Brakes - integration of steering and suspension

-

Upload

sumit-pandey -

Category

Documents

-

view

224 -

download

0

Transcript of Brakes - integration of steering and suspension

-

8/7/2019 Brakes - integration of steering and suspension

1/15

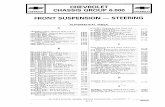

377

Integrated control of suspension and front steering toenhance vehicle handlingC March and T Shim*

Department of Mechanical Engineering, University of Michigan-Dearborn, Dearborn, Michigan, USA

The manuscript was received on 11 August 2005 and was accepted after revision for publication on 11 December 2006.

DOI: 10.1243/09544070JAUTO152

Abstract: Integration of vehicle chassis control system has gained increasing attention sinceit can improve the vehicle safety and performance through effective coordination of individualcontrol systems. This paper presents the development of an integrated control system of active

front steering and normal force control using fuzzy reasoning to enhance the vehicle-handlingperformance. Individual control systems were first developed, and then their performances

were compared with that of the integrated system. The simulation results indicate that theintegrated chassis control scheme utilizing the steering and suspension controllers has provento be more effective in attaining the desired performance that would not be attainedindividually.

Keywords: fuzzy logic, integrated chassis control, active suspension, active steering, normalforce control, handling.

1 INTRODUCTION growing electric and electronic technologies and thedecreasing cost associated with them, electronic con-trol of vehicle dynamics will probably be pervasiveIn recent years the use of electronic control systemsin the near future and there has been considerablehas become increasingly popular in automotiveeffort in the integration of individual active controlapplications, resulting in significant improvementsystems known as global chassis control [712]. Thein vehicle handling and passenger safety. Theresearch reported here addresses the integration ofactive vehicle control technologies, which integratenormal force control (NFC) and front steering controlelectronic components into existing vehicle hardware,to enhance the lateral dynamics of a vehicle.aim to improve the vehicle stability by controlling

It is well understood that lateral vehicle dynamicsits components when the vehicle is at the physicalare strongly influenced by passive normal loadlimit of manoeuvres. It allows the driver to keepchanges during cornering [1315]. When a car turnsultimate control of the vehicle and provides greatto the left, the right-side, or outside, tyres become

flexibility to make the vehicle adapt to environmental more loaded and the load decreases on the left, orvariations as well as emergency manoeuvres to avoidinside, tyres. Owing to the non-linear behaviour ofaccidents. Various types of active control system havepneumatic tyres [16], the total lateral force capabilitybeen developed in the past to enhance the stabilityof an axle decreases because of this load shift. Byand handling characteristics of a vehicle [16]. Activeadjusting the roll stiffness at the front and rear of thefront steering (AFS), active rear steering, four-wheelvehicle (using anti-sway bars, active or passive), thesteering, and direct yaw moment control (DYC) areloss of cornering capability can be directed towardssome of the options widely explored. With the fast-the front or rear as desired. The result of this adjust-ment is the ability to influence the oversteer or

* Corresponding author: Department of Mechanical Engineering, understeer characteristics of the vehicle. This type ofUniversity of Michigan-Dearborn, 4901 Evergreen Road, Dearborn, adjustment is made continuously in race situations

where drivers pit, complaining that the car pushes Michigan, 48128, USA. email: [email protected]

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

2/15

378 C March and T Shim

or is loose. If a vehicle is equipped with active 2 VEHICLE MODEL DEVELOPMENT

suspension, then the capability exists to modulate

the normal force at each corner. The research in In Fig. 1, the motion of the vehicle system is

described in terms of a body-fixed (moving) coordi-references [17] a n d [18] has shown the possible

benefits to be attained by modulating normal force nate system with axes in the X, Y, and Z directions

represented in the diagram by the velocities U,through active suspension control during cornering

manoeuvres. V, and W respectively. This figure represents the14-degree-of-freedom vehicle system on which theIntegrated chassis control systems typically com-

bine steer modulation, variable torque distribution, model is based. There are six degrees of freedom at

the centre of gravity of the lumped vehicle mass:and independent wheel braking. In this paper, a

novel approach to integrating active suspension linear and angular displacements along the X, Y, and

Z directions. There are also two degrees of freedomwith AFS to enhance vehicle handling is introduced.

