Ch 8 Suspension & Steering

-

Upload

justcheerful -

Category

Documents

-

view

225 -

download

0

Transcript of Ch 8 Suspension & Steering

-

8/14/2019 Ch 8 Suspension & Steering

1/41

ASSEMBLY 8-2REMOVAL INSTALLATION 8-2INSPECTION 8-2STUDS 8-2REMOVAL& INSTALLATION 8-2SUSPENSION 8-4SPRING 8-7REMOVAL& INSTALLATION 8-7OVERHAUL 8-7 ND OILSPRING 8-8REMOVAL&INSTALLATION 8-8OVERHAUL 8-9BALLJOINT 8-9REMOVAL& INSTALLATION 8-9INSPECTION 8-9CONTROLARM 8-10REMOVAL&INSTALLATION 8-10

BALLJOINT 8-10REMOVAL&INSTALLATION 8-10INSPECTION 8-10CONTROL RM 8-10REMOVAL&INSTALLATION 8-10BAR 8-12REMOVAL& INSTALLATION 8-12HUB, AND BEARING 8-13REMOVAL& INSTALLATION 8-13ALIGNMENT 8-16CASTER 8-16CAMBER 8-17TOE 8-17SUSPENSION 8-18AND COIL SPRING 8-21REMOVAL& INSTALLATION 8-21OVERHAUL 8-22CONTROLARMS 8-22REMOVAL INSTALLATION 8-22CONTROL RMS 8-23REMOVAL&INSTALLATION 8-23ARM 8-24REMOVAL& INSTALLATION 8-24BAR 8-25REMOVAL&INSTALLATION 8-25& BEARINGS 8-25ADJUSTMENT 8-25REMOVAL& INSTALLATION 8-25

WHEEL 8-27REMOVAL&INSTALLATION 8-27ON WITCH 8-29REMOVAL&INSTALLATION 8-29WIPERSWITCH 8-29REMOVAL&INSTALLATION 8-29LOCKCYLINDER 8-29 'REMOVAL&INSTALLATION 8-29SWITCH 8-30REMOVAL&INSTALLATION 8-30INKAGE 8-30REMOVAL&INSTALLATION 8-30RACKAND PINIONSTEERING

REMOVAL& INSTALLATION 8-31POWERRACKAND PINIONSTEERINGGEAR 8-32REMOVAL&INSTALLATION 8-32POWERSTEERINGUMP 8-34REMOVAL&INSTALLATION 8-34SYSTEMBLEEDING 8-36COMPONENT LOCATIONSFRONTSUSPENSION OMPONENTLOCATIONS 8-4REARSUSPENSION OMPONENTLOCATIONS 8-18SPECIFICATIONS CHARTS TORQUE PECIFICATIONS-39

-

8/14/2019 Ch 8 Suspension & Steering

2/41

NDSTEERING b

&INSTALLATIONSee Figures 1, 2, 3, and 4

1. Parkhe ehicle na evel urface.2. Removehe ack, ire ronand,f necessary,spareire rom heir torageompartments.3. Checkheownersmanual,r refer o Sectionof hismanualor he acking oints nyourvehi-Then, lacehe ack n heproper osition,4. If equippedith ugnut rimcaps, emoveeither nscrewingr pullinghem ff he ugappropriate.onsultheownersmanual,f5. If equippeditha wheel over r hub ap,he aperedndof he ire ron n hegroovepryoff hecover.6. Applyheparking rake ndblock hediago-opposite heelwitha wheel hock r wo.may be purchasedat yours store, or a block of wood cutmay be used. If possible, keeptwo of the chocks n your tire storaget, n case any of the tires has oon the side of the road.

7. If equippedithanautomatictransmission/transaxle,laceheselectorever n Por Park; itha manualransmission/transaxle,lacetheshiftern Reverse.8. With he ires till on heground, se he ireiron/wrencho breakhe ugnuts oose.*If a nut is stuck, never use heat to loosen tor damage o the wheel and bearingsmayoccur. If the nutsare seized, one or twoheavy hammerblows directly on the end ofthe bolt usually loosens he rust. Be careful,as continuedpoundingwill likely damage hebrake drum or rotor.

