than that of a springy, bending-dominated structure. The contact stiffness will typically be correspondingly greater for bulky solid structures.

– Examples of bulky contact include metal forging, wheel-on-rail, pin in a bearing block, etc.

– Examples of bending-dominated contact include leaf springs, sheet metal forming, etc.

00136130 May 2000

3-6

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

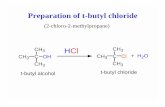

• For bulky solids, the Hertz contact stiffness often provides an appropriate basis for the penalty stiffness. This stiffness can be estimated from the element size and Young’s modulus.

• For a uniformly-shaped 3D element, the Hertz stiffness would be approximately kHertz a x E, where a is the characteristic element size, and E is the Young’s modulus.

• For 2D elements with thickness (t), Hertz stiffness would be approximately kHertz t x E.

– For 2D axisymmetric elements, the “thickness” is 1 radian x r, giving a Hertz stiffness of approximately kHertz r x E.

a

a

a

a

at

ra

a

00136130 May 2000

3-7

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• As a practical matter, a good first trial value for bulky contact stiffness would be kcontact = fbulk x kHertz, where fbulk is a factor usually between 0.1 and 10 for bulky solids.

– Because the starting estimated value of fbulk ranges over at least two orders of magnitude, and because kcontact will be adjusted by trial-and-error anyway, it is usually not justifiable to worry about the element’s size when estimating the penalty stiffness.

• For bulky solids, simply estimate the penalty stiffness by

k = fbulk x E

– where the factor fbulk is usually between 0.1 and 10, and a good starting value for fbulk is often fbulk = 1.0.

– This estimate assumes an approximate “unit” element size; for very large or very small elements, you might need to adjust the starting value of fbulk accordingly.

00136130 May 2000

3-8

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• If your contact involves two different materials, use E of the softer contacting material.

• Account for the reduced tangent modulus if plasticity will be active.

• For Mooney-Rivlin hyperelastic materials, the material law does not use a value of E. You will therefore have to estimate E for such materials.

– You can simply scale a modulus value from the appropriate portion of the stress-strain curve.

– Or, estimate an initial modulus by E = 6(a + b) where a and b are the first two Mooney-Rivlin constants.

00136130 May 2000

3-9

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• For flexible components (beam-like and shell-like models) the stiffness of the system may be much lower than the Hertz contact stiffness.

• In this situation you might run a static analysis with a unit load applied to the expected area of contact to determine the local stiffness of the model. The contact stiffness can then be estimated from:

k = fbend(P/)

• where P is the applied unit load, is the corresponding deflection, and for flexible body contact, fbend is a factor between 1 and 100. Setting fbend = 1 is usually a good starting value.

• For practical simplicity, you might merely estimate the contact stiffness by:

k = fbend x E/10

00136130 May 2000

3-10

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• In addition to transmitting normal action (pressure) between surfaces, contact elements also transmit tangential action (friction).

• The contact elements use a tangential penalty stiffness to enforce compatibility in the tangential direction.

Ftangent

Ftangent = ktangent

00136130 May 2000

3-11

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• The tangential penalty stiffness affects convergence and accuracy in exactly the same way as the normal penalty stiffness.

– Too soft a value leads to inaccurate results.

– Too stiff a value causes convergence difficulties.

– A “best” value should be determined by trial-and-error.

• As a starting estimate, try using

ktangent = 0.01 knormal

– This is the default value for most ANSYS contact elements.

• Of course, the tangent stress is limited by the value at which

sliding occurs: xp– Friction is discussed in the next chapter.

00136130 May 2000

3-12

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• For node-to-node and node-to-surface elements, you specify the value of penalty stiffness directly, in units of Force/Length.

– For variable mesh densities, the overall surface stiffness will be greater where the mesh is denser, and will be less where the mesh is coarser.

• This could lead to uneven contact pressures.

(Surfaces shown separated for clarity)

F

Stiffer at dense meshSofter at coarse mesh

00136130 May 2000

3-13

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• For surface-to-surface elements, you specify the penalty stiffness as a factor to be applied to a function of the underlying element stiffness.

– Alternatively, you can specify an absolute stiffness value, in units of (Force/Length)/Area.

– Because stiffness is specified per unit area, the overall surface stiffness varies much less with varying mesh density.

00136130 May 2000

3-14

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• Determining a good stiffness value usually requires some experimentation. The following procedure may be used as a guideline:– 1. Use a low value of stiffness to start.

– 2. Run the analysis to a fraction of the final load.

– 3. Check the penetration and number of equilibrium iterations used in each substep.

• As a rough, quick check, if you can visually detect penetration in a true-scale displaced plot of the entire model, the penetration is probably excessive. Increase the stiffness and restart.

• If many iterations are needed for convergence (or if convergence is never achieved), reduce the stiffness and restart.

– Note: Penalty stiffness can be modified from one load step to another, and can be adjusted in a restart.

00136130 May 2000

3-15

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

• Remember: The contact stiffness is the most important parameter affecting both accuracy and convergence behavior.

– If you can fully grasp this idea, you will be able to master most contact difficulties!

• If you are having convergence problems, reduce the stiffness value, and rerun.

• You should also verify the validity of your results by varying the penalty stiffness value in a sensitivity study.

– Tighten the stiffness in successive analyses, until important results items (contact pressure, max. SEQV, etc.) cease to change significantly.

00136130 May 2000

3-16

Ad

van

ced

Con

tact

Training Manual

Contact Stiffness

... Determining a value

… contact stiffness

• As an example, FKN was varied for an interference-fit analysis of a collar on a shaft. Maximum equivalent von Mises stress was monitored.

• In this particular case, a value of FKN = 1.0 proved to give adequate accuracy.

FKN Max. SEQV0.001 4,0000.01 20,0000.1 65,0001 91,000

10 92,900100 93,000