A fuzzy logic control (FLC) strategy is used in the at each of the four corners of the vehicle: unsprung

mass travel and wheel spin.development of controllers for steering and active

suspension systems. The use of FLC in handling In the development of the vehicle model, the

following assumptions were made.enhancement controller design has been successfully

utilized in references [8] and [19] to [23]. The con-1. A small angle is assumed for the major vehicletroller output consists of an additional steering

motions (pitch, roll, and yaw) to obviate the needangle and the suspension actuation obtained by thefor coordinate transformations.integration of the difference between the reference

2. The steering angles d of both front wheels, are yaw rate value as commanded by the driver andconsidered identical.the actual achieved vehicle yaw rate. Significant

3. The effect of unsprung mass is only considered inimprovements over the passive uncontrolled systemvertical motion and ignored in the vehicles lateraland individual controllers are seen in the areas ofand longitudinal motions.directional response, forward velocity at the end of

4. The tyre and suspension remain normal to thesteer manoeuvres, and body roll motion.ground during vehicle manoeuvres.The rest of the paper is organized as follows:

sections 2 and 3 show the development of the vehicleUsing Newtons laws, based on the moving coordi-model and its validation with measured test data.

nate system, the equations of motion for the lumpedSection 4 discusses the reference model to be used

mass can be derived asin the controller development. The controller develop-ment for steering and suspension is discussed in

m(U Vvy+Wv

p)

section 5. Section 6 looks at the simulation results

and, finally, section 7 draws the conclusions. =FLrf+F

Llf+F

Lrr+F

Llr(F

Crf+F

Clf)d (1)

Fig. 1 Schematic diagram of the vehicle model

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

3/15

379Integrated control of suspension and front steering

m(VWvr+Uv

y) For simulation purposes, the longitudinal and

lateral tyre forces are modelled using a magic formula=F

Crr+F

Clr+F

Crf+F

Clf+(F

Lrf+F

Llf)d (2)

tyre model [16]. This model has been implemented

in the MATLAB/Simulink environment to examine itsms(W Uv

p+Vv

r)=F

Srf+F

Slf+F

Srr+F

Slrm

sg

responses.(3)

Jrv

r= t

2(F

Slf+F

SlrF

SrfF

Srr) 3 MODEL VALIDATION

+h(FCrf+F

Clf+F

Crr+F

Clr) (4) The vehicle parameters of a compact car were used

in the vehicle model and a constant-speed variable-Jpv

p=b(F

Slr+F

Srr)h(F

Llf+F

Lrf+F

Llr+F

Lrr)

steer test, defined in SAE J266 [24], was performeda(F

Slf+F

Srf) (5) on it. Figure 3 shows the comparison of the vehicles

lateral acceleration and yaw rate responses betweenJyv

y=

t

2(F

Lrf+F

LrrF

LlfF

Llr)+a(F

Clf+F

Crf) the vehicle model and actual vehicle test data during

a constant-speed test. The test was carried out on ab(F

Clr+F

Crr) (6) uniform, dry, level, and hard road surface. A ramp

steering wheel input is applied while the vehicle runsFLij

, FCij

, and FSij

are the longitudinal, cornering, andat a speed of 60 mile/h. Vehicle data were recordedsuspension forces respectively at each wheel, whereat 200 Hz sampling rate. As shown, the responses of

the subscript i represents the left (l) or right (r) sidethe vehicle model were well matched with the actual

and the subscript j represents the front (f) or rear (r).vehicle measurements. The discrepancies shown at

Figure 2 shows the schematic diagram of thelateral acceleration levels beyond 0.5gcome from the

suspension and wheel at one corner of the vehicle.factors that are not modelled in the development

The force generated by the active and passiveof the vehicle model such as tyre non-linearity,

components of each suspension can be determinedsuspension effect (roll steer and roll camber), and

bylateral compliance steer.

Fsuspension

=ks(X

uX

s)+F

c+b

s(X

uX

s) (7)

The Fc

term in the above equation is the control input4 REFERENCE VEHICLE

to the system, and a positive force causes an upwardacceleration on the body while causing a negativeIt is difficult to determine the desired handling

acceleration on the wheel.characteristic of a vehicle during a cornering

The equations of motion for each wheel can bemanoeuvre since it is a comprehensive measure of

represented bythe vehicledriver combination. The neutral steer

MyF

LijRB=J

wv

w(8) vehicle characteristic is often considered as desirable

during the cornering manoeuvres and hence thewhere M

yis the driving torque, B is the braking

objective of handling enhancement is generally totorque, R is the effective radius of the wheel, F

Lijis

reduce the understeer behaviour of a vehicle withoutthe tyre force, J

wis the wheels moment of inertia,

allowing it to become oversteer.and v

wis the wheels angular acceleration.