9. Usinghe ack, aisehevehicle ntil he ireis clear f heground. upporthevehicle afely s-ing ackstands.10. Removehe ugnuts,hen emovehe ireandwheel ssembly.To install:11. Make ure hewheel ndhubmating ur-faces, swellas hewheelugstuds, reclean ndfreeof all foreignmaterial.lwaysemoveust romthewheelmountingurface nd hebrakeotorordrum. ailureo doso may ausehe ugnuts oloosenn service.12. Installhe ireandwheel ssemblyndhand-tightenhe ugnuts.

13. Usinghe irewrench,ighten ll the ugnuts,in a crisscrossattern,ntil heyaresnug.14. Raisehevehicle ndwithdrawhe ackstand,then ower hevehicle.15. Using orque rench,ightenhe ugnutsna crisscrossatterno 65-80 t. bs. 90-l 10Nm).Check ourownersmanualr refer o Section ofthismanualor heproperighteningequence.

Do not overtighten he lug nuts, as this maycause he wheel studs o stretch or the brakedisc (rotor) to warp.16. If soequipped,nstallhewheel over r hubcap.Make ure hevalve tem rotrudeshroughheproper pening eforeappinghewheel overntoposition.17. If equipped,nstallhe ugnut rimcaps y

pushinghem r screwinghem n,asapplicable.18. Removehe ack romunderhe ehicle, ndplacehe ackand ire ron/wrenchn heir toragecompartments.emovehewheel hock(s).19. If youhave emovedflator damagedire,placet in hestorageompartmentf hevehicle ndtake t to your ocal epair tationo havet fixedorreplacedssoon spossible.

Inspecthe ires or acerations,uncture arks,nailsandother harp bjects. epair r replace snecessary.lsocheckhe ires or readwearndairpressuresoutlinedn Section of hismanual.Checkhewheel ssembliesor dents, racks,ustandmetalatigue. epair r replaces necessary.

REMOVAL&INSTALLATION

Place the jackstandsunder he vehi-support the vehicles weight before

-

8/14/2019 Ch 8 Suspension & Steering

3/41

SUSPENSIONNDSTEERiNG -3

STUD

Fig. 5 View of the rotor and stud assembly1. Raiseand support he appropriate nd of theusing ackstands,hen remove he2. Remove he brake pads and caliper. Sup-de using wire or a coat hanger.please efer o Section 9 of this man-3 Remove he outerwheel bearingand iff offon wheel bearing emoval, n-and adjustment, lease efer o Section1 of4. Properlysupport he rotor us ing pressbars,e he stud out using an arbor press.a press s not available, CAREFULLYa blunt drift.SUREhe rotor is properly and evenlyor it may be damaged.

To install:5. Clean he stud hole with a wire brushandstudwith a hammerand drift pin. Doany ubricantor threadsealer.6. Finish nstalling he studwith the press.a press s not available, start the lughrough he bore n the hub, hen posi-4 flat washersover the stud andhe lug nut. Hold he hub/rotorwhilee studshould bento position. MAKESURE HESTUDSEATED,hen remove he lug nut7. Install he rotor and adjust he wheelbear-8. Install he brakecaliperand pads.9. Install he wheel, hen remove he ackstands

he vehicle.10. Tighten he ug nuts o the proper orque.

AXLE SHAFT

Im3goa3g. 8 Exploded view of the drum, axlelange and stud

PRESSRAM

PRESSSTOCK

Fig. 6 Pressing he s tud from the rotor

tcca$OiFig. 7 Use a press to install the stud into the rotorWith Drum Brakes To install:6. Positionabout4 flat washersover he studp See Figures 8, 9, and 10

1. Raise he vehicle and safelysupport t withjackstands,hen remove he wheel.2. Remove he brakedrum.3. If necessaryo provide clearance, emove hebrakeshoes,as outlined n Section9 of this manual.4. Using a largeC-clampand socket,press hestud rom he axle lange.5. Coat he serratedpartof the stud with liquidsoap and place t into the hole.

and hread he ug nut. Hold he langewhile ighten-ing he ug nut, and he stud should be drawn ntoposition. MAKESURETHESTUD S FULLYSEATED,then remove he ug nut andwashers.7. If applicable, nstall he brakeshoes.8. Install he brakedrum.9. Install he wheel. hen remove he ackstandsand carefully ower he vehicle.10. Tighten he ug nuts o the proper orque.