For the reference vehicle, the 14-degree-of-freedom

vehicle model was used. In order to model neutral

steer behaviour, the reference vehicle was derived bymoving the centre of gravity of the test vehicle model

back to the vehicles geometrical centre to equalize

the static weights on all four suspension corners. The

vehicles moments of inertia and the suspension

parameters were also modified in the model to reflect

the effects of the equalized axle weights.

Figure 4 shows the comparison of the steering

angle at the front wheels versus lateral acceleration

during the constant-speed variable-steer test for the

uncontrolled (passive) vehicle model, the theoreticalFig. 2 Schematic diagram of the quarter car model,and force and velocity components at the wheel neutral car (neutral steer bicycle model), and the

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

4/15

380 C March and T Shim

Fig. 3 Comparison of lateral acceleration and yaw rate between the vehicle model and test data

reference vehicle model represented in the controller. which is similar to that of the neutral steer vehicle

and is used for the reference vehicle in the controllerThe understeer gradient K, which is often used toclassify a vehicles handling characteristics, can be development.

determined from the steering gradient using

dd

d(ay/g)=

57.3Lg

V2+K (9)

5 DEVELOPMENT OF CONTROL SYSTEMS

where V is the vehicles forward velocity (m/s), L

is the wheelbase (m), and g is the acceleration due In order to achieve the handling characteristics of

the reference model, a fuzzy reasoning controlto gravity (m/s2). The line representing theoretical

neutral steer behaviour (K=0) is plotted on the methodology was used in the controller development.The control system is designed by using an error-steering diagram with a slope of 57.3Lg/V2. The

reference model has an understeer gradient of 0.17, reducing control technique to make the yaw rate of

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

5/15

381Integrated control of suspension and front steering

Fig. 4 Comparison of the steering diagram during the constant-speed variable-steer test

the actual vehicle follow that of the desired model. as fuzzy propositions; the TakagiSugeno or functional

fuzzy controllers, where only the antecedent con-Figure 5 shows a block diagram for the yaw rate

controller. The desired yaw rate Vd

is produced by a ditions are expressed as fuzzy propositions while the

consequent results are defined as algebraic (crisp)reference model when the steering input Ud

is

applied to the vehicle model. The yaw rate controller functions. The Mamdani-type fuzzy models were

used in the final stand-alone controllers. In the caseadjusts the normal force Fc

and additional steering

angle dc

in order to reduce the yaw rate error e of crisp inputs and outputs, a fuzzy inference system

implements a non-linear mapping from its input(=VdV) between the reference model and theactual vehicle. space to its output space. An input is first fuzzified

into a linguistic variable using input membershipFuzzy logic controllers were employed for the

primary controllers (NFC and AFS). Additional logic functions stored in the fuzzy knowledge base. The

flexibility of this methodology allows controllers to was also used to control the limits for controller

intervention and to work out how the individual have single or multiple inputs and outputs. A vast

number of choices are available and hence additionalcontrollers interact with each other. In general, there

are two types of fuzzy logic controller: the Mamdani membership functions and rules can be added to

fuzzify the input and output error further with moreor linguistic fuzzy controllers, where both the

antecedent and the consequent parts are formulated resolution; however, the chosen controller models

Fig. 5 (a) Schematic diagram of the yaw-rate based controller; (b) integration scheme

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

6/15

382 C March and T Shim

were found to be adequate for the purposes of this where ud

is based directly on the drivers steering

study. wheel angle input.The fuzzy models used in the controllers Figure 6 shows the yaw rate error and its time

described in this section utilize a centroid of area derivative being fed to the AFS fuzzy controller todefuzzification method, defined by determine the controlled steer addition.

The input domains of the Mamdani steering

controller are partitioned with seven membershipzCOA=z

mA

(z)zdz

zmA

(z) dz(10)

functions for the yaw rate error e, and three for its

derivative e. The membership functions range fromwhere zCOA

is the crisp output from the controllerthe most negative values NB, to one around zeroand m

Ais the respective degree of membership for

okay, and to the most positive values PB for e andthe output z of each rule. The centroid of areathe functions for e partition negative values fromdefuzzification method was more representative ofpositive values as well as the OK partition atthe control logic that is to be implemented. A per-approximately zero, as illustrated in Fig. 7.formance tuning approach based on parameterization

The concept of active steering has been around forand optimization of membership functions is usedsome time now and some key characteristics thatin the design of the fuzzy controllers discussed in

were defined in studies more than 30 years ago bythis paper. Gaussian membership functions wereKasselmann and Keranen [26] are still utilized inused because of their smoothness and concisesteering controllers today. One such characteristicnotation. They have the distinct advantage of beinglimits steer addition d

cto 3 (0.05 rad) [1]. Thissmooth and non-zero at all points [25].

was therefore used for the range of values in the

output domain of the AFS controller.5.1 Active front steering controllerFor this controller, 73=21 fuzzy rules need to

In a typical vehicle active steering system, the steer- be defined to cover all possible combinations ofing angle u at the tyre is set in part by the driver

linguistic variables of the two inputs. This rule basethrough the vehicle classical steering mechanism

is shown in Table 1.while an additional steering angle d

ccan be set by

The additional logic was designed to limit thethe controller using hydraulic or d.c. motor actuators

intervention of the AFS controller to zero when acombined with a differential mechanical device [1].

cornering manoeuvre has switched from left to rightThe steering angle is thus

while there is still a positive yaw rate error and vice

versa. AFS intervention is also disallowed when theu=ud+d

c(11)

Fig. 6 Structure of the AFS controller in the MATLAB simulink environment

Fig. 7 Input membership functions for the AFS controller

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

7/15

383Integrated control of suspension and front steering

Table 1 Rule table for AFS controller

Error for the following

Error rate NB NM NS okay PS PM PB

Negative NB NB NM NM PS PM PBOK NB NM NS OK PS PM PB

Positive NB NM NS PM PM PB PB

steer angle becomes zero and e is still non-zero. is actuated. This, however, yields the undesirable

Previous research [12] indicated that AFS is more effect of an increase in the body roll angle. This is

effective in the low to medium lateral acceleration illustrated in Fig. 8, which shows the changes in roll

range; so AFS intervention is phased out as this range angle and cornering force (based on normal forceis surpassed. input from the controller), with respect to the passive

vehicle without control. The abbreviations RF, RR, LF,

and LR on the x axis indicate the right front, right5.2 Normal force controller

rear, left front, and left rear corners respectively of

the vehicle. Based on this analysis, actuation at theIt is important to determine how much, when, andfront corner opposing the turn is deemed the bestwhere suspension actuation should be applied inlocation for enhancing vehicle handling.order to enhance vehicle handling. Thus, a sensitivity

With the inclusion of acceleration and brakeanalysis for the vehicles lateral forces was conductedinputs, it can still be seen that actuation at the frontby applying a step steer to the left at low, medium,

corner opposing the turn yields the best results asand high speeds with no brake input and no throttle.

far as its effect on cornering force is concerned. ItDuring these manoeuvres, the actuator inputs at

also yields the lowest roll motion of the combinationsthe four corners of the vehicle have been varied

independently and in a few combinations to see tested.

which combination yields the desired result of The normal force controller ultimately consists of

maximum cornering force. two identical fuzzy controller modules that controlThe following additional guidelines were also the suspension of each of the front wheels, as shown

used to determine the most effective actuation in Fig. 9. The yaw rate errors being fed to the con-combination. trollers are opposite in sign. The input domains of

each control module are partitioned with fourGuideline 1. Minimize body motion (i.e. roll angle). membership functions for the yaw rate error e, and

three for its derivative e. The membership functionsGuideline 2. Maximize peak transient cornering

range from approximately zero, okay, to the mostforce per total supplied actuation force (TSAF).

positive values, PB for e and the functions for eTSAF refers to the sum of all actuator forces being

partition negative values from positive values assupplied by the active suspension system. This is

well as the OK partition at approximately zero, astaken into consideration since for most actuators

illustrated in Fig. 10.the actuation force is directly related to the power

The output domains for both NFC modules arethat is required to produce that force.

normalized to range between the values of 0 and 1.