C-FRAME ANDCLAMP ASSEMBLY

Fig. 9 Use a C-clamp and socket to pressout the stud

NUT FLAT WASHERS

Fig. 10 Force he stud onto the axle flangeusingwashers and a lug nut

-

8/14/2019 Ch 8 Suspension & Steering

4/41

199340 MIRAGE FRONT SUSPENS ION COMPONENT LOCATIONS I1. Tie rod end2. Lower ball oint3. Lower control arm4. Lower controlarm mountsand bushings5. Sway bar assembly

6. Sway bar ink7. Strut assembly8. Huband bearing ssembly9. Halfshaftassembly

-

8/14/2019 Ch 8 Suspension & Steering

5/41

1994-98 GAIANT FRONT SUSPENSION COMPONENT LOCATIONS1. Shockandspringassembly2. Steering nuckle ssembly3. Huband bearingassembly4. Lowerball oints5. Compressionower control arm6. Lateral ower control arm

7. Lowercontrol arm mountsand bushings8. Steering ack and pinion9. Sway bar assembly10. Halfshaft ssembly11. Upperball oint12. Uppercontrol arm

-

8/14/2019 Ch 8 Suspension & Steering

6/41

1999-90 GAIANT FRONT SUSPENSION COMPONENT LOCATIONS1. Tie rod end 5. Sway bar assembly2. Lower ball oint 6. Strut assembly3. Lowercontrol arm 7. Huband bearing ssembly4. Lowercontrol arm mounts nd bushings 8. Halfshaftassembly

-

8/14/2019 Ch 8 Suspension & Steering

7/41

SUSPENSIONNDSTEERING -7

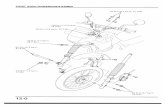

1 Cotter p,n2 Drive shaft3 Washer4 Caliper assembly connecf~on5 Self-IockIn g f6 Lower arm ball ,Olf Connectlo7 cotter PI8 T,e rod end connectton9 Drive Shaft10 Strut assembly connection11 Hub and knuckle

Mirage front suspension omponents-

1 Cutter PI2 Drtve shaft3 Washer4 Ca,,perassembly connect~o5 Self-locking nut6 Lower arm ball ,o,nt connection7 cotter PI8 Tie rod end connection9 Dwe shaft10 Strut assembly connection11 Hub and knuckie

ront suspension omponents

1

to knucklebolts Use a piece of wire to suspend heknuckle o keep he weightoff the brakehose.6. If equippedwith Active ElectronrcControlSuspension Active-ECS)perform he ollowrng:&INSTALLATION a. Loosen he nut hat secures he an line tothe to the too of the strut and discard he O-ring.e, 1990-93 Galant, and 1999-00

1. Disconnect he negativebattery able.2. Raiseand safelysupport he vehicle.3. Remove he brakehoseand he ube bracket.not pry the brake hose and ube clampwhen removino t.

b. Remove he bolts that secure he actuatorto the top of the strut and remove he compo-nent. Disconnect he wiring harness.*Before removing he top bolts, makematchmarks n he bodyand he strut insula-tor for proper reassembly.