A gain and a saturation block are applied to theGuideline 3. In the event that guidelines 1 and 2 donormalized output to limit the actuation forcenot coincide, then choose the actuator combinationbeing supplied to the vehicle model. Maximumthat yields the best improvement in corneringvalues of over 5500 N have been observed in previousforce with a corresponding roll motion that doesstudies [27]; thus this was the saturation force thatnot exceed the values for a passive system.

was used in the control scheme to limit the actuator

force. The output membership functions for theFrom the sensitivity analysis, it is observed thatcontrollers are shown in Fig. 11.either or a combination of both front wheels being

For these controllers, 43=12 fuzzy rules needactuated results in an increase in the transientto be defined to cover all possible combinationscornering force of the vehicle. In some cases a slightly

of linguistic variables of the two inputs. This rulelarger increase is observed when the inner front

wheel is actuated than when the outer front wheel base is shown in Table 2. Additional membership

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

8/15

384 C March and T Shim

Fig. 8 Effect of actuation location on the roll angle and cornering force

Fig. 9 NFC structure in the MATLAB simulink environment

Fig. 10 Input membership functions for the individual normal force controllers

functions and rules can be added to fuzzify the input 5.3 Integrated control system

error further with more resolution; however, the

above stated rules were found to be adequate for the The purpose of the integrated controller is to com-

bine intuitively the AFS and NFC strategies in orderpurposes of this study.

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

9/15

385Integrated control of suspension and front steering

handling dynamics. The major objectives of the

integrated system are as follows:

(a) to improve steering responses or yaw rate track-

ing performance of the vehicle in normal driving

conditions;

(b) to minimize the influence of the controller on

the vehicles longitudinal dynamics;

(c) to avoid discontinuity and to require seamless

transition from one subsystem to the other with

a change in the control priorities [12].

The AFS control strategy drives the yaw rate error

closer to zero throughout the duration of the laneFig. 11 Output membership functions for the indi- change manoeuvre than the NFC strategy. It is hence

vidual normal force controllers also able to match more closely the trajectory of the

reference vehicle. This is also expected since the AFS

control is active for the entire steer manoeuvre whileTable 2 Rule table for normal forcethe NFC is active only at the start of steer in eithercontrollers

direction. It is observed that the NFC strategy exhibitsError for the following a reduced effect on the longitudinal dynamics of the

vehicle since the NFC vehicle ends the manoeuvreError rate okay PS PM PBwith a higher velocity than the AFS-controlled car.

Negative No change PS PM PB Since the system needs to draw on the advantagesOK No change PS PM PB

of the individual controllers the integrated controllerPositive PM PM PB PBcan therefore be designed with the following in mind:

(a) to track the reference vehicle equally to or betterto attain a level of performance that would not than the AFS stand-alone system;otherwise be achievable by either individually. In (b) to equal or improve the final velocity at the endorder to determine how the strategies were to be of the manoeuvre in comparison with the AFScombined, the lane change manoeuvre with no brake stand-alone system;

or acceleration inputs was performed and the results (c) to reduce the power absorbed by the respectiveexamined. The integration strategy is hence obtained suspension systems from that observed in the

NFC system.through simulation investigation of the vehicle-

Fig. 12 Suspension controller look-up table

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

10/15

386 C March and T Shim

The integrated control was based primarily on yaw force Fc, to be added as well as the amount of

rate error, derived from the difference between the additional steer dc

, which should be added to the

actual and desired yaw rates. As shown in Fig. 5, the drivers steer input. In this system, when the yaw ratedifference in the yaw rates from the two models, e, error is no longer zero, the yaw moment demand willis used by the controller to determine the suspension be shared between the AFS and NFC control strategies.

The block diagram of the proposed integration

scheme is also illustrated in Fig. 5. As seen in thediagram, the major means of integration is the use

of a look-up table, which is shown in Fig. 12. Such

look-up tables are tunable by the control designer

and it is known that, in an actual controller, a multi-

dimensional table which is also dependent on the

vehicles forward velocity and other parameters can

be readily implemented in the controller.

Even though the controller used in this study pri-

marily controls the yaw rate error, it is known that

controlling only this parameter will not be sufficient

to ensure that in all cases the desired course is

followed. It is possible for yaw rate error to be accept-able while the vehicle is in lateral drift; therefore it

is desirable also to control another parameter suchFig. 13 Steering wheel input for 40 mile/h, 60 mile/h,and 80 mile/h as the lateral acceleration error.

Fig. 14 Comparison of the vehicle responses for varying levels of control during a 40 mile/hlane change manoeuvre

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

11/15

387Integrated control of suspension and front steering

6 SIMULATION RESULTS lation, driver inputs of the steering wheel angle and

wheel torque (accelerating and braking) were also

The vehicle parameters shown in Table 3 were used user definable.in the simulation of the vehicle model. The static

deflection at each corner together with the vehicles6.1 Single-lane-change manoeuvreinitial speed, the wheels no-slip wheel velocity, and

the road friction coefficient were used to initialize To compare the control strategies formulated, athe model prior to simulation. For any given simu- single-lane-change manoeuvre (SLCM) is used. The

lane change manoeuvre is an abbreviated version ofTable 3 Vehicle parameters the double-lane-change manoeuvre (DLCM) used by

the National Highway Traffic Safety AdministrationSymbol Units Test value Reference value

and the Consumer Union in their rollover propensitya m 1.053 1.306 analyses of vehicles. The SLCM represents a changingb m 1.559 1.306

vehicle path owing to an obstruction ahead. It canBsf

N/m/s 3000 2500Bsr

N/m/s 2000 2500 hence be regarded as a passing or a collisionh m 0.663 0.663 avoidance manoeuvre.

Jp

kg m2 2211.7 2211.7The manoeuvre is accomplished by a 2 s sinusoidalJ

rkg m2 496 496

Jw

kg m2 1.1 1.1 steering input. The steering is held constantly atJy kg m2 2324.8 2249.466 0 for the remainder of the simulation (shown inK

sfN/m 46 800 39 300

Ksr

N/m 31 800 39 300 Fig. 13). For the manoeuvre, the same input isKt

N/m 200 000 200 000 applied to the steering wheel of the vehicle travellingm kg 1349 1349

at 40 mile/h in its controlled and uncontrolled state.ms

kg 1176 1176Rw

m 0.285 0.285 The ratio of the steering to road wheel angle for thet m 1.483 1.483

test vehicle is 16 to 1.

Fig. 15 Suspension characteristics for a vehicle during a 40 mile/h lane change manoeuvre usingNFC and integrated control

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

12/15

388 C March and T Shim

Figure 14 compares the performance of the indi- The yaw rate error plot shows that the integrated

controller most closely matched the yaw rate of thevidual baseline controllers with that of the integrated

controller in the key areas of vehicle trajectory, roll reference vehicle.

It should be noted that the proposed controller isangle, forward velocity, and yaw rate error. It is

observed that, with all levels of control, the overall designed to enhance vehicle-handling performance

when the vehicle roll motion is in a stable region.lateral position of the vehicle is increased at the end

of the manoeuvre. The reference vehicle attains an Since a vehicle oversteer tendency makes a vehiclemore prone to rollover, if a wheel lift-off is detectedoverall lateral position of 4.18 m. This is 53.68 per

cent greater than the lateral position attained by the or a vehicle is in danger of rollover, the controller

which improves the vehicle yaw rate may result inuncontrolled vehicle. The normal force controller,

AFS controller, and integrated controller strategies vehicle rollover. Thus the proposed controller should

be modified to be effective in this region by consider-yielded respectable increases of 5 per cent, 48.8 per

cent and 49.6 per cent respectively. ing the rollover propensity in the development of the

controller.The roll behaviours for the normal force controller

and integrated controller strategies both indicate Figure 15 shows the suspension behaviour of the

vehicle as the suspension is actuated during the NFCreduced body roll during the manoeuvre (compared

with the AFS controller). It is shown in the vehicles and the integrated control modes. The peak-to-peak

suspension deflections for the NFC and integratedforward velocity plot that, while the AFS-controlled

vehicle reasonably matches the desired vehicle control modes for the right front suspension cornerare 0.078 m, 0.066 m, and 0.072 m respectively. Thepath, it also loses the most momentum during the

manoeuvre with a final velocity of 17.668 m/s and results for the left front corner for the same are

0.078 m, 0.064 m, and 0.079 m respectively. All areexperiences the highest degree of body roll. The

normal-force-controlled, integrated controlled, and seen to be well within the range that typical suspen-

sion systems are capable of providing. A reasonablethe uncontrolled vehicles end the simulation at

17.784 m/s, 17.675 m/s, and 17.78 m/s respectively. actuator power is also seen for both front corners.