7. Remove he strut uppernutsand remove hestrut assemblv rom the vehicle.4. If equippedwith ABS, disconnect he rontsensormountingclamp rom the strut.5. Support he ower arm and remove he strut

To instalf:8. Install he strut o the vehicle and ighten heuppermountingnuts o 33 ft. Ibs. (45 Nm)9 Align the strut o the knuckleandconnect

with the mountingbolts.Tighten he mountingboltsto 70-76 ft. Ibs. (90-105 Nm).10. If equippedwith Active-ECS,perform he ol-lowing,a. Install he air line with a new O-ring.b Install he actuator o the top of the strutConnect he wiring harness.11. Install he brakehose bracketand he ABSclamp, f equipped.12. Install he wheeland ire assembly.13. Havea front end alignmentperformed.

Mirage# See Figure 11

1, Disconnect he negativebatterycable.2. Raiseand safelysupportvehicle.3. Remove he brakehoseand ube bracket e-tainer bolt and bracket rom the ront strut. Do not prythe brakehoseand ubeclamp awaywhen emovrng.4. If equippedwith ABS, disconnect he rontspeedsensormountingclamp rom the strut.5. Support he lowerarm usmg loor jack orequivalent Remove he lowerstrut o knucklebolts.*Before removing he top bolts, makematchmarks n he bodyand he strut insula-tor for proper reassembly.

6. Remove he strut uppermountingbolts.7. Remove he strut assembly rom the vehicle.To install:8. Install he strut o the vehicle and nstall hetop mountingbolts,Tighten he mountrng olts o 29ft. Ibs. (40 Nm)9. Position he strut on the knuckleand mstallthe mountingbolts,While holdrng he headof thelower mountingbolt, ighten he nuts o 80-94 ft. Ibs.(110-130 Nm).10. Install he brakehose bracketand he ABSclamp, f equipped11 Install he wheeland ire assembly12. Havea front end alignmentperformed.OVERHAUL) See Figures 12 thru 22

1. Remove he strut assembly rom the vehicle,asoutlinedearlier n this Section.2. Mount he strut assembly nto a suitablespring compressor.3. Compress he strut approximately /a its heightafter nitial contactwith the op cap.

Never bottom he spring or dampener od!4. Remove he centernut rom the strut and re-move he uppermountingbracketand bushings.5. Remove he coil spring.To install:6. Install he compressed pring on the strut as-sembly.7. Install he upperbushingsand he mountingbracket Install he nut and ighten t to 43 ft. Ibs. (59Nm).8. Remove he strut rom the spring compressor.9. Install he strut nto he vehrcle

-

8/14/2019 Ch 8 Suspension & Steering

8/41

NDSTEERINGREMOVALINSTALLATION199443 Galantu See Figures 23 and 24

1a Disconnectheneaativeatterv able.I 3. Removeheappronnateheel ssembly.25 Nm18 fths.

I 2. Raise nd afelv u~oort ehicle.I I ,I. Disconnecthesway ar ink rom heoamperork.5. Removehedamperork ower hrough-boltandupper inch olt.Removehedamperorkas-sembly.6. Removeheshock bsorberpper uts ndremoveheshock nd pring ssemblyrom he e-hicle.To install:7. Installheupper racketssemblynd ositionit so hat he hree olts re n he orrect osition.

8. Installheupper ushing, asher, nd ock-nut.Tightenhe ocknuto 18 t.-lbs.9. Installheshock bsorbernd ightenheup-Removalsteps csution1. Brake hose clamp For vehicles with ABS, be careful when handling2. Front speed sensor the pole piece at the tip of the spaed sensor so as not to damage it by striking against other parts.3. Bolts4. Self-locking nut5. Strut assembly I 7wmA611 Front strut assembly and related parts---Mirage

ft. Ibs. 103Nm).11. Connectheswaybar ink o thedamoerork

permountingutso 32 t. Ibs. 44Nm).IO. Align heshocko hedamperorkand nstallthedamperork.Tightenhe ower hrough-bolt/nutto 65 t. Ibs. 88Nm) nd heupper inch olt o 76and ightenhe inknut b 29 t. Ibs. 39Nm):12. Installhewheel nd ireassembly.13. Have rontend lignmenterformed.

STRUT ASSEMBLY EXPLODED VIEW I ,- : -, : ;i, \ , .^ -_

I~. : : ; rL~~