Fig. 16 Comparison of vehicle responses for varying levels of control during a 60 mile/h lanechange manoeuvre

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

13/15

389Integrated control of suspension and front steering

To test the robustness of the controller, a similar a changing vehicle path based on predetermined

cone placement in the road, as shown in Fig. 17 [ 28].test was conducted at a speed of 60 mile/h. The resultThe manoeuvres were conducted on a dry road atfrom this test is shown in Fig. 16. It is observed from

an entry velocity of 45 mile/h just before the firstthese plots that at the higher speed the performancesteering input. No throttle input or brake applicationis similar to that achieved previously at 40 mile/h.

was simulated during the remainder of the simu-

lation. In order to follow the desired path, the con-6.2 Double-lane-change manoeuvretrolled vehicle and the uncontrolled vehicle had to

The International Standards Organization (ISO) 3888 have the radically different steering inputs illustratedPart 2 DLCM is used in this test to observe the vehicle in Fig. 18. Other key differences to note are the con-behaviour in response to steering wheel inputs being trolled vehicles reduced roll angle and the reduced

propensity to rollover as demonstrated by the factused in an emergency manoeuvre. The test represents

Fig. 17 ISO 3888 Part 2 DLCM

Fig. 18 Vehicle performance for varying levels of control during a 60 mile/h DLCM

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

14/15

390 C March and T Shim

5 Koibuchi, K., Yamamoto, M., Fukada, Y., andthat the tyres are further from lift-off. In the tyreInagaki, S. Vehicle Stability Control in Limitdeformation plots, tyre lift-offoccurs if and when theCornering by Active Brake. SAE technical papertyre tension becomes zero.960487, 1996.

6 Pascali, L., Gabrielli, P., and Caviasso, G. ImprovingVehicle Handling and Comfort Performance Using4WS. SAE technical paper 2003-01-0961, 2003.7 CONCLUSIONS

7 Nagai, M., Hirano, Y., and Yamanaka, S. Integratedcontrol of active rear wheel steering and direct yawNFC and AFS are reasonably efficient methods ofmoment control. Veh. System Dynamics, 1997, 27,enhancing vehicle handling. The implementation357370.

of NFC is very straightforward, given the prevalent8 Zeyada, Y., Karnopp, D., El-Arabi, M., and

use of active suspension systems today, and AFS El-Behiry, E. A combined active steering differentialis becoming more and more common in modern braking yaw rate control strategy for emergencyvehicle design. A full-vehicle model was used to maneuvers. SAE technical paper 980230, 1998.

9 Horiuchi, S., Okada, K., and Nohtomi, S. Integrateddemonstrate how the two strategies could be inte-control of four wheel steering and wheel torquesgrated and what the performance benefits that areusing nonlinear predictive controller. SAE technicallikely to be derived are.paper 9836464, 1998.

The use of fuzzy reasoning was also explored and10 Selby, M., Manning, W. J., Brown, M. D., and

it has been proven to be an effective means of chassis

Crolla, D. A. A coordination approach for DYC andcontrol. The membership functions and rules are active steering. SAE technical paper 2001-01-1275,tunable and the best combination will probably arise 2001.

11 Hac, A. and Bodie, M. Improvements of vehicleas a result of testing with a real vehicle. When this ishandling through integrated control of chassisachieved, further attempts at optimization shouldsystem. Int. J. Veh. Des., 2002, 29(1/2), 2350. yield even better results than those shown in this

12 He, J., Crolla, D. A., Levesley, M. C., andpaper. The important result here is that NFC and AFSManning, W. J. Integrated active steering and vari-

individually have a significant positive influence onable torque distribution control for vehicle handling

the lateral dynamics of a vehicle and integrating the and stability. SAE technical paper 2004-01-1071,two showed that both can readily be a part of future 2004.global chassis control strategies. 13 Mastinu, G., Babbel, E., Lugner, P., and Margolis,

D. L. Integrated controls of lateral vehicle dynamics.Veh. System Dynamics, 1994, 23, 358377.

14 Hrovat, D., Margolis, D. L., and Hubbard, M. AnACKNOWLEDGEMENT approach toward the optimal semi-active suspension.Trans. ASME, J. Dynamic Systems Measmt Control,

The authors wish to acknowledge the financial 1988, 110, 288295.support of the Center for Engineering Education and 15 Tobata, H., Kimura, T., Akatsu, Y., and Fukuyama, K.

Study on roll stiffness distribution control in anPractice at the University of Michigan-Dearborn.active suspension system. SAE technical paper928309, 1992.

16 Bakker, E., Nyborg, L., and Pacejka, H. B. Tyremodeling for use in vehicle dynamics studies. SAEREFERENCEStechnical paper 870421, 1987.

17 Blank, M. and Margolis, D. The effect of normal1 Ackerman, J., Odenthal, D., and Bunte, T.force variation on the lateral dynamics of auto-Advantages of active steering for vehicle dynamics

mobiles. SAE technical paper 960484, 1996.control. In Proceedings of the 32nd International 18 Shim, T. and Margolis, D. Dynamic normal forceSymposium on Automotive technology and auto-control for vehicle stability enhancement. Int. J.Veh.mation, Vienna, Austria, 1999, pp. 263270 (Auto-Autonomous Systems Des., 2005, 3(1), 114.motive Automation Ltd, Croydon, UK).

19 Buckholtz, K. R. Use of fuzzy logic in wheel slip2 Mammar, S. and Koenig, D. Vehicle handlingassignment Part I: yaw rate control. SAE technicalimprovement by active steering. Veh. Systempaper 2002-01-1221, 2002.Dynamics, 2002, 38(2), 211242.

20 Buckholtz, K. R. Use of fuzzy logic in wheel slip3 Shibahata, Y., Shimada, K., and Tomari, T.assignment Part II: yaw rate control with sideslipImprovement of vehicle maneuverability by directangle limitation. SAE technical paper 2002-01-1220,yaw moment control. Veh. System Dynamics, 1993,2002.22, 465481.

21 Abdelhady, M. A fuzzy controller for automobile4 Naito, G., Inoue, H., and Matsumoto, S. Improve-active suspension systems. SAE technical paperments in active safety through braking and traction

control. SAE technical paper 945151, 1994. 2003-01-1417, 2003.

JAUTO152 IMechE 2007Proc. IMechE Vol. 221 Part D: J. Automobile Engineering

-

8/7/2019 Brakes - integration of steering and suspension

15/15

391Integrated control of suspension and front steering

22 Yoshimura, T. and Emoto, Y. Steering and suspen- FLij

longitudinal force at the tyre (N)sion system of a full car model using fuzzy reasoning F

Sijsuspension force (N)

based on single input rule modules. Int. J. Veh. Des., g acceleration due to gravity (m/s2)2003, 1(2), 237255.

h centre of gravity height (m)23 Tahami, F., Farhangi, S., and Kazemi, R. A fuzzy

Jp

pitch moment of inertia (kg m2)logic direct yaw-moment control system for all-Jr

roll moment of inertia (kg m2) wheel-drive electric vehicle. Veh. System Dynamics,

Jw wheels moment of inertia (kg m2)2004, 41(3), 203221.24 Steady state directional control test procedures for J

yyaw moment of inertia (kg m2)

passenger cars and light trucks, Publication SAE ks

suspension stiffness (N/m)J266-1996, 1996 (SAE International, Warrendale, k

ttyres stiffness (N/m)

Pennsylvania). m vehicles mass (kg)25 MATLAB product manual, 2004 (The Mathworks

ms

vehicles sprung mass (kg)Inc., Natick, Massachusetts).

My

driving torque applied to the wheels (N m)26 Kasselmann, J. and Keranen, T. Adaptive steering.Rw

effective radius of the tyre (m)Bendix Tech. J., 1969, 2, 2635.t track width (m)27 Hudha, K., Jamaluddin, H., Samin, P. M., and

Rahman, R. Semi active roll control suspension U vehicles forward velocity, positive to the(SARCS) system on a new modified half car model. front (m/s)SAE technical paper 2003-01-2274, 2003. V vehicles lateral velocity, positive to the left

28 Forkenbrock, G., Garrott, W. R., Heitz, M.,and

(m/s)OHarra, B. C. An experimental examination ofW vehicles vertical velocity, positive upwards

double lane change maneuvers that may induce(m/s)on-road, untripped, light vehicle rollover. SAE

Xs

bodys vertical velocity at suspension,technical paper 2003-01-1009, 2003.positive upwards (m/s)

d roadwheel angle (rad)APPENDIX v

ppitch angular velocity (rad/s)

vr

roll angular velocity (rad/s)Notation v

wwheels rotational speed (rad/s)

vy

yaw angular velocity (rad/s)a distance from the centre of gravity to theV yaw rate of the actual vehiclefront axle (m)

Vd yaw rate of the neutral steer vehicleb distance from the centre of gravity to therear axle (m)

Subscriptbs

suspension damping (N/m s)B brake torque applied to wheels (N m) i =f denotes front;=r denotes rear

j =l denotes left;=r denotes rightFCij

cornering force at the tyre (N)

JAUTO152 IMechE 2007 Proc. IMechE Vol. 221 Part D: J. Automobile Engineering